ASTM F1741-02a

(Practice)Standard Practice for Installation of Machine Spiral Wound Poly (Vinyl Chloride) (PVC) Liner Pipe for Rehabilitation of Existing Sewers and Conduits

Standard Practice for Installation of Machine Spiral Wound Poly (Vinyl Chloride) (PVC) Liner Pipe for Rehabilitation of Existing Sewers and Conduits

SCOPE

1.1 This practice describes the procedures for the rehabilitation of sewer lines and conduits by the insertion of a machine-made field-fabricated spiral wound liner pipe into an existing pipeline. For existing pipelines 6 to 48 in., after insertion, the spiral wound liner pipe is expanded until it presses against the interior surface of the existing pipeline. Alternatively, for existing pipelines 6 to 108 in. in diameter, the spiral wound liner pipe is inserted as a fixed diameter into the existing pipeline and is not expanded, and the annular space between the spiral wound liner pipe and the existing pipe is grouted. This rehabilitation process can be used in a variety of gravity applications such as sanitary sewers, storm sewers, culverts, and process piping.

1.2 The values in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3.1 Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined spaces.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1741 – 02a

Standard Practice for

Installation of Machine Spiral Wound Poly (Vinyl Chloride)

(PVC) Liner Pipe for Rehabilitation of Existing Sewers and

1

Conduits

This standard is issued under the fixed designation F 1741; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope (PVC) Compounds and Chlorinated Poly (Vinyl Chloride)

3

(CPVC) Compounds

1.1 This practice describes the procedures for the rehabili-

4

F412 Terminology Relating To Plastic Piping Systems

tation of sewer lines and conduits by the insertion of a

F1417 Test Method for Installation Acceptance of Plastic

machine-made field-fabricated spiral wound liner pipe into an

4

Gravity Sewer Lines Using Low-Pressure Air

existing pipeline. For existing pipelines 6 to 48 in., after

F1697 Specification for Poly (Vinyl Chloride) (PVC) Pro-

insertion, the spiral wound liner pipe is expanded until it

file Strip for Machine Spiral Wound Liner Pipe Rehabili-

presses against the interior surface of the existing pipeline.

4

tation of Existing Sewers and Conduit

Alternatively,forexistingpipelines6to108in.indiameter,the

2.2 NASSCO Standard:

spiral wound liner pipe is inserted as a fixed diameter into the

Recommended Specifications for Sewer Collection System

existing pipeline and is not expanded, and the annular space

5

Rehabilitation

between the spiral wound liner pipe and the existing pipe is

2.3 Uni-Bell Standard:

grouted. This rehabilitation process can be used in a variety of

UNI-B-5-89 Recommended Practice for the Installation of

gravity applications such as sanitary sewers, storm sewers,

6

PVC Sewer Pipe

culverts, and process piping.

1.2 The values in parentheses are provided for information

3. Terminology

purposes only.

3.1 General—Definitions are in accordance with Termi-

1.3 This standard does not purport to address all of the

nologies D883 and F412. Abbreviations are in accordance

safety concerns, if any, associated with its use. It is the

with Terminology D1600, unless otherwise indicated.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 extruded PVC profile strip—a product available in

bility of regulatory limitations prior to use.

various widths, consisting of a smooth inside surface and a

1.3.1 Particular attention is drawn to those safety regula-

ribbedoutersurfacewithmechanicallylockedmaleandfemale

tions and requirements involving entering into and working in

edges which are self interlocking, or separate locking strips

confined spaces.

which serve the same purpose (Table 1 and Fig. 1).

2. Referenced Documents 3.2.2 insertion point—an existing manhole, existing access

shaft,orexcavatedpitthatservesasthepointwhereawinding

2.1 ASTM Standards:

machine field fabricates the spiral wound liner pipe and

C39/C39M Test Method for Compressive Strength of Cy-

2

simultaneously inserts the spiral wound liner pipe into the

lindrical Concrete Specimens

3

existing pipeline.

D883 Terminology Relating to Plastics

3.2.3 production run—a continuous extrusion of a given

D1600 Terminology for Abbreviated Terms Relating to

3

profile type.

