ASTM F2658-07(2013)

(Specification)Standard Specification for Type PSM Poly(Vinyl Chloride) (PVC) SDR 51 and SDR 64 Sewer Pipe and Fittings

Standard Specification for Type PSM Poly(Vinyl Chloride) (PVC) SDR 51 and SDR 64 Sewer Pipe and Fittings

ABSTRACT

This specification covers requirements and test methods for materials, dimensions, workmanship, flattening resistance, impact resistance, pipe stiffness, extrusion quality, joining systems and a form of marking for type PSM poly(vinyl chloride) (PVC) SDR 51 and SDR 64 sewer pipe and fittings. In the solvent cement joint, the pipe spigot wedges into the tapered socket and the surfaces fuse together. Joints made with pipe and fittings shall show no signs of leakage when tested. The pipe dimensions, fitting dimensions, pipe flattening, impact resistance, pipe stiffness, joint tightness, and extrusion quality shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, flattening resistance, impact resistance, pipe stiffness, extrusion quality, joining systems and a form of marking for type PSM poly(vinyl chloride) (PVC) SDR 51 and SDR 64 sewer pipe and fittings.

1.2 Pipe and fittings produced to this specification should be installed in accordance with Practice D2321.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2658 −07 (Reapproved 2013)

Standard Specification for

Type PSM Poly(Vinyl Chloride) (PVC) SDR 51 and SDR 64

Sewer Pipe and Fittings

This standard is issued under the fixed designation F2658; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2321PracticeforUndergroundInstallationofThermoplas-

tic Pipe for Sewers and Other Gravity-Flow Applications

1.1 This specification covers requirements and test methods

D2412Test Method for Determination of External Loading

for materials, dimensions, workmanship, flattening resistance,

Characteristics of Plastic Pipe by Parallel-Plate Loading

impact resistance, pipe stiffness, extrusion quality, joining

D2444Test Method for Determination of the Impact Resis-

systems and a form of marking for type PSM poly(vinyl

tance of Thermoplastic Pipe and Fittings by Means of a

chloride) (PVC) SDR 51 and SDR 64 sewer pipe and fittings.

Tup (Falling Weight)

1.2 Pipeandfittingsproducedtothisspecificationshouldbe

D2564Specification for Solvent Cements for Poly(Vinyl

installed in accordance with Practice D2321.

Chloride) (PVC) Plastic Piping Systems

D2749Symbols for Dimensions of Plastic Pipe Fittings

1.3 Thetextofthisspecificationreferencesnotes,footnotes,

and appendixes which provide explanatory material. These D2855Practice for Making Solvent-Cemented Joints with

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

notesandfootnotes(excludingthoseintablesandfigures)shall

not be considered as requirements of the specification. D3034Specification for Type PSM Poly(Vinyl Chloride)

(PVC) Sewer Pipe and Fittings

1.4 The values stated in inch-pound units are to be regarded

F412Terminology Relating to Plastic Piping Systems

as the standard. The values given in parentheses are for

2.2 Federal Standard:

information only.

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

1.5 The following precautionary caveat pertains only to the

2.3 Military Standard:

test methods portion, Section 8, of this specification. This

MIL-STD-129Marking for Shipment and Storage

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

3.1 Definitions—Definitions are in accordance with Termi-

practices and determine the applicability of regulatory limita-

nology F412, and abbreviations are in accordance with Termi-

tions prior to use.

nology D1600, unless otherwise specified.The abbreviation of

2. Referenced Documents

poly(vinyl chloride) plastics is PVC.

2 3.1.1 The term PSM is not an abbreviation but rather an

2.1 ASTM Standards:

arbitrary designation for a product having certain dimensions.

D618Practice for Conditioning Plastics for Testing

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

4. Significance and Use

tics

4.1 The requirements of this specification are intended to

D1784Specification for Rigid Poly(Vinyl Chloride) (PVC)

provide pipe and fittings suitable for non-pressure drainage of

Compounds and Chlorinated Poly(Vinyl Chloride)

sewage and surface water.

(CPVC) Compounds

NOTE 1—Industrial waste disposal lines should be installed only with

D2122Test Method for Determining Dimensions of Ther-

the specific approval of the cognizant code authority since chemicals not

moplastic Pipe and Fittings

commonlyfoundindrainsandsewersandtemperaturesinexcessof60°C

(140°F) may be encountered.

