ASTM F2251-13(2018)

(Test Method)Standard Test Method for Thickness Measurement of Flexible Packaging Material

Standard Test Method for Thickness Measurement of Flexible Packaging Material

SIGNIFICANCE AND USE

4.1 This test method provides a means for measuring a thickness dimension. Accurate measurement of thickness can be critical to meeting specifications and characterizing process, product, and material performance.

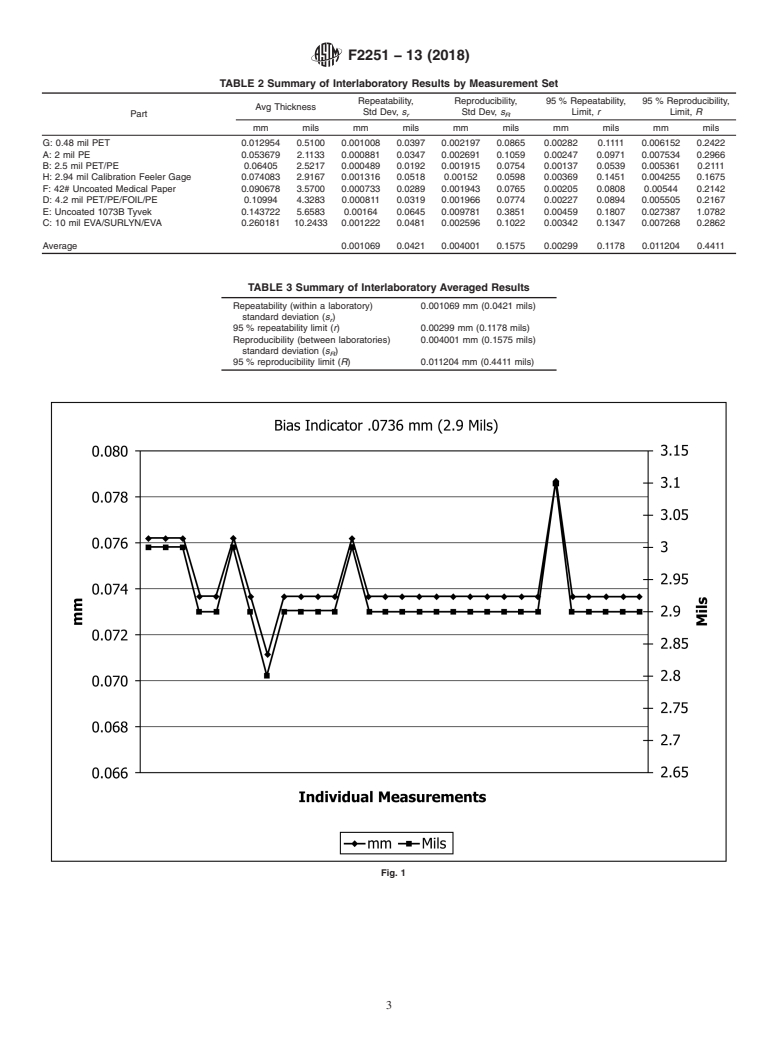

4.2 This test method does not address acceptability criteria. These need to be jointly determined by the user and producer of the product. Repeatability and reproducibility of measurement is shown in the Precision and Bias section. Attention should be given to the inherent variability of materials being measured as this can affect measurement outcome.

SCOPE

1.1 This test method covers the measurement of thickness of flexible packaging materials using contact micrometers.

1.2 The Precision and Bias statement for this test method was developed using both handheld and bench top micrometers with foot sizes ranging from 4.8 to 15.9 mm (3/16 to 5/8 in.).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2251 − 13 (Reapproved 2018)

Standard Test Method for

1

Thickness Measurement of Flexible Packaging Material

This standard is issued under the fixed designation F2251; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the measurement of thickness of

3

flexible packaging materials using contact micrometers. 2.2 ANSI/ASQ Standards:

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

1.2 The Precision and Bias statement for this test method

spection by Attributes

was developed using both handheld and bench top micrometers

ANSI/ASQC Z1.9 Sampling Procedures and Tables for In-

3 5

with foot sizes ranging from 4.8 to 15.9 mm ( ⁄16 to ⁄8 in.).

spection by Variables

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

3.1 Definitions:

system shall be used independently of the other. Combining

3.1.1 bench micrometer—tabletop measurement system us-

values from the two systems may result in non-conformance

ing a dead weight or spring.

with the standard.

