ASTM D7719-14c

(Specification)Standard Specification for High Aromatic Content Unleaded Hydrocarbon Aviation Gasoline

Standard Specification for High Aromatic Content Unleaded Hydrocarbon Aviation Gasoline

ABSTRACT

This specification covers formulating specifications for purchases of a high octane unleaded test fuel under contract and is intended solely for use by purchasing agencies for testing purposes. This specification also defines a specific type of high octane unleaded test fuel for use as an aviation spark-ignition fuel. A new high-octane unleaded test fuel has been developed, which maintains the key performance parameters of existing reciprocating aircraft engines.

SCOPE

1.1 This specification covers formulating specifications for purchases of a high aromatic content unleaded hydrocarbon aviation gasoline under contract and is intended solely for use by purchasing agencies.2

1.2 This specification defines a specific type of high aromatic content unleaded hydrocarbon aviation gasoline (hereafter also referred to as “D7719 fuel”) for use as an aviation spark-ignition fuel. It does not include all fuels satisfactory for reciprocating aviation engines. Certain equipment or conditions of use may permit a wider, or require a narrower, range of characteristics than is shown by this specification.

1.3 The D7719 fuel defined by this specification does not exhibit identical performance to those leaded fuels for which the existing aircraft and ground-based fuel handling equipment have been designed to operate on. Therefore, the suitability of this fuel for use on any specific aircraft, aircraft engine, or ground-based fuel handling equipment should be evaluated before use on that equipment.

1.4 Issuance of this specification does not constitute approval to operate certificated aircraft with this fuel. Fuels used in certified engines and aircraft are ultimately approved by the certifying authority subsequent to formal submission of evidence to the authority as part of the certification program for that aircraft and engine model.

1.5 This specification, unless otherwise provided, prescribes the required properties of unleaded fuel at the time and place of delivery.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7719 −14c AnAmerican National Standard

Standard Specification for

High Aromatic Content Unleaded Hydrocarbon Aviation

Gasoline

This standard is issued under the fixed designation D7719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This specification covers formulating specifications for

responsibility of the user of this standard to establish appro-

purchases of a high aromatic content unleaded hydrocarbon

priate safety and health practices and determine the applica-

aviation gasoline under contract and is intended solely for use

2 bility of regulatory limitations prior to use.

by purchasing agencies.

1.2 This specification defines a specific type of high aro- 2. Referenced Documents

matic content unleaded hydrocarbon aviation gasoline (hereaf-

2.1 ASTM Standards:

ter also referred to as “D7719 fuel”) for use as an aviation

D86Test Method for Distillation of Petroleum Products at

spark-ignition fuel. It does not include all fuels satisfactory for

Atmospheric Pressure

reciprocating aviation engines. Certain equipment or condi-

D130Test Method for Corrosiveness to Copper from Petro-

tionsofusemaypermitawider,orrequireanarrower,rangeof

leum Products by Copper Strip Test

characteristics than is shown by this specification.

D323TestMethodforVaporPressureofPetroleumProducts

(Reid Method)

1.3 The D7719 fuel defined by this specification does not

D873Test Method for Oxidation Stability ofAviation Fuels

exhibit identical performance to those leaded fuels for which

(Potential Residue Method)

theexistingaircraftandground-basedfuelhandlingequipment

D909TestMethodforSuperchargeRatingofSpark-Ignition

have been designed to operate on. Therefore, the suitability of

Aviation Gasoline

this fuel for use on any specific aircraft, aircraft engine, or

D910Specification for Leaded Aviation Gasolines

ground-based fuel handling equipment should be evaluated

D1094Test Method for Water Reaction of Aviation Fuels

before use on that equipment.

D1266TestMethodforSulfurinPetroleumProducts(Lamp

1.4 Issuance of this specification does not constitute ap-

Method)

proval to operate certificated aircraft with this fuel. Fuels used

D1298Test Method for Density, Relative Density, or API

in certified engines and aircraft are ultimately approved by the

Gravity of Crude Petroleum and Liquid Petroleum Prod-

certifying authority subsequent to formal submission of evi-

ucts by Hydrometer Method

dence to the authority as part of the certification program for

D1319Test Method for HydrocarbonTypes in Liquid Petro-

that aircraft and engine model.

leum Products by Fluorescent Indicator Adsorption

1.5 Thisspecification,unlessotherwiseprovided,prescribes

D2386Test Method for Freezing Point of Aviation Fuels

therequiredpropertiesofunleadedfuelatthetimeandplaceof

D2622Test Method for Sulfur in Petroleum Products by

delivery.