NOTE 2—See D2321 Standard Practice for Underground Installation of

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications for

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

installation recommendations.

Current edition approved Feb. 1, 2013. Published February 2013. Previous

edition approved in 2007 as F2658 – 07. DOI: 10.1520/F2658-07R13.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2658−07 (2013)

5. Basic Materials 7.2.2 Wall Thickness—Pipe wall thicknesses shall meet the

requirements of Table 1 when measured in accordance with

5.1 Pipe shall be made of PVC plastic having a cell

Test Method D2122 and 8.4.2. In the case of belled pipe and

classification of 12454 or 12364 as defined in Specification

fittings fabricated from pipe sections, the thickness of the wall

D1784.

in the bell shall be considered satisfactory if it was formed

5.2 Fittings shall be made of PVC plastic having a cell

from pipe meeting the preceding requirements.

classification of 12454 or 13343 as defined in Specification

7.2.3 Pipe Flattening—There shall be no evidence of

D1784.

splitting, cracking, or breaking when pipe is tested in accor-

dance with 8.6.

5.3 Pipe and Fitting—Compounds that have different cell

classifications, because one or more properties are superior to 7.2.4 Pipe Impact Strength—Theimpactstrengthofthepipe

shall not be less than the values given in Table 2 when tested

those of the specified compounds, are also acceptable.

in accordance with 8.7.

5.4 Rework Material—The manufacturer shall use only his

own clean pipe or fitting rework material; the pipe and fittings NOTE 4—This test is intended only for use as a quality control test, not

as a simulated service test.

produced shall meet all the requirements of this specification.

7.2.5 Pipe Stiffness—Pipe stiffness values for the pipe shall

6. Joining Systems

comply with Table 3 when tested in accordance with 8.8.

7.2.6 Pipe Extrusion Quality—The pipe shall not flake or

6.1 Solvent Cement Joints for Pipe and Fittings—In the

disintegrate when tested in accordance with 8.10.

solvent cement joint, the pipe spigot wedges into the tapered

socket and the surfaces fuse together. The tapered socket may

7.3 Requirements for Solvent Cemented Pipe and Fittings:

beaportionofamoldedfittingoritmaybeabelledendofthe

7.3.1 Socket Diameter—The inside diameter of the tapered

pipe section. Formed bells shall be concentric with the pipe

socketshallcomplywiththedimensionslistedinTable4when

axis. Fittings meeting the requirements of Specification D3034

determined in accordance with 8.5.1.

shall also be permitted to be used with pipe meeting the

7.3.2 Socket Depth—The socket depth shall not be less than

requirements of this standard.

thatshowninTable4whenmeasuredinaccordancewith8.5.2.

6.1.1 The assembly of joints shall be in accordance with

7.3.3 Alternate Fittings—Fittings meeting the requirements

Practice D2855.

of Specification D3034 shall also be permitted to be used in

6.1.2 Joint Tightness—Joints made with pipe and fittings

joining pipe specified in this standard.

shall show no signs of leakage when tested in accordance with

7.3.4 Spigot Length—The minimum distance from the

8.9.

spigotendtotheareawherethespigotdiameterchangesdueto

a socket, branch, or change in angle shall comply with the “C”

7. Requirements

dimension of Table 4.

7.1 Workmanship—The pipe and fittings shall be homoge-

7.4 Fabricated Fittings—Any fitting made from pipe or

neous throughout and free from visible cracks, holes, foreign

from a combination of pipe and molded parts shall be consid-

inclusions, or other injurious defects. The pipe shall be as

ered a fabricated fitting and the following provisions shall

uniform as commercially practical in color, opacity, density,

apply.

and other physical properties.

7.4.1 Over-Wrapped Fittings—Fabricated fittings that have

7.2 Pipe Requirements: an over-wrap of fiberglass reinforced thermosetting resin or

7.2.1 Diameter—The average outside diameter of the pipe other similar materials shall meet all of the requirements in

shallmeettherequirementsgiveninTable1whenmeasuredin 7.4.2 and 7.4.3.

accordance with 8.4.1.

