ASTM D4989-90a(2008)

(Test Method)Standard Test Method for Apparent Viscosity (Flow) of Roofing Bitumens Using the Parallel Plate Plastometer

Standard Test Method for Apparent Viscosity (Flow) of Roofing Bitumens Using the Parallel Plate Plastometer

ABSTRACT

This test method deals with the standards for the measurement of apparent viscosity of roofing bitumen by mean of a parallel plate plastometer. This method involves measuring viscosity using pre-determined arbitrary shear stress levels. The method involves molding the sample into a disc of specified dimensions, heating it to a selected temperature and placing it between the plates of a pre-heated apparatus and pressing under the standard conditions for a measured time.

SCOPE

1.1 This test method covers the measurement of apparent viscosity of roofing bitumen by means of a parallel plate plastometer. This test method is applicable for a viscosity range from 102 to 109 Pa·s (103 to 1010 poises). See Note 1.

Note 1—This relatively simple test method of measuring viscosity uses pre-determined arbitrary shear stress levels. Since roofing bitumens are non-Newtonian, other viscosity test methods may give different results.

1.2 The values stated in SI units are regarded as standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4989 −90a(Reapproved2008)

Standard Test Method for

Apparent Viscosity (Flow) of Roofing Bitumens Using the

Parallel Plate Plastometer

This standard is issued under the fixed designation D4989; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the measurement of apparent 4.1 The sample is molded into a disc of specified

viscosity of roofing bitumen by means of a parallel plate dimensions,heatedtotheselectedtemperature,placedbetween

plastometer.Thistestmethodisapplicableforaviscosityrange the plates of the pre-heated apparatus and pressed under

2 9 3 10

from 10 to 10 Pa·s (10 to 10 poises). See Note 1. standard conditions for a measured time. The apparent viscos-

ity is calculated from the final diameter of the pressed

NOTE1—Thisrelativelysimpletestmethodofmeasuringviscosityuses

specimen disc.

pre-determined arbitrary shear stress levels. Since roofing bitumens are

non-Newtonian, other viscosity test methods may give different results.

