ASTM D7387-07

(Test Method)Standard Test Method for Vibration Testing of Intermediate Bulk Containers (IBCs) Used for Shipping Liquid Hazardous Materials (Dangerous Goods)

Standard Test Method for Vibration Testing of Intermediate Bulk Containers (IBCs) Used for Shipping Liquid Hazardous Materials (Dangerous Goods)

SIGNIFICANCE AND USE

Shipping containers are exposed to complex dynamic stresses when subjected to vibration present in transportation vehicles. Approximating the actual damage, or lack of damage, experienced in shipping may require subjecting the container(s) and contents to vibration inputs.

Resonant responses during shipment can be severe and may lead to failure of the container and spillage or leakage of contents. Identification of critical frequencies and the nature of package stresses can aid in minimizing the effect of these occurrences.

This vibration test is based on methods currently used for the qualification of IBCs in CFR 49 and has demonstrated successful use in transportation.

Exposure to vibration can affect the shipping container, its means of closure, and its contents. This test method allows analysis of the interaction of these components. Design modification to one or more of these components may be utilized to achieve optimum performance in the shipping environment.

This test method is suitable for individual filled containers that are transported unrestrained on the bed of a vehicle.

This test method is not intended for testing intermediate bulk containers at a frequency that causes the container to go into resonance.

SCOPE

1.1 This test method covers vibration testing of filled intermediate bulk containers (IBCs) intended to contain liquid hazardous materials (dangerous goods) and is suitable for testing IBCs of any design or material with any means of closure. This test method has been used by the United States Department of Transportation (DOT) to test and qualify IBCs for shipping hazardous materials. The test method is used to determine that the IBCs maintain integrity and to prevent leakage or spillage of contents during shipping. This test method should be used as a screening tool or as a design qualification test. Other vibration methods are available to more closely simulate vibration experienced in transportation.

1.2 This test method is appropriate for testing IBCs ranging from 450 to 3000 L (119 to 793 gal). Packagings of smaller sizes should be tested using Test Methods D 999 or other applicable methods.

1.3 The ISO 2247 standard may not meet the requirements for this test method.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7387 − 07

StandardTest Method for

Vibration Testing of Intermediate Bulk Containers (IBCs)

Used for Shipping Liquid Hazardous Materials (Dangerous

Goods)

This standard is issued under the fixed designation D7387; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D996 Terminology of Packaging and Distribution Environ-

ments

1.1 This test method covers vibration testing of filled

D999 Test Methods for Vibration Testing of Shipping Con-

intermediate bulk containers (IBCs) intended to contain liquid

tainers

hazardous materials (dangerous goods) and is suitable for

D4169 Practice for Performance Testing of Shipping Con-

testing IBCs of any design or material with any means of

tainers and Systems

closure. This test method has been used by the United States

D4332 Practice for Conditioning Containers, Packages, or

Department of Transportation (DOT) to test and qualify IBCs

Packaging Components for Testing

for shipping hazardous materials. The test method is used to

E122 Practice for Calculating Sample Size to Estimate,With

determine that the IBCs maintain integrity and to prevent

Specified Precision, the Average for a Characteristic of a

leakage or spillage of contents during shipping. This test

Lot or Process

method should be used as a screening tool or as a design

2.2 ISO Standards:

qualification test. Other vibration methods are available to

ISO 2247 Packaging—Complete, Filled Transport

more closely simulate vibration experienced in transportation.

Packages—Vibration Test at Fixed Low Frequency

1.2 This test method is appropriate for testing IBCs ranging

2.3 Regulatory Documents:

from 450 to 3000 L (119 to 793 gal). Packagings of smaller

CFR 49 UnitedStatesDepartmentofTransportationCodeof

sizes should be tested using Test Methods D999 or other

Federal Regulations Title 49, Transportation, Parts

applicable methods.

100–199

1.3 The ISO 2247 standard may not meet the requirements

2.4 United Nations Document:

for this test method.