NOTE 5—Refer to Appendix X3 for geometric configurations of some

of the fittings being produced. Consult the individual manufacturer for

NOTE 3—As larger sizes of sewer pipe are needed, it is recommended

laying lengths.

thattheybemadewiththefollowingoutsidediameters:475,560,and630

mm.

7.4.2 Fabricated Fittings General Requirements:

7.4.2.1 Pipe used in fabricated fittings shall meet all quality

and dimensional requirements listed in the standard for that

TABLE 1 Pipe Dimensions

pipe.

Minimum Wall

Outside Diameter

Thickness

Nominal

TABLE 2 Minimum Pipe Impact Strength at 23°C (73°F)

Tolerance

Size

SDR SDR

Average on Pipe Size, Impact Strength,

51 64

Average in. J (ft·lbf)

3 3.250 ±0.008 0.064 0.051 3 135 (100)

4 4.215 ±0.009 0.083 0.066 4 203 (150)

6 6.275 ±0.011 0.123 0.098 6 284 (210)

8 8.400 ±0.012 0.165 0.131 8 284 (210)

9 9.440 ±0.014 0.185 0.148 9 299 (220)

10 10.500 ±0.015 0.206 0.164 10 299 (220)

12 12.500 ±0.018 0.245 0.195 12 299 (220)

15 15.300 ±0.023 0.300 0.239 15 299 (220)

F2658−07 (2013)

TABLE 3 Minimum Pipe Stiffness at 5% Deflection

7.4.2.5 No fitting shall have an inside diameter dimension

Pipe Stiffness, kPa (psi) smaller than the base inside diameter listed in Table X1.1 for

Pipe Size,

in.

SDR 51 SDR 64 that pipe size and DR.

3 and 4 99 (14) 49 (7)

7.4.2.6 All welds and solvent cement joints shall be sound

6to15 99(14) 49 (7)

and free of visible defects.

