ASTM B833-05

(Specification)Specification for Zinc and Zinc Alloy Wire for Thermal Spraying (Metallizing) for the Corrosion Protection of Steel

Specification for Zinc and Zinc Alloy Wire for Thermal Spraying (Metallizing) for the Corrosion Protection of Steel

SCOPE

1.1 This specification covers zinc and zinc alloy wire used in depositing zinc and zinc alloy coatings by thermal spraying (metallizing). Zinc and zinc alloy wire provided under this specification is intended for use in oxy-fuel and electric arc thermal spraying for the corrosion protection of iron and steel.

1.2 Zinc alloy wire compositions used in thermal spraying primarily for electronic applications are found in Specification B 943.

1.3 Zinc alloy wire compositions used as solders are found in Specification B 907.

1.4 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 833 – 05

Standard Specification for

Zinc and Zinc Alloy Wire for Thermal Spraying (Metallizing)

1

for the Corrosion Protection of Steel

This standard is issued under the fixed designation B 833; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* Determine Conformance with Specifications

E 527 Practice for Numbering Metals and Alloys (UNS)

1.1 This specification covers zinc and zinc alloy wire used

E 536 TestMethodsforChemicalAnalysisofZincandZinc

in depositing zinc and zinc alloy coatings by thermal spraying

Alloys

(metallizing). Zinc and zinc alloy wire provided under this

2.2 ANSI/AWS Standard:

specification is intended for use in oxy-fuel and electric arc

ANSI/AWS A5.33 Specification for Solid and Ceramic

thermal spraying for the corrosion protection of iron and steel.

3

Wires and Ceramic Rods for Thermal Spraying

1.2 Zinc alloy wire compositions used in thermal spraying

primarily for electronic applications are found in Specification

3. Terminology

B 943.

3.1 Terms shall be defined in accordance with Terminology

1.3 Zinc alloy wire compositions used as solders are found

B 899.

in Specification B 907.

1.4 The values stated in SI units are to be regarded as the

4. Ordering Information

standard. The values in parentheses are for information only.

4.1 In order to make the application of this specification

1.5 This standard does not purport to address all of the

complete, the purchaser shall supply the following information

safety concerns, if any, associated with its use. It is the

to the seller in the purchase order or other governing docu-

responsibility of the user of this standard to become familiar

ments:

with all hazards including those identified in the appropriate

4.1.1 Name, designation, and date of issue of this specifi-

Material Safety Data Sheet (MSDS) for this product/material

cation,

as provided by the manufacturer, to establish appropriate

4.1.2 Quantity (mass(weight) in kilograms (pounds)),

safety and health practices, and determine the applicability of

4.1.3 Diameter (see Table 1),

regulatory limitations prior to use.

4.1.4 Acceptance tests if other than specified (see Section

2

10),

2. Referenced Documents

4.1.5 Certification (see Section 11),

2.1 The following ASTM documents of the issue in effect

4.1.6 Packagingandpackingmaterials(seeSection12),and

on the date of material purchase form a part of this specifica-

4.1.7 Supplementary requirements, if applicable.

tion to the extent referenced herein:

B6 Specification for Zinc

5. Materials and Manufacture

B 899 Terminology Relating to Nonferrous Metals and

5.1 The zinc used to manufacture the wire shall conform to

Alloys

the requirements for High Grade Zinc (Z15001) or Special

B 907 SpecificationforZinc,TinandCadmiumBaseAlloys

High Grade Zinc (Z13001) as specified in SpecificationB6.

Used as Solders and for Thermal Spraying

B 943 Specification for Zinc and Tin Alloy Wire used in

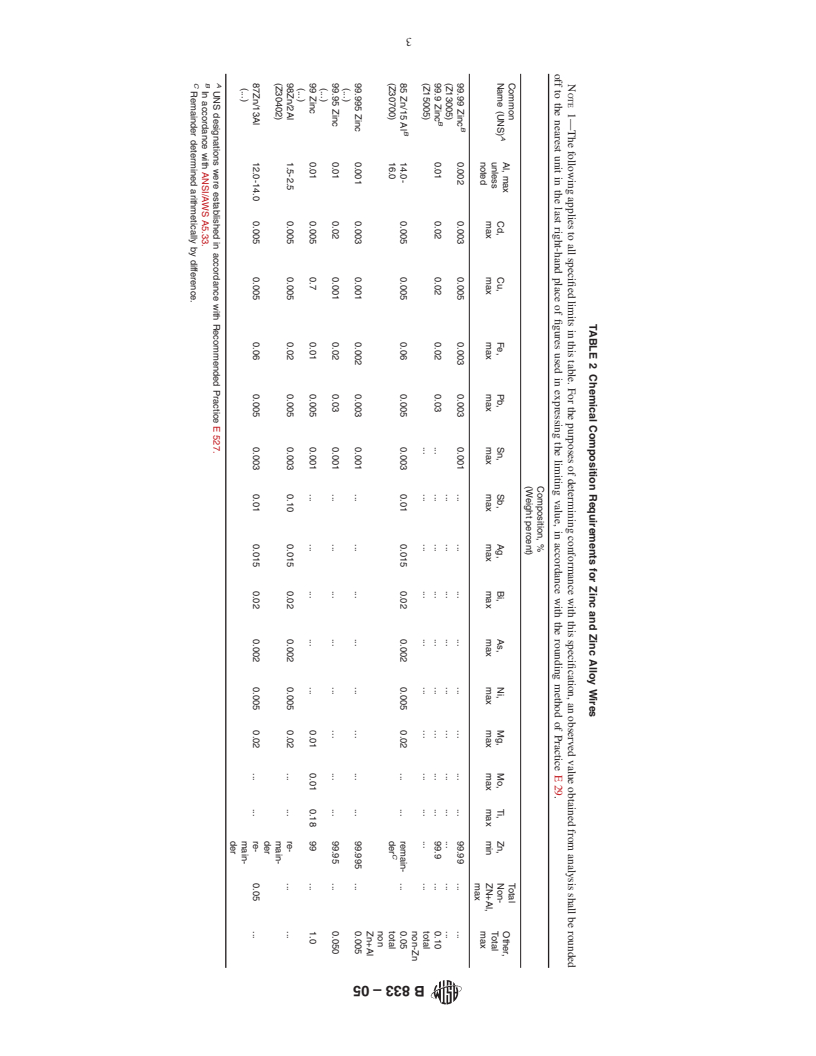

6. Chemical Composition

Thermal Spraying for Electronic Applications

6.1 The wire shall conform to the requirements prescribed

E29 Practice for Using Significant Digits in Test Data to

in Table 2.

7. Physical Properties and Mechanical Properties

1

This specification is under the jurisdiction of ASTM Committee B02 on

7.1 Appendix X1 shows typical physical properties for zinc

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

and zinc alloy wire and does not constitute a part of this

B02.04 on Zinc and Cadmium.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

specification but is provided for informational purposes only.

approved in 1993. Last previous edition approved in 2001 as B 833 - 01a.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the American Welding Society, 550 N.W. LeJeune Road,

the ASTM website. Miami, FL 33126.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B833–05

TABLE 1 Dimensions, Weights, and Permissible Variations

Nominal Wire Diameter Permissible Variation Nominal Weight Per Unit Length

mm (in.) mm (in.) g/m (lb/ft)

4.763 (0.1875) +0.0000 (+0.0000) 123.517-126.493 (0.083-0.085)

-0.0762 (-0.0030)

3.175 (0.125) +0.0000 (+0.0000) 55.062-56.550 (0.037-0.038)

-0.0508 (-0.0020)

2.311 (0.091) +0.0000 (+0.000

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.