ASTM D2925-01(2007)e1

(Test Method)Standard Test Method for Beam Deflection of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Pipe Under Full Bore Flow

Standard Test Method for Beam Deflection of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Pipe Under Full Bore Flow

SIGNIFICANCE AND USE

In the absence of deflection measurements from actual installed-above-ground piping, this test method may be used to evaluate the influence of span length on mid-span deflections at differing temperatures under full bore flow.

Note 3—A flat bearing area, small contact area, and narrow bearing width may induce high localized support interaction stresses, and constraints imposed by the supports may also adversely influence deflections and performance of the pipe.

SCOPE

1.1 This test method covers measurement of the deflection as a function of time of a specimen of fiberglass pipe supported on a flat non-arced support as a simple beam under full bore flow of water at elevated temperatures. Both glass-fiber-reinforced thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipes.

Note 1—For the purposes of this standard, polymer does not include natural polymers.

1.2 This test method can be used to determine deflection at varying conditions by substituting other test media.

1.3 Deflections observed using this test method are representative only of piping supported as a simple beam under full bore flow which has one diameter of pipe overhanging at each support.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.Note 2—There is no known ISO equivalent to this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D2925 −01(Reapproved 2007) An American National Standard

Standard Test Method for

Beam Deflection of “Fiberglass” (Glass-Fiber-Reinforced

Thermosetting Resin) Pipe Under Full Bore Flow

This standard is issued under the fixed designation D2925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Note 2 was revised editorially in April 2007.

1. Scope* D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1.1 This test method covers measurement of the deflection

D3567PracticeforDeterminingDimensionsof“Fiberglass”

asafunctionoftimeofaspecimenoffiberglasspipesupported

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

on a flat non-arced support as a simple beam under full bore

Fittings

flow of water at elevated temperatures. Both glass-fiber-

F412Terminology Relating to Plastic Piping Systems

reinforced thermosetting-resin pipe (RTRP) and glass-fiber-

reinforced polymer mortar pipe (RPMP) are fiberglass pipes.

3. Terminology

NOTE 1—For the purposes of this standard, polymer does not include

3.1 General—DefinitionsareinaccordancewithTerminolo-

natural polymers.

gies D883 and F412 and abbreviations are in accordance with

1.2 This test method can be used to determine deflection at

Terminology D1600, unless otherwise indicated.

varying conditions by substituting other test media.

3.2 Definitions of Terms Specific to This Standard:

1.3 Deflections observed using this test method are repre-

3.2.1 aggregate—a siliceous sand conforming to the re-

sentative only of piping supported as a simple beam under full

quirements of Specification C33, except that the requirements

bore flow which has one diameter of pipe overhanging at each

for gradation shall not apply.

support.

3.2.2 fiberglass pipe—a tubular product containing glass

1.4 The values stated in SI units are to be regarded as the

fiber reinforcement embedded in or surrounded by cured

standard. The values given in parentheses are provided for

thermosetting resin; the composite structure may contain

information purposes only.

aggregate, granular or platelet fillers, thixotropic agents,

pigments, or dyes; thermoplastic or thermosetting liners may

NOTE 2—There is no known ISO equivalent to this standard.

be included.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.3 reinforced thermosetting resin pipe (RTRP)—a fiber-

glass pipe without aggregate.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.2.4 reinforced polymer mortar pipe (RPMP)—a fiberglass

pipe with aggregate.

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents

4.1 In the absence of deflection measurements from actual

2.1 ASTM Standards:

installed-above-groundpiping,thistestmethodmaybeusedto

C33Specification for Concrete Aggregates

evaluatetheinfluenceofspanlengthonmid-spandeflectionsat

D883Terminology Relating to Plastics

differing temperatures under full bore flow.

NOTE 3—A flat bearing area, small contact area, and narrow bearing

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

width may induce high localized support interaction stresses, and con-

and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

straints imposed by the supports may also adversely influence deflections

Piping Systems and Chemical Equipment.

and performance of the pipe.

