ASTM D2846/D2846M-99

(Specification)Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Hot- and Cold-Water Distribution Systems

Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Hot- and Cold-Water Distribution Systems

SCOPE

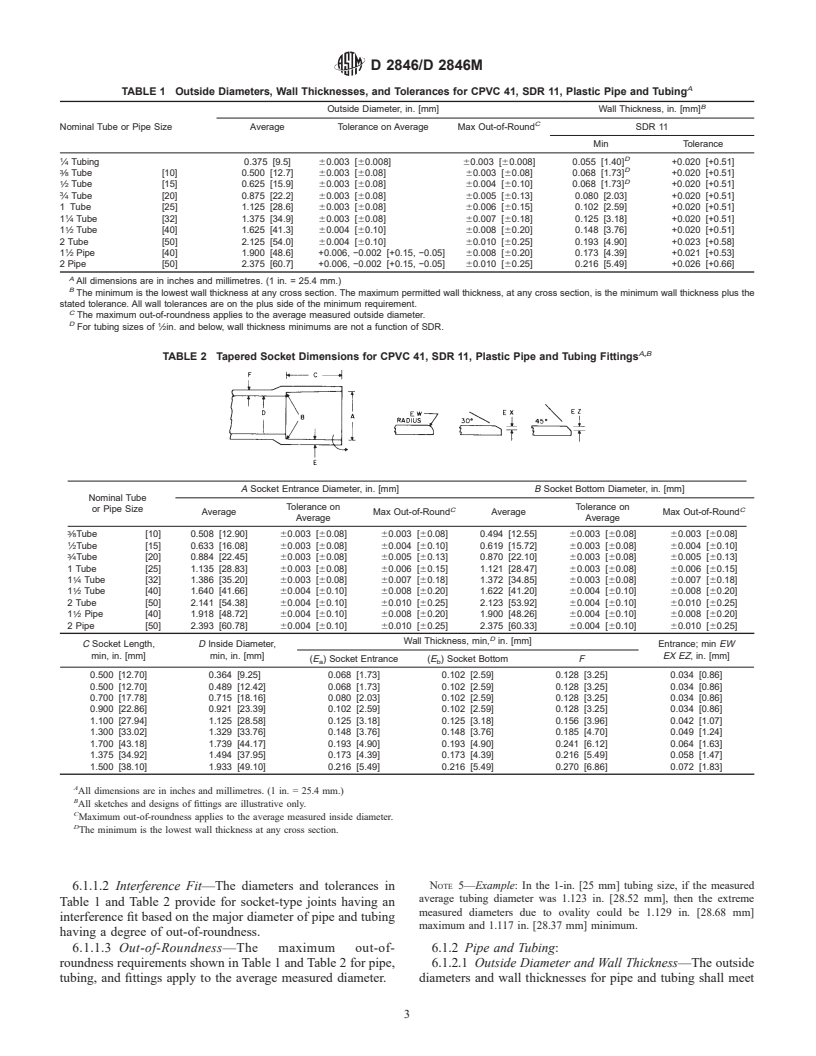

1.1 This specification covers requirements, test methods, and methods of marking for chlorinated poly(vinyl chloride) plastic hot- and cold-water distribution system components made in one standard dimension ratio and intended for water service up to and including 180°F (82°C). These components comprise pipe and tubing, socket-type fittings, street fittings, plastic-to-metal transition fittings, solvent cements, and adhesives. Requirements and methods of test are included for materials, workmanship, dimensions and tolerances, hydrostatic sustained pressure strength, and thermocycling resistance. The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Note 1-Suggested hydrostatic design stresses and hydrostatic pressure ratings for pipe, tubing, and fittings are listed in Appendix X1. Design, assembly, and installation considerations are discussed in Appendix X2. An optional performance qualification and an in-plant quality control program are recommended in Appendix X3.

1.4 The following safety hazards caveat pertains only to the test method portion, Sections 9 and 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2846/D 2846M – 99

Standard Specification for

Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Hot- and

1

Cold-Water Distribution Systems

This standard is issued under the fixed designation D 2846/D 2846M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

NOTE 2—Suggested hydrostatic design stresses and hydrostatic pres-

1. Scope

sure ratings for pipe, tubing, and fittings are listed in Appendix X1.

1.1 This specification covers requirements, test methods,

Design, assembly, and installation considerations are discussed in Appen-

and methods of marking for chlorinated poly(vinyl chloride)

dix X2. An optional performance qualification and an in-plant quality

plastic hot- and cold-water distribution system components

control program are recommended in Appendix X3.

made in one standard dimension ratio and intended for water

1.5 The following safety hazards caveat pertains only to the

service up to and including 180°F (82°C). These components

test method portion, Sections 9 and 10, of this specification:

comprise pipe and tubing, socket-type fittings, street fittings,

This standard does not purport to address all of the safety

plastic-to-metal transition fittings, solvent cements, and adhe-

concerns, if any, associated with its use. It is the responsibility

sives. Requirements and methods of test are included for

of the user of this standard to establish appropriate safety and

materials, workmanship, dimensions and tolerances, hydro-

health practices and determine the applicability of regulatory

static sustained pressure strength, and thermocycling resis-

limitations prior to use.

tance. The components covered by this specification are

intended for use in residential and commercial, hot and cold,

2. Referenced Documents

potable water distribution systems.

2.1 ASTM Standards:

1.2 The products covered by this specification are intended

D 1598 Test Method for Time-to-Failure of Plastic Pipe

for use with the distribution of pressurized liquids only, which

2

Under Constant Internal Pressure

are chemically compatible with the piping materials. Due to

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

inherent hazards associated with testing components and sys-

2

sure of Plastic Pipe, Tubing, and Fittings

tems with compressed air or other compressed gases some

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

manufacturers do not allow pneumatic testing of their products.

Compounds and Chlorinated Poly(Vinyl Chloride)

Consult with specific product/component manufacturers for

3

(CPVC) Compounds

their specific testing procedures prior to pneumatic testing.

3

D 1898 Practice for Sampling of Plastics

NOTE 1—Pressurized (compressed) air or other compressed gases D 2122 Test Method for Determining Dimensions of Ther-

2

contain large amounts of stored energy which present serious saftey

moplastic Pipe and Fittings

hazards should a system fail for any reason.

D 2444 Test Method for Impact Resistance of Thermoplas-

2

tic Pipe and Fittings by Means of a Tup (Falling Weight)

1.3 The text of this specification references notes, footnotes,

D 2837 Test Method for Obtaining Hydrostatic Design

and appendixes which provide explanatory material. These

2

Basis for Thermoplastic Pipe Materials

notes and footnotes (excluding those in tables and figures) shall

F 402 Practice for Safe Handling of Solvent Cements,

not be considered as requirements of the specification.

Primers, and Cleaners Used for Joining Thermoplastic Pipe

1.4 The values stated in either inch-pound or SI units are to

2

and Fittings

be regarded separately as standard. Within the text, SI units are

2

F 412 Terminology Relating to Plastic Piping Systems

shown in brackets. The values stated in each system are not

F 493 Specification for Solvent Cements for Chlorinated

exact equivalents; therefore, each system shall be used inde-

2

Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

pendently of the other. Combining values from the two systems

F 1498 Specification for Taper Pipe Threads 60° for Ther-

may result in nonconformance with the specification.

2

moplastic Pipe and Fittings

2.2 ANSI Standards:

1

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

2

Current edition approved May 10, 1999. Published July 1999. Originally Annual Book of ASTM Standards, Vol 08.04.

3

published as D 2846 – 69. Last previous edition D 2846 – 97. Annual Book of A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.