ASTM C1689-08

(Practice)Standard Practice for Subsampling of Uranium Hexafluoride

Standard Practice for Subsampling of Uranium Hexafluoride

SIGNIFICANCE AND USE

Uranium hexafluoride is normally produced and handled in large (typically 1- to 14-ton) quantities and must, therefore be characterized by reference to representative samples. The quantities involved, physical properties, chemical reactivity, and hazardous nature of UF6 are such that for representative sampling, specially designated equipment must be used and operated in accordance with the most carefully controlled and stringent procedures. This practice indicates appropriate principles, equipment and procedures currently in use for subsampling of liquid UF6. It is used by UF6 converters, enrichers and fuel fabricators to review the effectiveness of existing procedures or to design equipment and procedures for future use. Other subsampling procedures such as UF6 vapor sampling are not directly representative of the chemical quality of liquid UF6.

It is emphasized that this test guide is not meant to address conventional or nuclear criticality safety issues.

SCOPE

1.1 This practice is applicable to subsampling uranium hexafluoride (UF6), using heat liquefaction techniques, from bulk containers, obtained in conformance with C 1052, into smaller sample containers, which are required for laboratory analyses.

1.2 It is assumed that the liquid UF6 being sampled comprises a single quality and quantity of material. This practice does not address any special additional arrangement that might be required for taking proportional or composite samples.

1.3 The number of samples to be taken, their nominal sample weight, and their disposition shall be agreed upon between the parties.

1.4 The scope of this practice does not include provisions for preventing criticality incidents.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1689 – 08

Standard Practice for

Subsampling of Uranium Hexafluoride

This standard is issued under the fixed designation C 1689; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ANSI N14.1 Uranium Hexafluoride: Packaging for Trans-

port

1.1 This practice is applicable to subsampling uranium

ISO/DIS 7195 Packaging of Uranium Hexafluoride (UF )

hexafluoride (UF ), using heat liquefaction techniques, from

for Transport

bulk containers, obtained in conformance with C 1052, into

USEC-651 The UF Manual: Good Handling Practices for

smaller sample containers, which are required for laboratory

Uranium Hexafluoride, latest revision

analyses.

1.2 It is assumed that the liquid UF being sampled com-

3. Terminology

prises a single quality and quantity of material. This practice

3.1 Terms shall be defined in accordance with Terminology

does not address any special additional arrangement that might

C 859 except for the following:

be required for taking proportional or composite samples.

3.1.1 sample bottle—the vessel (typically a 1S or 2S bottle)

1.3 The number of samples to be taken, their nominal

into which the sample of UF is withdrawn from the container

sample weight, and their disposition shall be agreed upon

for transfer to the laboratory, analysis or dispatch to the

between the parties.

customer.

1.4 The scope of this practice does not include provisions

3.1.2 subsample tube—the small vessel (for example, a P10

for preventing criticality incidents.

tube ) into which a subsample of UF is withdrawn from the

1.5 This standard does not purport to address all of the

sample bottle for analysis of UF quality or dispatch to the

safety concerns, if any, associated with its use. It is the

customer.

responsibility of the user of this standard to establish appro-

3.1.3 subsample rig—the equipment to perform the transfer

priate safety and health practices and determine the applica-

of liquid UF from the sample bottle into the subsample tube,

bility of regulatory limitations prior to use.

typically a vacuum manifold equipped with heating and a

2. Referenced Documents liquid nitrogen trap.

2.1 ASTM Standards:

4. Summary of Practice

C 787 Specification for Uranium Hexafluoride for Enrich-

4.1 Two methods of withdrawing a subsample of UF are

ment

3 described which differ based on safety requirements namely:

C 859 Terminology Relating to Nuclear Materials

(1) homogenizing of liquefied UF by agitation before liquid

C 996 Specification for Uranium Hexafluoride Enriched to

transfer and (2) homogenizing of liquefied UF by convection

Less Than 5 % U

before liquid transfer. The first method involves homogeniza-

C 761 Test Methods for Chemical, Mass Spectrometric,

tion of liquified UF in sample bottle by vigorous shaking.

