ASTM F2435-05

(Specification)Standard Specification for Steel Reinforced Polyethylene (PE) Corrugated Pipe

Standard Specification for Steel Reinforced Polyethylene (PE) Corrugated Pipe

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, elongation, impact resistance, pipe stiffness, perforations, and markings for steel reinforced corrugated polyethylene (PE) piping systems of nominal sizes 8 in. (200 mm), through 80 in. (2000 mm). The steel reinforced polyethylene pipes governed by this standard are intended for use in underground applications where soil provides support for their flexible walls. These pipes will be used to collect or convey stormwater runoff for storm sewers and drainage pipes, or both.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 There is no similar or equivalent ISO standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F 2435 – 05

Standard Specification for

Steel Reinforced Polyethylene (PE) Corrugated Pipe

This standard is issued under the fixed designation F 2435; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

1.1 This specification covers requirements and test methods

D 2321 Practice for Underground Installation of Thermo-

for materials, dimensions, workmanship, elongation, impact

plastic Pipe for Sewers and Other Gravity Flow Applica-

resistance, pipe stiffness, perforations, and markings for steel

tions

reinforced corrugated polyethylene (PE) piping systems of

D 2412 Test Method for Determination of External Loading

nominal sizes 8 in. (200 mm), through 80 in. (2000 mm). The

Characteristics of Plastic Pipe by Parallel-Plate Loading

steel reinforced polyethylene pipes governed by this standard

D 3212 Specification for Joints for Drain and Sewer Plastic

are intended for use in underground applications where soil

Pipes Using Flexible Elastomeric Seals

provides support for their flexible walls. These pipes will be

D 3350 Specification for Polyethylene Plastics Pipe and

used to collect or convey stormwater runoff for storm sewers

Fittings Materials

and drainage pipes, or both.

F 412 Terminology Relating to Plastic Piping Systems

1.2 The values stated in inch-pound units are to be regarded

F 449 Practice for Subsurface Installation of Corrugated

as standard. The values given in parentheses are mathematical

Thermoplastic Pipe for Agricultural Drainage or Water

conversions to SI units that are provided for information only

Table Control

and are not considered standard.

F 477 Specification for Elastomeric Seals (Gaskets) for

1.3 There is no similar or equivalent ISO standard.

Joining Plastic Pipe

1.4 This standard does not purport to address all of the

F 2136 Test Method for Notched Constant Ligament Stress

safety concerns, if any, associated with its use. It is the

(NCLS) test to Determine Slow Crack Growth Resistance

responsibility of the user of this standard to establish appro-

of HDPE resins or HDPE Corrugated Pipe

priate safety and health practices and determine the applica-

2.2 Federal Standards:

bility of regulatory limitations prior to use.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2. Referenced Documents 2.3 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

2.1 ASTM Standards:

A 591A/A 591M Specification for Steel Sheet, Electrolytic

3. Terminology

Zinc-Coated, for Light Coating Weight [Mass] Applica-

3.1 Definitions—Definitions used in this specification are in

tions

accordance with Terminology F 412, unless otherwise noted.

A 1008/A 1008M Specification for Steel, Sheet, Cold-

3.2 Definitions of Terms Specific to This Standard:

Rolled Carbon Structural, High Strength Low-Alloy with

3.2.1 double-wall steel reinforced polyethylene corrugated

Improved Formability

pipe—polyethylene corrugated pipe with steel reinforcing

D 618 Practice for Conditioning Plastics and Electrical

helical V-shaped plates encapsulated within the corrugations

Insulating Materials for Testing

and with an closed channel on the inside of the pipe (See Fig.