United Nations Recommendations on the Transport of Dan-

gerous Goods—Model Regulations

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

3. Terminology

only.

3.1 For definitions of terms used in these test methods, see

1.5 This standard does not purport to address all of the

Terminology D996.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.2 Definitions of Terms Specific to This Standard:

3.2.1 double amplitude, n—the maximum value of a sinu-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau- soidal quantity (peak-to-peak).

tionary statements are given in Section 6.

3.2.2 repetitive shock, n—impacts of a package on a test

platform which occur cyclically from input oscillatory motion.

2. Referenced Documents

3.2.3 resonance, n—for the purposes of this test method,

2.1 ASTM Standards:

resonance is obtained when the input frequency of the table

causes excessive, violent, and uncontrollable movement of the

This test method is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

Containers and Systems - Application of Performance Test Methods. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Oct. 15, 2007. Published November 2007. DOI: 4th Floor, New York, NY 10036, http://www.ansi.org.

10.1520/D7387-07. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.access.gpo.gov.

Standards volume information, refer to the standard’s Document Summary page on Available from United Nations, 866 United Nations Plaza, New York, NY

the ASTM website. 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7387 − 07

IBC. Testing at this frequency over an extended period of time ment of 25 mm (1 in.) 6 1 mm. The test machine shall have a

is overly severe and may cause damage and failure to the platform with a known mass and with a horizontal surface of

container not likely to be experienced in transportation. sufficient strength and rigidity so that all points of the surface

willfollowtheverticalmotionofthesupportingstructurewhen

4. Significance and Use

loadedwiththeIBC.Thetestsurfaceshallprotrudebeyondthe

IBC on all sides and shall have hardness adequate for its

4.1 Shipping containers are exposed to complex dynamic

intended use (recommend at least equal to oak wood) firmly

stresses when subjected to vibration present in transportation

attached to a mild steel structure. The platform shall be

vehicles.Approximating the actual damage, or lack of damage,

supported by a mechanism that moves the platform so the

experienced in shipping may require subjecting the contain-

motion is a vertical sinusoidal input. (A rotary motion of the

er(s) and contents to vibration inputs.

platform is not acceptable.)The vibration test machine shall be

4.2 Resonant responses during shipment can be severe and

equipped with fences, barricades, or other restraints to keep the

may lead to failure of the container and spillage or leakage of

IBC from falling off the platform without restricting its vertical

contents. Identification of critical frequencies and the nature of

motion.

package stresses can aid in minimizing the effect of these

5.1.1 Shim—A metal shim with the following specification

occurrences.

is used in determining when the shipping container is leaving

4.3 This vibration test is based on methods currently used

the testing platform by a sufficient amount:

for the qualification of IBCs in CFR 49 and has demonstrated

5.1.1.1 Width—50 mm (2.0 in.) minimum.

successful use in transportation.

