ASTM D941-88

(Test Method)Test Method for Density and Relative Density (Specific Gravity) of Liquids by Lipkin Bicapillary Pycnometer (Withdrawn 1993)

Test Method for Density and Relative Density (Specific Gravity) of Liquids by Lipkin Bicapillary Pycnometer (Withdrawn 1993)

General Information

Standards Content (Sample)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

An An&an National Standard

Designation: D 941 - 88

1916 Race SI., Philadelphia. Pa. 19103

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

If not listed in the current combined index. will appear in the next edition.

Standard Test Method for

Density and Relative Density (Specific Gravity) of Liquids by

Lipkin Bicapillary Pycnometer’

This standard is issued under the fixed designation D 941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapprovat. A

superscript epsilon (3 indicates an editorial change since the last revision or reapproval.

This standard has been approvedfor use by agencies of the Department of Defense to replace Method 402 of Test Method Standard No

791b. Consult the DOD Index of Specijcations and Standards for the speci/ic year of issue which has been adopted by the Department

of Defense.

1. Scope 4. Summary of Test Method4

4.1 The liquid sample is drawn into the pycnometer and

1.1 This test method covers the measurement of the

weighed. It is then equilibrated at the test temperature, and

density of any hydrocarbon material that can be handled in a

the positions of the liquid levels are observed. The density or

normal fashion as a liquid at the specified test temperatures

relative density of the sample is then calculated from its

of 20 to 25°C. Its application is restricted to liquids having

weight, a calibration factor proportional to an equal volume

vapor pressures less than 80 kPa (600 mm Hg) and having

of water, and a term that corrects for the buoyancy of air.

viscosities less than 15 mm’/s (cst) at 20°C.

Ii2 Two procedures are covered as follows:

5. Significance and Use

1.2.1 Procedure A, for pure compounds and mixtures

5.1 Density is a fundamental physical property which can

which are not highly volatile.

be used in conjunction with other properties to characterize

1.2.2 Procedure B, for highly volatile mixtures.

both the light and heavy fractions of petroleum and to assess

1.3 This test method provides a calculation procedure for

the quality of crude oils.

converting density to relative density.

5.2 Determination of the density or relative density of

1.4 This standard may involve hazardous materials, oper-

petroleum and its products is necessary for the conversion of

ations, and equipment. This standard does not purport to

measured volumes to volumes at the standard temperatures

address all of the. safety problems associated with its use. It is

of 15°C or 60°F.

the responsibility of the user of this standard to establish

6. Apparatus

appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use. Specific

6.-l Pycnometer-A pycnometer conforming to the di-

hazard statements are given in Notes 1, 2, 6 and Annex Al,

mensions given in Fig. 1, constructed of borosilicate glass,

and having a total weight not exceeding 30 g.

6.2 Constant-Temperature Bath-A water bath having a

depth of at least 12 in. (305 mm), provided with means for

2. Referenced Documents

maintaining a temperature of 20 f 0.02”C or 25 +- 0.02”C.

6.3 Bath Thermometer-No suitable ASTM Celsius ther-

2.1 ASTM Standards:

mometers are available; ASTM Kinematic Viscosity Ther-

D 1250 Petroleum Measurement Tables2

mometers 44F and 45F designed for tests at 68°F (20°C) and

E 1 Specification for ASTM Thermometers3

77°F (25°C) and conforming to the requirements prescribed

in Specification E 1 are therefore specified. Ice point and

bore corrections must be known to the nearest 0.02”F. In

3. Teiminology’

use, the thermometers must be immersed to a point at least

2°F above the test temperature,

3.1 density-mass per unit volume.

