ASTM C1514-08(2017)

(Test Method)Standard Test Method for Measurement of 235U Fraction Using Enrichment Meter Principle

Standard Test Method for Measurement of <sup> 235</sup>U Fraction Using Enrichment Meter Principle

SIGNIFICANCE AND USE

5.1 The enrichment meter principle provides a nondestructive measurement of the 235U fraction of uranium-bearing items. Sampling is not required and no waste is generated, minimizing exposure to hazardous materials and resulting in reduced sampling error.

5.2 This method relies on a fixed and controlled geometry. The uranium-bearing materials in the measured items and calibration reference materials used for calibration must fill the detector field of view.

5.3 Use of a low resolution detector (for example, NaI detector) to measure uranium with 235U fraction approximately 10 % which is contained in a thin-walled container can provide a rapid (typically 100 s), easily portable measurement system with precision of 0.6 % and bias of less than 1 %.

5.4 Use of a high resolution detector (for example, high-purity germanium) can provide measurement with a precision better than 0.2 % and a bias less than 1 % within a 300-s measurement time when measuring uranium with 235U fraction in the range of 0.711 % or above which is contained in thin-walled containers.

5.5 In order to obtain optimum results using this method, the chemical composition of the item must be well known, the container wall must permit transmission of the 185.7 keV gamma-ray, and the uranium-bearing material within the item must be infinitely thick with respect to the 185.7 keV gamma-ray. All items must be in identical containers or must have a known container wall thickness and composition.

5.6 Items to be measured must be homogeneous with respect to both 235U fraction and chemical composition.

5.7 When measuring items, using low-resolution detectors, in thin-walled containers that have not reached secular equilibrium (more than about 120 days after processing), either the method should not be used, additional corrections should be made to account for the age of the uranium, or high-resolution measurements should be performed.

5.8 The method is often used as a enrichment verificatio...

SCOPE

1.1 This test method covers the quantitative determination of the fraction of 235U in uranium using measurement of the 185.7 keV gamma-ray produced during the decay of 235U.

1.2 This test method is applicable to items containing homogeneous uranium-bearing materials of known chemical composition in which the compound is considered infinitely thick with respect to 185.7 keV gamma-rays.

1.3 This test method can be used for the entire range of 235U fraction as a weight percent, from depleted (0.2 % 235U) to highly enriched (97.5 % 235U).

1.4 Measurement of items that have not reached secular equilibrium between 238U and 234Th may not produce the stated bias when low-resolution detectors are used with the computational method listed in Annex A2.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1514 − 08 (Reapproved 2017)

Standard Test Method for

Measurement of U Fraction Using Enrichment Meter

Principle

This standard is issued under the fixed designation C1514; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1592 Guide for Nondestructive Assay Measurements

C26.10 Terminology Guide

1.1 This test method covers the quantitative determination

2.2 ANSI Standard:

of the fraction of U in uranium using measurement of the

N42.14 Calibration and Use of Germanium Spectrometers

185.7 keV gamma-ray produced during the decay of U.

for the Measurement of Gamma-Ray Emission Rates of

1.2 This test method is applicable to items containing

Radionuclides

homogeneous uranium-bearing materials of known chemical

composition in which the compound is considered infinitely

3. Terminology

thick with respect to 185.7 keV gamma-rays.

3.1 For definitions of terms used in this test method, refer to

1.3 Thistestmethodcanbeusedfortheentirerangeof U

Terminology C26.10.

fraction as a weight percent, from depleted (0.2 % U) to

highly enriched (97.5 % U).

4. Summary of Test Method

1.4 Measurement of items that have not reached secular

4.1 The test method consists of measuring the emission rate

238 234

equilibrium between U and Th may not produce the

of 185.7 keV gamma-rays from an item in a controlled

stated bias when low-resolution detectors are used with the

geometry and correlating that emission rate with the enrich-

computational method listed in Annex A2.

ment of the uranium contained in the item.

