ASTM D5934-96

(Test Method)Standard Test Method for Determination of Modulus of Elasticity for Rigid and Semi-Rigid Plastic Specimens by Controlled Rate of Loading Using Three-Point Bending

Standard Test Method for Determination of Modulus of Elasticity for Rigid and Semi-Rigid Plastic Specimens by Controlled Rate of Loading Using Three-Point Bending

SCOPE

1.1 This test method covers the use of controlled rate of loading mechanical instrumentation for gathering and reporting the modulus of elasticity of thermoplastic and thermosetting resins and composite systems in the form of rectangular bars molded directly or cut from sheets, plates, or molded shapes. The data generated, using three-point bending techniques, may be used to identify the thermomechanical properties of a plastics material or composition using a controlled rate of loading mechanical instrument. Results obtained from this test method may or may not be comparable to results obtained using D 790.

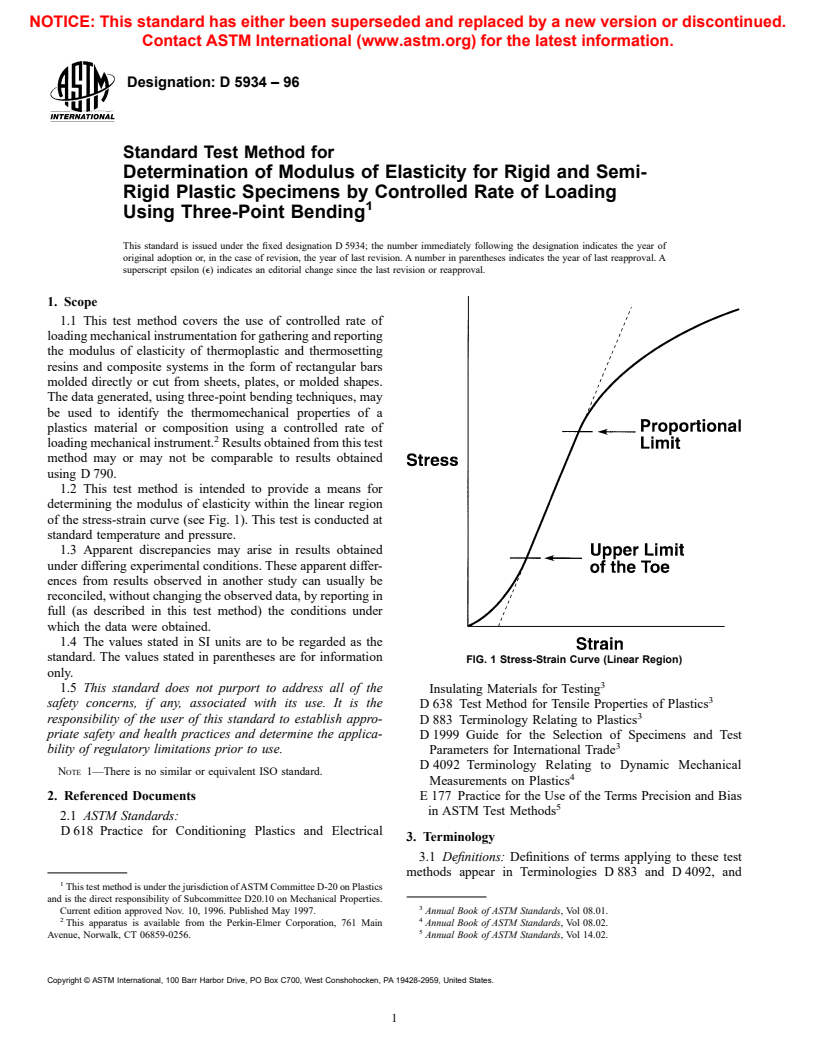

1.2 This test method is intended to provide a means for determining the modulus of elasticity within the linear region of the stress-strain curve (see Fig 1). This test is conducted at standard temperature and pressure.

1.3 Apparent discrepancies may arise in results obtained under differing experimental conditions. These apparent differences from results observed in another study can usually be reconciled, without changing the observed data, by reporting in full (as described in this test method) the conditions under which the data were obtained.