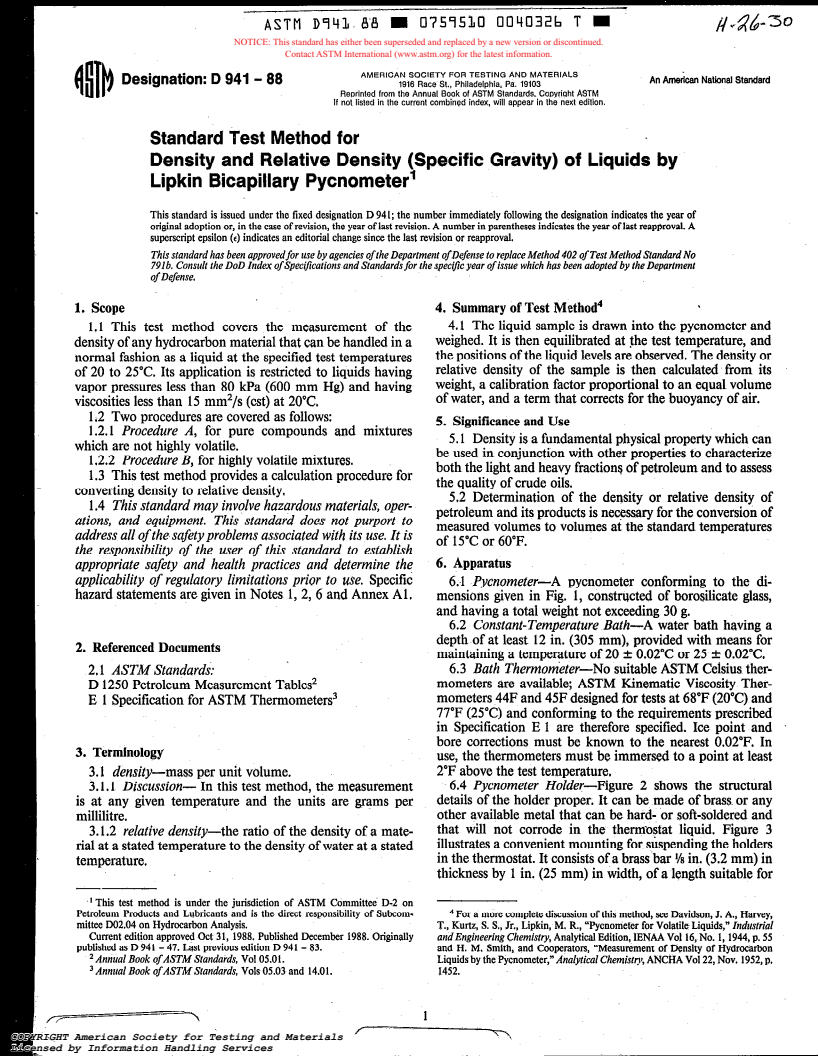

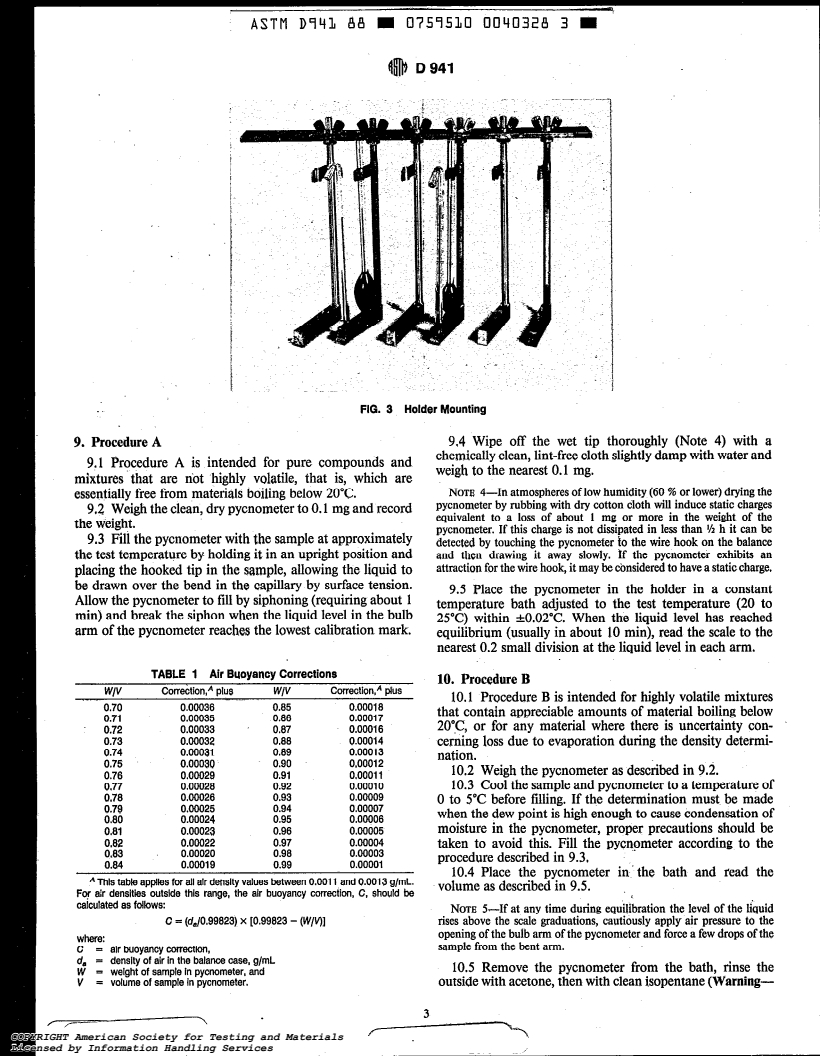

6.4 Pycnometer Holder-Figure 2 shows the structural

3.1.1 Discussion- In this test method, the measurement

details of the holder proper. It can be made of brass. or any

is at any given temperature and the units are grams per

other available metal that can be hard- or soft-soldered and

millilitre.

that will not corrode in the thermostat liquid. Figure 3

3.1.2 relative density-the ratio of the density of a mate-

illustrates a convenient mounting for suspending the holders

rial at a stated temperature to the density of water at a stated

in the thermostat. It consists of a bra&bar ‘/8 in. (3.2 mm) in

temperature,

thickness by 1 in. (25 mm) in width, of a length suitable for

‘r This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricanfs and is the direct responsibility of Subcom- 4 For a more complete discussion of this method, see Davidson, J. A., Harvey,

mittee DO2.04 on Hydrocarbon Analysis. T., Kurtz, S. S., Jr., Lipkin, M. R., “Pycnometer for Volatile Liquids,” Indusfrial

Current edition approved Ott 31, -1988. Published December

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.