ASTM B173-95

(Specification)Standard Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conductors

Standard Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conductors

SCOPE

1.1 This specification covers bare rope-lay-stranded conductors having concentric-stranded members made from round copper wires, either uncoated or coated with tin, lead, or lead-alloy for use as electrical conductors (Explanatory Note 1 and Note 2).

1.2 Coated wires shall include only those wires with finished diameters and densities substantially equal to the respective diameters and densities of uncoated wires.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values, stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.3.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 173 – 95

Standard Specification for

Rope-Lay-Stranded Copper Conductors Having Concentric-

Stranded Members, for Electrical Conductors

This standard is issued under the fixed designation B 173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Classification

1.1 This specification covers bare rope-lay-stranded con- 3.1 For the purpose of this specification rope-lay-stranded

ductors having concentric-stranded members made from round conductors having concentric-stranded members are classified

copper wires, either uncoated or coated with tin, lead, or as follows:

lead-alloy for use as electrical conductors (Explanatory Note 1 3.1.1 Class G—Conductors consisting of 7 to 61 rope-lay-

and Note 2). stranded members, each of which consists of 7 to 19

1.2 Coated wires shall include only those wires with fin- concentric-stranded wires, with total conductor sizes ranging

2 2

ished diameters and densities substantially equal to the respec- from No. 14 AWG (2.08 mm ) to 5 000 000 cmil (2534 mm ).

tive diameters and densities of uncoated wires. (Typical use is for rubber-sheathed conductor, apparatus con-

1.3 The SI values for density are regarded as the standard. ductor, portable conductor, and similar applications.)

For all other properties the inch-pound values are to be 3.1.2 Class H—Conductors consisting of 19 to 91 rope-lay-

regarded as standard and the SI units may be approximate. stranded members, each of which consists of 7 to 19

concentric-stranded wires, with total conductor sizes ranging

2 2

2. Referenced Documents

from No. 9 AWG (6.63 mm ) to 5 000 000 cmil (2534 mm ).

2.1 The following documents of the issue in effect at the

Class K construction produces a conductor with greater flex-

time of reference form a part of this specification to the extent ibility than class G. (Typical use is for rubber-sheathed cord

referenced herein:

and applications where flexibility is required such as on

2.2 ASTM Standards: take-up reels over sheaves and extra-flexible apparatus con-

B 3 Specification for Soft or Annealed Copper Wire

ductor.)

B 8 Specification for Concentric-Lay-Stranded Copper

4. Ordering Information

Conductors, Hard, Medium-Hard, or Soft

B 33 Specification for Tinned Soft or Annealed Copper 4.1 Orders for material under this specification shall include

Wire for Electrical Purposes the following information:

B 172 Specification for Rope-Lay-Stranded Copper Con- 4.1.1 Quantity of each size and class,

ductors Having Bunch-Stranded Members, for Electrical 4.1.2 Conductor size: circular-mil area or AWG (Section 7),

Conductors 4.1.3 Class (Section 3 and Table 1),

B 189 Specification for Lead-Coated and Lead-Alloy- 4.1.4 Whether coated or uncoated; if coated, designate type

Coated Soft Copper Wire for Electrical Purposes of coating (see 11.1),

B 263 Test Method for Determination of Cross-Sectional 4.1.5 Details of special-purpose lays, if required (see 6.2

Area of Stranded Conductors and 6.3) and (Explanatory Note 3),

B 354 Terminology Relating to Uninsulated Metallic Elec- 4.1.6 Package size (see 14.1),

trical Conductors 4.1.7 Special package marking, if required (Section 15),

2.3 American National Standard: 4.1.8 Lagging, if required (see 14.2), and

ANSI C42.35 Definitions of Electrical Terms 4.1.9 Place of inspection (Section 13).

4.1.10 In addition, Supplementary Requirements shall apply

only when specified by the purchaser in the inquiry, contract, or

This specification is under the jurisdiction of ASTM Committee B-1 on

purchase order for direct procurement by agencies of the U. S.

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Government (S1, S2, and S3).

Conductors of Copper and Copper Alloys.

Current edition approved July 15, 1995. Published September 1995. Originally

5. Joints

issued 1942 to replace portions of B 158 – 41 T. Last previous edition B 173 – 90.

Annual Book of ASTM Standards, Vol 02.03.