1.5 The values stated in SI units are to be regarded as

4.2 Calibration is achieved using reference materials of

standard. No other units of measurement are included in this

known enrichment. Corrections are made for attenuating ma-

standard.

terials present between the uranium-bearing material and the

1.6 This standard may involve hazardous materials,

detector and for chemical compounds different from the

operations, and equipment. This standard does not purport to

calibration reference materials used for calibration.

address all of the safety concerns, if any, associated with its

4.3 The measured items must completely fill the field of

use. It is the responsibility of the user of this standard to

view of the detector, and must contain a uranium-bearing

establish appropriate safety and health practices and deter-

material which is infinitely thick with respect to the 185.7 keV

mine the applicability of regulatory limitations prior to use.

gamma-ray. If the field of view is not filled, a correction factor

must be applied.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

C1030 TestMethodforDeterminationofPlutoniumIsotopic

5.1 The enrichment meter principle provides a nondestruc-

Composition by Gamma-Ray Spectrometry

tive measurement of the U fraction of uranium-bearing

C1490 GuidefortheSelection,TrainingandQualificationof

items. Sampling is not required and no waste is generated,

Nondestructive Assay (NDA) Personnel

minimizing exposure to hazardous materials and resulting in

reduced sampling error.

This test method is under the jurisdiction ofASTM Committee C26 on Nuclear

5.2 This method relies on a fixed and controlled geometry.

Fuel Cycle and is the direct responsibility of Subcommittee C26.10 on Non

The uranium-bearing materials in the measured items and

Destructive Assay.

calibration reference materials used for calibration must fill the

Current edition approved Jan. 1, 2017. Published January 2017. Originally

approved in 2002. Last previous edition approved in 2008 as C1514 – 08. DOI:

detector field of view.

10.1520/C1514-08R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1514 − 08 (2017)

5.3 Use of a low resolution detector (for example, NaI 6.5 Any impurities present in the measured items must be

detector) to measure uranium with U fraction approximately homogeneously distributed and well characterized. The pres-

10 % which is contained in a thin-walled container can provide ence of impurities, at concentrations which can measurably

a rapid (typically 100 s), easily portable measurement system attenuate the 185.7 keV gamma-ray and which are not ac-

with precision of 0.6 % and bias of less than 1 %. counted for will result in a bias.

5.4 Use of a high resolution detector (for example, high- 6.6 The presence of radioactive impurities can affect the

purity germanium) can provide measurement with a precision determination of the 185.7 keV peak area. This type of

better than 0.2 % and a bias less than 1 % within a 300-s interference is most often encountered in low-resolution

measurement time when measuring uranium with U fraction measurement, but can affect high-resolution measurements.

in the range of 0.711 % or above which is contained in

6.7 Other factors, such as the paint on the outside of the

thin-walled containers.

cylinders and the condition of the cylinder inner walls after

5.5 In order to obtain optimum results using this method, exposure to UF , may affect the precision and bias for both the

the chemical composition of the item must be well known, the NaI and the HPGe measurement methods.

container wall must permit transmission of the 185.7 keV

7. Apparatus

gamma-ray, and the uranium-bearing material within the item

must be infinitely thick with respect to the 185.7 keV gamma-

7.1 Gamma-Ray Detector System—General guidelines for

ray. All items must be in identical containers or must have a

selection of detectors and signal-processing electronics are

known container wall thickness and composition.

discussed in Guide C1592, Test Method C1030, and ANSI

standard N42.14. Refer to the References section for a list of

5.6 Items to be measured must be homogeneous with

other recommended references (1). This system typically

respect to both U fraction and chemical composition.

consists of a gamma-ray detector, spectroscopy grade

5.7 When measuring items, using low-resolution detectors,

amplifier, high-voltage bias supply, multi-channel analyzer,

in thin-walled containers that have not reached secular equi-

and detector collimator. The system may also include detector

librium (more than about 120 days after processing), either the

backshielding,anultrasonicthicknessgauge,anoscilloscope,a

method should not be used, additional corrections should be

spectrum stabilizer, a computer, and a printer.

made to account for the age of the uranium, or high-resolution

7.2 A high-resolution detector system or a low-resolution

measurements should be performed.

detectorsystemshouldbeselected,dependingonprecisionand

5.8 The method is often used as a enrichment verification

bias requirements for the measurements. Additional detector

technique.

selection considerations are measurement time, cost, and ease

of use. High-resolution detector systems are generally larger,

6. Interferences

heavier, and more costly than low-resolution detector systems.

6.1 Appropriate corrections must be made for attenuating

Inaddition,thecostofhigh-resolutiondetectorsissignificantly

materials present between the uranium-bearing material and

higher (roughly an order of magnitude) than the cost of

the detector. Inappropriate correction for this effect can result

low-resolution detectors. High-resolution systems, however,

in significant biases.

provide better results than low-resolution systems, and elimi-

nate some interferences.

