ASTM F479-95(2001)

(Specification)Standard Specification for In-Service Care of Insulating Blankets

Standard Specification for In-Service Care of Insulating Blankets

SCOPE

1.1 This specification covers the in-service care, inspection, testing, and use voltage of insulating blankets for protection from electrical shock. The product requirements and acceptance testing are as shown in Specification D1048.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use . See Section 6 for specific precautionary statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 479 – 95 (Reapproved 2001)

Standard Specification for

In-Service Care of Insulating Blankets

This standard is issued under the fixed designation F 479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 electrical testing facility—a location with qualified

personnel,testingequipment,andproceduresfortheinspection

1.1 This specification covers the in-service care, inspection,

and electrical testing of electrical insulating protective equip-

testing, and use voltage of insulating blankets for protection

ment (in accordance with Definitions F 819).

from electrical shock. The product requirements and accep-

3.1.5 electrode—the energized or grounded conductor por-

tance testing are as shown in Specification D 1048.

tion of electrical test equipment which is placed near or in

1.2 This standard does not purport to address all of the

contact with the material or equipment being tested (in

safety problems, if any, associated with its use. It is the

accordance with Definitions F 819).

responsibility of the user of this standard to establish appro-

3.1.6 flashover—the electrical discharge or arc occurring

priate safety and health practices and determine the applica-

between electrodes and over or around, but not through, the

bility of regulatory limitations prior to use. See Section 6 for

equipment being tested.

specific precautionary statements.

3.1.7 ozone—a very active form of oxygen that may be

2. Referenced Documents

produced by corona, arcing, or ultra-violet rays.

3.1.8 ozone cutting and checking—the cracks produced by

2.1 ASTM Standards:

ozone in a material under mechanical stress.

D 1048 Specification for Rubber Insulating Blankets

3.1.9 retest—the tests given after the initial acceptance test

D 2865 Practice for Calibration of Standards and Equip-

usually performed at regular periodic intervals or as required

ment for Electrical Insulating Materials Testing

because of physical inspection.

F 819 Definitions of Terms Relating to Electrical Protective

3.1.10 unassigned blankets—blankets that are in storage

Equipment for Workers

prior to being issued for use.

2.2 ANSI Standard:

3.1.11 voltage, maximum use—the a-c voltage (rms), clas-

C 84.1 Voltage Ratings for Electric Power Systems and

sification of the protective equipment that designates the

Equipment (60 Hz)

maximum nominal design voltage of the energized system that

3. Terminology

may be safely worked. The nominal design voltage is equal to

the phase-to-phase voltage on multiphase circuits.

3.1 Definitions:

3.1.11.1 If there is no multiphase exposure in a system area,

3.1.1 breakdown—the electrical discharge or arc occurring

andthevoltageexposureislimitedtothephase(polarityond-c

betweentheelectrodesandthroughtheequipmentbeingtested.

systems) to ground potential, the phase (polarity on d-c

3.1.2 compatible—not injurious to or changing the physical

systems) to ground potential shall be considered to be the

or electrical characteristics of the blankets or affecting their

nominal design voltage.

application, use, or acceptability.

3.1.11.2 If electrical equipment and devices are insulated or

3.1.3 designated person—an individual who is qualified by

isolated, or both, such that the multiphase exposure on a

experience or training to perform an assigned task.

grounded wye circuit is removed, then the nominal design

voltage may be considered as the phase-to-ground voltage on

This specification is under the jurisdiction of ASTM Committee F18 on

that circuit.

Electrical Protective Equipment for Workers and is the direct responsibility of

3.1.12 voltage, maximum retest—the voltage, either a-c rms

Subcommittee F18.25 on Insulating Cover-up Equipment.

or d-c avg, that is equal to the proof test voltage for new

Current edition approved Aug. 15, 1995. Published October 1995. Originally

published as F 479 – 76. Last previous edition F 479 – 93.

protective equipment.

Annual Book of ASTM Standards, Vol 10.03.

3.1.13 voltage, retest—the voltage, either a-c rms or d-c

Annual Book of ASTM Standards, Vol 10.02.

avg, that used protective equipment must be capable of

Available from the American National Standards Institute, Inc., 11 West 42nd

St., 13th Floor, New York, NY 10036. withstanding for a specified test period without breakdown.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 479

3.1.14 voltage, nominal design—a nominal value consistent 7.1.1 Check in, washing, and preliminary inspection,

with the latest revision of ANSI C84.1, assigned to the circuit 7.1.2 Repair,

or system for the purpose of conveniently designating its

7.1.3 Electrical test,

voltage class.