Wavelength Dispersive X-ray Fluorescence Spectrometry

D2624Test Methods for Electrical Conductivity ofAviation

1.6 The values stated in SI units are to be regarded as

and Distillate Fuels

standard. No other units of measurement are included in this

D2700Test Method for Motor Octane Number of Spark-

standard.

Ignition Engine Fuel

D3237TestMethodforLeadinGasolinebyAtomicAbsorp-

tion Spectroscopy

This specification is under the jurisdiction of ASTM Committee D02 on

D4052Test Method for Density, Relative Density, and API

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Gravity of Liquids by Digital Density Meter

Subcommittee D02.J0.02 on Spark and Compression Ignition Aviation Engine

Fuels.

Current edition approved Oct. 15, 2014. Published November 2014. Originally

approved in 2011. Last previous edition approved in 2014 as D7719–14b. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D7719-14C. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Supporting data have been filed atASTM International Headquarters and may Standards volume information, refer to the standard’s Document Summary page on

be obtained by requesting Research Report RR:D02-1721. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D7719−14c

D4057Practice for Manual Sampling of Petroleum and 3.1.1 binary, adj—characterized by, or consisting of, two

Petroleum Products components.

D4171Specification for Fuel System Icing Inhibitors

3.1.2 biomass, n—biological material including any mate-

D4177Practice for Automatic Sampling of Petroleum and

rial other than fossil fuels which is or was a living organism or

Petroleum Products

component or product of a living organism.

D4306Practice for Aviation Fuel Sample Containers for

3.1.3 non-hydrocarbon, n—compound or compounds com-

Tests Affected by Trace Contamination

posedofcarbon,hydrogen,andotherelementssuchasoxygen,

D4809Test Method for Heat of Combustion of Liquid

nitrogen, sulfur, and phosphorus.

Hydrocarbon Fuels by Bomb Calorimeter (Precision

3.1.4 unleaded hydrocarbon aviation gasoline, n—gasoline

Method)

intended for use in aircraft powered by reciprocating spark-

D4814Specification for Automotive Spark-Ignition Engine

ignition engines, where lead is not intentionally added for the

Fuel

purpose of enhancing octane performance and which excludes

D4865Guide for Generation and Dissipation of Static Elec-

non-hydrocarbons, except for additives approved in this speci-

tricity in Petroleum Fuel Systems

fication.

D5006Test Method for Measurement of Fuel System Icing

Inhibitors (Ether Type) in Aviation Fuels

4. General

D5059Test Methods for Lead in Gasoline by X-Ray Spec-

4.1 Thisspecification,unlessotherwiseprovided,prescribes

troscopy

the required properties of a high aromatic content unleaded

D5191Test Method for Vapor Pressure of Petroleum Prod-

hydrocarbonaviationgasolineatthetimeandplaceofdelivery.

ucts (Mini Method)

D6469GuideforMicrobialContaminationinFuelsandFuel

5. Classification

Systems

D6733Test Method for Determination of Individual Com- 5.1 One grade of high aromatic content unleaded hydrocar-

ponents in Spark Ignition Engine Fuels by 50-Metre

bon aviation gasoline is provided, known as UL102.

Capillary High Resolution Gas Chromatography

6. Materials and Manufacture

D7826Guide for Evaluation of NewAviation Gasolines and

New Aviation Gasoline Additives

6.1 D7719 fuel, except as otherwise specified in this

E29Practice for Using Significant Digits in Test Data to

specification, shall consist of blends of refined reformate

Determine Conformance with Specifications

hydrocarbons. The sources for these hydrocarbons include

biomass, natural gas, or crude petroleum.