6.2 Incorrect knowledge of chemical form of the uranium-

7.2.1 High-Resolution Detector—Ahigh-resolution detector

bearing materials can result in a bias.

with a resolution of 1200 eV or better, full width at half

6.3 Depending on the dead-time correction method used,

maximum, at 122 keV is recommended. Either a planar or

excessive dead time can cause errors in live time correction

coaxial detector can be used, although excessive dead time can

and, thus, result in a measurement bias. Excessive dead time

resultifacoaxialdetectorwithhigh(>15 %)efficiencyisused.

can usually be eliminated by modifications to the detector

The selected detector should be of sufficient size (including a

collimator and aperture.

combination of surface area and thickness) to provide the

6.4 Background gamma-rays near 185.7 keV can result in a

desired counting-statistics based uncertainty within a reason-

bias. Table 1 is a list of interfering gamma-rays which may

able counting time.

cause an interference.

7.2.2 Low-Resolution Detector—A low-resolution detector

with the following specifications is recommended: a 5-cm

diam, 1.25-cm thick or larger detector with a resolution of

15 % or better at 122 keV.

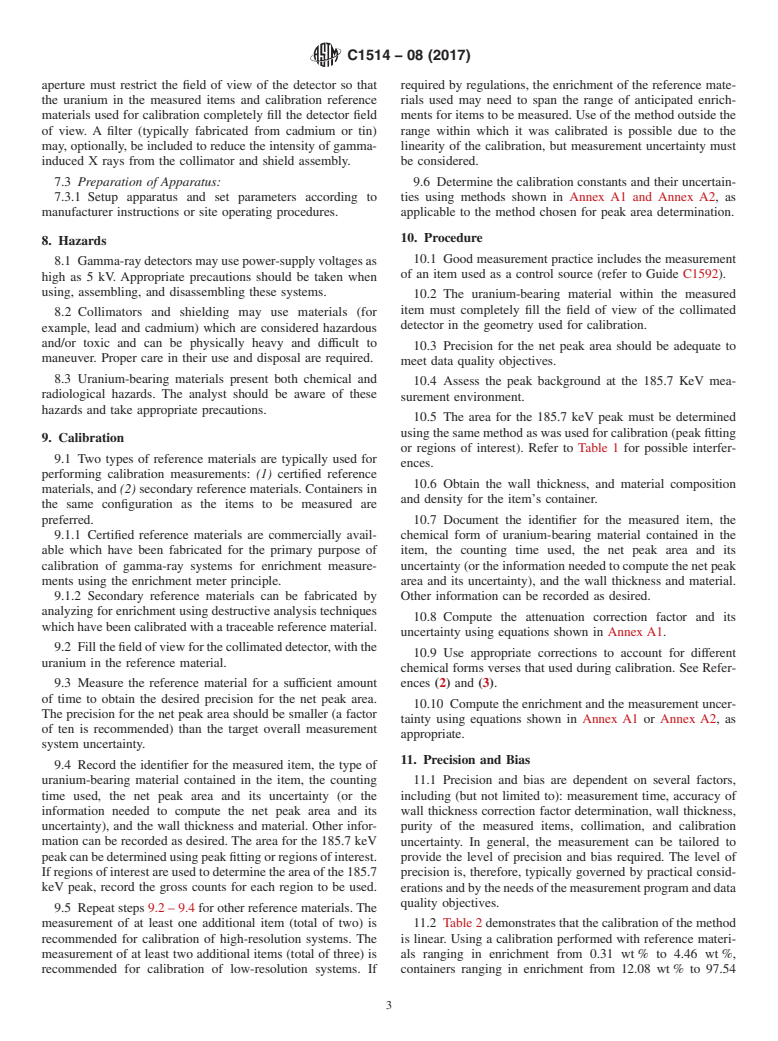

TABLE 1 Interfering Gamma-Rays

7.2.3 Collimator and Shield Assembly—The detector colli-

Gamma-Ray Energy

Isotope Parent Measurement Affected

(keV)

mator and shield assembly must be of sufficient thickness to

Ra N/A 185.9 High Resolution,

attenuate in excess of 99.9 % of the 185.7 keV gamma-rays

Low Resolution

212 232

incident upon it. The detector collimator must also block in

Pb U 238.6 Low Resolution

224 232

Ra U 241.0 Low Resolution

excess of 99.9 % of the gamma-rays incident upon it and the

233 237

Pa Np 300.1 Low Resolution

233 237

Pa Np 311.9 Low Resolution

234 238

Th U Bremsstrahlung Low Resolution

Tc N/A Bremsstrahlung Low Resolution The boldface numbers in parentheses refer to the list of references at the end of

this standard.