Spectrochemical, Nuclear, and Radiochemical Analysis of

Subsequentlythesamplebottleisinvertedandconnectedtothe

Uranium Hexafluoride

top of a heated vacuum-manifold system, and the subsample

C 1052 Practice for Bulk Sampling of Liquid Uranium

Hexafluoride

2.2 Other Documents:

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from International Organization for Standardization (ISO), 1, ch. de

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

This practice is under the jurisdiction of ASTM Committee C26 on Nuclear www.iso.ch.

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of AvailablefromUnitedStatesEnrichmentCorp.,6903RockledgeDr.,Bethesda,

Test. MD 20817, http://www.usec.com.

Current edition approved Aug. 1, 2008. Published September 2008. Polychlorotrifluoroethylene P10 tubes are widely accepted by the industry for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or subsample collection and subsequent UF quality analyses or dispatch to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM customer. Other types of subsample tubes, for example P-20, P-80 or P100 , can be

Standards volume information, refer to the standard’s Document Summary page on used for internal subsample collection and processing. Dispatch of these subsample

the ASTM website. tubes may be agreed upon by buyer and seller and subject to (local) transport

Withdrawn. regulations.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1689–08

tube is attached to the appropriate port of the system. The sampling, specially designated equipment must be used and

system is evacuated and the liquid UF allowed to flow by operated in accordance with the most carefully controlled and

gravity into the subsample tube. In the second method the stringent procedures. This practice indicates appropriate prin-

sample bottle containing solid UF is connected to the top of a ciples, equipment and procedures currently in use for subsam-

manifold system, and a subsample tube is attached to the pling of liquid UF . It is used by UF converters, enrichers and

6 6

appropriateportofthesystem.Thewholesystemisenclosedin fuel fabricators to review the effectiveness of existing proce-

secondary containment that can be heated (hot-box). After dures or to design equipment and procedures for future use.

evacuation the complete system is heated for specific period Other subsampling procedures such as UF vapor sampling are

(typically > 1.5 hr) to allow for complete homogenization of not directly representative of the chemical quality of liquid

the liquid UF by convection. Subsequently the liquid UF is UF .

6 6 6

allowed to flow by gravity either directly or via graduated

5.2 It is emphasized that this test guide is not meant to

volume into the subsample tube.

address conventional or nuclear criticality safety issues.

4.2 For both methods of sampling, the presence of residues

may have significant implications for the quality of UF . For

6. Apparatus

safety and quality reasons, sample bottles and an subsample

6.1 Hot Water Bath.

tubes shall be clean, dry, and empty before filling.