3. Terminology

6.1.1 See Appendix X1 for one particular composition that

3.1 Definitions: meets the parameters of Table 1.

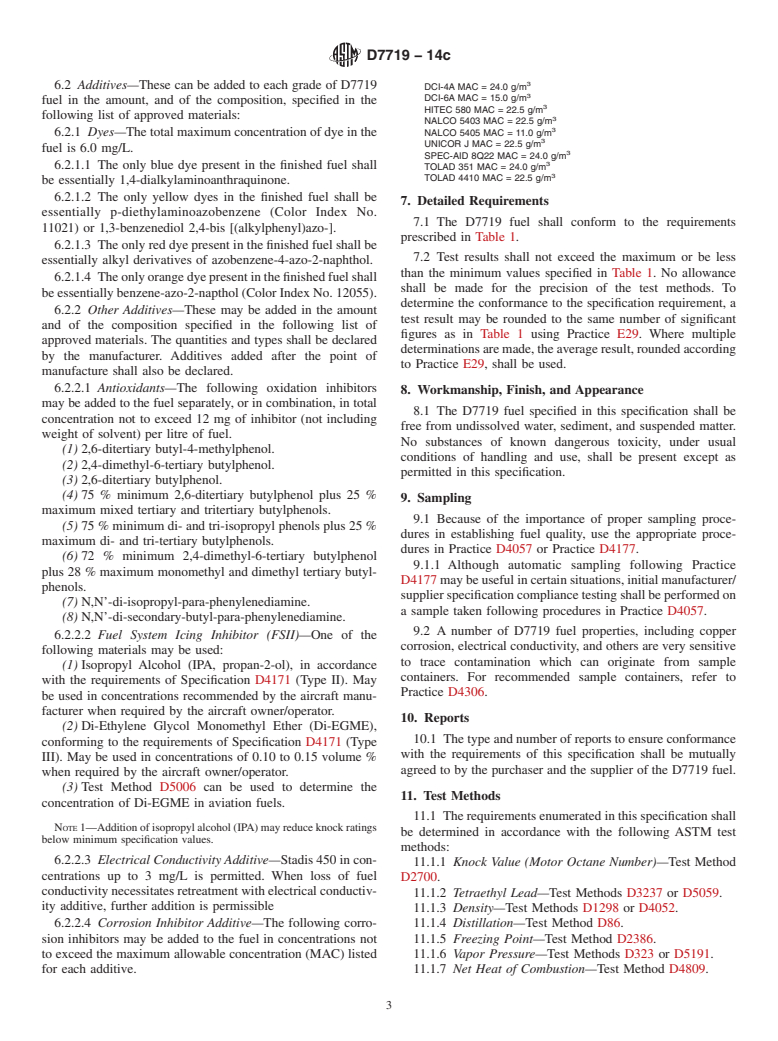

TABLE 1 Detailed Requirements for High Aromatic Content Unleaded Hydrocarbon Aviation Gasoline

Octane Ratings Grade UL102 ASTM Test Method

Knock value, Motor Octane Number min 102.2 D2700

Density at 15 °C, kg/m min 790

D1298 or D4052

max 825

Distillation D86

Initial boiling point, °C Report D86

Fuel Evaporated D86

10 volume % at °C max 75 D86

40 volume % at °C min 75 D86

50 volume % at °C max 165 D86

90 volume % at °C max 165 D86

Final boiling point, °C max 180 D86

Sumof10%+50% evaporated min 135 D86

temperatures, °C

Recovery, volume % min 97 D86

Residue, volume % max 1.5 D86

Loss, volume % max 1.5 D86

Vapor pressure, 37.8 °C, kPa min 38.0

D323 orD5191

max 49.0

Freezing point, °C max -58 D2386

Sulfur, mass % max 0.05 D1266 or D2622

Net heat of combustion, MJ/kg min 41.5 D4809

Corrosion, copper strip, 2 h at 100 °C max No. 1 D130

Oxidation stability (5 h aging)

D873

Potential gum, mg/100 mL max 6

Water reaction

D1094

Volume change, mL max ±2

Electrical conductivity, pS/m max 450 D2624

Tetraethyl Lead, g Pb/L max 0.013 D3237 or D5059

TotalAromatics, vol% min 70 D1319 or D6733

D7719−14c

6.2 Additives—These can be added to each grade of D7719

DCI-4A MAC = 24.0 g/m

DCI-6A MAC = 15.0 g/m

fuel in the amount, and of the composition, specified in the

HITEC 580 MAC = 22.5 g/m

following list of approved materials:

NALCO 5403 MAC = 22.5 g/m

6.2.1 Dyes—Thetotalmaximumconcentrationofdyeinthe NALCO 5405 MAC = 11.0 g/m

UNICOR J MAC = 22.5 g/m

fuel is 6.0 mg/L.