3.1.2 foot—the moving component of the micrometer that

1.4 This standard does not purport to address all of the

comes in contact with the sample.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 This test method provides a means for measuring a

1.5 This international standard was developed in accor-

thickness dimension. Accurate measurement of thickness can

dance with internationally recognized principles on standard-

be critical to meeting specifications and characterizing process,

ization established in the Decision on Principles for the product, and material performance.

Development of International Standards, Guides and Recom-

4.2 This test method does not address acceptability criteria.

mendations issued by the World Trade Organization Technical

These need to be jointly determined by the user and producer

Barriers to Trade (TBT) Committee.

of the product. Repeatability and reproducibility of measure-

ment is shown in the Precision and Bias section. Attention

2. Referenced Documents

should be given to the inherent variability of materials being

2

2.1 ASTM Standards:

measured as this can affect measurement outcome.

D374/D374M Test Methods for Thickness of Solid Electri-

cal Insulation

5. Apparatus

D5947 Test Methods for Physical Dimensions of Solid

5.1 Mechanical gage, suitable for measuring thickness:

Plastics Specimens

5.1.1 The thickness gage may be either a bench or hand-held

D6988 Guide for Determination of Thickness of Plastic Film

mechanical model.

Test Specimens

5.1.2 The gage should be capable of accurately measuring in

E171/E171M Practice for Conditioning and Testing Flexible

increments of 2.5 µm (0.0001 in.).

Barrier Packaging

5.1.3 The foot size and foot pressure should be known and

1

identified. Because of the compressibility of different materials

This test method is under the jurisdiction of ASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on

it is important when comparing results between different

Physical Properties.

laboratories that the size of the foot and pressure be the same.

Current edition approved Sept. 1, 2018. Published November 2018. Originally

Refer to Guide D6988 for further guidance on foot pressures.

approved in 2003. Last previous edition approved in 2013 as F2251 – 13. DOI:

10.1520/F2251-13R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Instititute (ANSI) 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2251 − 13 (2018)

