ASTM F1817-17(2022)

(Test Method)Standard Test Method for Performance of Conveyor Ovens

Standard Test Method for Performance of Conveyor Ovens

SIGNIFICANCE AND USE

5.1 The energy input rate test and thermostat calibration are used to confirm that the conveyor oven is operating properly prior to further testing and to insure that all test results are determined at the same temperature.

5.2 Preheat energy and time can be useful to food service operators to manage power demands and to know how quickly the conveyor oven can be ready for operation.

5.3 Idle Energy Rate—This test provides a measure of an empty oven’s energy consumption and pilot energy during noncooking periods, at a typical cooking temperature setting. It also provides an indicator of the combined effectiveness of components of the oven’s design (for example, insulation, door seals, and combustion efficiency) that influence its energy consumption.

5.4 Cooking Energy Efficiency—A precise indicator of conveyor oven energy performance while cooking a typical food product under various loading conditions. If energy performance information is desired using a food product other than the specified test food, the test method could be adapted and applied. Energy performance information allows an end user to better understand the operating characteristics of a conveyor oven.

5.5 Production capacity information can help an end user to better understand the production capabilities of a conveyor oven as it is used to cook a typical food product and this could help in specifying the proper size and quantity of equipment. If production information is desired using a food product other than the specified test food, the test method could be adapted and applied.

SCOPE

1.1 This test method covers an evaluation of the energy consumption and cooking performance of conveyor ovens. The food service operator can use this evaluation to select a conveyor oven and understand its energy consumption.

1.2 This test method is applicable to gas and electric conveyor ovens.

1.3 The conveyor oven can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate and thermostat calibration (see 10.2),

1.3.2 Preheat energy consumption and time (see 10.3),

1.3.3 Idle energy rate (see 10.4),

1.3.4 Pilot energy rate (if applicable) (see 10.5), and

1.3.5 Cooking energy efficiency and production capacity (see 10.6).

1.4 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1817 − 17 (Reapproved 2022) An American National Standard

Standard Test Method for

Performance of Conveyor Ovens

This standard is issued under the fixed designation F1817; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers an evaluation of the energy 2.1 ASHRAE Documents:

consumptionandcookingperformanceofconveyorovens.The 2013ASHRAE Handbook of FundamentalsChapter 1, Psy-

chrometrics

food service operator can use this evaluation to select a

2014ASHRAE Handbook—Refrigeration Chapter 19Ther-

conveyor oven and understand its energy consumption.

mal Conductivity of Foods, page 9 (R19.9); Diffusivity of

1.2 This test method is applicable to gas and electric

foods, R19.17, and Enthalpy of foods R19.8

conveyor ovens.

ASHRAE Guideline 2-1986 (RA90)Engineering Analysis

of Experimental Data

1.3 The conveyor oven can be evaluated with respect to the

ASHRAE Guideline 2 2010 (RA 2014)Engineering Analy-

following (where applicable):

sis of Experimental Data

1.3.1 Energy input rate and thermostat calibration (see

2.2 Other Document:

10.2),

AOAC Procedure 984.25Moisture (Loss of Mass on Dry-

1.3.2 Preheat energy consumption and time (see 10.3), 3

ing) in Frozen French Fried Potatoes

1.3.3 Idle energy rate (see 10.4),

3. Terminology

1.3.4 Pilot energy rate (if applicable) (see 10.5), and

1.3.5 Cooking energy efficiency and production capacity 3.1 Definitions of Terms Specific to This Standard:

3.1.1 chamber stabilization pizzas, n—full cooking cavity

(see 10.6).

loadofnominal12in.pizzasloadedatbeginningofproduction

1.4 The values stated in inch-pound units are to be regarded

capacity test.

asstandard.Nootherunitsofmeasurementareincludedinthis

3.1.2 conveyor oven, n—an appliance that carries the food

standard.

product on a moving conveyor into and through a heated

1.5 This test method may involve hazardous materials,

chamber.The chamber may be heated by gas or electric forced

operations, and equipment. This standard does not purport to convection, radiant, or quartz tubes. Top and bottom heat may

be independently controlled.

address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to

3.1.3 cooking energy effıciency, n—quantity of energy im-

establish appropriate safety, health, and environmental prac-

parted to the specified food product, expressed as a percentage

tices and determine the applicability of regulatory limitations of energy consumed by the conveyor oven during the cooking

event.

prior to use.

