ASTM F910-04(2023)

(Specification)Standard Specification for Face Guards for Youth Baseball

Standard Specification for Face Guards for Youth Baseball

ABSTRACT

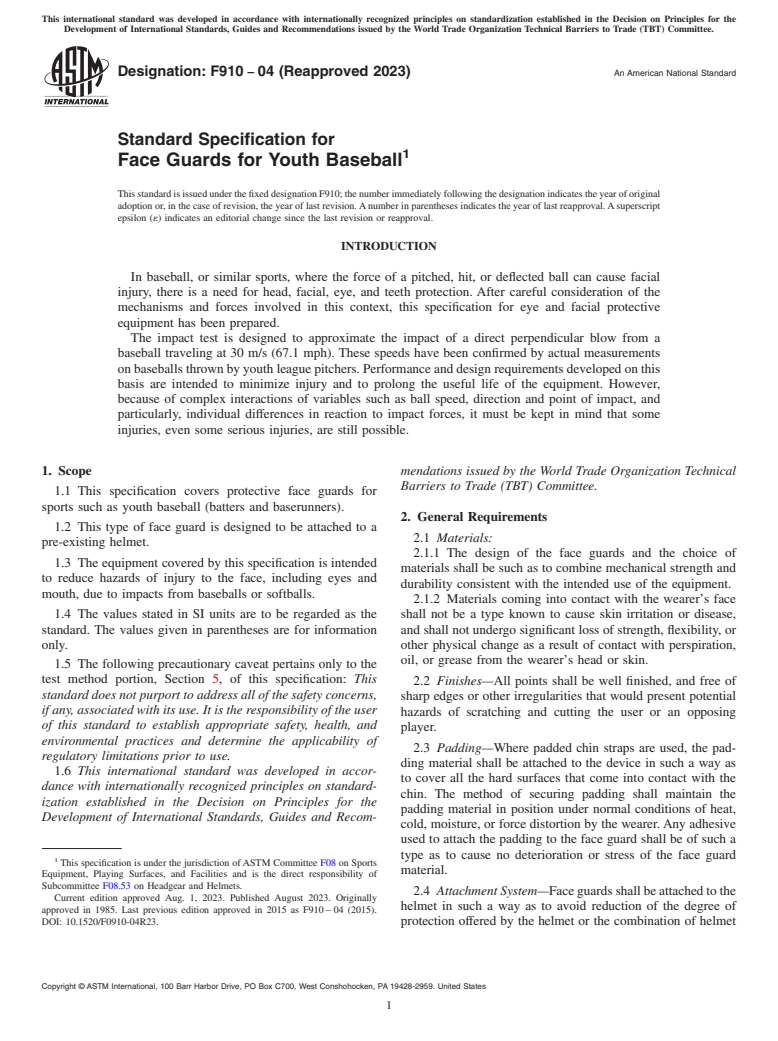

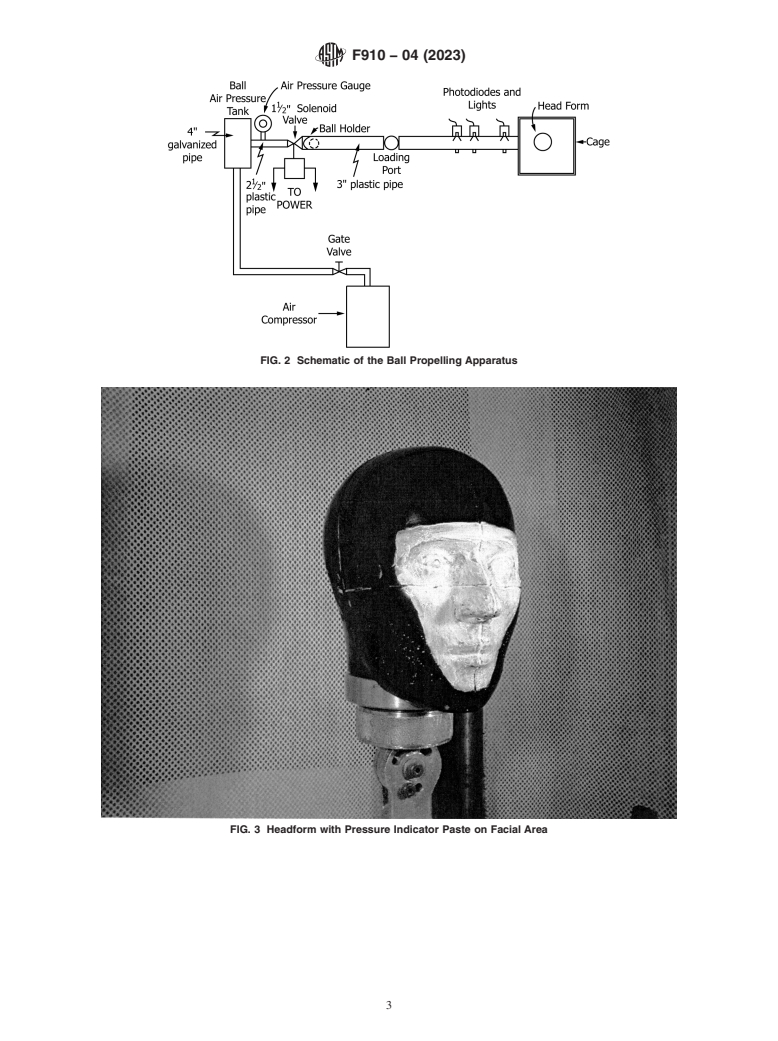

This specification covers protective face guards designed to be attached to a pre-existing helmet for youth baseball. General requirements for protective face guards shall include mechanical strength, durability, flexibility, finish, padding, attachment system, and shall not cause skin irritation. The face guard shall undergo velocity and impact testing using apparatus such as headform and mounting, ball propelling device, and gage.

SCOPE

1.1 This specification covers protective face guards for sports such as youth baseball (batters and baserunners).

1.2 This type of face guard is designed to be attached to a pre-existing helmet.

1.3 The equipment covered by this specification is intended to reduce hazards of injury to the face, including eyes and mouth, due to impacts from baseballs or softballs.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following precautionary caveat pertains only to the test method portion, Section 5, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F910 − 04 (Reapproved 2023) An American National Standard

Standard Specification for

Face Guards for Youth Baseball

This standard is issued under the fixed designation F910; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

In baseball, or similar sports, where the force of a pitched, hit, or deflected ball can cause facial

injury, there is a need for head, facial, eye, and teeth protection. After careful consideration of the

mechanisms and forces involved in this context, this specification for eye and facial protective

equipment has been prepared.

The impact test is designed to approximate the impact of a direct perpendicular blow from a

baseball traveling at 30 m/s (67.1 mph). These speeds have been confirmed by actual measurements

on baseballs thrown by youth league pitchers. Performance and design requirements developed on this

basis are intended to minimize injury and to prolong the useful life of the equipment. However,

because of complex interactions of variables such as ball speed, direction and point of impact, and

particularly, individual differences in reaction to impact forces, it must be kept in mind that some

injuries, even some serious injuries, are still possible.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers protective face guards for

sports such as youth baseball (batters and baserunners).

2. General Requirements

1.2 This type of face guard is designed to be attached to a

2.1 Materials:

pre-existing helmet.

2.1.1 The design of the face guards and the choice of

1.3 The equipment covered by this specification is intended

materials shall be such as to combine mechanical strength and

to reduce hazards of injury to the face, including eyes and

durability consistent with the intended use of the equipment.

mouth, due to impacts from baseballs or softballs.