1)

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

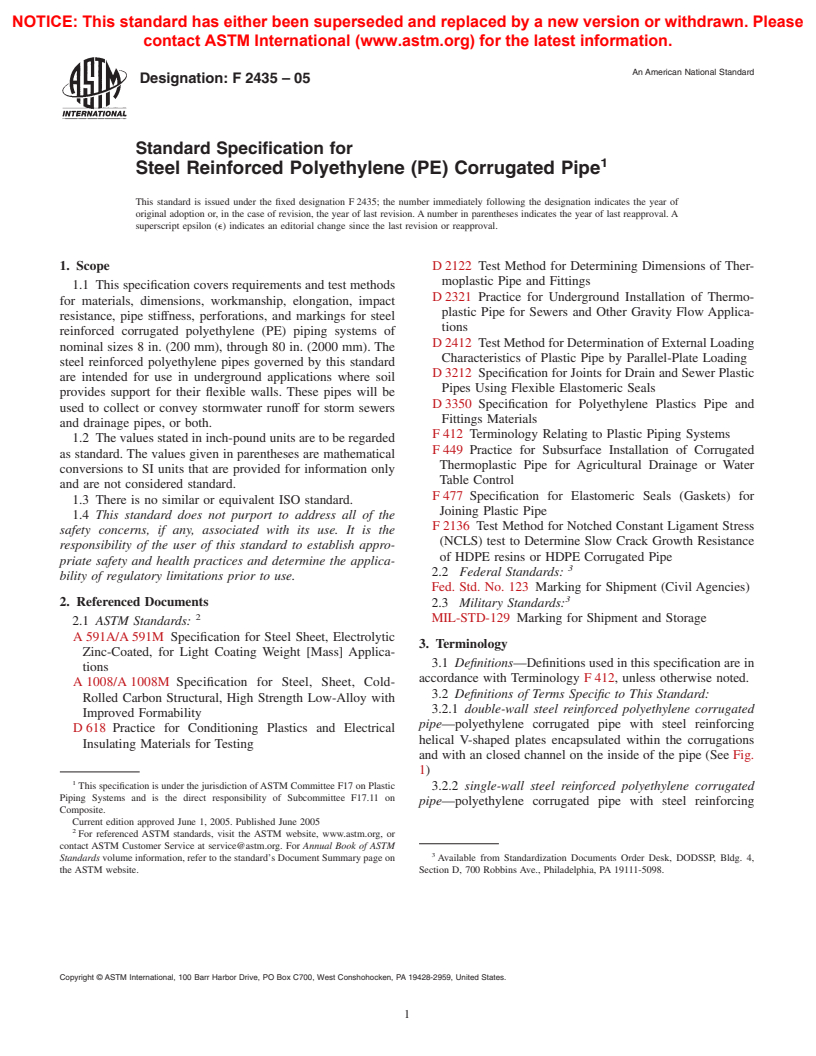

3.2.2 single-wall steel reinforced polyethylene corrugated

Piping Systems and is the direct responsibility of Subcommittee F17.11 on

pipe—polyethylene corrugated pipe with steel reinforcing

Composite.

Current edition approved June 1, 2005. Published June 2005

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

the ASTM website. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

F2435–05

FIG. 1 Single - Wall Steel Reinforced Corrugated Polyethylene

Pipe

helical V-shaped plates encapsulated within the corrugations flexible walls. Their major use is to collect or convey storm

and with a open channel on the inside of the pipe (See Fig. 2) water run-off for sewers and drains, or both.

4.2 Exclusions from recommended use:

4. Significance and Use

4.2.1 Permanent exposure to sunlight and exposure to

4.1 Steel reinforced corrugated PE pipes are used for

chemicals whose compatibility with the pipe and fittings is not

underground applications where soil provides support to their

known.

5. Materials

5.1 Polyethylene Materials:

5.1.1 Polyethylene compounds used in the manufacture of

steel reinforced corrugated PE drainage pipe shall meet or

exceed the requirements of cell classification of 344430C as

defined and described in Specification D 3350.

5.1.2 Slow crack growth resistance of the polyethylene

natural resin shall be determined by testing in accordance with

Test Method F 2136. The applied stress shall be 600 psi (4100

kPa). The test specimens must exceed 24 h with no failures.