1.6 This international standard was developed in accor- 3.1.4 cooking energy rate, n—average rate of energy con-

sumption (Btu/h or kW) during the cooking energy efficiency

dance with internationally recognized principles on standard-

tests.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.5 cooking stabilization pizzas, n—full cooking chamber

mendations issued by the World Trade Organization Technical

ofnominal12in.pizzascontinuouslyloadeddirectlyfollowing

Barriers to Trade (TBT) Committee.

the test pizzas. Pizzas keep the cooking chamber consistent

during the measured test pizzas.

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on Available from American Society of Heating, Refrigerating, and Air-

Productivity and Energy Protocol. Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

Current edition approved May 1, 2022. Published June 2022. Originally 30329.

approved in 1997. Last previous edition approved in 2017 as F1817–17. DOI: Available from AOAC International, 2275 Research Blvd., Suite 300,

10.1520/F1817-17R22. Rockville, MD 20850-3250, http://www.aoac.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1817 − 17 (2022)

3.1.6 energy input rate, n—peak rate at which a conveyor 4.6 Cooking Uniformity—The uniformity of heating within

oven consumes energy (Btu/h or kW). the oven’s cavity is determined and reported based on the

product cooked temperature per cooking position and visual of

3.1.7 idle energy rate, n—the conveyor oven’s rate of

product appearance top and bottom.

energy consumption (kW or Btu/h), when empty, required to

maintain its cavity temperature at the specified thermostat set

5. Significance and Use

point.

5.1 The energy input rate test and thermostat calibration are

3.1.8 oven cavity, n—that portion of the conveyor oven in

used to confirm that the conveyor oven is operating properly

which food products are heated or cooked.

prior to further testing and to insure that all test results are

determined at the same temperature.

3.1.9 pilot energy rate, n—rate of energy consumption

(Btu/h) by a conveyor oven’s continuous pilot (if applicable).

5.2 Preheat energy and time can be useful to food service

operators to manage power demands and to know how quickly

3.1.10 preheat energy, n—amount of energy consumed (Btu

the conveyor oven can be ready for operation.

or kWh), by the conveyor oven while preheating its cavity

fromambienttemperaturetothespecifiedthermostatsetpoint.

5.3 Idle Energy Rate—This test provides a measure of an

empty oven’s energy consumption and pilot energy during

3.1.11 preheat time, n—time (min.) required for the con-

noncookingperiods,atatypicalcookingtemperaturesetting.It

veyor oven cavity to preheat from ambient temperature to the

also provides an indicator of the combined effectiveness of

specified thermostat set point.

componentsoftheoven’sdesign(forexample,insulation,door

3.1.12 production capacity, n—maximum rate (lb/h) at

seals, and combustion efficiency) that influence its energy

which a conveyor oven can bring the specified food product to

consumption.

a specified “cooked” condition.

5.4 Cooking Energy Effıciency—Aprecise indicator of con-

3.1.13 production rate, n—rate (lb/h) at which a conveyor

veyor oven energy performance while cooking a typical food

oven brings the specified food product to a specified“ cooked”

product under various loading conditions. If energy perfor-

condition. Does not necessarily refer to maximum rate. Pro-

mance information is desired using a food product other than

duction rate varies with the amount of food being cooked.

the specified test food, the test method could be adapted and

3.1.14 test pizzas, n—full cooking chamber of nominal 12

applied.Energyperformanceinformationallowsanenduserto

in. pizzas continuously loaded directly following the stabiliza-

better understand the operating characteristics of a conveyor

tion load. These are the pizzas measured for production

oven.

capacity.

5.5 Production capacity information can help an end user to

3.1.15 uncertainty, n—measure of systematic and precision

better understand the production capabilities of a conveyor

errors in specified instrumentation or measure of repeatability

oven as it is used to cook a typical food product and this could

of a reported test result.

helpinspecifyingthepropersizeandquantityofequipment.If

production information is desired using a food product other

4. Summary of Test Method

than the specified test food, the test method could be adapted

and applied.

4.1 Accuracyoftheconveyoroventhermostatischeckedat

a setting of 475°F (246°C) and the thermostat is adjusted as

6. Apparatus

necessary.

6.1 Analytical Balance Scale, for measuring weights up to

4.2 Energy Input Rate—Determined to confirm that the

20 lb (9.1 kg), with a resolution of 0.01 lb (0.005 kg) and an

conveyorovenisoperatingwithin5%ofthenameplateenergy

uncertainty of 60.01 lb (60.005 kg).

inputrate.Forgasconveyoroven,thepilotenergyrateandthe

6.2 Barometer, for measuring absolute atmospheric

fanandcontrolenergyratesarealsodetermined.Theinputrate

pressure, with a range from 28 to 32 in. to be used for

of the oven is determined to check whether the oven is

adjustment of measured natural gas volume to standard condi-

operatingproperly.Ifthemeasuredinputrateisnotwithin5%

tions. Shall have a resolution of 0.2 in. Hg and an uncertainty

of the rated input, all further testing ceases until the appliance

of 60.2 in. Hg.

