ASTM D5380-93(2021)

(Test Method)Standard Test Method for Identification of Crystalline Pigments and Extenders in Paint by X-Ray Diffraction Analysis

Standard Test Method for Identification of Crystalline Pigments and Extenders in Paint by X-Ray Diffraction Analysis

SIGNIFICANCE AND USE

4.1 The choice of pigments and extenders influences the appearance, durability, cost, and other properties of paint. This test method is a convenient way, and probably the most reliable, to identify pigments in paint.

SCOPE

1.1 This test method covers the identification of crystalline pigments and extenders in liquid paint and dry paint film. It is applicable to both water-reducible and solvent-reducible paint. It also may be used to identify pigment and extender in grind paste or alone as dry powder. It is not applicable to amorphous components such as carbon black, amorphous silica, or highly processed clay.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5380 −93 (Reapproved 2021)

Standard Test Method for

Identification of Crystalline Pigments and Extenders in Paint

by X-Ray Diffraction Analysis

This standard is issued under the fixed designation D5380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Whether the substance is present alone or in a mixture, it

produces its pattern independently and can be identified by it.

1.1 This test method covers the identification of crystalline

An X-ray diffraction pattern of a sample is recorded. Each

pigments and extenders in liquid paint and dry paint film. It is

crystalline substance in the sample is identified by the

applicable to both water-reducible and solvent-reducible paint.

Hanawalt or Fink method or other systematic procedure based

It also may be used to identify pigment and extender in grind

on comparison of the diffraction pattern of the sample with

paste or alone as dry powder. It is not applicable to amorphous

3,4,5

reference patterns of standards.

components such as carbon black, amorphous silica, or highly

processed clay.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as

4.1 The choice of pigments and extenders influences the

standard. No other units of measurement are included in this

appearance, durability, cost, and other properties of paint.This

standard.

test method is a convenient way, and probably the most

1.3 This standard does not purport to address all of the

reliable, to identify pigments in paint.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 5. Apparatus

priate safety, health, and environmental practices and deter-

5.1 X-ray Diffractometer, suitable for collecting intensity

mine the applicability of regulatory limitations prior to use.

versus two theta (20) angle diffraction patterns in the range

Specific hazard statements are given in Section 6.

from 5° to 65° 20. It is preferred that the diffractometer be

1.4 This international standard was developed in accor-

equippedwithacoppertargetX-raytubeandamonochromator

dance with internationally recognized principles on standard-

that passes only copper K-alpha radiation. If a monochromator

ization established in the Decision on Principles for the

is not available, then a suitable filter may be used to remove

Development of International Standards, Guides and Recom-

copper K-beta radiation from the diffracted X-ray beam. A

mendations issued by the World Trade Organization Technical

nickel filter may be used for this purpose when a copper target

Barriers to Trade (TBT) Committee.

tube is employed.

2. Referenced Documents NOTE 1—Follow the recommendations of the manufacturer of the

diffractometer used.

2.1 ASTM Standards:

5.2 Liquid Paint or Grind Paste:

D3925Practice for Sampling Liquid Paints and Related

5.2.1 Paint Shaker.

Pigmented Coatings

5.2.2 Film Applicator, that will produce a 3- to 10-mil (75-

to 250 µm) wet film thickness.

3. Summary of Test Method

5.2.3 Plastic Sheet, such as polyester film, that contains no

3.1 Every crystalline substance, in this case pigment or

crystalline components that would produce interfering X-ray

extender, has a characteristic X-ray diffraction pattern.

diffraction peaks and is not attacked by paint solvent.

5.2.4 Perforated Suction Plate or other flat surface.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

5.3 Paint Chips or Pigment Powder:

and Related Coatings, Materials, andApplications and is the direct responsibility of

5.3.1 Miniature Reciprocating Ball Mill.

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved Feb. 1, 2021. Published February 2021. Originally

approved in 1993. Last previous edition approved in 2014 as D5380–93(2014).

DOI: 10.1520/D5380-93R21. Search Manual, (Hanawalt), “Inorganic Phases,” International Centre for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or DiffractionData,(ICDD),CatalogNo.HA42,NewtownSquareCorporateCampus,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 12 Campus Blvd., Newtown Square, PA19073-3273.