SPEC-AID 8Q22 MAC = 24.0 g/m

6.2.1.1 The only blue dye present in the finished fuel shall

TOLAD 351 MAC = 24.0 g/m

TOLAD 4410 MAC = 22.5 g/m

be essentially 1,4-dialkylaminoanthraquinone.

6.2.1.2 The only yellow dyes in the finished fuel shall be

7. Detailed Requirements

essentially p-diethylaminoazobenzene (Color Index No.

7.1 The D7719 fuel shall conform to the requirements

11021) or 1,3-benzenediol 2,4-bis [(alkylphenyl)azo-].

prescribed in Table 1.

6.2.1.3 Theonlyreddyepresentinthefinishedfuelshallbe

7.2 Test results shall not exceed the maximum or be less

essentially alkyl derivatives of azobenzene-4-azo-2-naphthol.

than the minimum values specified in Table 1. No allowance

6.2.1.4 Theonlyorangedyepresentinthefinishedfuelshall

shall be made for the precision of the test methods. To

beessentiallybenzene-azo-2-napthol(ColorIndexNo.12055).

determine the conformance to the specification requirement, a

6.2.2 Other Additives—These may be added in the amount

test result may be rounded to the same number of significant

and of the composition specified in the following list of

figures as in Table 1 using Practice E29. Where multiple

approved materials. The quantities and types shall be declared

determinationsaremade,theaverageresult,roundedaccording

by the manufacturer. Additives added after the point of

to Practice E29, shall be used.

manufacture shall also be declared.

6.2.2.1 Antioxidants—The following oxidation inhibitors

8. Workmanship, Finish, and Appearance

may be added to the fuel separately, or in combination, in total

8.1 The D7719 fuel specified in this specification shall be

concentration not to exceed 12 mg of inhibitor (not including

free from undissolved water, sediment, and suspended matter.

weight of solvent) per litre of fuel.

No substances of known dangerous toxicity, under usual

(1)2,6-ditertiary butyl-4-methylphenol.

conditions of handling and use, shall be present except as

(2)2,4-dimethyl-6-tertiary butylphenol.

permitted in this specification.

(3)2,6-ditertiary butylphenol.

(4)75 % minimum 2,6-ditertiary butylphenol plus 25 %

9. Sampling

maximum mixed tertiary and tritertiary butylphenols.

9.1 Because of the importance of proper sampling proce-

(5)75 % minimum di- and tri-isopropyl phenols plus 25 %

dures in establishing fuel quality, use the appropriate proce-

maximum di- and tri-tertiary butylphenols.

dures in Practice D4057 or Practice D4177.

(6)72 % minimum 2,4-dimethyl-6-tertiary butylphenol

9.1.1 Although automatic sampling following Practice

plus 28 % maximum monomethyl and dimethyl tertiary butyl-

D4177maybeusefulincertainsituations,initialmanufacturer/

phenols.

supplierspecificationcompliancetestingshallbeperformedon

(7)N,N’-di-isopropyl-para-phenylenediamine.

a sample taken following procedures in Practice D4057.

(8)N,N’-di-secondary-butyl-para-phenylenediamine.

9.2 A number of D7719 fuel properties, including copper

6.2.2.2 Fuel System Icing Inhibitor (FSII)—One of the

corrosion, electrical conductivity, and others are very sensitive

following materials may be used:

to trace contamination which can originate from sample

(1)Isopropyl Alcohol (IPA, propan-2-ol), in accordance

containers. For recommended sample containers, refer to

with the requirements of Specification D4171 (Type II). May

Practice D4306.

be used in concentrations recommended by the aircraft manu-

facturer when required by the aircraft owner/operator.

10. Reports

(2)Di-Ethylene Glycol Monomethyl Ether (Di-EGME),

10.1 Thetypeandnumberofreportstoensureconformance

conforming to the requirements of Specification D4171 (Type

with the requirements of this specification shall be mutually

III). May be used in concentrations of 0.10 to 0.15 volume %

agreed to by the purchaser and the supplier of the D7719 fuel.

when required by the aircraft owner/operator.

(3)Test Method D5006 can be used to determine the

11. Test Methods

concentration of Di-EGME in aviation fuels.