5.1 Necessary joints in wires or in groups of wires shall be

Available from American National Standards Institute, 11 West 42nd St., 13th

made in accordance with accepted commerical practice, taking

Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 173

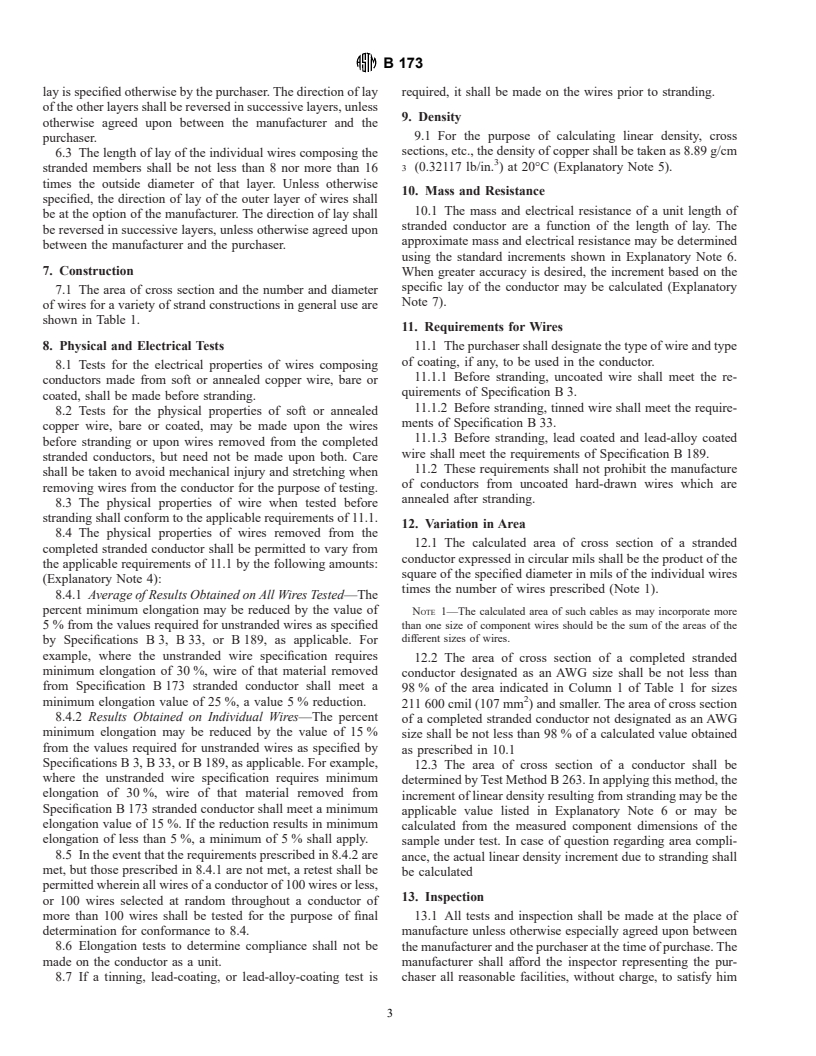

A

TABLE 1 Construction Requirements of Rope-Lay Stranded Copper Conductors Having Concentric-Stranded Members

Class G Class H

B B

Area of Cross Completed Conductor Completed Conductor

Number Number

Diameter of Diameter of

Section

Size

Number of Nominal Nominal of Nominal Nominal

Wires Wires

Number

AWG

of Wires Diameter Mass Wires Diameter Mass

of Wires

Wires in Each in Each

lb/1000 lb/1000

Member

cmil mm in. mm Member in mm kg/km in. mm in. mm kg/km

ft. ft.

5 000 000 2534 . 1159 0.0657 1.67 19 2.957 75.1 16 052 23 888 1729 0.0538 1.37 19 2.959 75.2 16 057 23 896

4 500 000 2280 . 1159 0.0623 1.58 19 2.804 71.2 14 433 21 479 1729 0.0510 1.30 19 2.805 71.2 14 429 21 473

4 000 000 2027 . 1159 0.0587 1.49 19 2.642 67.1 12 814 19 069 1729 0.0481 1.22 19 2.646 67.2 12 835 19 101

3 500 000 1773 . 1159 0.0550 1.40 19 2.475 62.9 11 249 16 741 1729 0.0450 1.14 19 2.475 62.9 11 234 16 718

3 000 000 1520 . 1159 0.0509 1.29 19 2.291 58.2 9635 14 338 1729 0.0417 1.06 19 2.294 58.3 9647 14 356

2 500 000 1267 . 703 0.0596 1.51 19 2.086 53.0 8012 11 924 1159 0.0464 1.18 19 2.088 53.0 8006 11 915