Standards volume information, refer to the standard’s Document Summary page on Search Manual, (Fink), “Inorganic Phases,” ICDD.

the ASTM website. “Powder Diffraction File, Inorganic,” ICDD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5380 − 93 (2021)

5.3.2 Stainless Steel Vials, with agitator for ball mill. to the same dimensions as the specimen holder and use the

5.3.3 Powder Specimen Holders, for X-ray diffractometer. specimen without the holder.

NOTE 3—An X-ray diffraction pattern collected for coating on a panel

6. Hazards

will be a superposition of the diffraction patterns of the crystalline

6.1 Precaution—As exposure to excessive quantities of components in the coating on the panel and, to the extent that X-rays

diffracted from the substrate reach the detector, the diffraction pattern of

X-radiation is injurious to health, X-ray producing equipment

the substrate.

can be dangerous to both the operator and persons in the

7.2 Mount the specimen in the specimen holder, taking care

immediate vicinity unless safety precautions are strictly ob-

to insure that the surface of the specimen is flush with the

served. Therefore, users should avoid exposing any parts of

optical plane of the holder.

their bodies, not only to the direct beam, but also to secondary

or scattered radiation that occurs when an X-ray beam strikes

NOTE 4—Failure to place the specimen surface in the optical plane

orpassesthroughanymaterial.Itisstronglyrecommendedthat

illuminated by the X-ray source and viewed by the detector will result in

users check the degree of exposure by film carried on them or a systematic shift from the correct position of peaks in the observed

diffractogram. The greater the shift, the greater the difficulty in using the

by the use of dosimeters and that blood counts be made

observed diffractogram to identify components in the specimen.

periodically. Before utilizing the equipment, all persons desig-

nated or authorized to operate X-ray instrumentation or super-

8. Procedure

viseitsoperation,shouldhaveafullunderstandingofitsnature

8.1 Experimental:

andshouldalsobecomefamiliarwithestablishedsafeexposure

8.1.1 Turn on the diffractometer and allow it to stabilize

factors by a careful study of the NIST handbook, “X-ray

thoroughly before beginning collection of results. With the aid

RecommendationsoftheInternationalRoentgenRayCommit-

of the manufacturer’s literature, select instrument operation

tee on X-ray Protection,” the manufacturer’s instruction

conditions that permit collection of X-ray diffractograms

manual, and other standard publications on the subject. Inqui-

spanning the two-theta range from 5 to 65°. The conditions

ries should be made of state agencies as to existing require-

chosen must be suitable for qualitative analysis of a multicom-

ments.

ponent mixture assuming the presence of a minor component

present at approximately one percent by weight. Results

7. Specimen Preparation

collected must be available as the d-spacing and intensity,

7.1 Prepare a specimen from the sample using one of the

preferably the integrated intensity, of each peak. In the case of

following methods:

diffractometers not equipped with a computer, the two-theta

7.1.1 Liquid Paint or Pigment Paste—Thoroughly mix and

and intensity data must be measured manually from plotted

sample the paint or paste in accordance with Practice D3925.

diffractionpatternsandthe d-spacingsthencalculatedfromthe

Place a plastic sheet on the perforated suction plate. On the

two-theta angles of the peaks. In the latter case, the diffraction

sheet make a drawdown of the sample.Awet film thickness of

patterns must be plotted with two-theta scale expansion that

3.0 to 10.0 mil (75 to 250 µm) is suggested. Cut from the

permits the angle of each peak to be measured to the nearest

drawdown on the plastic sheet a specimen of shape and size

0.01 Å for peaks in the range above 3.5 Å and to the nearest

suitable for the mounting in the specimen holder of the

0.001 Å for peaks below approximately 3.5 Å.

diffractometer.

NOTE 5—If not already established, then make sure that the two-theta

7.1.2 Paint Chip—Using a ball mill, grind to a powder the

calibration of the goniometer of the diffractometer is verified at two or

paint chip or, if it contains more than one layer, the part of the

moreanglesinaccordancewithrecommendationsofthemanufacturerand

chipofinterest.Preparesufficientspecimentofillthespecimen

correctedasneeded.Theprocedurewillentailcomparisonoftheobserved

holder or to satisfy the requirements of the preparation tech-

andexpected d-spacingofdiffractionpeaksofhighlycrystallinereference

nique to be used. In cases where the chip has a planar surface materials at least at one high and one low two-theta angle.

anduniformthickness,itmaybepossibletocutthechiptothe

8.1.2 For each sample correct the diffraction pattern span-

required dimensions and mount it directly in the specimen

ning at least from 5 to 65° two-theta.

holder with no preparation.