11.1 Therequirementsenumeratedinthisspecificationshall

NOTE1—Additionofisopropylalcohol(IPA)mayreduceknockratings

be determined in accordance with the following ASTM test

below minimum specification values.

methods:

6.2.2.3 Electrical Conductivity Additive—Stadis450incon-

11.1.1 Knock Value (Motor Octane Number)—Test Method

centrations up to 3 mg/L is permitted. When loss of fuel

D2700.

conductivitynecessitatesretreatmentwithelectricalconductiv-

11.1.2 Tetraethyl Lead—Test Methods D3237 or D5059.

ity additive, further addition is permissible

11.1.3 Density—Test Methods D1298 or D4052.

6.2.2.4 Corrosion Inhibitor Additive—The following corro- 11.1.4 Distillation—Test Method D86.

sion inhibitors may be added to the fuel in concentrations not 11.1.5 Freezing Point—Test Method D2386.

to exceed the maximum allowable concentration (MAC) listed 11.1.6 Vapor Pressure—Test Methods D323 or D5191.

for each additive. 11.1.7 Net Heat of Combustion—Test Method D4809.

D7719−14c

11.1.8 Sulfur—Test Methods D1266 or D2622. 11.1.11 Water Reaction—Test Method D1094.

11.1.9 Corrosion (Copper Strip)—Test Method D130,2h

11.1.12 Electrical Conductivity—Test Method D2624.

test at 100°C in bomb.

11.1.13 Aromatic Content—Test Methods D1319 or D6733.

11.1.10 Potential Gum and Visible Lead Precipitate—Test

Method D873 except that wherever the letter X occurs (refer-

12. Keywords

ring to oxidation time) insert the number 5, designating the

12.1 aviation gasoline; binary; hydrocarbon; unleaded

number of hours prescribed in this specification.

APPENDIXES

(Nonmandatory Information)

X1. HIGH AROMATIC CONTENT BINARY UNLEADED HYDROCARBON AVIATION GASOLINE COMPOSITION

X1.1 Introduction hydrocarbon aviation gasoline developed for existing spark-

ignition aircraft engines.

X1.1.1 Anew high aromatic content unleaded hydrocarbon

aviation gasoline has been developed for reciprocating aircraft

X1.2 Composition

engines. The two essential performance parameters of MON

X1.2.1 The origin of the fuel lies in two essential engine

and VP are inversely related with respect

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7719 − 14b D7719 − 14c

Standard Specification for

High-Octane Unleaded FuelHigh Aromatic Content Unleaded

Hydrocarbon Aviation Gasoline

This standard is issued under the fixed designation D7719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers formulating specifications for purchases of a high-octane (MON) unleaded fuel high aromatic

content unleaded hydrocarbon aviation gasoline under contract and is intended solely for use by purchasing agencies.

1.2 This specification defines a specific type of high-octane (MON) unleaded fuel high aromatic content unleaded hydrocarbon

aviation gasoline (hereafter also referred to as “D7719 fuel”) for use as an aviation spark-ignition fuel. It does not include all fuels

satisfactory for reciprocating aviation engines. Certain equipment or conditions of use may permit a wider, or require a narrower,

range of characteristics than is shown by this specification.

1.3 The D7719 fuel defined by this specification does not exhibit identical performance to those leaded fuels for which the

existing aircraft and ground-based fuel handling equipment have been designed to operate on. Therefore, the suitability of this fuel

for use on any specific aircraft, aircraft engine, or ground-based fuel handling equipment should be evaluated before use on that

equipment.

1.4 Issuance of this specification does not constitute approval to operate certificated aircraft with this fuel. Fuels used in certified

engines and aircraft are ultimately approved by the certifying authority subsequent to formal submission of evidence to the

authority as part of the certification program for that aircraft and engine model.

1.5 This specification, unless otherwise provided, prescribes the required properties of unleaded fuel at the time and place of

delivery.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D323 Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D873 Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

D909 Test Method for Supercharge Rating of Spark-Ignition Aviation Gasoline

D910 Specification for Leaded Aviation Gasolines

D1094 Test Method for Water Reaction of Aviation Fuels

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

This specification is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.J0.02 on Spark and Compression Ignition Aviation Engine Fuels.

Current edition approved Oct. 1, 2014Oct. 15, 2014. Published November 2014. Originally approved in 2011. Last previous edition approved in 2014 as

D7719 – 14a.D7719 – 14b. DOI: 10.1520/D7719-14B.10.1520/D7719-14C.