7.4.3 Fabrication Joint Test Requirements :

7.4.3.1 These test requirements apply only to tee, wye, and

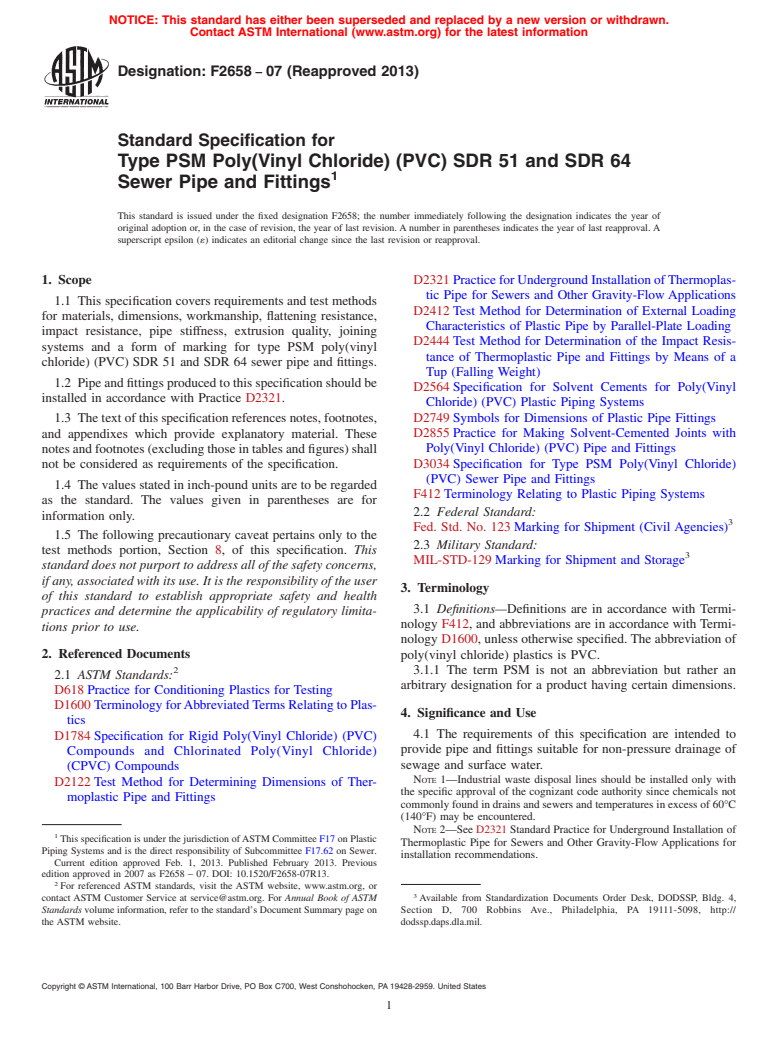

TABLE 4 Solvent Cement Socket Dimensions

bendfabricatedfittingsthataremanufacturedusingfabrication

methods that join together a combination of pipe sections or

pipe sections and molded parts to form a fitting configuration.

Other fitting configurations using the same manufacturing

proceduresasthosetestedsuccessfullyshallbesuitableforsale

and use. Fittings fabricated from a single-piece of pipe to form

Bends and Sweeps shall not be subject to this requirement.

NOTE 6—A brittle fitting may violently fragment during testing. To

preclude serious injury or death, suitable and appropriate safety proce-

dures shall be used during any test procedure.

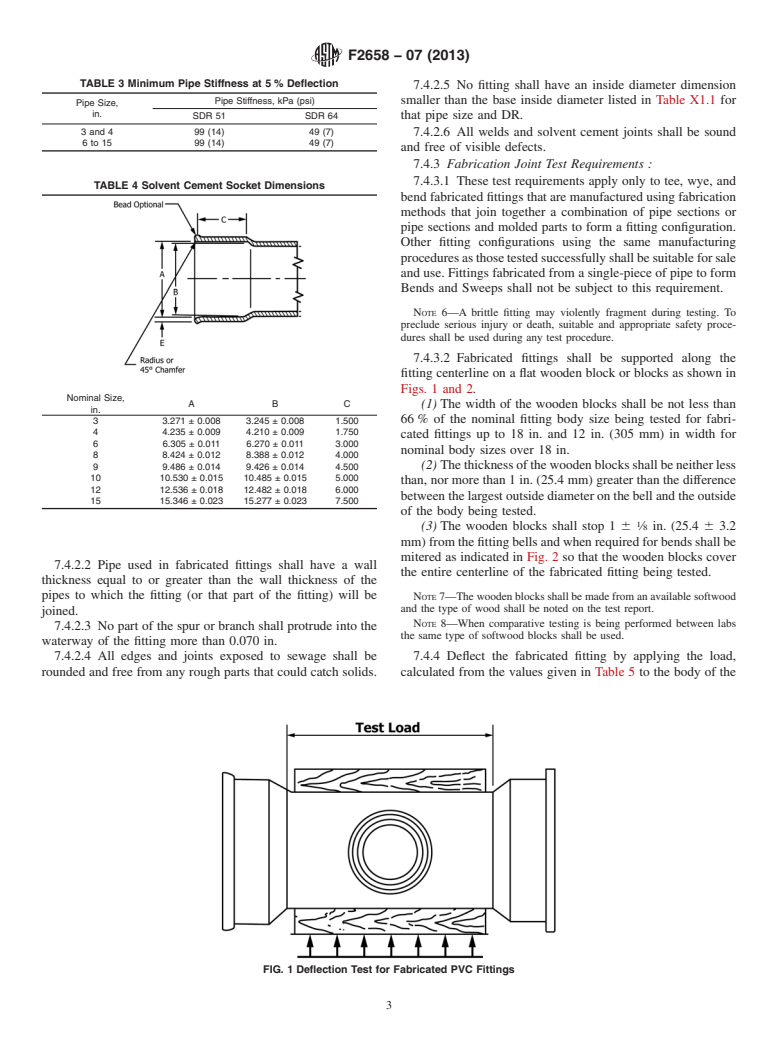

7.4.3.2 Fabricated fittings shall be supported along the

fitting centerline on a flat wooden block or blocks as shown in

Figs. 1 and 2.

Nominal Size,

AB C

(1)The width of the wooden blocks shall be not less than

in.

66% of the nominal fitting body size being tested for fabri-

3 3.271 ± 0.008 3.245 ± 0.008 1.500

4 4.235 ± 0.009 4.210 ± 0.009 1.750

cated fittings up to 18 in. and 12 in. (305 mm) in width for

6 6.305 ± 0.011 6.270 ± 0.011 3.000

nominal body sizes over 18 in.

