ASTM F409-99a

(Specification)Standard Specification for Thermoplastic Accessible and Replaceable Plastic Tube and Tubular Fittings

Standard Specification for Thermoplastic Accessible and Replaceable Plastic Tube and Tubular Fittings

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions and tolerances, hydrostatic pressure, joint integrity, and solvent cement for thermoplastic tube and fittings for accessible and replaceable domestic waste connections. Marking requirements are also included. Plastic which does not meet the material requirements specified in Section is excluded.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F 409 – 99a

Standard Specification for

Thermoplastic Accessible and Replaceable Plastic Tube and

Tubular Fittings

This standard is issued under the fixed designation F 409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 2564 Specification for Solvent Cements for Poly(Vinyl

Chloride) (PVC) Plastic Piping Systems

1.1 This specification covers requirements and test methods

D 2609 Specification for Plastic Insert Fittings for Polyeth-

for materials, dimensions and tolerances, hydrostatic pressure,

ylene (PE) Plastic Pipe

joint integrity, and solvent cement for thermoplastic tube and

D 2657 Practice for Heat Joining of Polyolefin Pipe and

fittings for accessible and replaceable domestic waste connec-

Fittings

tions. Marking requirements are also included. Plastic which

D 2661 Specification for Acrylonitrile-Butadiene-Styrene

does not meet the material requirements specified in Section 5

(ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe

is excluded.

and Fittings

1.2 The text of this specification references notes, footnotes,

D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

and appendixes which provide explanatory material. These

tic Drain, Waste, and Vent Pipe and Fittings

notes and footnotes (excluding those in tables and figures) shall

D 3965 Specification for Rigid Acrylonitrile-Butadiene-

not be considered as requirements of the specification.

Styrene (ABS) Compounds for Pipe and Fittings

1.3 The values stated in inch-pound units are to be regarded

D 4101 Specification for Propylene Plastic Injection and

as the standard. The values given in parentheses are for

Extrusion Materials

information only.

F 402 Practice for Safe Handling of Solvent Cements,

1.4 The following safety hazards caveat pertains only to the

Primers, and Cleaners Used for Joining Thermoplastic Pipe

test methods portion, Section 8, of this specification: This

and Fittings

standard does not purport to address all of the safety concerns,

F 412 Terminology Relating to Plastic Piping Systems

if any, associated with its use. It is the responsibility of the user

F 1498 Specification for Taper Pipe Thread 60° for Ther-

of this standard to establish appropriate safety and health

moplastic Pipe and Fittings

practices and determine the applicability of regulatory limita-

2.2 Federal Standard:

tions prior to use.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2. Referenced Documents

2.3 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

2.1 ASTM Standards:

2.4 ANSI/ASME Standard:

D 618 Practice for Conditioning Plastics for Testing

B1.20.1 Pipe Threads, General Purpose (Inch)

D 1600 Terminology for Abbreviated Terms Relating to

2.5 Other Document:

Plastics

Uniform Plumbing Code

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

Compounds and Chlorinated Poly(Vinyl Chloride)

3. Terminology

(CPVC) Compounds

3.1 Definitions—Definitions are in accordance with Termi-

D 2122 Test Method for Determining Dimensions of Ther-

3 nology F 412, and abbreviations are in accordance with Ter-

moplastic Pipe and Fittings

minology D 1600, unless otherwise specified.

D 2235 Specification for Solvent Cement for Acrylonitrile-

3 3.1.1 The plumbing terminology used in this specification is

Butadiene-Styrene (ABS) Plastic Pipe and Fittings

1 4

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic Annual Book of ASTM Standards, Vol 08.02.

Piping Systems and is the direct responsibility of Subcommittee F17.63 on Drain, Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Waste, and Vent Pipe and Tube. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Current edition approved August 10, 1999. Published September 1999. Origi- Available from the American National Standards Institute, 11 West 42nd St.,

nally published as F 409 – 75. Last previous edition F 409 – 99. 13th Fl., New York, NY 10036.

2 7

Annual Book of ASTM Standards, Vol 08.01. Available from the International Association of Plumbing and Mechanical

Annual Book of ASTM Standards, Vol 08.04. Officials, 20001 E. Walnut Drive, South Walnut, CA 917892825.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 409

in accordance with the definitions given in the Uniform 6.3 Straight Pipe Threads (NPSM)—For all fittings having

Plumbing Code, unless otherwise indicated. straight pipe threads, threads shall conform to ANSI B1.20.1

(NPSM) and be gaged in accordance with 8.6.