9. Identification

NOTE 2—X-ray diffraction patterns collected for specimens consisting

ofwholechipswillrevealthecompositionofallpaintlayersprobedbythe 9.1 Prepare a list of all diffraction peaks exhibited by the

X-rays.ThedepthprobedwilldependuponthewavelengthofX-rayused,

sample including both the d-spacing and intensity (preferably

thecompositionofthepaintlayerorlayersthroughwhichtheX-rayspass,

integrated intensity) of each peak, listed in decreasing order of

thecompositionofthedeepestlayerprobed,thetwo-thetaangle,andother

d-spacing. The d-spacing of each peak should be stated at the

factors. When a copper X-ray tube is used, the depth probed may range

nearest hundredth of an angstrom for d-spacings greater than

from as little as approximately 2 mils (75 µm) in the case of very high

density coatings to as much as 197 mils (0.5 cm) in the case of

3.5 Å and stated to the nearest thousandth of an angstrom for

unpigmented resin.

d-values of less than about 3.5 Å.

7.1.3 Paint Film on Panel—Cut from the panel a specimen

9.2 Identify the crystalline phase or phases that account for

ofdimensionssuitableformountinginthespecimenholder.As

allpeaksinthediffractionpatternofthesampleunderanalysis,

an alternative, it may be convenient to cut a piece of specimen

using the Hanawalt Method, Fink Method, or other systematic

procedure. Full identification of the crystalline components

may be speeded by use of information about components

NIST Handbook, X-Ray Recommendations for the International Roentgen Ray

Committee on X-Ray Protection, NIST, Gaithersburg, MD, 20899. known to be or suspected of being in the sample (that is,

D5380 − 93 (2021)

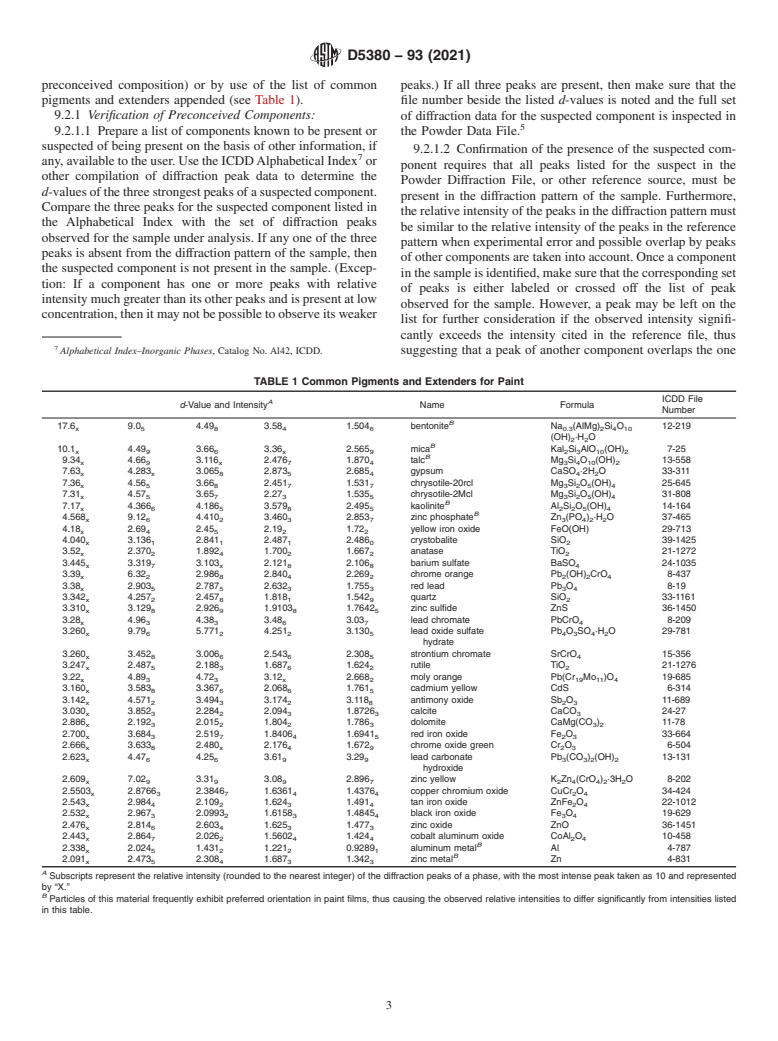

preconceived composition) or by use of the list of common peaks.) If all three peaks are present, then make sure that the

pigments and extenders appended (see Table 1). file number beside the listed d-values is noted and the full set