1.4 The values stated in SI units are to be regarded as the standard. The values stated in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5934 – 96

Standard Test Method for

Determination of Modulus of Elasticity for Rigid and Semi-

Rigid Plastic Specimens by Controlled Rate of Loading

Using Three-Point Bending

This standard is issued under the fixed designation D 5934; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the use of controlled rate of

loading mechanical instrumentation for gathering and reporting

the modulus of elasticity of thermoplastic and thermosetting

resins and composite systems in the form of rectangular bars

molded directly or cut from sheets, plates, or molded shapes.

The data generated, using three-point bending techniques, may

be used to identify the thermomechanical properties of a

plastics material or composition using a controlled rate of

loading mechanical instrument. Results obtained from this test

method may or may not be comparable to results obtained

using D 790.

1.2 This test method is intended to provide a means for

determining the modulus of elasticity within the linear region

of the stress-strain curve (see Fig. 1). This test is conducted at

standard temperature and pressure.

1.3 Apparent discrepancies may arise in results obtained

under differing experimental conditions. These apparent differ-

ences from results observed in another study can usually be

reconciled, without changing the observed data, by reporting in

full (as described in this test method) the conditions under

which the data were obtained.

1.4 The values stated in SI units are to be regarded as the

standard. The values stated in parentheses are for information

FIG. 1 Stress-Strain Curve (Linear Region)

only.

1.5 This standard does not purport to address all of the

Insulating Materials for Testing

safety concerns, if any, associated with its use. It is the

D 638 Test Method for Tensile Properties of Plastics

responsibility of the user of this standard to establish appro-

D 883 Terminology Relating to Plastics

priate safety and health practices and determine the applica-

D 1999 Guide for the Selection of Specimens and Test

bility of regulatory limitations prior to use.

Parameters for International Trade

D 4092 Terminology Relating to Dynamic Mechanical

NOTE 1—There is no similar or equivalent ISO standard.

Measurements on Plastics

2. Referenced Documents E 177 Practice for the Use of the Terms Precision and Bias

in ASTM Test Methods

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics and Electrical

3. Terminology

3.1 Definitions: Definitions of terms applying to these test

methods appear in Terminologies D 883 and D 4092, and

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved Nov. 10, 1996. Published May 1997. Annual Book of ASTM Standards, Vol 08.01.

2 4

This apparatus is available from the Perkin-Elmer Corporation, 761 Main Annual Book of ASTM Standards, Vol 08.02.

Avenue, Norwalk, CT 06859-0256. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5934

Annex A1 and Annex A2 of Test Method D 638.

4. Summary of Test Method

4.1 A specimen of rectangular cross section is tested in

flexure as a beam. The bar rests on two supports and is loaded

by means of a loading nose midway between the supports. The

test specimen of known geometry is placed under mechanical

linear displacement at isothermal conditions by using a con-

trolled rate of loading. The modulus of elasticity is measured

using three-point bending.