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02-1721.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7719 − 14c

D2386 Test Method for Freezing Point of Aviation Fuels

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D2624 Test Methods for Electrical Conductivity of Aviation and Distillate Fuels

D2700 Test Method for Motor Octane Number of Spark-Ignition Engine Fuel

D3237 Test Method for Lead in Gasoline by Atomic Absorption Spectroscopy

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4171 Specification for Fuel System Icing Inhibitors

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4306 Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

D4809 Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method)

D4814 Specification for Automotive Spark-Ignition Engine Fuel

D4865 Guide for Generation and Dissipation of Static Electricity in Petroleum Fuel Systems

D5006 Test Method for Measurement of Fuel System Icing Inhibitors (Ether Type) in Aviation Fuels

D5059 Test Methods for Lead in Gasoline by X-Ray Spectroscopy

D5191 Test Method for Vapor Pressure of Petroleum Products (Mini Method)

D6469 Guide for Microbial Contamination in Fuels and Fuel Systems

D6733 Test Method for Determination of Individual Components in Spark Ignition Engine Fuels by 50-Metre Capillary High

Resolution Gas Chromatography

D7826 Guide for Evaluation of New Aviation Gasolines and New Aviation Gasoline Additives

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions:

3.1.1 aviation gasoline fuel, n—fuel possessing specific properties suitable for operating aircraft powered by reciprocating

spark-ignition engines.

3.1.1 binary, adj—characterized by, or consisting of, two components.

3.1.2 biomass, n—biological material including any material other than fossil fuels which is or was a living organism or

component or product of a living organism.

3.1.3 high-octane,non-hydrocarbon, adj—n—possessing a Motor octane number (MON) greater than 100.compound or

compounds composed of carbon, hydrogen, and other elements such as oxygen, nitrogen, sulfur, and phosphorus.

3.1.4 unleaded hydrocarbon aviation gasoline, n—gasoline intended for use in aircraft powered by reciprocating spark-ignition

engines, where lead is not intentionally added for the purpose of enhancing octane performance and which excludes

non-hydrocarbons, except for additives approved in this specification.

4. General

4.1 This specification, unless otherwise provided, prescribes the required properties of a binary aviation fuelhigh aromatic

content unleaded hydrocarbon aviation gasoline at the time and place of delivery.

5. Classification

5.1 One grade of high-octane unleaded fuel high aromatic content unleaded hydrocarbon aviation gasoline is provided, known

as UL102.

6. Materials and Manufacture

6.1 High-octaneD7719 unleaded fuel, except as otherwise specified in this specification, shall consist of blends of refined

reformate hydrocarbons. The sources for these hydrocarbons include biomass, natural gas, or crude petroleum.

6.1.1 See Appendix X1 for one particular composition that meets the parameters of Table 1.

6.2 Additives—These can be added to each grade of high-octaneD7719 unleaded aviation fuel in the amount, and of the

composition, specified in the following list of approved materials:

6.2.1 Dyes—The total maximum concentration of dye in the fuel is 6.0 mg/L.

6.2.1.1 The only blue dye present in the finished fuel shall be essentially 1,4-dialkylaminoanthraquinone.

6.2.1.2 The only yellow dyes in the finished fuel shall be essentially p-diethylaminoazobenzene (Color Index No. 11021) or

1,3-benzenediol 2,4-bis [(alkylphenyl)azo-].

6.2.1.3 The only red dye present in the finished fuel shall be essentially alkyl derivatives of azobenzene-4-azo-2-naphthol.

6.2.1.4 The only orange dye present in the finished fuel shall be essentially benzene-azo-2-napthol (Color Index No. 12055).