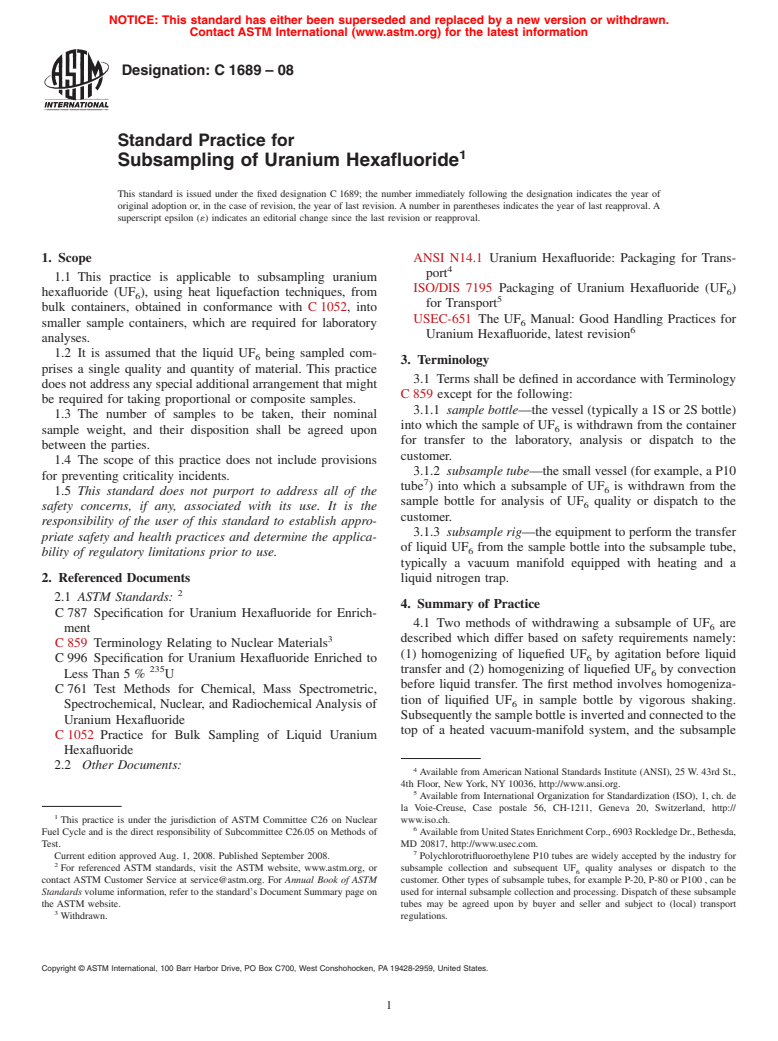

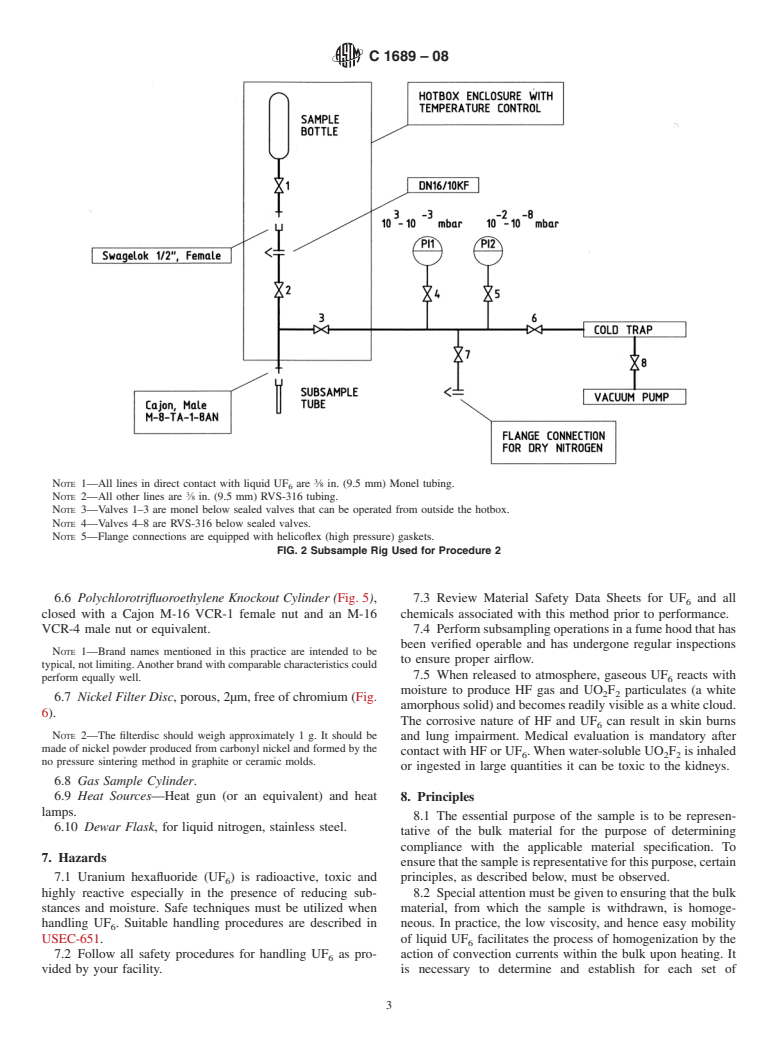

6.2 Subsample Rig—For Procedure 1 see Fig. 1 and Proce-

4.3 Various types of sample bottles and tubes are in use and

dure 2 see Fig. 2. Materials of construction in direct contact

are described in detail in the applicable national and interna-

with liquid UF are made from nickel, high nickel alloys, or

tional standards, for example,ANSI N14.1 and ISO/DIS 7195.

materials having comparable resistance to UF corrosion.