4. Significance and Use

6.4 All tube and fittings made from propylene plastic shall

4.1 The requirements of this specification are intended to be assembled by either mechanical connections or by heat

provide accessible and replaceable tube and fittings to convey fusion, in accordance with Practice D 2657.

domestic waste from fixtures to the drain, waste, and vent

7. Requirements

(DWV) system.

7.1 General—The tube and fittings shall be homogeneous

5. Materials and Manufacture

throughout and free of visible cracks, holes, foreign inclusions,

5.1 Tube—The tube shall be made of one of the following or other injurious defects. They shall be as uniform as

materials: commercially practicable in color, opacity, density, and other

5.1.1 Virgin acrylonitrile-butadiene-styrene (ABS) plastic physical properties.

which shall meet the requirements of Specification D 3965, 7.2 Dimensions and Tolerances:

Cell Classification 4-2-2-2-2. 7.2.1 Tube:

5.1.2 Virgin poly(vinyl chloride) (PVC) plastic which shall 7.2.1.1 Tube Dimensions—The tube dimensions shall meet

meet the requirements for 12454C materials in accordance with the requirements given in Table 1 when measured in accor-

Specification D 1784, or dance with Test Method D 2122.

5.1.3 Virgin polypropylene plastic which shall meet the 7.2.1.2 Tube Length—The tolerance on tube lengths is 6 ⁄8

requirements of Specification D 4101, Cell Classification in. (63 mm).

PP0110B55140 and PP0105G20A33350. 7.2.2 Fittings:

5.2 Fittings and Mechanical Joint Components—The fit- 7.2.2.1 Fitting Dimensions—The dimensions of fittings

tings and components of mechanical joints shall be comprised shall meet the requirements of Table 2 when measured in

of one or more of the following materials: accordance with Test Method D 2122.

7.2.2.2 Fitting Laying Length Dimensions— The laying

5.2.1 Virgin ABS plastic which shall meet the requirements

of Specification D 3965, Cell Classification 2-0-2-1-1. lengths and other critical dimensions of fittings are shown in

Tables 3-13.

5.2.2 Virgin PVC plastics which shall meet the requirements

of 12454C materials as defined in Specification D 1784, or 7.2.2.3 Where applicable for assembly, refer to Table A1.1

5.2.3 Virgin polypropylene plastic which shall meet the in Specification D 2661, ABS Schedule 40 Fittings.

requirements of Specification D 4101, Cell Classification 7.2.2.4 Where applicable for assembly, refer to Table 1 in

PP0110B55140 and PP0105G20A33350 . Specification D 2665, PVC Schedule 40 Fittings.

5.3 Rework Material—The manufacturers shall use only 7.3 Hydrostatic Pressure—Tube, fittings, and assemblies

their own clean rework tube and fitting material and the tube or shall withstand a hydrostatic pressure of 25 psi (170 kPa) when

fittings produced shall meet all the requirements of this tested in accordance with 8.3.

specification. The different types of material shall not be 7.4 Axial Stress—Threaded connections shall withstand a

mixed. minimum axial load of 50 lbf (220 N) when tested in

5.4 Solvent Cement—The solvent cement shall meet the accordance with 8.4.

requirements of Specification D 2235 or Specification D 2564.

8. Test Methods

No cement joining of propylene plastic (PP) is permissible.

8.1 Sampling—Take at random a sample of the tube, fit-

6. Mechanical Connections

tings, or assemblies from each lot or shipment that is sufficient

6.1 Compression or threaded connections shall incorporate to determine conformance with this specification.

American National Straight Pipe Thread, Mechanical Joints for 8.2 Conditioning—Unless otherwise specified, condition

Fixtures (NPSM). The thread form shall be the form of the specimens prior to test at 70 to 77°F (23 6 2°C) and 50 6

American National Straight Pipe Thread and the dimensions 5 % relative humidity for not less than 40 h in accordance with

shall be in accordance with ANSI B1.20.1 (NPSM). All threads Procedure A of Practice D 618 for those tests where condition-

shall have a minimum three-thread engagement for fittings and ing is required and in all cases of disagreement.

plastic nuts. 8.3 Hydrostatic Pressure—Subject the tube and fittings, as

6.2 Taper Pipe Threads—For all fittings having taper pipe an assembly, to an internal hydrostatic pressure of 25 psi (170

threads, threads shall conform to Specification F 1498 and be kPa) for 1 h. The tube, fittings, and joints shall show no

gaged in accordance with 8.5. evidence of leaking.