2 000 000 1013 . 703 0.0533 1.35 19 1.866 47.4 6408 9536 1159 0.0415 1.05 19 1.868 47.4 6405 9531

1 900 000 963 . 703 0.0520 1.32 19 1.820 46.2 6099 9077 1159 0.0405 1.03 19 1.823 46.3 6100 9077

1 800 000 912 . 703 0.0506 1.29 19 1.771 45.0 5775 8594 1159 0.0394 1.00 19 1.773 45.0 5773 8591

1 750 000 887 . 703 0.0499 1.27 19 1.747 44.4 5617 8358 1159 0.0389 0.99 19 1.751 44.5 5627 8374

1 700 000 861 . 703 0.0492 1.25 19 1.722 43.7 5460 8125 1159 0.0383 0.97 19 1.724 43.8 5455 8118

1 600 000 811 . 703 0.0477 1.21 19 1.670 42.4 5132 7638 1159 0.0372 0.94 19 1.674 42.5 5146 7658

1 500 000 760 . 427 0.0593 1.51 7 1.601 40.7 4772 7102 703 0.0462 1.17 19 1.617 41.1 4815 7165

1 400 000 709 . 427 0.0573 1.46 7 1.547 39.3 4456 6631 703 0.0446 1.13 19 1.561 39.6 4487 6677

1 300 000 659 . 427 0.0552 1.40 7 1.490 37.8 4135 6154 703 0.0430 1.09 19 1.505 38.2 4171 6207

1 250 000 633 . 427 0.0541 1.37 7 1.461 37.1 3972 5911 703 0.0422 1.07 19 1.477 37.5 4017 5978

1 200 000 608 . 427 0.0530 1.35 7 1.431 36.3 3812 5673 703 0.0413 1.05 19 1.446 36.7 3847 5726

1 100 000 557 . 427 0.0508 1.29 7 1.372 34.8 3502 5212 703 0.0396 1.01 19 1.386 35.2 3537 5264

1 000 000 507 . 427 0.0484 1.23 7 1.307 33.2 3179 4731 703 0.0377 0.96 19 1.320 33.5 3206 4771

900 000 456 . 427 0.0459 1.17 7 1.239 31.5 2859 4255 703 0.0358 0.91 19 1.253 31.8 2891 4302

800 000 405 . 427 0.0433 1.10 7 1.169 29.7 2544 3787 703 0.0337 0.86 19 1.180 30.0 2562 3812

750 000 380 . 427 0.0419 1.06 7 1.131 28.7 2383 3546 703 0.0327 0.83 19 1.145 29.1 2412 3589

700 000 355 . 427 0.0405 1.03 7 1.094 27.8 2226 3313 703 0.0316 0.80 19 1.106 28.1 2252 3352

650 000 329 . 427 0.0390 0.99 7 1.053 26.7 2064 3072 703 0.0304 0.77 19 1.064 27.0 2085 3102

600 000 304 . 427 0.0375 0.95 7 1.013 25.7 1908 2840 703 0.0292 0.74 19 1.022 26.0 1923 2862

550 000 279 . 427 0.0359 0.91 7 0.969 24.6 1749 2603 703 0.0280 0.71 19 0.980 24.9 1768 2632

500 000 253 . 259 0.0439 1.12 7 0.922 23.4 1579 2350 427 0.0342 0.87 7 0.923 23.4 1587 2362

450 000 228 . 259 0.0417 1.06 7 0.876 22.3 1425 2120 427 0.0325 0.83 7 0.878 22.3 1433 2133

400 000 203 . 259 0.0393 1.00 7 0.825 21.0 1265 1883 427 0.0306 0.78 7 0.826 21.0 1271 1891

350 000 177 . 259 0.0368 0.93 7 0.773 19.6 1109 1651 427 0.0286 0.73 7 0.772 19.6 1110 1652

300 000 152 . 259 0.0340 0.86 7 0.714 18.1 947 1409 427 0.0265 0.67 7 0.716 18.2 953 1418

250 000 127 . 259 0.0311 0.79 7 0.653 16.6 792 1179 427 0.0242 0.61 7 0.653 16.6 795 1183

211 600 107 0000 133 0.0399 1.01 7 0.599 15.2 667 992 259 0.0286 0.73 7 0.601 15.3 670 997

167 800 85.0 000 133 0.0355 0.90 7 0.533 13.5 528 785 259 0.0255 0.65 7 0.536 13.6 533 793

133 100 67.4 00 133 0.0316 0.80 7 0.474 12.0 418 622 259 0.0227 0.58 7 0.477 12.1 422 628