8 8.424 ± 0.012 8.388 ± 0.012 4.000

9 9.486 ± 0.014 9.426 ± 0.014 4.500 (2)Thethicknessofthewoodenblocksshallbeneitherless

10 10.530 ± 0.015 10.485 ± 0.015 5.000

than, nor more than 1 in. (25.4 mm) greater than the difference

12 12.536 ± 0.018 12.482 ± 0.018 6.000

betweenthelargestoutsidediameteronthebellandtheoutside

15 15.346 ± 0.023 15.277 ± 0.023 7.500

of the body being tested.

(3)The wooden blocks shall stop 1 6 ⁄8 in. (25.4 6 3.2

mm)fromthefittingbellsandwhenrequiredforbendsshallbe

mitered as indicated in Fig. 2 so that the wooden blocks cover

7.4.2.2 Pipe used in fabricated fittings shall have a wall

the entire centerline of the fabricated fitting being tested.

thickness equal to or greater than the wall thickness of the

pipes to which the fitting (or that part of the fitting) will be

NOTE7—Thewoodenblocksshallbemadefromanavailablesoftwood

and the type of wood shall be noted on the test report.

joined.

NOTE 8—When comparative testing is being performed between labs

7.4.2.3 No part of the spur or branch shall protrude into the

the same type of softwood blocks shall be used.

waterway of the fitting more than 0.070 in.

7.4.2.4 All edges and joints exposed to sewage shall be 7.4.4 Deflect the fabricated fitting by applying the load,

rounded and free from any rough parts that could catch solids. calculated from the values given in Table 5 to the body of the

FIG. 1Deflection Test for Fabricated PVC Fittings

F2658−07 (2013)

FIG. 2

A

TABLE 5 Fabricated Fitting Loads, F

NOTE 10—If the test samples are to be retained they shall be

permanently marked in such a way as to indicate that they have been

Fitting Body Pipe Size, F

in. (lb/in. of length) tested.

4 13.3

7.5 Solvent Cement—The cement shall meet the require-

6 20.0

ments of Specification D2564.

8 26.7

9 30.0

10 33.3

8. Test Methods

12 40.0

15 50.0

8.1 Conditioning—Condition the test specimens at

A

F is the load required to produce 7.5 % deflection in SDR 35 (PS46) PVC pipe.

23 62°C (73.4 6 3.6°F) and 50 6 5% relative humidity for

not less than 40 h prior to test in accordance with ProcedureA

of Practice D618, for those tests where conditioning is re-

fitting as shown in Fig. 1. The body length for this calculation

quired.

shallnotincludeanypartofataperortransitionalareabetween

8.2 Test Conditions—Conduct tests in the standard labora-

the fitting body and the bell as shown in Fig. 2. Apply the

tory atmosphere of 23 6 2°C and 50 6 5% relative humidity,

calculated load at a constant rate overa1to2min period and

unless otherwise specified in the test methods or in this

thenmaintaintheloadfor5(five)minutes.Thecalculatedload

specification.

required shall be applied to a second wooden block or blocks

that are located along the fitting centerline on top of the fitting

8.3 Sampling—The selection of the sample or samples of

as shown in Fig. 2.

pipe or fitting shall be as agreed upon between the purchaser

7.4.4.1 Inspect all welds and fabrication joints while the

and the seller. In case of no prior agreement, any sample

load is on the fabricated fitting, and again after the load has

selected by the testing laboratory shall be deemed adequate.

been maintained for 5 (five) minutes. Any evidence of

8.4 Pipe Dimensions:

cracking, splitting, breaking, or separation shall constitute

8.4.1 Pipe Diameters—Measure the average outside diam-

failure of this requirement.

eter of the pipe in accordance with the applicable section of

7.4.4.2 Aftercompletingtheloadtest,plugallopeningsand

Test Method D2122. Either a tapered sleeve gage or a vernier

pressure test at a gage pressure of 10.8 psi (74 kPa) 25-ft head

circumferential wrap tape accurate to 60.02 mm (60.001 in.)

of water for 10 min. Any visible leakage of water at the

may

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.