ASTM B763/B763M-13e1

(Specification)Standard Specification for Copper Alloy Sand Castings for Valve Applications

Standard Specification for Copper Alloy Sand Castings for Valve Applications

SCOPE

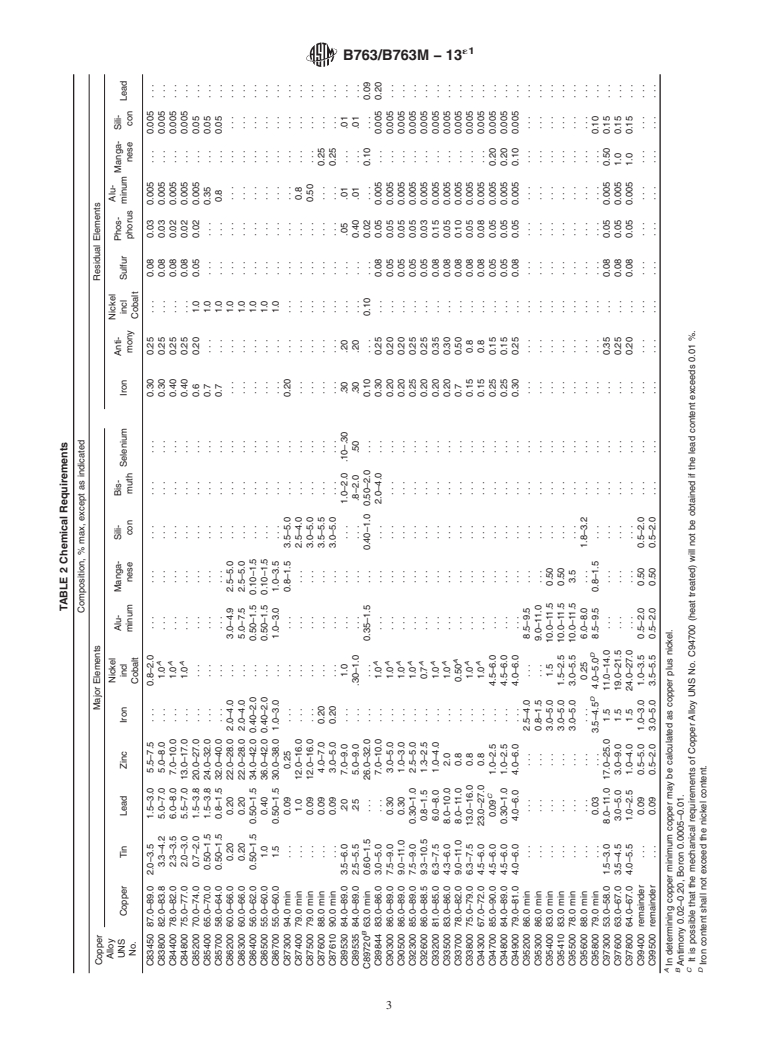

1.1 This specification establishes requirements for copper alloy sand castings for valve applications. Nominal compositions of the alloys defined by this specification are shown in Table 1.2 Note 1—This specification does not cover Copper Alloy UNS Nos. C83600, C92200, C96200, and C96400. These alloys are also used in valve applications. They are covered by the following specifications:

C83600: B62

C92200: B61

C96200: B369

C96400: B369

1.2 The castings produced under this specification are used in products which may be manufactured in advance and supplied for sale from stock by the manufacturer.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:B763/B763M −13

StandardSpecification for

1

Copper Alloy Sand Castings for Valve Applications

This standard is issued under the fixed designation B763/B763M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

ε NOTE—Designation was corrected editorially in October 2013.

1. Scope* B62 Specification for Composition Bronze or Ounce Metal

Castings

1.1 This specification establishes requirements for copper

B208 Practice for Preparing Tension Test Specimens for

alloy sand castings for valve applications. Nominal composi-

Copper Alloy Sand, Permanent Mold, Centrifugal, and

tions of the alloys defined by this specification are shown in

2 Continuous Castings

Table 1.

B369 Specification for Copper-Nickel Alloy Castings

NOTE 1—This specification does not cover Copper Alloy UNS Nos.

B824 Specification for General Requirements for Copper

C83600, C92200, C96200, and C96400. These alloys are also used in

Alloy Castings

valve applications. They are covered by the following specifications:

E10 Test Method for Brinell Hardness of Metallic Materials

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

C83600: B62

C92200: B61

C96200: B369

3. General Requirements

C96400: B369

3.1 The following sections of Specification B824 form a

part of this specification.

3.1.1 Terminology,

1.2 The castings produced under this specification are used

3.1.2 Other Requirements,

in products which may be manufactured in advance and

3.1.3 Dimensions, Mass, and Permissible Variations,

supplied for sale from stock by the manufacturer.

3.1.4 Workmanship, Finish, and Appearance,

1.3 Units—The values stated in either SI units or inch-

3.1.5 Sampling,

pound units are to be regarded separately as standard. The

3.1.6 Number of Tests and Retests,

values stated in each system may not be exact equivalents;

3.1.7 Specimen Preparation,

therefore,eachsystemshallbeusedindependentlyoftheother.

3.1.8 Test Methods,

Combining values from the two systems may result in non-

3.1.9 Significance of Numerical Limits,

conformance with the standard.

3.1.10 Inspection,

3.1.11 Rejection and Rehearing,

2. Referenced Documents

3.1.12 Certification,

3

2.1 ASTM Standards:

3.1.13 Test Report,

B61 Specification for Steam or Valve Bronze Castings

3.1.14 Product Marking,

3.1.15 Packaging and Package Marking, and

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper 3.1.16 Supplementary Requirements.

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

Castings and Ingots for Remelting.

4. Ordering Information

Current edition approved April 1, 2013. Published April 2013. Originally

approved in 1986. Last previous edition approved in 2012 as B763 – 12. DOI:

4.1 Include the following information when placing orders

10.1520/B0763_B0763M-13E01.

for product under this specification, as applicable:

2

The UNS system for copper and copper alloys (see Practice E527) is a simple

4.1.1 Specification title, number, and year of approval,

expansion of the former standard designation system accomplished by the addition

4.1.2 Quantity of castings,

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate

composition variations of the base alloy.

4.1.3 Copper Alloy UNS Number and temper (as-cast,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

heat-treated, etc.),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.4 Pattern or drawing number and condition (as-cast,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. machined, etc.),

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

B763/B763M−13

TABLE 1 Nominal Compositions

Copper Alloy Alumi- Man- Sili- Sele-

Classification Commercial Designation Copper Tin Lead Zinc Nickel Iron Bismuth

UNS No. num ganese con nium

1 1

Leaded red brass C83450 88 2 ⁄226 ⁄2 1 . . . . . .

C83800 83-4-6-7 or commercial red brass 83 4 6 7 . . . . . . . . . . . . . . . . . . . . .

Leaded semi-red brass C84400 81-3-7-9 or valve composition 81 3 7 9 . . . . . . . . . . . . . . . . . . . . .

1 1 1 1

C84800 76-2 ⁄2-6 ⁄2-15, or semi-red brass 76 2 ⁄2 6 ⁄2 15 . . . . . . .

Leaded yellow brass C85200 high-copper yellow brass 72 1 3 24 . . . . . . . . . . . . . . . . . . . . .

C85400 commercial No. 1 yel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.