For a given type of sample bottle, the detailed configuration,

6.3 Polychlorotrifluoroethylene Subsample Tube and Clos-

for example valve orientation, terminal fittings and the like,

ing Disc (Fig. 3)—The tube must be of uniform density, free

may vary. Hence the type and configuration of bottles used for

from cracks or occlusions and able to withstand temperatures

the withdrawal of samples shall be agreed upon between the

from –195°C to +150°C. Materials of construction in direct

parties.

contact with liquid UF are made from polychlorotrifluoroet-

5. Significance and Use

hylene, PTFE/TFE (gaskets), or materials having comparable

resistance to UF corrosion.

5.1 Uraniumhexafluorideisnormallyproducedandhandled

6.4 FlareNutandPlug—Flarenutsandplugsforsubsample

in large (typically 1- to 14-ton) quantities and must, therefore

tube closure, storage and transport can be constructed from

be characterized by reference to representative samples. The

Monel, nickel, high nickel alloys or 316 SS.

quantities involved, physical properties, chemical reactivity,

and hazardous nature of UF are such that for representative 6.5 Gaseous Isotopic Abundance Sample Tube (Fig. 4).

NOTE 1—All lines are ⁄8 in. (9.5 mm) Monel tubing.

NOTE 2—All valves are Monel diaphragm type valves.

NOTE 3—The valves and lines are wrapped with heating tape to maintain a system temperature of about 80°C.

NOTE 4—Valve 2 is a 3-way valve modified to make it a 4-way valve. When the valve is closed, the polychlorotrifluoroethylene tube is isolated from

the system, but the lines from valve 1 to valve 3 and to the bulk container are open.

FIG. 1 Subsample Rig Used for Procedure 1

C1689–08

NOTE 1—All lines in direct contact with liquid UF are ⁄8 in. (9.5 mm) Monel tubing.

NOTE 2—All other lines are" in. (9.5 mm) RVS-316 tubing.

NOTE 3—Valves 1–3 are monel below sealed valves that can be operated from outside the hotbox.

NOTE 4—Valves 4–8 are RVS-316 below sealed valves.

NOTE 5—Flange connections are equipped with helicoflex (high pressure) gaskets.

FIG. 2 Subsample Rig Used for Procedure 2

6.6 Polychlorotrifluoroethylene Knockout Cylinder (Fig. 5), 7.3 Review Material Safety Data Sheets for UF and all

closed with a Cajon M-16 VCR-1 female nut and an M-16 chemicals associated with this method prior to performance.

VCR-4 male nut or equivalent. 7.4 Performsubsamplingoperationsinafumehoodthathas

been verified operable and has undergone regular inspections

NOTE 1—Brand names mentioned in this practice are intended to be

to ensure proper airflow.

typical, not limiting.Another brand with comparable characteristics could

7.5 When released to atmosphere, gaseous UF reacts with

perform equally well. 6

moisture to produce HF gas and UO F particulates (a white

2 2

6.7 Nickel Filter Disc, porous, 2µm, free of chromium (Fig.

amorphoussolid)andbecomesreadilyvisibleasawhitecloud.

6).

The corrosive nature of HF and UF can result in skin burns

NOTE 2—The filterdisc should weigh approximately 1 g. It should be

and lung impairment. Medical evaluation is mandatory after

made of nickel powder produced from carbonyl nickel and formed by the

contact with HF or UF . When water-soluble UO F is inhaled

6 2 2

no pressure sintering method in graphite or ceramic molds.

or ingested in large quantities it can be toxic to the kidneys.

6.8 Gas Sample Cylinder.

6.9 Heat Sources—Heat gun (or an equivalent) and heat

8. Principles

lamps.