C1514 − 08 (2017)

aperture must restrict the field of view of the detector so that required by regulations, the enrichment of the reference mate-

the uranium in the measured items and calibration reference rials used may need to span the range of anticipated enrich-

materials used for calibration completely fill the detector field ments for items to be measured. Use of the method outside the

of view. A filter (typically fabricated from cadmium or tin) range within which it was calibrated is possible due to the

may, optionally, be included to reduce the intensity of gamma- linearity of the calibration, but measurement uncertainty must

induced X rays from the collimator and shield assembly. be considered.

7.3 Preparation of Apparatus: 9.6 Determine the calibration constants and their uncertain-

7.3.1 Setup apparatus and set parameters according to ties using methods shown in Annex A1 and Annex A2,as

manufacturer instructions or site operating procedures. applicable to the method chosen for peak area determination.

10. Procedure

8. Hazards

10.1 Good measurement practice includes the measurement

8.1 Gamma-raydetectorsmayusepower-supplyvoltagesas

of an item used as a control source (refer to Guide C1592).

high as 5 kV. Appropriate precautions should be taken when

using, assembling, and disassembling these systems.

10.2 The uranium-bearing material within the measured

item must completely fill the field of view of the collimated

8.2 Collimators and shielding may use materials (for

detector in the geometry used for calibration.

example, lead and cadmium) which are considered hazardous

and/or toxic and can be physically heavy and difficult to

10.3 Precision for the net peak area should be adequate to

maneuver. Proper care in their use and disposal are required.

meet data quality objectives.

8.3 Uranium-bearing materials present both chemical and

10.4 Assess the peak background at the 185.7 KeV mea-

radiological hazards. The analyst should be aware of these

surement environment.

hazards and take appropriate precautions.

10.5 The area for the 185.7 keV peak must be determined

using the same method as was used for calibration (peak fitting

9. Calibration

or regions of interest). Refer to Table 1 for possible interfer-

9.1 Two types of reference materials are typically used for

ences.

performing calibration measurements: (1) certified reference

10.6 Obtain the wall thickness, and material composition

materials, and (2) secondary reference materials. Containers in

and density for the item’s container.

the same configuration as the items to be measured are

preferred. 10.7 Document the identifier for the measured item, the

9.1.1 Certified reference materials are commercially avail- chemical form of uranium-bearing material contained in the

able which have been fabricated for the primary purpose of item, the counting time used, the net peak area and its

calibration of gamma-ray systems for enrichment measure- uncertainty (or the information needed to compute the net peak

ments using the enrichment meter principle. area and its uncertainty), and the wall thickness and material.

9.1.2 Secondary reference materials can be fabricated by Other information can be recorded as desired.

analyzing for enrichment using destructive analysis techniques

10.8 Compute the attenuation correction factor and its

which have been calibrated with a traceable reference material.

uncertainty using equations shown in Annex A1.

9.2 Fillthefieldofviewforthecollimateddetector,withthe

10.9 Use appropriate corrections to account for different

uranium in the reference material.

chemical forms verses that used during calibration. See Refer-

9.3 Measure the reference material for a sufficient amount ences (2) and (3).

of time to obtain the desired precision for the net peak area.

10.10 Compute the enrichment and the measurement uncer-

The precision for the net peak area should be smaller (a factor

tainty using equations shown in Annex A1 or Annex A2,as

of ten is recommended) than the target overall measurement

appropriate.

system uncertainty.

11. Precision and Bias

9.4 Record the identifier for the measured item, the type of

uranium-bearing material contained in the item, the counting 11.1 Precision and bias are dependent on several factors,

time used, the net peak area and its uncertainty (or the including (but not limited to): measurement time, accuracy of

information needed to compute the net peak area and its wall thickness correction factor determination, wall thickness,

uncertainty), and the wall thick

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.