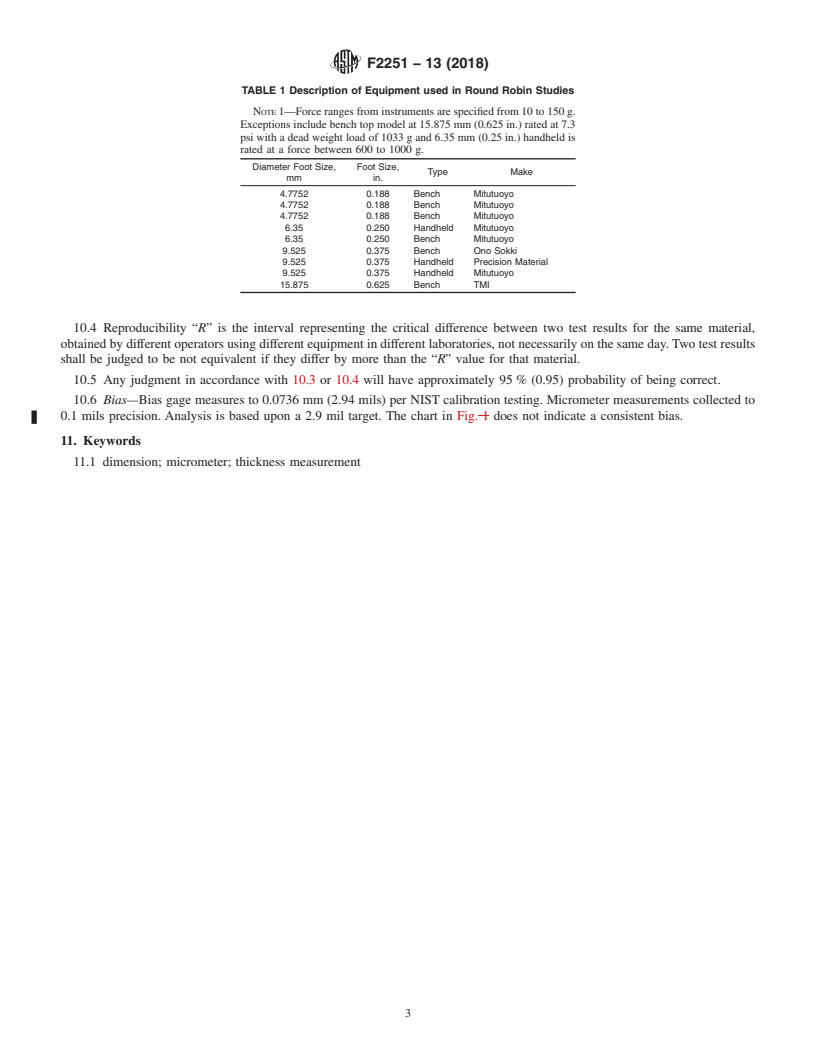

5.1.4 It is recommended that a calibration be performed on 10. Precision and Bias

4

the apparatus used and certified to a recognized industry

10.1 Precision—A research report describes a round robin

standard such as National In

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2251 − 13 F2251 − 13 (Reapproved 2018)

Standard Test Method for

1

Thickness Measurement of Flexible Packaging Material

This standard is issued under the fixed designation F2251; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of thickness of flexible packaging materials using contact micrometers.

1.2 The Precision and Bias statement for this test method was developed using both handheld and bench top micrometers with

3 5

foot sizes ranging from 4.8 to 15.9 mm ( ⁄16 to ⁄8 in.).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D374D374/D374M Test Methods for Thickness of Solid Electrical Insulation (Metric) D0374_D0374M

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D6988 Guide for Determination of Thickness of Plastic Film Test Specimens

E171E171/E171M Practice for Conditioning and Testing Flexible Barrier Packaging

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 ANSI/ASQ Standards:

ANSI/ASQC Z1.4 Sampling Procedures and Tables for Inspection by Attributes

ANSI/ASQC Z1.9 Sampling Procedures and Tables for Inspection by Variables

3. Terminology

3.1 Definitions:

3.1.1 bench micrometer—tabletop measurement system using a dead weight or spring.

3.1.2 foot—the moving component of the micrometer that comes in contact with the sample.

4. Significance and Use

4.1 This test method provides a means for measuring a thickness dimension. Accurate measurement of thickness can be critical

to meeting specifications and characterizing process, product, and material performance.

4.2 This test method does not address acceptability criteria. These need to be jointly determined by the user and producer of

the product. Repeatability and reproducibility of measurement is shown in the Precision and Bias section. Attention should be

given to the inherent variability of materials being measured as this can affect measurement outcome.

1

This test method is under the jurisdiction of ASTM Committee F02 on FlexiblePrimary Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on

Physical Properties.

Current edition approved Aug. 1, 2013Sept. 1, 2018. Published October 2013November 2018. Originally approved in 2003. Last previous edition approved in 20082013

as F2251 – 03F2251 – 13. (Reapproved 2008). DOI: 10.1520/F2251-13.10.1520/F2251-13R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Instititute (ANSI) 25 W. 43rd St., 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2251 − 13 (2018)

5. Apparatus

5.1 Mechanical gage, suitable for measuring thickness:

5.1.1 The thickness gage may be either a bench or hand-held mechanical model.

5.1.2 The gage should be capable of accurately measuring in increments of 2.5 μm (0.0001 in.).

5.1.3 The foot size and foot pressure should be known and identified. Because of the compressibility of different materials it

is important when

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.