ASTM D4434-96

(Specification)Standard Specification for Poly(Vinyl Chloride) Sheet Roofing

Standard Specification for Poly(Vinyl Chloride) Sheet Roofing

SCOPE

1.1 This specification covers flexible sheet made from poly(vinyl/chloride) resin as the primary polymer intended for use in single-ply roofing membranes exposed to the weather. The sheet shall contain reinforcing fibers or reinforcing fabrics.

1.2 The tests and property limits used to characterize the sheet are values intended to ensure minimum quality for the intended purpose. In-place roof system design criteria, such as fire resistance, material compatibility, wind uplift resistance, in-situ shrinkage, among others, are factors that must be considered but are beyond the scope of this specification.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4434 – 96

Standard Specification for

Poly(Vinyl Chloride) Sheet Roofing

This standard is issued under the fixed designation D 4434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope (Xenon-Arc Type) With and Without Water for Exposure

of Nonmetallic Materials

1.1 This specification covers flexible sheet made from

G 53 Practice for Operating Light- and Water-Exposure

poly(vinyl/chloride) resin as the primary polymer intended for

Apparatus (Fluorescent UV/Condensation Type) for Expo-

use in single-ply roofing membranes exposed to the weather.

sure of Nonmetallic Materials

The sheet shall contain reinforcing fibers or reinforcing fabrics.

1.2 The tests and property limits used to characterize the

3. Classification

sheet are values intended to ensure minimum quality for the

3.1 Type II:

intended purpose. In-place roof system design criteria, such as

3.1.1 Grade 1—Reinforced sheet in which fibers are incor-

fire resistance, material compatibility, wind uplift resistance,

porated into a production process, for example as a carrier,

in-situ shrinkage, among others, are factors that must be

without appreciably affecting such physical property charac-

considered but are beyond the scope of this specification.

teristics of the finished product as tensile strength or ultimate

1.3 The values stated in SI units are to be regarded as the

elongation, but may provide other desirable characteristics,

standard. The values stated in parentheses are for information

such as dimensional stability.

only.

3.1.2 Grade 2—Externally reinforced sheet utilizing a fab-

2. Referenced Documents ric backing.

3.2 Type III—Sheet that is internally reinforced with fabric

2.1 ASTM Standards:

and which may also have a fabric backing.

D 570 Test Method for Water Absorption of Plastics

3.3 Type IV—Sheet that is internally reinforced with fabric

D 638 Test Method for Tensile Properties of Plastics

and which may also have a fabric backing with minimum

D 751 Test Methods for Coated Fabrics

thickness of 0.91 mm (0.036 in.).

D 1004 Test Method for Initial Tear Resistance of Plastic

Film and Sheeting

4. Materials and Manufacture

D 1204 Test Method for Linear Dimensional Changes of

4.1 The sheet shall consist of poly(vinyl chloride) resin in

Nonrigid Thermoplastic Sheeting or Film at Elevated

2 amounts greater than 50 % of the total polymer content

Temperature

suitably compounded with plasticizers, stabilizers, fillers, pig-

D 2136 Test Method for Coated Fabrics—Low Temperature

4 ments, and other ingredients to satisfy the physical property

Bend Test

5 requirements and accelerated durability tests.

D 3045 Practice for Heat Aging of Plastics Without Load

4.2 To make seams and repairs, the sheet shall be capable of

D 5602 Test Method for Static Puncture Resistance of

6 being bonded watertight to itself during the design service life

Roofing Membrane Samples

of the sheets. The manufacturer shall recommend a suitable

D 5635 Test Method for Dynamic Puncture Resistance of

6 method. Design service life is defined as the designated time

Roofing Membrane Samples

period of intended system performance.

G 26 Practice for Operating Light-Exposure Apparatus

5. Physical Requirements

5.1 The sheet shall conform to the physical requirements

This specification is under the jurisdiction of ASTM Committee D08 on

prescribed in Table 1.

Roofing, Waterproofing, and Bituminous Materials and is the direct responsibility of

Subcommittee D08.18 on Nonbituminous Organic Roof Coverings.

6. Dimensions

Current edition approved Nov. 10, 1996. Published January 1997. Originally

published as D 4434 – 85. Last previous edition D 4434 – 95.

6.1 The width and length of the sheet shall be agreed upon

Annual Book of ASTM Standards, Vol 08.01.

between the purchaser and the supplier as part of the purchase

Annual Book of ASTM Standards, Vol 09.02.

Annual Book of ASTM Standards, Vol 09.01.

Annual Book of ASTM Standards, Vol 08.02.

6 7

Annual Book of ASTM Standards, Vol 04.04. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4434–96