D7719 − 14c

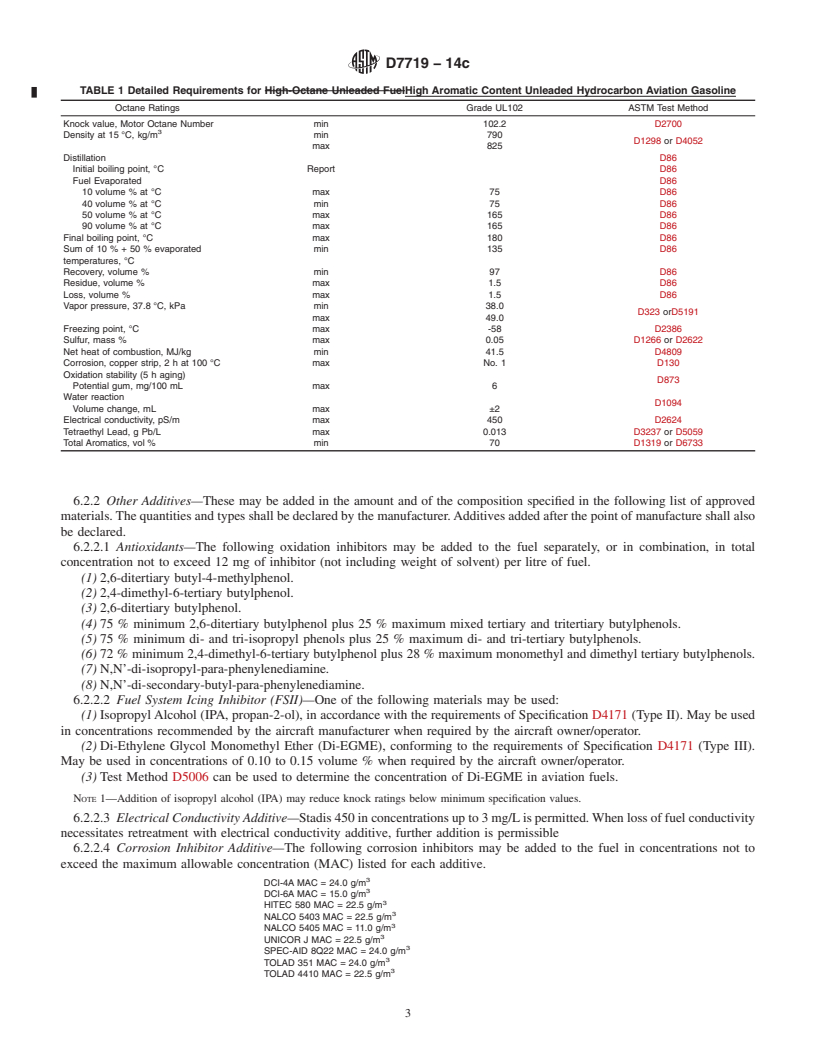

TABLE 1 Detailed Requirements for High-Octane Unleaded FuelHigh Aromatic Content Unleaded Hydrocarbon Aviation Gasoline

Octane Ratings Grade UL102 ASTM Test Method

Knock value, Motor Octane Number min 102.2 D2700

Density at 15 °C, kg/m min 790

D1298 or D4052

max 825

Distillation D86

Initial boiling point, °C Report D86

Fuel Evaporated D86

10 volume % at °C max 75 D86

40 volume % at °C min 75 D86

50 volume % at °C max 165 D86

90 volume % at °C max 165 D86

Final boiling point, °C max 180 D86

Sum of 10 % + 50 % evaporated min 135 D86

temperatures, °C

Recovery, volume % min 97 D86

Residue, volume % max 1.5 D86

Loss, volume % max 1.5 D86

Vapor pressure, 37.8 °C, kPa min 38.0

D323 orD5191

max 49.0

Freezing point, °C max -58 D2386

Sulfur, mass % max 0.05 D1266 or D2622

Net heat of combustion, MJ/kg min 41.5 D4809

Corrosion, copper strip, 2 h at 100 °C max No. 1 D130

Oxidation stability (5 h aging)

D873

Potential gum, mg/100 mL max 6

Water reaction

D1094

Volume change, mL max ±2

Electrical conductivity, pS/m max 450 D2624

Tetraethyl Lead, g Pb/L max 0.013 D3237 or D5059

Total Aromatics, vol % min 70 D1319 or D6733

6.2.2 Other Additives—These may be added in the amount and of the composition specified in the following list of approved

materials. The quantities and types shall be declared by the manufacturer. Additives added after the point of manufacture shall also

be declared.

6.2.2.1 Antioxidants—The following oxidation inhibitors may be added to the fuel separately, or in combination, in total

concentration not to exceed 12 mg of inhibitor (not including weight of solvent) per litre of fuel.

(1) 2,6-ditertiary butyl-4-methylphenol.

(2) 2,4-dimethyl-6-tertiary butylphenol.

(3) 2,6-ditertiary butylphenol.

(4) 75 % minimum 2,6-ditertiary butylphenol plus 25 % maximum mixed tertiary and tritertiary butylphenols.