TABLE 1 Dimensions and Tolerances for Outside Diameters and Thickness of Plastic Tube

Outside Diameter Wall Thickness

Nominal Tube Size Average Tolerance on Average Out-of-Roundness Minimum

(maximum minus minimum)

in. in. (mm) in. (mm) in. (mm) in. (mm)

1 ⁄4 1.250 (31.75) 60.005 (60.127) 0.020 (0.51) 0.062 (1.575)

1 ⁄2 1.500 (38.10) 60.005 (60.127) 0.020 (0.51) 0.062 (1.575)

F 409

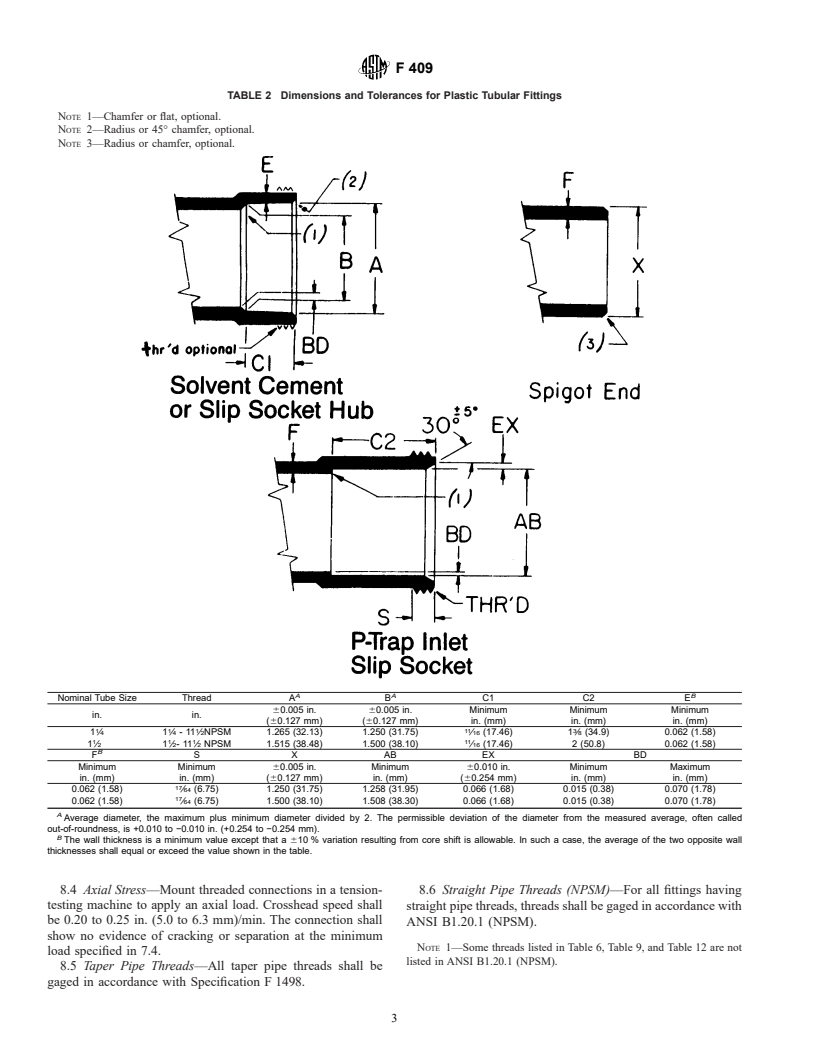

TABLE 2 Dimensions and Tolerances for Plastic Tubular Fittings

NOTE 1—Chamfer or flat, optional.

NOTE 2—Radius or 45° chamfer, optional.

NOTE 3—Radius or chamfer, optional.

A A B

Nominal Tube Size Thread A B C1 C2 E

60.005 in. 60.005 in. Minimum Minimum Minimum

in. in.

(60.127 mm) (60.127 mm) in. (mm) in. (mm) in. (mm)

1 1 1 11 3

1 ⁄4 1 ⁄4 -11 ⁄2NPSM 1.265 (32.13) 1.250 (31.75) ⁄16 (17.46) 1 ⁄8 (34.9) 0.062 (1.58)

1 1 1 11

1 ⁄2 1 ⁄2-11 ⁄2 NPSM 1.515 (38.48) 1.500 (38.10) ⁄16 (17.46) 2 (50.8) 0.062 (1.58)

B

F S X AB EX BD

Minimum Minimum 60.005 in. Minimum 60.010 in. Minimum Maximum

in. (mm) in. (mm) (60.127 mm) in. (mm) (60.254 mm) in. (mm) in. (mm)

0.062 (1.58) ⁄64 (6.75) 1.250 (31.75) 1.258 (31.95) 0.066 (1.68) 0.015 (0.38) 0.070 (1.78)

0.062 (1.58) ⁄64 (6.75) 1.500 (38.10) 1.508 (38.30) 0.066 (1.68) 0.015 (0.38) 0.070 (1.78)

A

Average diameter, the maximum plus minimum diameter divided by 2. The permissible deviation of the diameter from the measured average, often called

out-of-roundness, is +0.010 to −0.010 in. (+0.254 to −0.254 mm).

