ASTM C1165-90(2005)

(Test Method)Standard Test Method for Determining Plutonium by Controlled-Potential Coulometry in H2SO4 at a Platinum Working Electrode

Standard Test Method for Determining Plutonium by Controlled-Potential Coulometry in H<sub>2</sub>SO<sub>4</sub> at a Platinum Working Electrode

SIGNIFICANCE AND USE

This test method is to be used to ascertain whether or not materials meet specifications for plutonium content or plutonium assay, or both.

A chemical calibration of the coulometer is necessary for accurate results.

FIG. 1 Example of a Cell Design Used at Los Alamos National Laboratory (LANL)

SCOPE

1.1 This test method covers the determination of milligram quantities of plutonium in unirradiated uranium-plutonium mixed oxide having a U/Pu ratio range of 0.1 to 10. This test method is also applicable to plutonium metal, plutonium oxide, uranium-plutonium mixed carbide, various plutonium compounds including fluoride and chloride salts, and plutonium solutions.

1.2 The recommended amount of plutonium for each aliquant in the coulometric analysis is 5 to 10 mg. Precision worsens for lower amounts of plutonium, and elapsed time of electrolysis becomes impractical for higher amounts of plutonium.

1.3 The values stated in SI units are to be regarded as standard. No other units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concens, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1165–90(Reapproved2005)

Standard Test Method for

Determining Plutonium by Controlled-Potential Coulometry

in H SO at a Platinum Working Electrode

2 4

This standard is issued under the fixed designation C1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C833 Specification for Sintered (Uranium-Plutonium) Di-

oxide Pellets

1.1 This test method covers the determination of milligram

C859 Terminology Relating to Nuclear Materials

quantities of plutonium in unirradiated uranium-plutonium

C1009 GuideforEstablishingaQualityAssuranceProgram

mixed oxide having a U/Pu ratio range of 0.1 to 10. This test

for Analytical Chemistry Laboratories Within the Nuclear

methodisalsoapplicabletoplutoniummetal,plutoniumoxide,

Industry

uranium-plutonium mixed carbide, various plutonium com-

C1068 GuideforQualificationofMeasurementMethodsby

pounds including fluoride and chloride salts, and plutonium

a Laboratory Within the Nuclear Industry

solutions.

C1108 Test Method for Plutonium by Controlled-Potential

1.2 The recommended amount of plutonium for each ali-

Coulometry

quant in the coulometric analysis is 5 to 10 mg. Precision

C1128 Guide for Preparation of Working Reference Mate-

worsens for lower amounts of plutonium, and elapsed time of

rials for Use in Analysis of Nuclear Fuel Cycle Materials

electrolysis becomes impractical for higher amounts of pluto-

C1156 Guide for Establishing Calibration for a Measure-

nium.

ment Method Used to Analyze Nuclear Fuel Cycle Mate-

1.3 The values stated in SI units are to be regarded as

rials

standard. No other units of measurement are included in this

C1168 Practice for Preparation and Dissolution of Pluto-

standard.

nium Materials for Analysis

1.4 This standard does not purport to address all of the

C1210 GuideforEstablishingaMeasurementSystemQual-

safety concerns, if any, associated with its use. It is the

ityControlProgramforAnalyticalChemistryLaboratories

responsibility of the user of this standard to establish appro-

Within the Nuclear Industry

priate safety and health practices and determine the applica-

C1297 Guide for Qualification of Laboratory Analysts for

bility of regulatory limitations prior to use. Specific precau-

the Analysis of Nuclear Fuel Cycle Materials

tionary statements are given in Section 8.

3. Summary of Test Method

2. Referenced Documents

3.1 In controlled-potential coulometry, the analyte reacts at

2.1 ASTM Standards:

an electrode having a maintained potential that precludes

C757 Specification for Nuclear-Grade Plutonium Dioxide

reactionsofasmanyimpuritycomponentsasisfeasible.Inthe

Powder, Sinterable

electrolysis, current decreases exponentially as the reaction

C758 Test Methods for Chemical, Mass Spectrometric,

proceeds until a selected background current is reached. The

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

quantity of analyte reacted is calculable by Faraday’s law.

Nuclear-Grade Plutonium Metal

Detailed discussions of the theory and applications of this

C759 Test Methods for Chemical, Mass Spectrometric,

technique are presented in Refs (1) and (2).