canbemadetooperatewithinthisspecification.Forgasovens,

6.3 Canopy Exhaust Hood, 4 ft (1.2 m) in depth, wall-

thepilotenergyrateandthefanandcontrolenergyratearealso

mounted with the lower edge of the hood 6 ft , 6 in. (1.98 m)

determined.

from the floor and with the capacity to operate at a nominal

4.3 Preheat Energy Consumption and Time—The time and

exhaust ventilation rate of 300 cfm per linear foot of active

energy required to preheat the oven from room temperature 75

hood length. This hood shall extend a minimum of 6 in. (152

6 5°F (24 6 2.8°C) to 475 6 5°F (246 6 2.8°C) determined.

mm)pastbothsidesandthefrontofthecookingapplianceand

4.4 Idle Energy Rate—The idle energy rate (kBtu/h or kW)

shall not incorporate side curtains or partitions. Makeup air

is determined with the oven set to maintain 475 6 5°F (246 6

shall be delivered through face registers or from the space, or

2.8°C).

both.

4.5 Cooking energy efficiency and production rate are 6.4 ConvectionDryingOven,withtemperaturecontrolledat

determined during heavy-load cooking tests using pizza as a 220 6 5°F (104 6 –2.8°C), to be used to determine moisture

food product. content of pizza crust, pizza sauce and pizza cheese.

F1817 − 17 (2022)

6.5 Gas Meter, for measuring the gas consumption of a 6.11 Temperature Readout Device, connected to bare junc-

conveyor oven, shall be a positive displacement type with a tionthermocoupleprobes,witharangefrom0to450°F(−17.8

resolution of at least 0.01 ft and a maximum uncertainty no

to232°C),aresolutionof0.1°F(0.06°C),andanuncertaintyof

greaterthan1%ofthemeasuredvalueforanydemandgreater

61.0°F (60.6°C), used to measure the temperature of air

than 2.2 ft /h. If the meter is used for measuring the gas

(ambient and cavity), and ice/water mixture. The device

consumed by the pilot lights, it shall have a resolution of at

readout shall be capable of displaying required average tem-

least 0.01 ft and a maximum uncertainty no greater than 2%

perature(s) during cooking energy efficiency and cooking

of the measured value.

uniformity tests (minimum of 20 thermocouples needed).

6.6 Pressure Gage, for monitoring natural gas pressure.

6.12 Watt-Hour Meter, for measuring the electrical energy

Shall have a range of 0 to 15 in. H O, a resolution of 0.2 in.

consumption of a conveyor oven, shall have a resolution of at

H O, and an uncertainty of 60.1in. H O.

2 2

least 10Wh and a maximum uncertainty no greater than 1.5%

6.7 Stop Watch, with a 1-s resolution.

of the measured value for any demand greater than 100W. For

6.8 Temperature Sensor, for measuring natural gas tempera- any demand less than 100 W, the meter shall have a resolution

ture in the range of 50 to 100°F with an uncertainty of 61°F .

of at least 10 Wh and a maximum uncertainty no greater than

10%.