Testing shall be done on polyethylene material taken from the

finished pipe.

5.1.3 Carbon Black Content—Minimum 2.0 wt. % to a

maximum3.0wt. %ofthetotalofthepolyethylenecompound.

5.2 Steel Materials:

5.2.1 The minimum thickness of the steel sheet shall be

0.0078 inches (0.20 mm) and the minimum yield strength shall

not be less than 15 ksi (105 MPa). The steel substrate shall

conform to Specification A 1008/A 1008M. The zinc-

galvanized coating shall have a minimum zinc coating desig-

nationof20Z(intermediatecoating)asdefinedinSpecification

FIG. 2 Double - Wall Steel Reinforced Corrugated Polyethylene

Pipe A 591/A 591M.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

F2435–05

5.2.2 Steel Material Content—Maximum 46 % (62%) of and circumference of the pipe in a size, shape, and pattern

the total weight of the pipe. The steel material is fully suited to the needs of the user. Perforations shall be in the

encapsulated by the polyethylene material with a minimum valley portion of the pipe. The reinforcing steel material shall

thickness of the polyethylene of 0.055 in. (1.4 mm). not be exposed by these perforations.

5.3 Rework Material—Rework material is not to be used in 6.3.2 The inlet area of the perforations shall be a minimum

2 2

the manufacture of this product. of 1 in. /ft (21 cm /m) of pipe.

5.4 Gaskets—Elastomeric gaskets shall comply with the 6.4 Pipe Stiffness—The pipe shall have a minimum pipe

requirements specified in Specification F 477. stiffness of 58 psi (0.40 MPa) at 5 % deflection, when tested in

5.5 Lubricant—Thelubricantusedforassemblyofgasketed accordance with section 8.7.

joints shall have no detrimental effect on the gasket or on the

NOTE 1—The 5 % deflection criteria was selected for testing conve-

pipe.

nience and should not be considered as a limitation with respect to in-use

deflection.

6. Requirements

6.5 Bonding of the Steel to the Polyethylene—The mechani-

6.1 Workmanship—The inside and outside surfaces of the

cal bond between the steel reinforcing V-shaped plate and the

pipe shall be semi-matte or glossy in appearance and free of

polyethylene shall be greater than the tensile strength of the

chalking, sticky, or tacky materials. The pipe wall shall not

polyethylene resin required for this standard. It shall not be

have cracks, holes, blisters, voids, foreign inclusions or other

possible to separate any two layers with a probe or with the

defects that are visible to the naked eye and that can affect the

point of a knife blade so that the layers separate cleanly, or the

wall integrity or the bonding to the steel reinforcement. Holes

probe or knife moves freely between the layers. There shall be

deliberately placed in perforated pipe are permitted. The

no separation of the polyethylene from the steel reinforcing

surface shall be free of bloom.

plate, when the pipe is deflected 40 %, in accordance with Test

6.2 Pipe Dimensions and Tolerances:

Method D 2412.