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

3.2 Plutonium and many impurity element ions are initially

Nuclear-Grade Plutonium Nitrate Solutions

reduced in a 0.5 M H SO electrolyte at a platinum working

2 4

electrode (3) maintained at+0.310 V versus a saturated

calomelelectrode(SCE).PlutoniumisthenoxidizedtoPu(IV)

ThistestmethodisunderthejurisdictionofASTMCommitteeC26onNuclear

at a potential of+0.670 V. The quantity of plutonium is

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of

calculatedfromthenumberofcoulombsrequiredforoxidation

Test.

Current edition approved June 1, 2005. Published December 2005. Originally

according to Faraday’s law.

´1

approved in 1990. Last previous edition approved in 2000 as C1165–90(2000) .

t

Q 5 * idt 5 nwF/M (1)

DOI: 10.1520/C1165-90R05.

o

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. the text.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1165–90 (2005)

Rearrangement to solve for w gives: oxidation of Pu(III) to Pu(IV), organic matter, anions that

complex plutonium, and oxygen.

w 5 MQ/nF (2)

5.2 The major interfering metallic impurity element, of

where:

those usually included in specifications for FBR mixed oxide

w = weight of Pu(III) oxidized to Pu(IV), g,

fuel, is iron (4). In the 0.5 M H SO electrolyte, the

2 4

M = gram-molecular mass of plutonium (adjusted for iso-

Fe(II)−Fe(III) and Pu(III)−Pu(IV) couples have essentially

o

topic composition), grams/equivalent,

the same E value of+0.490 V. The iron interference, there-

Q = number of coulombs to oxidize Pu(III) to Pu(IV),

fore, is quantitative and is corrected based on its measured

coulombs,

value that can be determined by a spectrophotometric method

n = number of electron change to oxidize Pu(III) to

(5). Alternatively, other techniques such as ICP, DCP, or

Pu(IV)=1, and

emission spectrometry can also be used if the iron content is

F = Faraday constant, coulomb/equivalent.

sufficiently low. When the iron result is <20µ g/g, the lower

3.3 An electrolyte of sulfuric acid, that selectively com-

limit of the spectrophotometric method, no correction is

plexes Pu(IV), provides very reproducible electrolysis of

necessary. The best available method for iron determination is

Pu(III) to Pu(IV). In a 0.5 M H SO electrolyte, the reduction

2 4

recommended since the uncertainty in the iron correction

potential of+0.310 V for conversion of Pu(IV and VI) to

contributes to the uncertainty in the plutonium value.

Pu(III) and the oxidation potential of+0.670Vfor conversion

5.3 Organic matter usually is not present in calcined mixed

of Pu(III) to Pu(IV) accounts for about 99.9% (as calculated

oxide fuel pellets nor in mixed oxide powder blends prepared

from the Nernst equation) conversion of the total plutonium in

using calcined uranium oxide and calcined plutonium oxide.

solution. There are few interferences at the selected potentials

However, it may be introduced as an impurity in reagents.The

ofthemetallicimpuritiesusuallylistedinspecificationsforfast

sulfuric acid fuming of reference material and of samples that

breederreactor(FBR)mixedoxidefuel.Achemicalcalibration

precedes the coulometric analysis volatilizes most organic

of the coulometric system using the selected potentials tech-

components.

nique is necessary to correct for the less than 100% conver-

5.4 The sulfuric acid fuming volatilizes nitrate, nitrite,

sions of Pu(III) and Pu(IV).

fluoride, and chloride, that are introduced by the use of a

3.4 Sulfuric acid is a convenient electrolyte since it is used

nitric-hydrofluoric acid mixture or acid mixtures containing

for preliminary fuming of samples to volatilize interfering

chloride for the dissolution of samples and interfere in the

components (see 5.3 and 5.4). The preliminary fuming with

coulometric determination of plutonium.

sulfuric acid also serves to depolymerize any polymeric

5.5 Oxygen interferes and must be purged continuously

plutonium species, which tend to be electrolytically inactive

from both the solution and atmosphere in the electrolysis cell

(3).

with an oxygen-free inert gas before and during the electroly-

sis.

4. Significance and Use

NOTE 1—The purge gas tube extends through the cell cover and is

4.1 Thistestmethodistobeusedtoascertainwhetherornot

positioned approximately 1 cm above the sample solution in the cell.The

materials meet specifications for plutonium content or pluto-

inert gas flow is maintained at a flow rate that causes a dimple to be seen

nium assay, or both.

on the surface of the solution with the stirrer off. The inert gas flow rate

4.2 A chemical calibration of the coulometer is necessary should be such that no splashing occurs.

for accurate results.