5. Significance and Use

5.1 This test method provides a simple means of character-

izing the mechanical behavior of plastics materials using very

small amounts of material. The data obtained may be used for

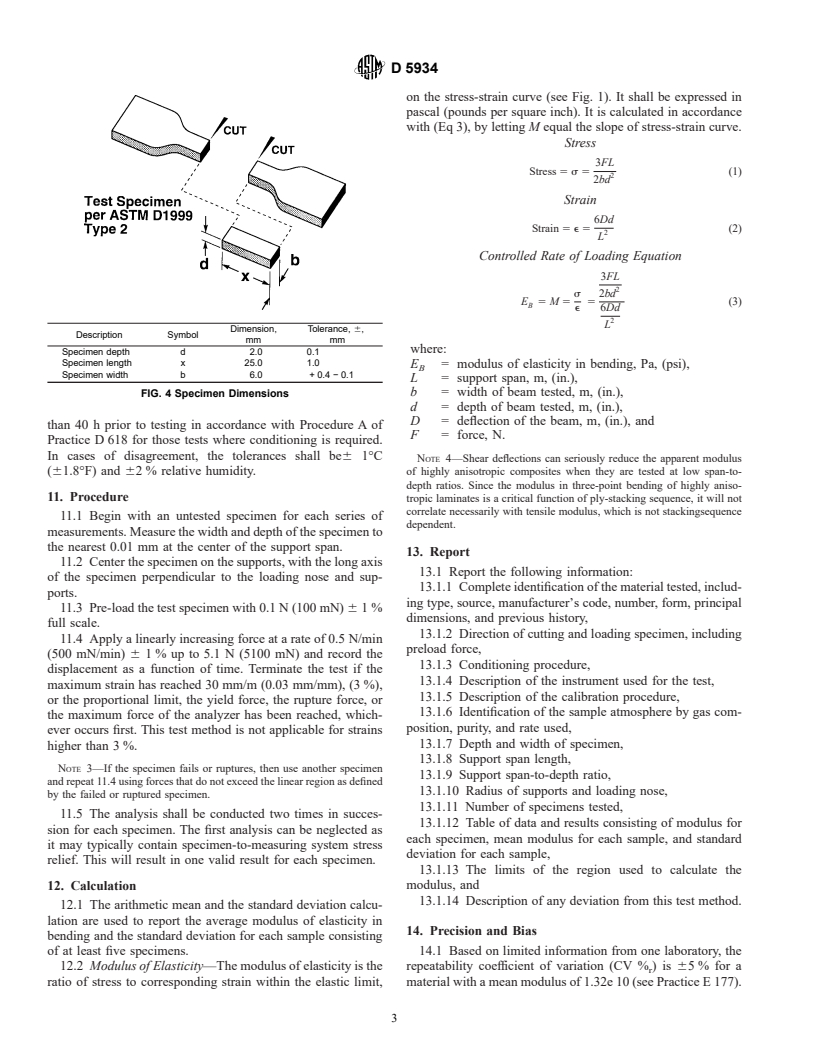

Dimensions

quality control, research and development, and establishment

Dimen- Tolerance,6

of optimum processing conditions.

Description Symbol sion, ,

5.2 Mechanical testing provides a sensitive test method for

mm mm

determining mechanical characteristics by measuring the

Support span L 20.0 0.1

modulus of elasticity.

Loading nose ra- r 3.0 0.5

dius

NOTE 2—Materials that are suspected to be too anisotropic may not be

Support radius r 1.0 0.1

suitable for this test method.

FIG. 2 Loading Members

5.3 This test method can be used to assess:

5.3.1 The effects of processing treatment,

7.3.2 Nitrogen—Or other inert gas supply, for purging

5.3.2 Relative resin behavioral properties, including cure,

purposes.

5.3.3 The effects of substrate types and orientation (fabri-

8. Test Specimens

cation) on modulus, and

5.3.4 The effects of formulation additives that might affect

8.1 The specimens may be cut from sheets, plates, or

processability or performance.

molded shapes, or may be molded to the desired finished

dimensions. Specimens shall be long enough to allow over-

6. Interferences

hanging on each end of at least 10 % of the support span.

6.1 Since small test specimen geometries are used, it is

Overhang shall be sufficient to prevent the specimen from

essential that the specimens be representative of the polymeric

slipping through the supports. A typical rectangular test beam

material being tested.

is tested flatwise on a support span (see Fig. 3 and Fig. 4).

8.2 At least five specimens shall be tested for each sample.

7. Apparatus

7.1 The function of the apparatus is to hold a rectangular

9. Calibration

test specimen of a polymeric material system so that the

9.1 Calibrate the instrument using procedures recommended

material acts as the elastic and dissipative element in a

by the manufacturer.

mechanically driven linear displacement system. Displace-

ments (deflections) are generated using a controlled loading

10. Conditioning

rate applied to a specimen in three-point bending configuration.

10.1 Conditioning—Condition the test specimens at 23 6

7.2 The apparatus shall consist of the following:

2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

7.2.1 Loading Nose and Supports—The loading nose and

supports sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.