8.1 The essential purpose of the sample is to be represen-

6.10 Dewar Flask, for liquid nitrogen, stainless steel.

tative of the bulk material for the purpose of determining

compliance with the applicable material specification. To

7. Hazards

ensurethatthesampleisrepresentativeforthispurpose,certain

7.1 Uranium hexafluoride (UF ) is radioactive, toxic and principles, as described below, must be observed.

highly reactive especially in the presence of reducing sub- 8.2 Special attention must be given to ensuring that the bulk

stances and moisture. Safe techniques must be utilized when material, from which the sample is withdrawn, is homoge-

handling UF . Suitable handling procedures are described in neous. In practice, the low viscosity, and hence easy mobility

USEC-651. of liquid UF facilitates the process of homogenization by the

7.2 Follow all safety procedures for handling UF as pro- action of convection currents within the bulk upon heating. It

vided by your facility. is necessary to determine and establish for each set of

C1689–08

FIG. 3 Isotopic Abundance Sample Tube.

FIG. 4 Example of a Polychlorotrifluoroethylene Subsample Tube

subsampling equipment the physical conditions, normally a 8.3 Uranium hexafluoride is very reactive and corrosive. It

combination of the minimum time and temperature for which reacts readily with water, atmospheric moisture and many

liquefied uranium hexafluoride is held, which guaranty homo- organic materials. For reasons of safety and to avoid contami-

geneity of the bulk UF . nation, precautions must be taken to avoid contact with such

C1689–08

FIG. 5 Example of a Polychlorotrifluoroethylene Knock-out Tube

FIG. 6 Filter Disc Unit for Determination of Soluble and Insoluble Chromium

materials. The subsampling equipment and subsample tube are comparable resistance to UF corrosion. The formation of an

therefore fabricated to appropriate high standards of vacuum

inert fluoride layer is often an important feature of UF

integrity, and components in direct contact with liquid UF are

made from nickel, high nickel alloys, or materials having

C1689–08

corrosion resistance, and hence internal surfaces are generally 10.1.2 After the UF has been liquefied, remove the con-

conditioned with a suitable fluorinating agent, sometimes UF tainer from the bath, shake to homogenize the sample, and

itself. connect it at the top of the vacuum-manifold system shown in

8.4 Cross-contamination may occur between subsequent Fig. 1. The container will be inverted if liquid UF must be

samples taken using the same equipment, and appropriate subsampled.

precautions must be taken to prevent this. It is therefore

10.1.3 When a liquid subsample is required for uranium

recommended that, before taking definitive samples, the equip-

analysis or chemical impurity (metal, halogen), and TIMS

ment is flushed through with an aliquot of the material to be

isotopic analysis, connect a tared polychlorotrifluoroethylene

sampled. This is normally accomplished by taking an initial

sample tube at the Cajon connection at the bottom of the

volume which is then rejected and not used for definitive

system. If this subsample is not required, attach a blind fitting

analysis. Alternative procedures to prevent cross-

at this point.

contamination are possible and should be validated individu-

10.1.4 When a liquid subsample is required for gaseous

ally.

isotopic analysis or all gas carbon compound determination,

8.5 Ifsamplebottlesaretakenforananalyticalneedsuchas

attach a tared isotopic abundance sample tube to the sample

liquidUF subsamplingforP10tubesorliquidUF transferfor

6 6

tube connection. If a subsample is not required, attach a cap at

FTIR quantification, it is recommended, in order to minimize

this point.

the gas phase contribution to the sample bottle, to fill the bottle

10.1.5 When a total gas UF transfer is necessary, connect

with more than 10 % of its total volume.

the UF bulk container without inversion. Attach a polychlo-

rotrifluoroethylene knockout cylinder at the tube connection

9. Subsampling Schemes for UF Specification Analyses

and attach a cap at the fitting for isotopic abundance sample

9.1 The number and type of subsamples taken from a

tube.

sample bottle (typically 1S or 2S bottle) depends both on the

10.1.6 Close valve 4, then evacuate the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.