6. Apparatus

5. Interferences 6.1 Controlled-Potential Coulometer—A potentiostat hav-

ing stable potential control at approximately 200 mAand 20V

5.1 Categories of interferences are diverse metal ions that

and an integrator capable of 0.05% reproducibility are re-

oxidize or reduce at the potential of+0.670 V used for the

quired. The linearity of the integrator should be better than

0.1% for the selected range.

NOTE 2—To obtain maximum precision, it is recommended that the

referenceandsamplealiquantscontainapproximatelythesameamountof

plutonium.

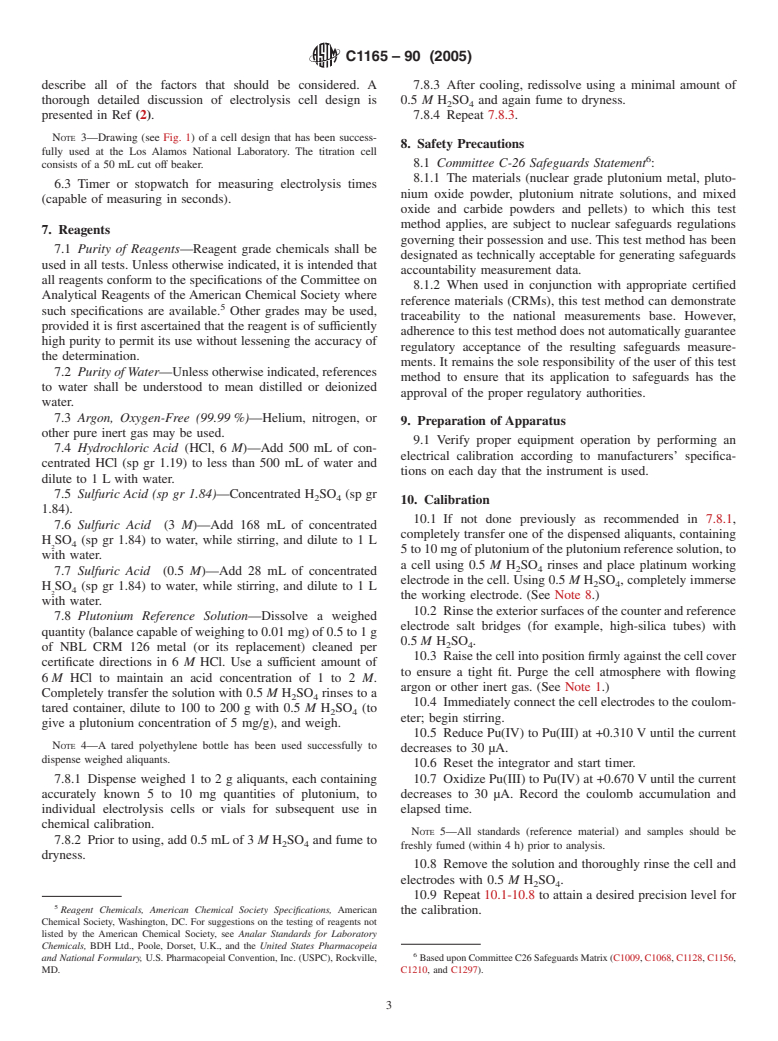

6.2 Cell Assembly—A cell assembly similar to the one

describedinRef (5)hasbeenusedsatisfactorily.Celldesignis

very critical in controlled-potential coulometry. There are

many factors that must be considered in choosing or designing

a cell assembly. It is beyond the scope of this test method to

Thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime

is EG&G Princeton Applied Research Corp. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters.

FIG. 1 Example of a Cell Design Used at Los Alamos National Your comments will receive careful consideration at a meeting of the responsible

Laboratory (LANL) technical committee, which you may attend.

C1165–90 (2005)

describe all of the factors that should be considered. A 7.8.3 After cooling, redissolve using a minimal amount of

thorough detailed discussion of electrolysis cell design is 0.5 M H SO and again fume to dryness.

2 4

presented in Ref (2). 7.8.4 Repeat 7.8.3.

NOTE 3—Drawing (see Fig. 1) of a cell design that has been success-

8. Safety Precautions

fully used at the Los Alamos National Laboratory. The titration cell

8.1 Committee C-26 Safeguards Statement :

consists of a 50 mL cut off beaker.