Current edition approved March 1, 2007. Published April 2007. Originally

approved in 1970. Last previous edition approved in 2001 as D2925–01. DOI:

5. Apparatus

10.1520/D2925-01R07E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Rigid Support with edges rounded to a 6-mm ( ⁄4-in.)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

radius, consisting of two uprights of a convenient height. The

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. uprights are to be spaced at a predetermined distance over

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2925−01 (2007)

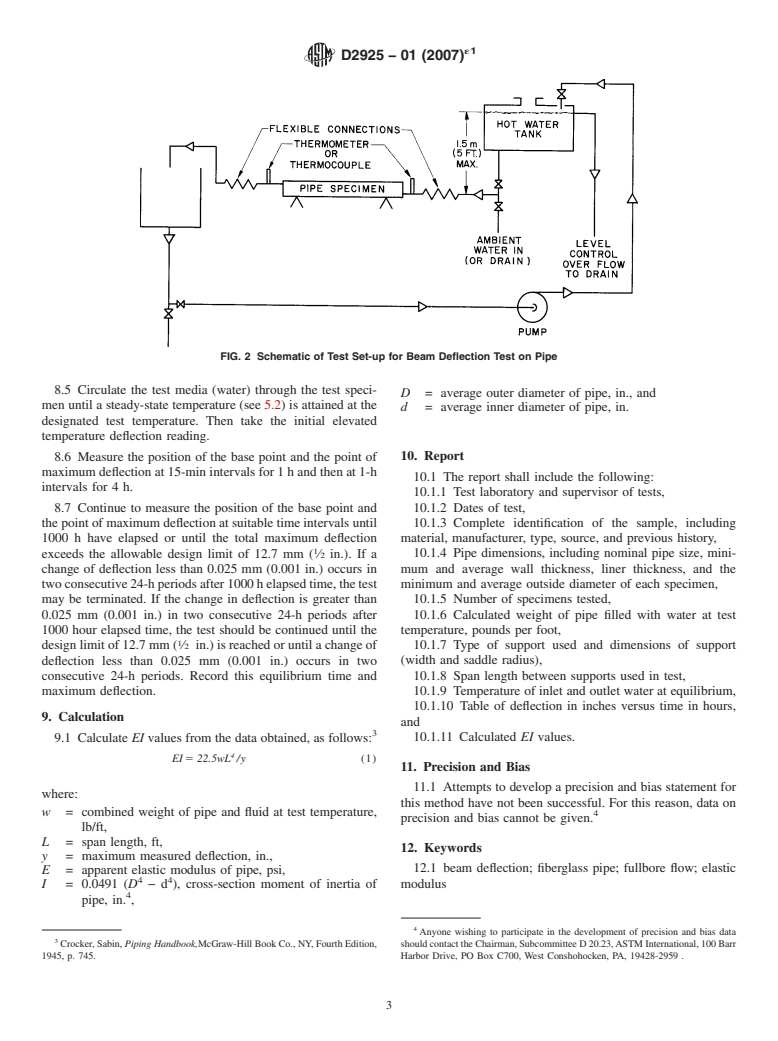

which deflection is to be determined as shown on Fig. 1. The 5.6 Temperature and Pressure Gages and suitable control

uprights shall have lateral guides, a saddle, groove, or inden- devices to maintain standard test conditions.

tation on the top to keep the pipe specimen from rolling off

when placed in position. 6. Test Specimens

5.1.1 The support space distance shall be estimated for a

6.1 The test specimens shall be sections of fiberglass pipe

maximumallowablesagof12.7mm( ⁄2 in.)attestconditions.

cuttoaprecalculatedspanlengthplustwopipediameters 613

This estimate may be made by solving Eq 1 for L, using y=

mm (60.5 in.), essentially straight and of a diameter and wall

12.7 mm ( ⁄2 in.) and assuming an elastic modulus, E=

thickness to be specified.

1 000 000 psi, unless a more accurate value is available.

6.2 At least three specimens shall be tested for any given

5.2 Source of Hot Water and a Feed System maintained at

pipe size.

conditions such that when this source is coupled to the pipe

specimen and the water is fed into the specimen, the water

7. Test Temperature

emerging from the specimen shall be maintained continuously

7.1 The test temperature selected should be the maximum

at the controlled temperature within 62°C (3.6°F). The water

recommended service temperature for the piping unless it is

shallbefedintothespecimenataheadnote

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.