5. Apparatus

1.2 The values stated in SI units are regarded as standard.

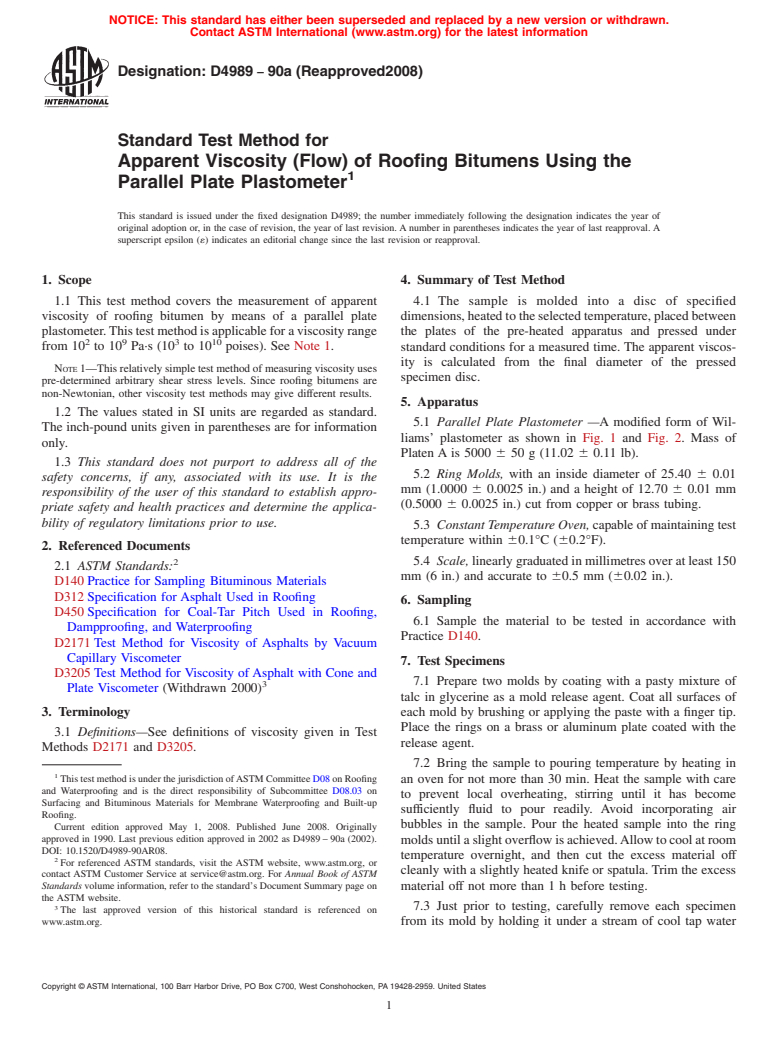

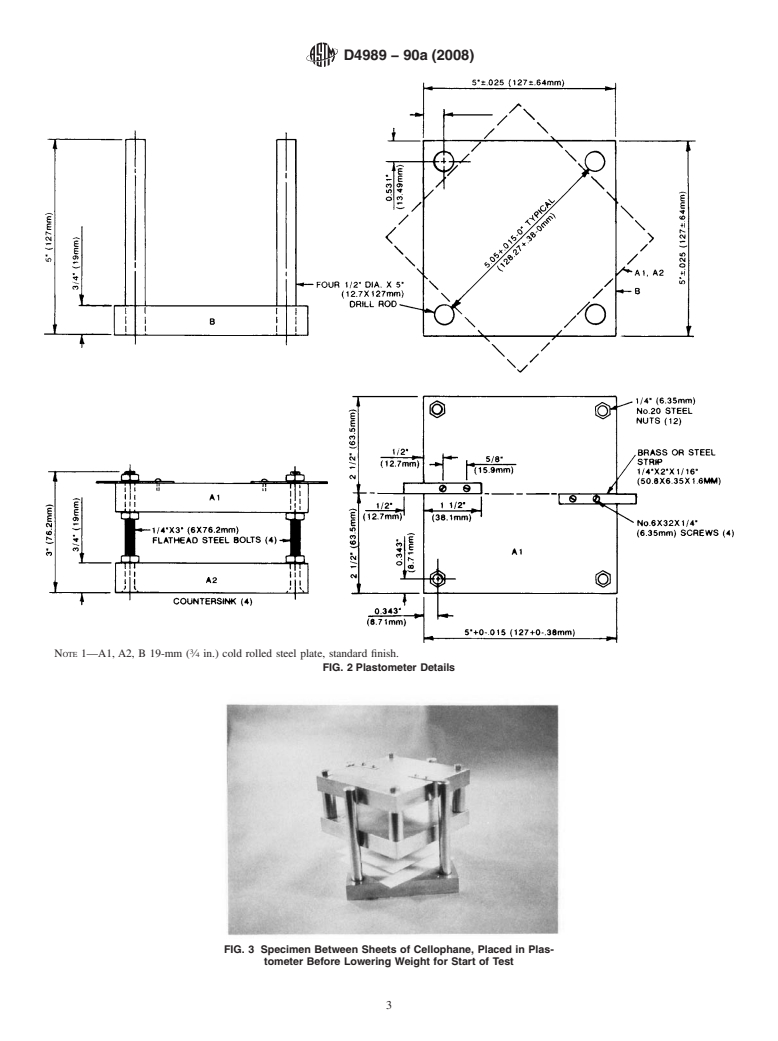

5.1 Parallel Plate Plastometer —A modified form of Wil-

The inch-pound units given in parentheses are for information

liams’ plastometer as shown in Fig. 1 and Fig. 2. Mass of

only.

Platen A is 5000 6 50 g (11.02 6 0.11 lb).

1.3 This standard does not purport to address all of the

5.2 Ring Molds, with an inside diameter of 25.40 6 0.01

safety concerns, if any, associated with its use. It is the

mm (1.0000 6 0.0025 in.) and a height of 12.70 6 0.01 mm

responsibility of the user of this standard to establish appro-

(0.5000 6 0.0025 in.) cut from copper or brass tubing.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.3 Constant Temperature Oven, capable of maintaining test

temperature within 60.1°C (60.2°F).

2. Referenced Documents

5.4 Scale, linearly graduated in millimetres over at least 150

2.1 ASTM Standards:

mm (6 in.) and accurate to 60.5 mm (60.02 in.).

D140 Practice for Sampling Bituminous Materials

D312 Specification for Asphalt Used in Roofing

6. Sampling

D450 Specification for Coal-Tar Pitch Used in Roofing,

6.1 Sample the material to be tested in accordance with

Dampproofing, and Waterproofing

Practice D140.

D2171 Test Method for Viscosity of Asphalts by Vacuum

Capillary Viscometer

7. Test Specimens

D3205 Test Method for Viscosity of Asphalt with Cone and

7.1 Prepare two molds by coating with a pasty mixture of

Plate Viscometer (Withdrawn 2000)

talc in glycerine as a mold release agent. Coat all surfaces of

3. Terminology each mold by brushing or applying the paste with a finger tip.

Place the rings on a brass or aluminum plate coated with the

3.1 Definitions—See definitions of viscosity given in Test

release agent.

Methods D2171 and D3205.

7.2 Bring the sample to pouring temperature by heating in

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

an oven for not more than 30 min. Heat the sample with care

and Waterproofing and is the direct responsibility of Subcommittee D08.03 on

to prevent local overheating, stirring until it has become

Surfacing and Bituminous Materials for Membrane Waterproofing and Built-up

sufficiently fluid to pour readily. Avoid incorporating air

Roofing.

bubbles in the sample. Pour the heated sample into the ring

Current edition approved May 1, 2008. Published June 2008. Originally

approved in 1990. Last previous edition approved in 2002 as D4989 – 90a (2002).

moldsuntilaslightoverflowisachieved.Allowtocoolatroom

DOI: 10.1520/D4989-90AR08.

temperature overnight, and then cut the excess material off

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cleanly with a slightly heated knife or spatula. Trim the excess

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on material off not more than 1 h before testing.

the ASTM website.

7.3 Just prior to testing, carefully remove each specimen

The last approved version of this historical standard is referenced on

www.astm.org. from its mold by holding it under a stream of cool tap water

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4989−90a(2008)

Record the test temperature to the nearest 0.1°C (0.2°F), and

the time under load in minutes.

9. Calculation

9.1 Calculate the average final diameter of the specimen

disc from the five measurements recorded.

9.2 Calculate the average apparent viscosity as follows:

18 10

3.60 310 t 2.08 310 t

Pa·s 5 ; viscosity, cps 5 (1)

8 S 8 D

d d

~ !

where:

FIG. 1 Plastometer With Platens in Open and Closed Positions

t = time interval of the test in minutes, and

d = final average diameter of the specimen in inches (mil-

limetres) (see Note 3).

and pressing the specimen from the ring with the fingers.W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.