(5) 75 % minimum di- and tri-isopropyl phenols plus 25 % maximum di- and tri-tertiary butylphenols.

(6) 72 % minimum 2,4-dimethyl-6-tertiary butylphenol plus 28 % maximum monomethyl and dimethyl tertiary butylphenols.

(7) N,N’-di-isopropyl-para-phenylenediamine.

(8) N,N’-di-secondary-butyl-para-phenylenediamine.

6.2.2.2 Fuel System Icing Inhibitor (FSII)—One of the following materials may be used:

(1) Isopropyl Alcohol (IPA, propan-2-ol), in accordance with the requirements of Specification D4171 (Type II). May be used

in concentrations recommended by the aircraft manufacturer when required by the aircraft owner/operator.

(2) Di-Ethylene Glycol Monomethyl Ether (Di-EGME), conforming to the requirements of Specification D4171 (Type III).

May be used in concentrations of 0.10 to 0.15 volume % when required by the aircraft owner/operator.

(3) Test Method D5006 can be used to determine the concentration of Di-EGME in aviation fuels.

NOTE 1—Addition of isopropyl alcohol (IPA) may reduce knock ratings below minimum specification values.

6.2.2.3 Electrical Conductivity Additive—Stadis 450 in concentrations up to 3 mg/L is permitted. When loss of fuel conductivity

necessitates retreatment with electrical conductivity additive, further addition is permissible

6.2.2.4 Corrosion Inhibitor Additive—The following corrosion inhibitors may be added to the fuel in concentrations not to

exceed the maximum allowable concentration (MAC) listed for each additive.

DCI-4A MAC = 24.0 g/m

DCI-6A MAC = 15.0 g/m

HITEC 580 MAC = 22.5 g/m

NALCO 5403 MAC = 22.5 g/m

NALCO 5405 MAC = 11.0 g/m

UNICOR J MAC = 22.5 g/m

SPEC-AID 8Q22 MAC = 24.0 g/m

TOLAD 351 MAC = 24.0 g/m

TOLAD 4410 MAC = 22.5 g/m

D7719 − 14c

7. Detailed Requirements

7.1 The high-octaneD7719 unleaded fuel shall conform to the requirements prescribed in Table 1.

7.2 Test results shall not exceed the maximum or be less than the minimum values specified in Table 1. No allowance shall be

made for the precision of the test methods. To determine the conformance to the specification requirement, a test result may be

rounded to the same number of significant figures as in Table 1 using Practice E29. Where multiple determinations are made, the

average result, rounded according to Practice E29, shall be used.

8. Workmanship, Finish, and Appearance

8.1 The high-octaneD7719 unleaded fuel specified in this specification shall be free from undissolved water, sediment, and

suspended matter. No substances of known dangerous toxicity, under usual conditions of handling and use, shall be present except

as permitted in this specification.

9. Sampling

9.1 Because of the importance of proper sampling procedures in establishing fuel quality, use the appropriate procedures in

Practice D4057 or Practice D4177.

9.1.1 Although automatic sampling following Practice D4177 may be useful in certain situations, initial manufacturer/supplier

specification compliance testing shall be performed on a sample taken following procedures in Practice D4057.

9.2 A number of high-octaneD7719 unleaded fuel properties, including copper corrosion, electrical conductivity, and others are

very sensitive to trace contamination which can originate from sample containers. For recommended sample containers, refer to

Practice D4306.

10. Reports

10.1 The type and number of reports to ensure conformance with the requirements of this specification shall be mutually agreed

to by the purchaser and the supplier of the high-octaneD7719 unleaded fuel.

11. Test Methods

11.1 The requirements enumerated in this specification shall be determined in accordance with the following ASTM test

methods:

11.1.1 Knock Value (Lean Rating)—(Motor Octane Number)—Test Method D2700.

11.1.2 Tetraethyl Lead—Test Methods D3237 or D5059.

11.1.3 Density—Test Methods D1298 or D4052.

11.1.4 Distillation—Test Method D86.

11.1.5 Freezing Point—Test Method D2386.

11.1.6 Vapor Pressure—Test Methods D323 or D5191.

11.1.7 Net Heat of Combustion—Test Method D4809.

11.1.8 Sulfur—Test Methods D1266 or D2622.

11.1.9 Corrosion

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.