ASTM A660/A660M-11(2016)

(Specification)Standard Specification for Centrifugally Cast Carbon Steel Pipe for High-Temperature Service

Standard Specification for Centrifugally Cast Carbon Steel Pipe for High-Temperature Service

ABSTRACT

This specification covers carbon steel pipe made by the centrifugal casting process intended for use in high-temperature, high-pressure service. This pipe shall be suitable for fusion welding, bending, and other forming operations. Grades for carbon steels shall conform to the required chemical composition for carbon, manganese, phosphorous, sulfur, and silicon. Manufacturing of the material shall be done by machining and heat treatment. Pyrometers shall be used to control the furnace temperatures. Tensile properties shall conform to the required values for tensile strength, elongation, and reduction of area. Mechanical properties shall conform to the following: transverse or longitudinal tension test; flattening test; and hydrostatic test.

SCOPE

1.1 This specification2 covers carbon steel pipe made by the centrifugal casting process intended for use in high-temperature, high-pressure service. Pipe ordered under this specification shall be suitable for fusion welding, bending, and other forming operations.

1.2 Several grades of carbon steels are covered. Their compositions are given in Table 1. (A) For each reduction of 0.01 % below the specified maximum carbon content, an increase of 0.04 % manganese above the specified maximum will be permitted up to a maximum of 1.10 %.(B) For each reduction of 0.01 % below the specified maximum carbon content, an increase of 0.04 % manganese above the specified maximum will be permitted to a maximum of 1.40 %.

1.3 Supplementary requirements (S1 to S9) of an optional nature are provided. The supplementary requirements call for additional tests to be made, and when desired shall be so stated in the order, together with the number of such tests required.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of each other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A660/A660M −11 (Reapproved 2016)

Standard Specification for

Centrifugally Cast Carbon Steel Pipe for High-Temperature

1

Service

This standard is issued under the fixed designationA660/A660M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E94 Guide for Radiographic Examination Using Industrial

2 Radiographic Film

1.1 This specification covers carbon steel pipe made by the

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

centrifugal casting process intended for use in high-

Contact Testing

temperature, high-pressure service. Pipe ordered under this

E125 Reference Photographs for Magnetic Particle Indica-

specification shall be suitable for fusion welding, bending, and

tions on Ferrous Castings

other forming operations.

E142 Method for Controlling Quality of Radiographic Test-

4

1.2 Several grades of carbon steels are covered. Their

ing (Withdrawn 2000)

compositions are given in Table 1.

1

E186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2 in.

(50.8 to 114 mm)) Steel Castings

1.3 Supplementary requirements (S1 to S9) of an optional

nature are provided. The supplementary requirements call for E381 Method of Macroetch Testing Steel Bars, Billets,

Blooms, and Forgings

additional tests to be made, and when desired shall be so stated

in the order, together with the number of such tests required. E446 Reference Radiographs for Steel Castings Up to 2 in.

(50.8 mm) in Thickness

1.4 The values stated in either inch-pound units or SI units

2.2 ANSI Standards:

are to be regarded separately as standard. Within the text, the

B36.10 American Standard for Welded and Seamless

SI units are shown in brackets. The values stated in each

5

Wrought Steel Pipe

system are not exact equivalents; therefore, each system must

5

B46.1 Surface Texture

be used independently of each other. Combining values from

the two systems may result in nonconformance with the

2.3 MSS Standards:

specification.

SP-54 Quality Standard for Steel Castings for Valves,

Flanges, and Fittings and Other Piping Components -

1.5 This international standard was developed in accor-

6

dance with internationally recognized principles on standard- Radiographic Examination Method

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3. Ordering Information

mendations issued by the World Trade Organization Technical

3.1 Orders for material under this specification should

Barriers to Trade (TBT) Committee.

include the following, as required, to describe the desired

material adequately:

2. Referenced Documents

3.1.1 Quantity (feet, metres, or number of lengths),

3

2.1 ASTM Standards:

3.1.2 Name of material (centrifugally cast pipe),

A530/A530M Specification for General Requirements for

3.1.3 Grade (Table 1),

Specialized Carbon and Alloy Steel Pipe

3.1.4 Size (outside or inside diameter and minimum wall

thickness),

3.1.5 Length (specific or random), (Permissible Variations

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

in Length Section of Specification A530/A530M),

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.18 on Castings.

Current edition approved Sept. 1, 2016. Published September 2016. Originally

approved in 1972. Last previous edition approved in 2011 as A660/A660M – 11.

4

DOI: 10.1520/A0660_A0660M-11R16. The last approved version of this historical standard is referenced on

2

For ASME Boiler and Vessel Code applications see related Specification www.astm.org.