7.1.4 Final inspection,

7.1.5 Recordkeeping and marking, and

4. Significance and Use

7.1.6 Packing for storage and shipping.

4.1 Compliance with this specification should continue to

7.2 Dirty blankets should be cleaned. They may be washed

provide personnel with insulating blankets of known and

with a mild soap or mild detergent and water. Mild household-

acceptable quality after initial acceptance in accordance with

type chlorine bleach may be used for disinfectant purposes.

Specification D 1048. The standards herein are to be consid-

Soaps, detergents, and bleaches shall not be used at strengths

ered as minimum requirements.

that would attack or harm the rubber surface. They shall be

rinsed thoroughly with water to remove all of the soap or

5. Classification

detergent. Severe dirt and grime may be wiped off using a

5.1 Blankets covered under this specification shall be des-

compatible solvent.

ignated as Type I or Type II; Class 0, Class 1, Class 2, Class 3,

7.2.1 The cleaning agent shall not degrade the insulating or

or Class 4; Style A or Style B.

physical qualities of the blankets.

5.2 Type I, not resistant to ozone, made from a high-grade

7.2.2 A commercial tumble type washing machine may be

cis-1,4-polyisoprene rubber compound of natural or synthetic

used. Caution must be observed to eliminate any interior

origin, properly vulcanized.

surfaces or edges that may damage the blankets.

5.3 Type II, ozone-resistant, made of any elastomer or

7.3 Ifwashed,blanketsshouldbeair-dried.Theairtempera-

combination of elastomeric compounds.

ture should not be over 150°F (65.5°C).

5.4 The class designation shall be based on the electrical

7.4 Prior to the electrical test, the blankets shall be given a

properties as shown in Specification D 1048.

preliminary inspection for punctures, cuts, corona cutting, or

5.5 Style A, constructed of the elastomers indicated under

any obvious condition which would adversely affect the

Type I or Type II, shall be free of any reinforcement.

performance. If any of these conditions are found, blankets

5.6 Style B, constructed of the elastomers indicated under

shall be rejected or repaired.

Type I or Type II, shall incorporate a reinforcement. This

7.5 The blankets shall be tested in accordance with Section

reinforcement shall not affect adversely the dielectric charac-

8.

teristics of the blankets.

7.6 After the test, the blankets shall be given an inspection

for corona and ozone damage.