B

The wall thickness is a minimum value except that a 610 % variation resulting from core shift is allowable. In such a case, the average of the two opposite wall

thicknesses shall equal or exceed the value shown in the table.

8.4 Axial Stress—Mount threaded connections in a tension- 8.6 Straight Pipe Threads (NPSM)—For all fittings having

testing machine to apply an axial load. Crosshead speed shall

straight pipe threads, threads shall be gaged in accordance with

be 0.20 to 0.25 in. (5.0 to 6.3 mm)/min. The connection shall

ANSI B1.20.1 (NPSM).

show no evidence of cracking or separation at the minimum

NOTE 1—Some threads listed in Table 6, Table 9, and Table 12 are not

load specified in 7.4.

listed in ANSI B1.20.1 (NPSM).

8.5 Taper Pipe Threads—All taper pipe threads shall be

gaged in accordance with Specification F 1498.

F 409

A

TABLE 3 Fittings

NOTE 1—Baffle optional.

NOTE 2—See Table 2 for solvent cement or slip socket hub dimensions.

Nominal

GJ N

Tube Size

in. in. (mm)

B

1 13 13 1

1 ⁄2 ⁄16 (20.6) ⁄16(20.6) ⁄16 (1.6)

A

All dimensions are minimum.

B

See Table 2.

9. Retest and Rejection manufacturer’s name or trademark, the size, and “ABS Tubular

F 409,” “PVC Tubular F 409,” or “P Tubular F 409.”

9.1 If the results of any test(s) do not meet the requirements

10.3 All baffle tees and such fittings as so required shall be

of this specification, the test(s) shall be conducted again only

by agreement between the purchaser and seller. Under such marked with arrows indicating the direction of flow when

correctly installed.

agreement, minimum requirements shall not be lowered,

changed, or modified, nor shall specification limits be changed.

If upon request, failure occurs, the quantity of product repre- 11. Quality Assurance

sented by the test(s) does not meet the requirements of this

11.1 When the product is marked with this designation,

specification.

F 409, the manufacturer affirms that the product was manufac-

tured, inspected, sampled, and tested in accordance with this

10. Product Marking

specification and has been found to meet the require-ments of

10.1 Tube—The tube shall be marked in letters not less than

this specification.

⁄8 in. (3 mm) high in a contrasting color and shall at least

consist of the nominal size, manufacturer’s name or trademark,

12. Keywords

and “ABS Tubular F 409,” “PVC Tubular F 409,” or “PP

Tubular F 409” at intervals of not greater than 2 ft (610 mm). 12.1 ABS; cellular; DWV; fittings; pipe; plastic; Schedule

10.2 Fittings—All fittings shall be marked on the body or 40; thermoplastic

hub on both sides. The marking shall consist, at least, of the

F 409

TABLE 4 End Outlet Continuous Waste

NOTE 1—Radius optional.

NOTE 2—Baffle optional.

NOTE 3—Arm shall either be one-piece construction or assembled. If assembled, socket shall conform to Table 2.

NOTE 4—Shall be swivel nut, slip nut, or slip socket connection (shown in Table 5).

NOTE 5—Dishwasher branch optional.

NOTE 6—See Table 6.

NOTE 7—See Table 2.

LHJ GG

Minimum Minimum

Adjustable in four sizes, in. (mm)

in. (mm) in. (mm)

6 (152.4) 1 ⁄2(38.1) 12 (305) 16 (406) 21 (533) 25 (635)

F 409

TABLE 5 Center Outlet Continuous Waste

NOTE 1—See Table 2.

NOTE 2—Radius optional.

NOTE 3—Baffle optional.

NOTE 4—Arm shall be either one-piece construction or assembled. If assembled, socket shall conform to Table 2.

NOTE 5—Shall also be swivel connection as shown in Table 4.

HL GG

Minimum Minimum

Adjustable in four sizes, in. (mm)

in. (mm) in. (mm)

1 ⁄2 (38.1) 6 (152.4) 12 (305) 16 (406) 21 (533) 25 (635)

F 409

A

TABLE 6 Dishwasher Branch Tailpiece

NOTE 1—May be swivel or slip connect construction.

NOTE 2—Baffle optional.

NOTE 3—See Table 2.

B

NOTE 4—See footnote below.

C

HP S Z LJ XN

Minimum

in. (mm) in. (m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.