8.1.1 The materials (nuclear grade plutonium metal, pluto-

6.3 Timer or stopwatch for measuring electrolysis times

nium oxide powder, plutonium nitrate solutions, and mixed

(capable of measuring in seconds).

oxide and carbide powders and pellets) to which this test

method applies, are subject to nuclear safeguards regulations

7. Reagents

governing their possession and use. This test method has been

7.1 Purity of Reagents—Reagent grade chemicals shall be

designated as technically acceptable for generating safeguards

used in all tests. Unless otherwise indicated, it is intended that

accountability measurement data.

all reagents conform to the specifications of the Committee on

8.1.2 When used in conjunction with appropriate certified

Analytical Reagents of theAmerican Chemical Society where

reference materials (CRMs), this test method can demonstrate

such specifications are available. Other grades may be used,

traceability to the national measurements base. However,

provided it is first ascertained that the reagent is of sufficiently

adherencetothistestmethoddoesnotautomaticallyguarantee

high purity to permit its use without lessening the accuracy of

regulatory acceptance of the resulting safeguards measure-

the determination.

ments. It remains the sole responsibility of the user of this test

7.2 Purity of Water—Unlessotherwiseindicated,references

method to ensure that its application to safeguards has the

to water shall be understood to mean distilled or deionized

approval of the proper regulatory authorities.

water.

7.3 Argon, Oxygen-Free (99.99 %)—Helium, nitrogen, or

9. Preparation of Apparatus

other pure inert gas may be used.

9.1 Verify proper equipment operation by performing an

7.4 Hydrochloric Acid (HCl, 6 M)—Add 500 mL of con-

electrical calibration according to manufacturers’ specifica-

centrated HCl (sp gr 1.19) to less than 500 mL of water and

tions on each day that the instrument is used.

dilute to 1 L with water.

7.5 Sulfuric Acid (sp gr 1.84)—Concentrated H SO (sp gr

2 4

10. Calibration

1.84).

10.1 If not done previously as recommended in 7.8.1,

7.6 Sulfuric Acid (3 M)—Add 168 mL of concentrated

completely transfer one of the dispensed aliquants, containing

HSO (sp gr 1.84) to water, while stirring, and dilute to 1 L

5to10mgofplutoniumoftheplutoniumreferencesolution,to

with water.

a cell using 0.5 M H SO rinses and place platinum working

2 4

7.7 Sulfuric Acid (0.5 M)—Add 28 mL of concentrated

electrode in the cell. Using 0.5 M H SO , completely immerse

2 4

HSO (sp gr 1.84) to water, while stirring, and dilute to 1 L

the working electrode. (See Note 8.)

with water.

10.2 Rinsetheexteriorsurfacesofthecounterandreference

7.8 Plutonium Reference Solution—Dissolve a weighed

electrode salt bridges (for example, high-silica tubes) with

quantity(balancecapableofweighingto0.01mg)of0.5to1g

0.5 M H SO .

2 4

of NBL CRM 126 metal (or its replacement) cleaned per

10.3 Raisethecellintopositionfirmlyagainstthecellcover

certificate directions in 6 M HCl. Use a sufficient amount of

to ensure a tight fit. Purge the cell atmosphere with flowing

6 M HCl to maintain an acid concentration of 1 to 2 M.

argon or other inert gas. (See Note 1.)

Completely transfer the solution with 0.5 M H SO rinses to a

2 4

10.4 Immediatelyconnectthecellelectrodestothecoulom-

tared container, dilute to 100 to 200 g with 0.5 M H SO (to

2 4

eter; begin stirring.

give a plutonium concentration of 5 mg/g), and weigh.

10.5 Reduce Pu(IV) to Pu(III) at +0.310 V until the current

NOTE 4—A tared polyethylene bottle has been used successfully to

decreases to 30 µA.

dispense weighed aliquants.

10.6 Reset the integrator and start timer.

7.8.1 Dispense weighed 1 to 2 g aliquants, each containing 10.7 Oxidize Pu(III) to Pu(IV) at +0.670Vuntil the current

accurately known 5 to 10 mg quantities of plutonium, to decreases to 30 µA. Record the coulomb accumulation and

individual electrolysis cells or vials for subsequent use in elapsed time.

chemical calibration.

NOTE 5—All standards (reference material) and samples should be

7.8.2 Prior to using, add 0.5 mLof 3 M H SO and fume to

2 4

freshly fumed (within 4 h) prior to analysis.

dryness.

10.8 Remove the solution and thoroughly rinse the cell and

electrodes with 0.5 M H SO .

2 4

10.9 Repeat 10.1-10.8 to attain a desired precision level for

Reagent Chemicals, American Chemical Society Specifications, American

the calibration.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.