5.1.1.2 Thickness—1.6 mm ( ⁄16 in.).

5.1.1.3 Length—254 mm (10 in.) minimum.

4.4 Exposure to vibration can affect the shipping container,

its means of closure, and its contents. This test method allows

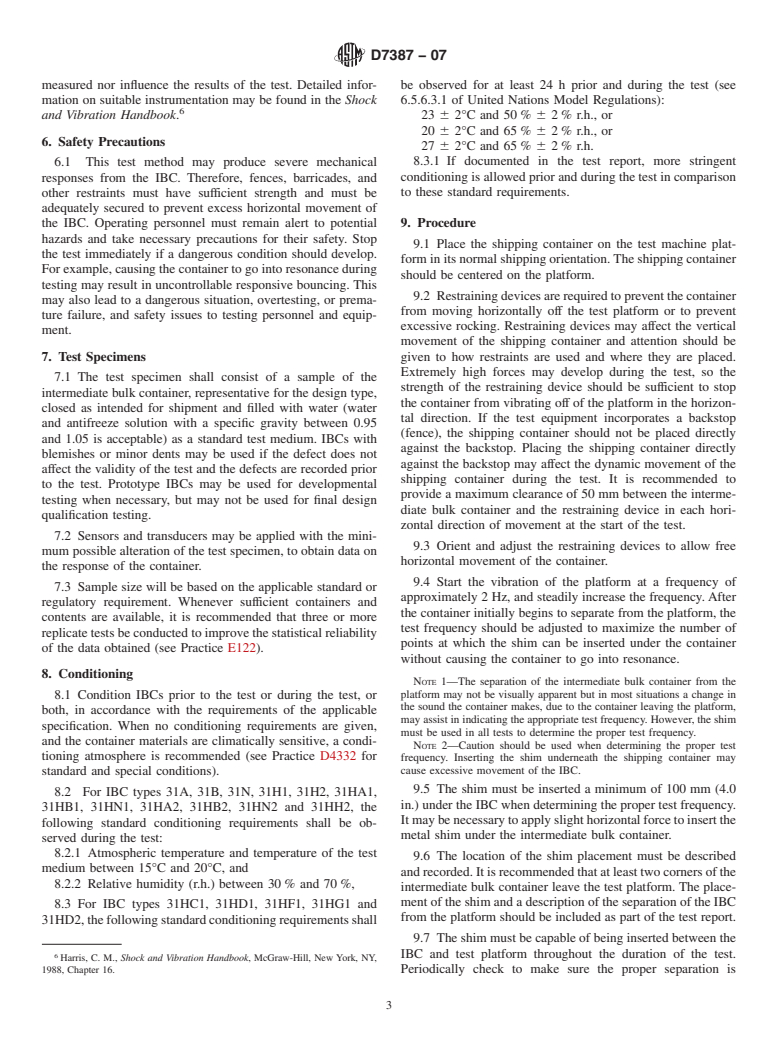

5.2 Fig. 1 shows an intermediate bulk container on a test

analysis of the interaction of these components. Design modi-

apparatus.

fication to one or more of these components may be utilized to

5.3 Instrumentation—Instrumentation of the test unit and

achieve optimum performance in the shipping environment.

table as described below is not required but may be used to

4.5 This test method is suitable for individual filled contain-

obtain additional data.

ers that are transported unrestrained on the bed of a vehicle.

5.3.1 Accelerometers, signal conditioners, and data display

4.6 This test method is not intended for testing intermediate or storage devices may be used to measure and control the

bulk containers at a frequency that causes the container to go accelerations at the test surface or on various locations of the

into resonance. intermediate bulk container to measure response. They are not

required to conduct the test.

5. Apparatus

5.3.2 If an instrumentation system is used, it is recom-

5.1 Vertical Motion Vibration Machine—This test is to be mended that it shall have a response accurate to within 65%

over the range specified for the test.

conducted with vibration test equipment that provides vertical

vibration, and is capable of producing frequencies in the range 5.3.3 Accelerometers should be small and light weight

of 2 to at least 5 Hz, with a fixed double amplitude displace- enough as to not influence the response of the item being

FIG. 1 Intermediate Bulk Container Test Specimen on Vibration

Machine

D7387 − 07

measured nor influence the results of the test. Detailed infor- be observed for at least 24 h prior and during the test (see

mation on suitable instrumentation may be found in the Shock 6.5.6.3.1 of United Nations Model Regulations):

and Vibration Handbook. 23 6 2°C and 50 % 6 2 % r.h., or

20 6 2°C and 65 % 6 2 % r.h., or

6. Safety Precautions

27 6 2°C and 65 % 6 2 % r.h.

8.3.1 If documented in the test report, more stringent

6.1 This test method may produce severe mechanical

conditioning is allowed prior and during the test in comparison

responses from the IBC. Therefore, fences, barricades, and

other restraints must have sufficient strength and must be to these standard requirements.

adequately secured to prevent excess horizontal movement of

the IBC. Op

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.