6.9 Thermocouple, fiberglass insulated, 24 gage, Type K

thermocouple wire, connected at the exposed ends by tightly

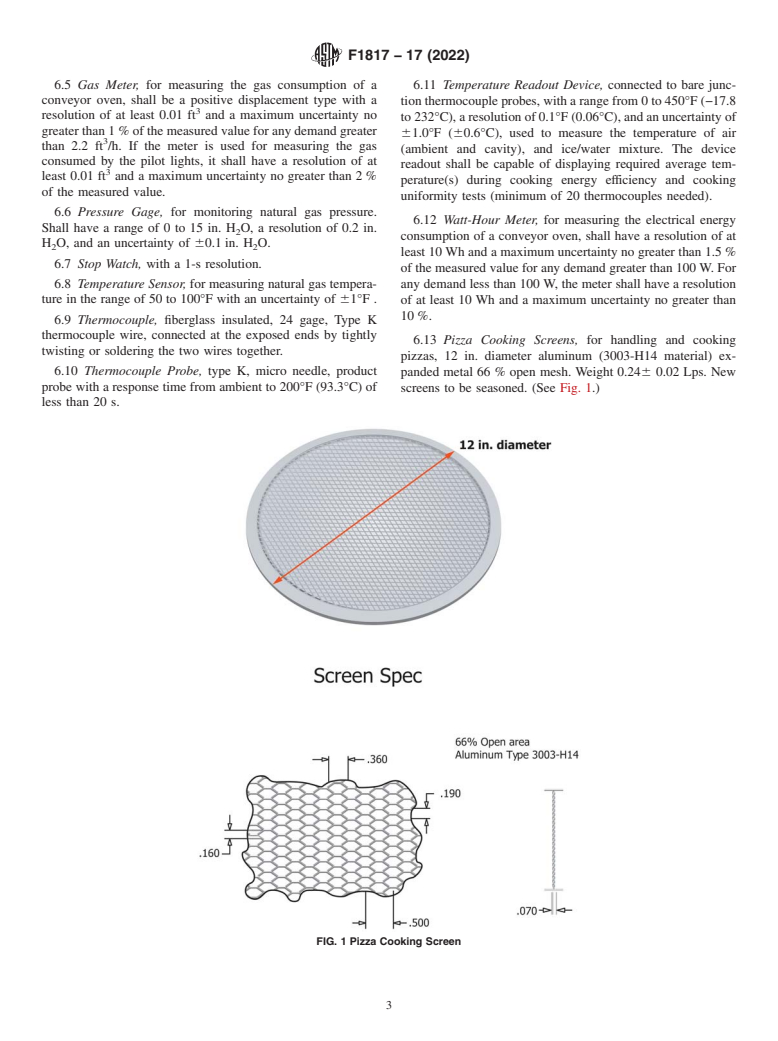

6.13 Pizza Cooking Screens, for handling and cooking

twisting or soldering the two wires together.

pizzas, 12 in. diameter aluminum (3003-H14 material) ex-

6.10 Thermocouple Probe, type K, micro needle, product

panded metal 66 % open mesh. Weight 0.246 0.02 Lps. New

probe with a response time from ambient to 200°F (93.3°C) of

screens to be seasoned. (See Fig. 1.)

less than 20 s.

FIG. 1 Pizza Cooking Screen

F1817 − 17 (2022)

FIG. 2 Discharge Gap Minimum 2.25 in. (57.2 mm); Load Minimum Gap 1.25 in. (31.8 mm)

NOTE 1—Minimum Discharge Opening 2.25 in.

FIG. 3 Pizza Exit Must Clear Discharge Opening Without Touching

7. Reagents and Materials 0.25 lb of pizza sauce on top of a pizza crust to within 0.5 in.

oftheedgeofthecrustandcoverthepizzasaucewith0.375lb

7.1 Pizza Crust shall be a 12 in. diameter, prebaked or

of pizza cheese.

parbaked crust, weighing 0.9 6 0.2 lb and having a moisture

content of 36 6 3% by weight, based on a gravimetric 7.5 Gravimetric moisture analysis shall be performed as

moisture analysis. Refrigerate to 39 6 1°F. follows: to determine moisture content, place a thawed, refrig-

erated 38 6 2°F pizza on a dry, aluminum sheet pan and place

7.2 Pizza Sauce shall be a simple, tomato based sauce with

the pan in a convection drying oven at a temperature of 220 6

a moisture content of 90 6 2% by weight, based on a

5°F (104 6 2.8°C) for a period of 24 h. Weigh the sample

gravimetric moisture analysis. Refrigerate to 39 6 1°F.

7.3 Pizza Cheese shall be a part skim, low moisture,

The Food Service Technology Center has found that Villa Prima – Frozen

shredded mozzarella cheese with a moisture content of 50 6

(25.85 oz), 4 Cheese Pizza, Item # 73184 – complies with the pizza specification

2% by weight, based on a gravimetric moisture analysis.

requirements for this test method. The sole source of supply of the pizza known to

Refrigerate to 39 6 1°F. the committee at this time is Schwan’s Food Company Inc., Marshall, MN, 56258.

If you are aware of alternative suppliers, please provide this information toASTM

7.4 Pizza shall be comprised of a pizza crust, pizza sauce

International Headquarters. Your comments will receive careful consideration at a

and pizza cheese according to the following: uniformly spread meeting of the responsible technical committee, which you may attend.

F1817 − 17 (2022)

separate appliances in accordance with this test method.

before it is placed in the oven and after it is removed and

determine the percent moisture content based on the percent

9.4 For a gas conveyor oven, adjust (during maximum

weight loss of the sample. The sample must be thoroughly

energy input) the gas supply pressure downstream from the

chopped ( ⁄8 in. or smaller squares) and spread evenly over the

appliance’s pressure regulator to within 62.5% of the operat-

surface of the sheet pan in order for all of the moisture to

ing manifold pressure specified by the manufacturer. Make

evaporate during drying and it is permissible to spread the

adjustments to the appliance following the manufact

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.