6. Safety Precautions

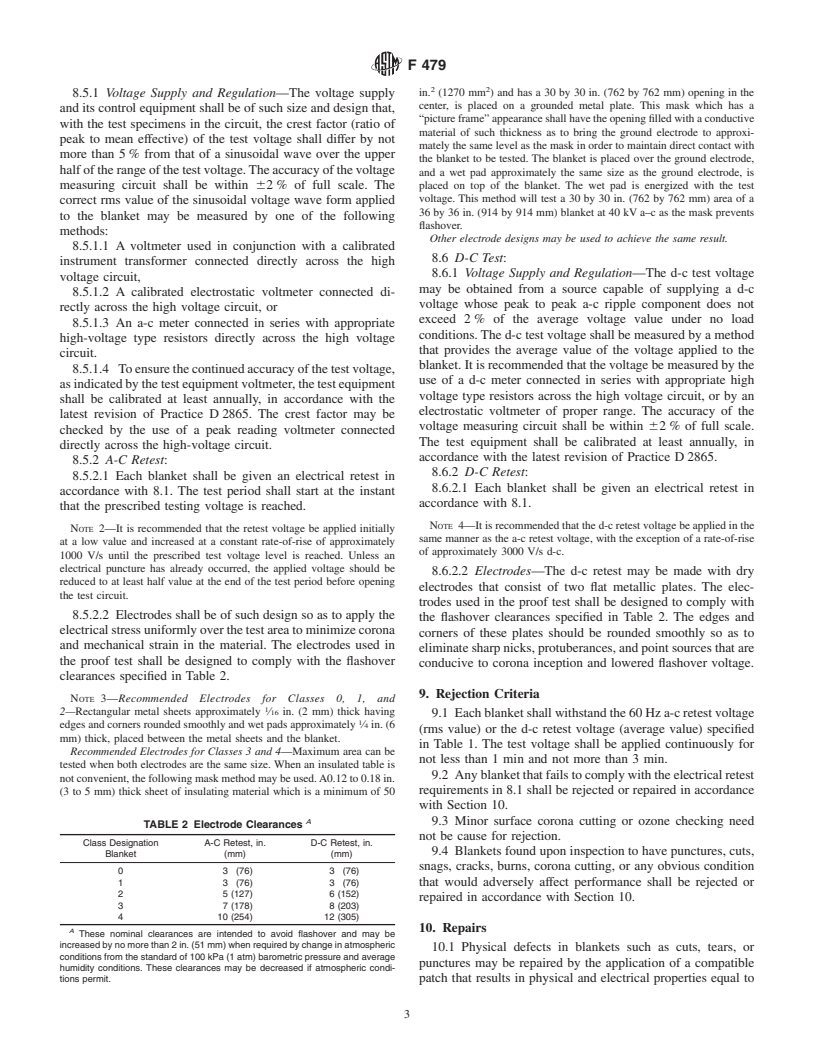

6.1 A margin of safety shall be provided between the

8. Electrical Tests

maximum use voltage on which the blankets are used and the

8.1 All blankets issued for service shall be retested. The

voltage at which they are retested. The relationship between

interval between date of issue and retests shall be based on

retest voltage and maximum use voltage at which the blankets

work practices and test experience, but shall not exceed 1 year.

shall be used is shown in Table 1.

Blankets that have been tested electrically, but not issued for

6.2 The user of this type of protective equipment shall be

service, shall not be placed into service unless they have been

knowledgeable of and instructed in the correct and safe visual

tested electrically within the previous 12 months.

inspection and use of this equipment.

8.1.1 Where a visual inspection indicates that there may be

7. Inspection and Testing at an Electrical Testing Facility reason to suspect the electrical integrity of a blanket, an

electrical test shall be performed before reissuing the blanket

7.1 The recommended sequence for inspection and testing

for service.

of insulating blankets at the electrical testing facility is as

8.2 The test apparatus shall be designed to afford the

follows:

operator full protection in the performance of his duties.

Reliable means of de-energizing and grounding the high

TABLE 1 Voltage Requirements for Blankets

voltage circuit shall be provided. It is particularly important to

Class A-C Use A-C Retest D-C Retest

incorporate positive means of grounding the high voltage

Designation of Voltage, Voltage, Voltage,

A

section of d-c test apparatus due to the likely presence of

Blankets rms, max max max

high-voltage capacitance charges at the conclusion of the test.

0 1 000 5 000 20 000

1 7 500 10 000 40 000 8.3 Botha-candd-cvoltageretestmethodsareincludedand

2 17 000 20 000 50 000

either method may be selected for electrical testing.

3 26 500 30 000 60 000

8.4 All electrical tests shall be performed on clean blankets

4 36 000 40 000 70 000

A at normal room temperatures.

The maximum use voltage is based on the following equations:

Maximum a-c use voltage = 0.95 a–c maximum retest voltage − 2 000

v

NOTE 1—All blankets should be in an unstressed physical condition

Classes 1, 2, 3, and 4.

prior to testing. Failure to achieve this may result in excessive breakdown

Maximum a-c use voltage = 0.95 d–c maximum retest voltage − 30 500

v

Classes 1, 2, 3, and 4. or damage.

Maximum a-c use voltage = 0.95 d–c maximum retest voltage − 18 000

v

Class 0. 8.5 A-C Test:

F 479

2 2

in. (1270 mm ) and has a 30 by 30 in. (762 by 762 mm) opening in the

8.5.1 Voltage Supply and Regulation—The voltage supply

center, is placed on a grounded metal plate. This mask which has a

and its control equipment shall be of such size and design that,

“pictureframe”appearanceshallhavetheopeningfilledwithaconductive

with the test specimens in the circuit, the crest factor (ratio of

material of such thickness as to bring the ground electrode to approxi-

peak to mean effective) of the test voltage shall differ by not

mately the same level as the mask in order to maintain direct contact with

more than 5 % from that of a sinusoidal wave over the upper

the blanket to be tested. The blanket is placed over the ground electrode,

halfofther

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.