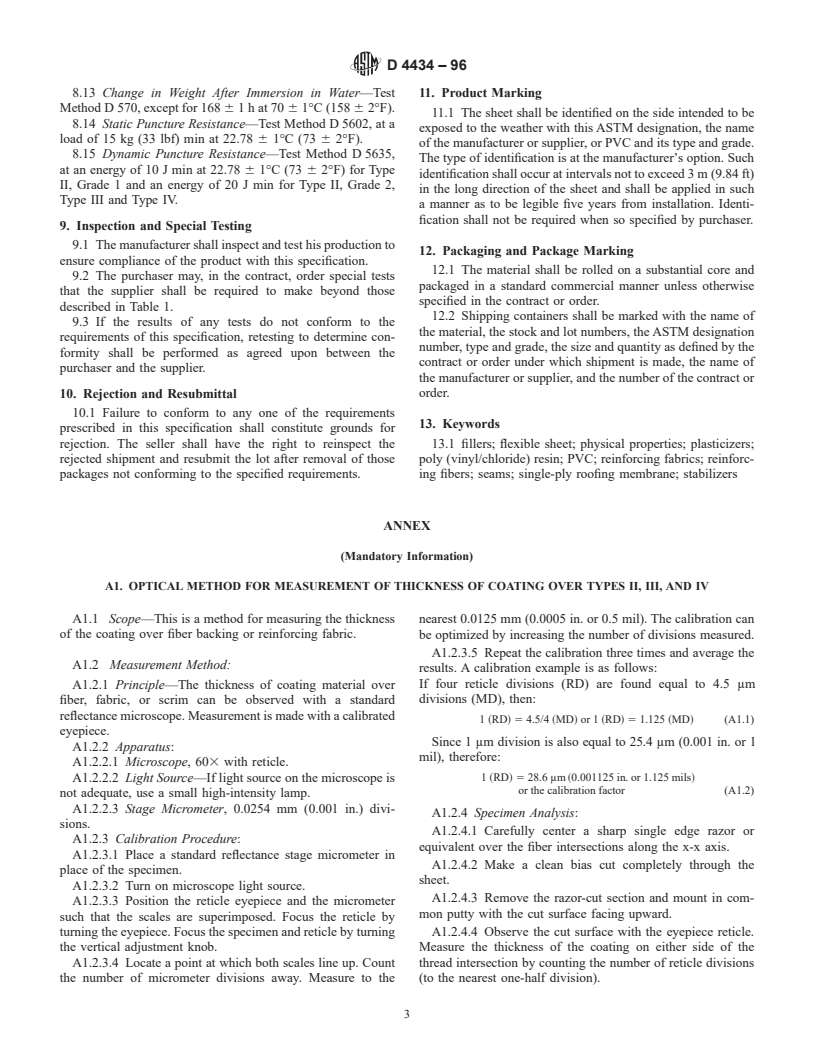

TABLE 1 Physical Requirements for Poly(Vinyl Chloride) Sheet

Type II

Property Type III Type IV

Grade 1 Grade 2

Overall thickness of PVC sheet, min, mm (in.) 1.14 (0.045) 1.14 (0.045) 1.14 (0.045) 0.91 (0.036)

Tensile strength at break, min, MPa (psi):

Machine direction 10.4 (1500) . . .

Cross-machine direction 10.4 (1500) . . .

Breaking strength, min, kN/m (lbf/in.) . 35 (200) 35 (200) 48 (275)

Elongation at break, min, %:

A A

Machine direction 250 15 15 25

A A

Cross-machine direction 220 15 15 25

Seam strength, min, % of tensile or breaking strength 75 75 75 75

Retention of properties after heat aging:

Tensile strength, min, % of original 90 . . .

Breaking strength, min, % of original . 90 90 90

Elongation, min, % of original 90 90 90 90

Tear resistance, min, N (lbf) 45.0 (10.0) . . .

Tearing strength, min, N (lbf) . 200 (45.0) 200 (45.0) 400 (90.0)

Low temperature bend pass pass pass pass

Accelerated weathering test:

Cracking (73 magnification) none none none none

Crazing (73 magnification) none none none none

Linear dimensional change, max, % 0.1 0.1 0.5 0.5

Change in weight after immersion in water, max, % 63.0 63.0 63.0 63.0

Static Puncture Resistance pass pass pass pass

B B B B

Dynamic Puncture Resistance pass pass pass pass

A

For reinforcing fabric only; elongation of PVC material shall be the same as Type II, Grade 1.

B

For Type II, Grade 1 products dynamic puncture shall be evaluated at an energy level of 10 J min. For Type II, Grade 2 and Type III products dynamic puncture shall

be evaluated at an energy level of 20 J min.

contract. The width and length tolerance shall be+3%,−0% 8.5 Elongation at Break—Test Method D 638 for Type II,

after permitting the sheet to relax for1hat21 6 3°C (70 6 Grade 1 and Test Methods D 751, A-Grab Method, for Type II,

5°F). Grade 2, Type III and Type IV.

6.2 The thickness and thickness tolerance shall be agreed 8.6 Seam Strength—Test Method D 638 for Type II, Grade

upon between the purchaser and the supplier as part of the 1 and Test Methods D 751, A-Grab Method, for Type II, Grade

purchase contract subject to the requirements specified in Table 2, Type III and Type IV. All testing shall be performed on

1. seamed specimens with the passing criteria specified as a

6.3 Type II, Type III, and Type IV sheet shall have a percent of either unseamed sample tensile strength at break or

minimum coating or laminant thickness of 0.40 mm (0.016 in.) unseamed sample breaking strength, dependent on type.

above the cross points of any fabric or fiber and the surface

8.7 Heat Aging—Practice D 3045 at 80 6 1°C (176 6 2°F)

exposed to the weather. for 56 days 6 1h.

8.8 Tear Resistance—Test Method D 1004, for Type II,

7. Workmanship, Finish, and Appearance

Grade 1.

7.1 The sheet and any factory seams shall be watertight. It 8.9 Tearing Strength—Test Methods D 751, B-Tongue Tear

shall be visually free of pinholes, particles of foreign matter, Method, for Type II, Grade 2, Type III, and Type IV. Specimen

undispersed raw material, protruding fibers or reinforcement, size shall be 200 mm 3 200 mm (8 in. by 8 in.).

or other manufacturing defects that might affect serviceability. 8.10 Low Temperature Bend Test—Test Method D 2136,

7.2 The sheet shall be visually free of nicks and cuts, voids, at − 40°C (−40°F).

thin areas, delaminations, or other defects. 8.11 Accelerated Weathering Test—Perform accelerated

7.3 Edges of the sheet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.