ASTM A1053/A1053M-12e1

(Specification)Standard Specification for Welded Ferritic-Martensitic Stainless Steel Pipe

Standard Specification for Welded Ferritic-Martensitic Stainless Steel Pipe

ABSTRACT

This specification covers seam welded ferritic-martensitic stainless steel pipe intended for abrasive and general corrosion service. The pipes are classified according to sizes, from NPS 2 to NPS 36. The pipe shall be made using Electric Resistance Welding (ERW) or an automatic fusion welding process with no addition of filler metal during the welding process. All pipes shall be made from heat treated strip or plate, cold formed and welded. Tensile test, flattening test, hydrostatic test, and nondestructive electric test shall be made in accordance with the pipe specification to conform to the requirements specified.

SCOPE

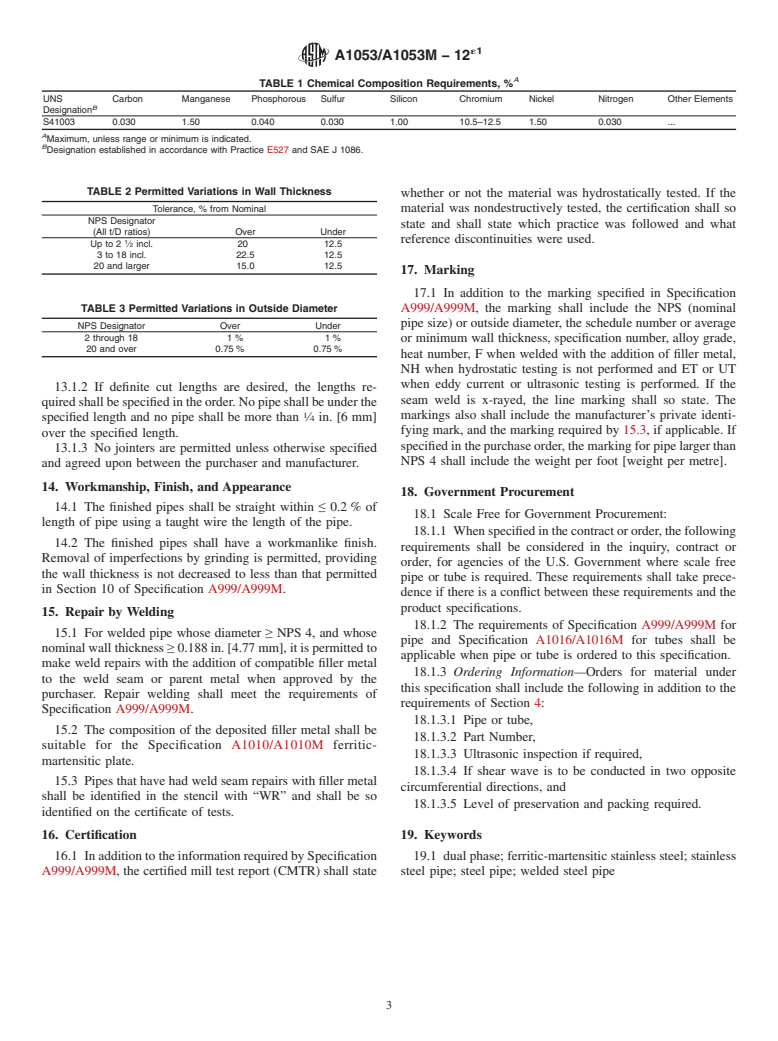

1.1 This specification covers seam welded ferritic-martensitic (dual phase) stainless steel pipe intended for abrasive and general corrosion service, manufactured with or without the addition of filler metal. Nominal sizes are NPS 2 to NPS 36 inclusive, with nominal (average) wall thickness up to 0.75-in. (19 mm).

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents. Therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation is specified in the order.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A1053/A1053M −12

Standard Specification for

1

Welded Ferritic-Martensitic Stainless Steel Pipe

This standard is issued under the fixed designation A1053/A1053M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially updated reference in 14.2 in April 2014.

1. Scope* A1016/A1016M Specification for General Requirements for

Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless

1.1 This specification covers seam welded ferritic-

Steel Tubes

martensitic (dual phase) stainless steel pipe intended for

E527 Practice for Numbering Metals and Alloys in the

abrasive and general corrosion service, manufactured with or

Unified Numbering System (UNS)

without the addition of filler metal. Nominal sizes are NPS 2 to

3

2.2 ANSI/ASME Standards:

NPS 36 inclusive, with nominal (average) wall thickness up to

B1.20.1 Pipe Threads, General Purpose

0.75-in. (19 mm).

B36.10 Welded and Seamless Wrought Steel Pipe

1.2 The values stated in either inch-pound units or SI units

B36.19 Stainless Steel Pipe

are to be regarded separately as standard. Within the text, the 4

ASME Boiler and Pressure Vessel Code, Section IX

SI units are shown in brackets. The values stated in each

2.3 Other Standard:

system may not be exact equivalents. Therefore, each system

SAE J1086 Practice for Numbering Metals and Alloys

shall be used independently of the other. Combining values

5

(UNS)

from the two systems may result in non-conformance with the

standard. The inch-pound units shall apply unless the “M”

3. Terminology

designation is specified in the order.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 The definitions in Specification A999/A999M and

safety concerns, if any, associated with its use. It is the

Terminology A941 are applicable to this specification.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Ordering Information

bility of regulatory limitations prior to use.

4.1 Orders for material to this specification shall conform to

the requirements of the current edition of Specification A999/

2. Referenced Documents

A999M.

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing 5. General Requirements

of Steel Products

5.1 Material furnished under this specification shall con-

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

form to the applicable requirements of the current edition of

Alloys, and Ferroalloys

Specification A999/A999M unless otherwise provided herein.

A999/A999M Specification for General Requirements for

Alloy and Stainless Steel Pipe

6. Materials and Manufacture

A1010/A1010M Specification for Higher-Strength Marten-

6.1 Material:

sitic Stainless Steel Plate, Sheet, and Strip

6.1.1 The material for this pipe shall conform to Specifica-

tion A1010/A1010M Grade 50 dual phase stainless steel.

6.2 Manufacture:

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

3

Current edition approved Sept. 1, 2012. Published November 2012. Originally Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

approved in 2006. Last previous edition approved in 2011 as A1053/A1053M–11. 4th Floor, New York, NY 10036, http://www.ansi.org.

4

DOI: 10.1520/A1053_A1053M-12E01. Available from American Society of Mechanical Engineers (ASME), ASME

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A1053/A1053M−12

6.2.1 The pipe shall be made using the following welding 10. Tensile Requirements

methods: Electric Resistance Welding (ERW) without the

10.1 The tensile properties of the pipe shall conform to the

addition of filler metal, submerged arc welding (SAW), or an

requirements prescribed in Table 5.

automatic fusion welding process with or without the addition

of filler me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.