5

SA-660 in Section II of that Code. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

6

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Standards volume information, refer to the standard’s Document Summary page on Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

the ASTM website. hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A660/A660M−11 (2016)

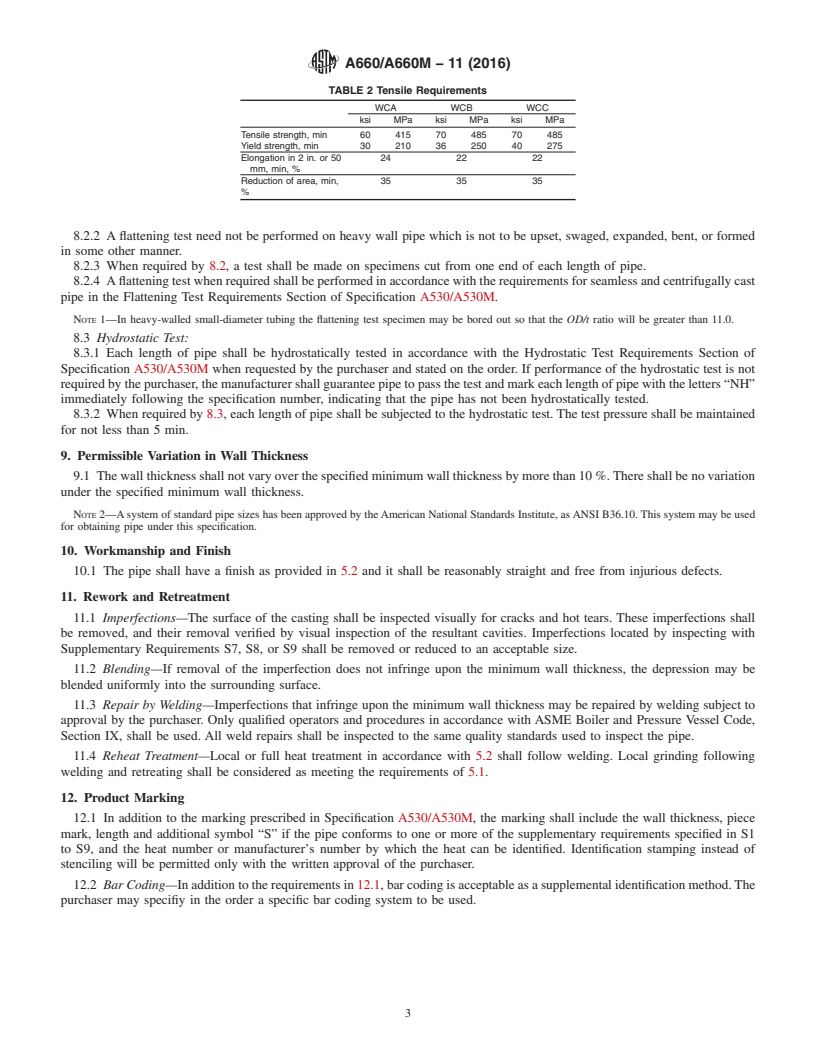

TABLE 1 Chemical Requirements

7.2.3 If the analysis of one of the tests specified in 7.2.1

Composition, max,% does not conform to the requirements specified, an analysis of

Grade WCA Grade WCB Grade WCC each pipe from the same heat may be m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A660/A660M − 11 A660/A660M − 11 (Reapproved 2016)

Standard Specification for

Centrifugally Cast Carbon Steel Pipe for High-Temperature

1

Service

This standard is issued under the fixed designation A660/A660M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers carbon steel pipe made by the centrifugal casting process intended for use in high-temperature,

high-pressure service. Pipe ordered under this specification shall be suitable for fusion welding, bending, and other forming

operations.

1.2 Several grades of carbon steels are covered. Their compositions are given in Table 1.

1.3 Supplementary requirements (S1 to S9) of an optional nature are provided. The supplementary requirements call for

additional tests to be made, and when desired shall be so stated in the order, together with the number of such tests required.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of each other. Combining values from the two systems may result in nonconformance with the specification.

2. Referenced Documents

3

2.1 ASTM Standards:

A530/A530M Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

E94 Guide for Radiographic Examination

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing

E125 Reference Photographs for Magnetic Particle Indications on Ferrous Castings

4

E142 Method for Controlling Quality of Radiographic Testing (Withdrawn 2000)

1

E186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2 in. (50.8 to 114 mm)) Steel Castings

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E446 Reference Radiographs for Steel Castings Up to 2 in. (50.8 mm) in Thickness

2.2 ANSI Standards:

5

B36.10 American Standard for Welded and Seamless Wrought Steel Pipe

5

B46.1 Surface Texture

2.3 MSS Standards:

SP-54 Quality Standard for Steel Castings for Valves, Flanges, and Fittings and Other Piping Components - Radiographic

6

Examination Method

3. Ordering Information

3.1 Orders for material under this specification should include the following, as required, to describe the desired material

adequately:

3.1.1 Quantity (feet, metres, or number of lengths),

3.1.2 Name of material (centrifugally cast pipe),

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved Nov. 1, 2011Sept. 1, 2016. Published December 2011September 2016. Originally approved in 1972. Last previous edition approved in 20102011

as A660 – 96A660/A660M – 11. (2010). DOI: 10.1520/A0660_A0660M-11.10.1520/A0660_A0660M-11R16.

2

For ASME Boiler and Vessel Code applications see related Specification SA-660 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

5

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

6

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A660/A660M − 11 (2016)

TABLE 1 Chemical Requirements

Composition, max,%

Grade WCA Grade WCB Grade WCC

A B

Carbon 0.25 0.30 0.25

A B

Manganese 0.70 1.00 1.20

Phosphorus 0.035 0.035 0.035

Sulfur 0.035 0.035 0.035

Silicon 0.60 0.60 0.60

A

For each reduction of 0.01 % below the specified maximum carbon content, an

increase of 0.04 % manganese above the specified maximum will be permitted up

to a maximum of 1.10 %.

B

For each reduction of 0.01 % bel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.