2.1.2 Materials coming into contact with the wearer’s face

1.4 The values stated in SI units are to be regarded as the shall not be a type known to cause skin irritation or disease,

standard. The values given in parentheses are for information and shall not undergo significant loss of strength, flexibility, or

only. other physical change as a result of contact with perspiration,

oil, or grease from the wearer’s head or skin.

1.5 The following precautionary caveat pertains only to the

test method portion, Section 5, of this specification: This

2.2 Finishes—All points shall be well finished, and free of

standard does not purport to address all of the safety concerns,

sharp edges or other irregularities that would present potential

if any, associated with its use. It is the responsibility of the user

hazards of scratching and cutting the user or an opposing

of this standard to establish appropriate safety, health, and

player.

environmental practices and determine the applicability of

2.3 Padding—Where padded chin straps are used, the pad-

regulatory limitations prior to use.

ding material shall be attached to the device in such a way as

1.6 This international standard was developed in accor-

to cover all the hard surfaces that come into contact with the

dance with internationally recognized principles on standard-

chin. The method of securing padding shall maintain the

ization established in the Decision on Principles for the

padding material in position under normal conditions of heat,

Development of International Standards, Guides and Recom-

cold, moisture, or force distortion by the wearer. Any adhesive

used to attach the padding to the face guard shall be of such a

type as to cause no deterioration or stress of the face guard

This specification is under the jurisdiction of ASTM Committee F08 on Sports

material.

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.53 on Headgear and Helmets.

2.4 Attachment System—Face guards shall be attached to the

Current edition approved Aug. 1, 2023. Published August 2023. Originally

helmet in such a way as to avoid reduction of the degree of

approved in 1985. Last previous edition approved in 2015 as F910 – 04 (2015).

DOI: 10.1520/F0910-04R23. protection offered by the helmet or the combination of helmet

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F910 − 04 (2023)

and guard. The protection offered by the helmet or guard shall any part of the face guard (from Zone A) as a result of the

be considered impaired if there is visual evidence of stress to impact specified in 5.3.1. Paste residue transferred from “no

the helmet or guard or any disengagement of the guard contact areas” as determined above and in Fig. 4 will constitute

following the tests as set forth in 5.3 or while in use. a failure. The paste can be colored using a food coloring or

other suitable material in order to apply different colors to Zone

3. Performance Requirements

A and Zone B so that areas of facial contact are more easily

distinguishable when examining the ball and face guard.

3.1 All testing shall be done with the face guard mounted on

a helmet of a make or model specified by the face guard

4. Sample Preparation

manufacturer and placed on a headform as specified in 5.1.1.

3.2 Impact Requirements: 4.1 Test only face guards as offered for sale and only when

attached to an appropriate helmet.

3.2.1 When testing in accordance with Section 5, the fol-

lowing applies:

4.2 Condition face guards at the temperatures of 36 6 2°C

3.2.1.1 The wire face guard shall be deemed a failure if any

(97 6 4°F) and at 10 6 2°C (50 6 4°F) for a minimum period

weld completely separates or if any fractures in the wire

of 4 h prior to test. The face guard will be tested within 3 min

between any two welds occur on any specimen as a result of

from removal from the conditioning environment. The face

impact.

guard/helmet assemblies may be returned to the conditioning

3.2.1.2 The plastic face guard shall be deemed a failure if

environment in order to meet this requirement. Prior to the

any full-thickness cracks or fractures occur on any specimen as

resumption of testing, specimens must remain in the condition-

a result of impact.

ing environment for a minimum of 15 min for each period up

3.2.1.3 The protection by the face guard shall be deemed a

to 5 min long that they are out of the conditioning environment.

failure if the face guard becomes disengaged from the helmet

4.3 Assemble face guards to the helmets in accordance with

during testing in accordance with 5.3.

instructions provided. (See 7.1.)

3.2.2 Neither the ball nor the face guard may contact Zone

A of Fig. 4. The ball may not contact Zone B, but the face

5. Impact Test Method

guard may contact Zone B as the result o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.