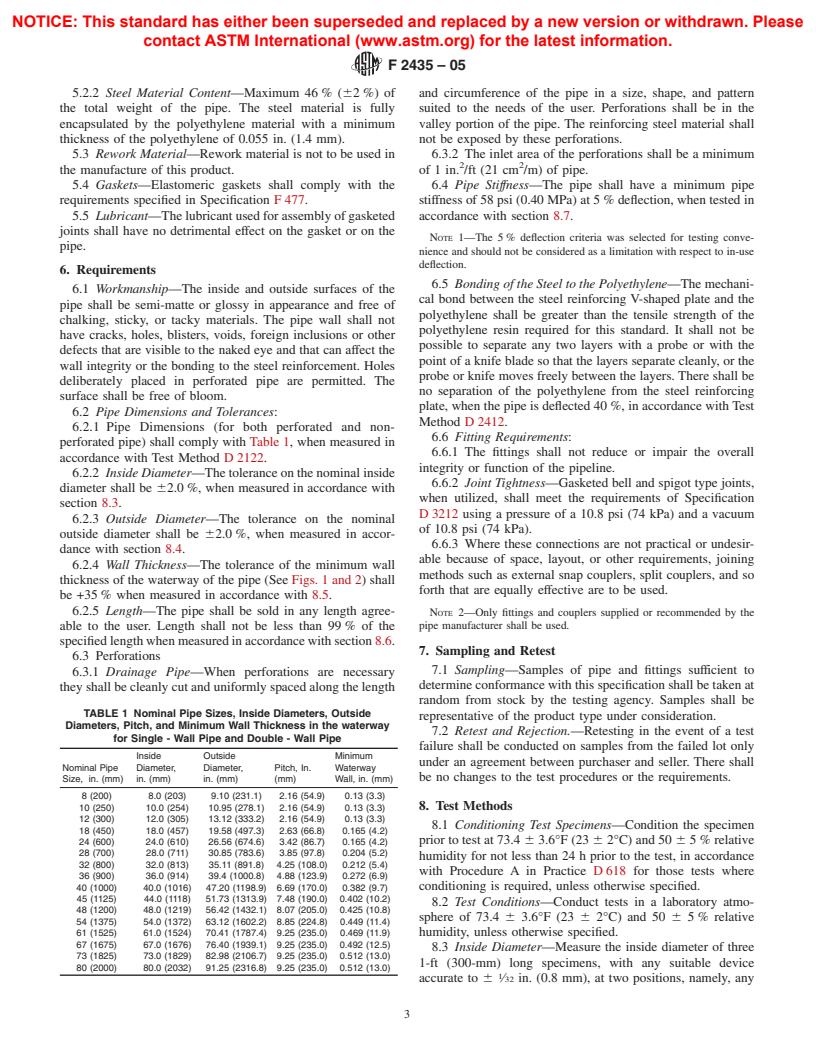

6.2.1 Pipe Dimensions (for both perforated and non-

6.6 Fitting Requirements:

perforated pipe) shall comply with Table 1, when measured in

6.6.1 The fittings shall not reduce or impair the overall

accordance with Test Method D 2122.

integrity or function of the pipeline.

6.2.2 Inside Diameter—The tolerance on the nominal inside

6.6.2 Joint Tightness—Gasketed bell and spigot type joints,

diameter shall be 62.0 %, when measured in accordance with

when utilized, shall meet the requirements of Specification

section 8.3.

D 3212 using a pressure of a 10.8 psi (74 kPa) and a vacuum

6.2.3 Outside Diameter—The tolerance on the nominal

of 10.8 psi (74 kPa).

outside diameter shall be 62.0 %, when measured in accor-

6.6.3 Where these connections are not practical or undesir-

dance with section 8.4.

able because of space, layout, or other requirements, joining

6.2.4 Wall Thickness—The tolerance of the minimum wall

methods such as external snap couplers, split couplers, and so

thickness of the waterway of the pipe (See Figs. 1 and 2) shall

forth that are equally effective are to be used.

be +35 % when measured in accordance with 8.5.

6.2.5 Length—The pipe shall be sold in any length agree-

NOTE 2—Only fittings and couplers supplied or recommended by the

pipe manufacturer shall be used.

able to the user. Length shall not be less than 99 % of the

specifiedlengthwhenmeasuredinaccordancewithsection8.6.

7. Sampling and Retest

6.3 Perforations

7.1 Sampling—Samples of pipe and fittings sufficient to

6.3.1 Drainage Pipe—When perforations are necessary

determine conformance with this specification shall be taken at

they shall be cleanly cut and uniformly spaced along the length

random from stock by the testing agency. Samples shall be

TABLE 1 Nominal Pipe Sizes, Inside Diameters, Outside

representative of the product type under consideration.

Diameters, Pitch, and Minimum W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.