Plastics

3.2.4 spiral wound liner pipe—a product field fabricated

D 1784 Specification for Rigid Poly (Vinyl Chloride)

from extruded PVC profile strip to a round shape (see Fig. 2).

3.2.5 termination point—an existing manhole, existing ac-

1 cessshaft,oranexcavatedpitthatservesasthepointofexitof

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on the spiral wound liner pipe from the existing pipe.

Trenchless Plastic Pipeline Technology.

Current edition approved Sept. 10, 2002. Published February 2003. Originally

4

published as F 1741–96. Last previous edition E1741–02. Annual Book of ASTM Standards, Vol 08.04.

2 5

Annual Book of ASTM Standards, Vol 04.02. Available from NASSCO, 140 Circle Drive, Suite 103, Maitland, FL 32751.

3 6

Annual Book of ASTM Standards, Vol 08.01. Available from Uni-Bell, 2655Villa Creek Drive, Suite 155, DallasTX 75234.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1741 – 02a

TABLE 1 Typical Profile Strip Moments of Inhertia and Stiffness Factors

C

Moment of Inertia, I Depth to Neutral Axis, y¯ Minimum Height, H Profile Area Minimum Stiffness Factor, EI

AB

Profile Type

4 4 2 2 3 2 3

in. /in. (mm /m) in. (mm) in. (mm) i

...

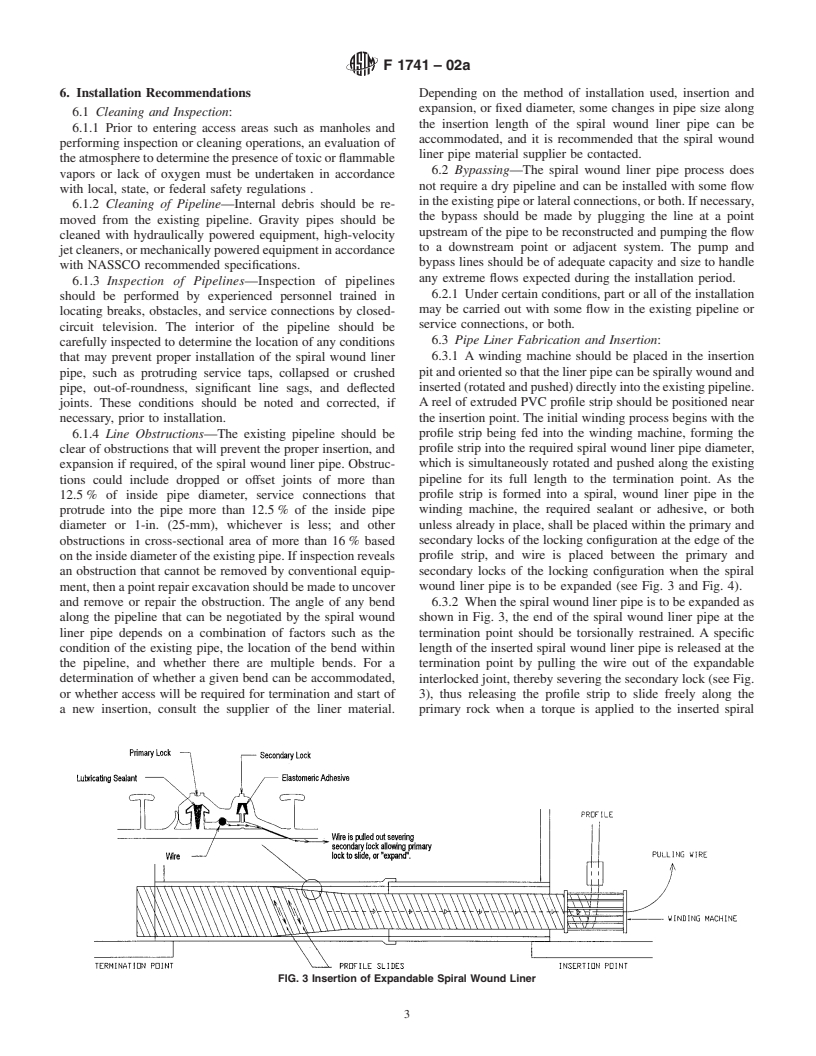

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.