9.2.1 Verification of Preconceived Components:

of diffraction data for the suspected component is inspected in

9.2.1.1 Prepare a list of components known to be present or the Powder Data File.

suspected of being present on the basis of other information, if

9.2.1.2 Confirmation of the presence of the suspected com-

any,availabletotheuser.UsetheICDDAlphabeticalIndex or

ponent requires that all peaks listed for the suspect in the

other compilation of diffraction peak data to determine the

Powder Diffraction File, or other reference source, must be

d-valuesofthethreestrongestpeaksofasuspectedcomponent.

present in the diffraction pattern of the sample. Furthermore,

Compare the three peaks for the suspected component listed in

therelativeintensityofthepeaksinthediffractionpatternmust

the Alphabetical Index with the set of diffraction peaks

be similar to the relative intensity of the peaks in the reference

observed for the sample under analysis. If any one of the three

pattern when experimental error and possible overlap by peaks

peaks is absent from the diffraction pattern of the sample, then

ofothercomponentsaretakenintoaccount.Onceacomponent

the suspected component is not present in the sample. (Excep-

inthesampleisidentified,makesurethatthecorrespondingset

tion: If a component has one or more peaks with relative

of peaks is either labeled or crossed off the list of peak

intensitymuchgreaterthanitsotherpeaksandispresentatlow

observed for the sample. However, a peak may be left on the

concentration,thenitmaynotbepossibletoobserveitsweaker

list for further consideration if the observed intensity signifi-

cantly exceeds the intensity cited in the reference file, thus

Alphabetical Index–Inorganic Phases, Catalog No. Al42, ICDD. suggesting that a peak of another component overlaps the one

TABLE 1 Common Pigments and Extenders for Paint

ICDD File

A

d-Value and Intensity Name Formula

Number

B

17.6 9.0 4.49 3.58 1.504 bentonite Na (AlMg) Si O 12-219

x 5 8 4 6 0.3 2 4 10

(OH) ·H O

2 2

B

10.1 4.49 3.66 3.36 2.565 mica Kal Si AlO (OH) 7-25

x 9 6 x 9 2 3 10 2

B

9.34 4.66 3.116 2.476 1.870 talc Mg Si O (OH) 13-558

x 9 x 7 4 3 4 10 2

7.63 4.283 3.065 2.873 2.685 gypsum CaSO ·2H O 33-311

x x 8 5 4 4 2

7.36 4.56 3.66 2.451 1.531 chrysotile-20rcl Mg Si O (OH) 25-645

x 5 8 7 7 3 2 5 4

7.31 4.57 3.65 2.27 1.535 chrysotile-2Mcl Mg Si O (OH) 31-808

x 5 7 3 5 3 2 5 4

B

7.17 4.366 4.186 3.579 2.495 kaolinite Al Si O (OH) 14-164

x 6 5 8 5 2 2 5 4

B

4.568 9.12 4.410 3.460 2.853 zinc phosphate Zn (PO ) ·H O 37-465

x 6 2 3 7 3 4 2 2

4.18 2.69 2.45 2.19 1.72 yellow iron oxide FeO(OH) 29-713

x 4 5 2 2

4.040 3.136 2.841 2.487 2.486 crystobalite SiO 39-1425

x 1 1 1 0 2

3.52 2.370 1.892 1.700 1.667 anatase TiO 21-1272

x 2 4 2 2 2

3.445 3.319 3.103 2.121 2.106 barium sulfate BaSO 24-1035

x 7 x 8 8 4

3.39 6.32 2.986 2.840 2.269 chrome orange Pb (OH) CrO 8-437

x 2 8 4 2 2 2 4

3.38 2.903 2.787 2.632 1.755 red lead Pb O 8-19

x 5 5 3 3 3 4

3.342 4.257 2.457 1.818 1.542 quartz SiO 33-1161

x 2 8 1 9 2

3.310 3.129 2.926 1.9103 1.7642 zinc sulfide ZnS 36-1450

x 8 9 8 5

3.28 4.96 4.38 3.48 3.03 lead chromate PbCrO 8-209

x 3 3 6 7 4

3.260 9.79 5.771 4.251 3.130 lead oxide sulfate Pb O SO ·H O 29-78

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.