105 600 53.5 0 133 0.0282 0.72 7 0.423 10.7 333 495 259 0.0202 0.51 7 0.424 10.8 334 497

83 690 42.4 1 133 0.0251 0.64 7 0.377 9.58 264 393 259 0.0180 0.46 7 0.378 9.60 265 395

66 360 33.6 2 49 0.0368 0.93 7 0.331 8.41 207 308 259 0.0160 0.41 7 0.335 8.51 210 312

52 620 26.7 3 49 0.0328 0.83 7 0.295 7.49 164 245 133 0.0199 0.51 7 0.299 7.59 166 247

41 740 21.1 4 49 0.0292 0.74 7 0.263 6.68 130 194 133 0.0177 0.45 7 0.266 6.76 131 195

33 090 16.8 5 49 0.0260 0.66 7 0.234 5.94 103 154 133 0.0158 0.40 7 0.237 6.02 105 156

26 240 13.3 6 49 0.0231 0.59 7 0.208 5.28 81.5 121 133 0.0140 0.36 7 0.210 5.33 82.1 122

20 820 10.5 7 49 0.0206 0.52 7 0.185 4.70 64.8 96.5 133 0.0125 0.32 7 0.188 4.78 65.4 97.4

16 510 8.37 8 49 0.0184 0.47 7 0.166 4.22 51.7 77.0 133 0.0111 0.28 7 0.167 4.24 51.6 76.8

13 090 6.63 9 49 0.0163 0.41 7 0.148 3.76 40.6 60.4 133 0.0099 0.25 7 0.149 3.78 41.0 61.1

10 380 5.26 10 49 0.0146 0.37 7 0.131 3.33 32.6 48.5

6530 3.31 12 49 0.0115 0.29 7 0.104 2.64 20.2 30.1

4110 2.08 14 49 0.0092 0.23 7 0.083 2.11 12.9 19.2

A

The constructions shown in this table are typical of those used in the industry. It is not intended that this table preclude other constructions using the same total number

of wires which may be desireable for specific applications. The constructions shown provide for a finished, non-covered, stranded conductor approximately of the area

indicated. When specified by the purchaser, the number or size of wires may be increased to provide additional area to compensate for draw-down during subsequent

processing.

B

Values for the nominal diameter and mass of the completed conductor are approximate. The mass values are based upon the standard stranding increments listed

in Explanatory Note 6.

into account the size of the wire or group of wires as related to 6. Lay (Explanatory Note 3)

the size of the entire conductor.

6.1 Conductors of the same size and description furnished

5.2 Concentric-stranded members forming the completed

on one order shall have the same lay.

conductor may be joined as a unit by soldering, brazing, or

6.2 The length of lay of the outer layer of the rope-

welding.

laystranded conductor shall be not less than 8 nor more than 16

5.3 Joints shall be so constructed and so disposed through-

times the outside diameter of the completed conductor. The

out the conductor that the diameter or configuration of the

length of lay of the other layers shall be at the option of the

completed conductor is not substantially affected, and so that

manufacturer unless specifically agreed upon. The direction of

the flexibility of the completed conductor is not adversely

affected. lay of the outer layer shall be left-hand, unless the direction of

B 173

lay is specified otherwise by the purchaser. The direction of lay required, it shall be made on the wires prior to stranding.

of the other layers shall be reversed in successive layers, unless

9. Density

otherwise agreed upon between the manufacturer and the

9.1 For the purpose of calculating linear density, cross

purchaser.

sections, etc., the density of copper shall be taken as 8.89 g/cm

6.3 The length of lay of the individual wires composing the

3 (0.32117 lb/in. ) at 20°C (Explanatory Note 5).

stranded members shall be not less than 8 nor more than 16

times the outside diameter of that layer. Unless otherwise

10. Mass and Resistance

specified, the direction of lay of the outer layer of wires shall

10.1 The mass and electrical resistance of a unit length of

be at the option of the manufacturer. The direction of lay shall

stranded conductor are a function of the length of lay. The

be reversed in successive layers, unless otherwise agreed upon

approximate mass and electrical resistance may be determined

between the manufacturer and the purchaser.

using the standard increments shown in Explanatory Note 6.

7. Construction

When greater accuracy is desired, the increment based on the

specific lay of the conductor may be calculated (Explanatory

7.1 The area of cross section and the number and diameter

Note 7).

of wires for a variety of strand constructions in general use are

shown in Table 1.

11. Requirements for Wires

8. Physical and Electrical Tests 11.1 The purchaser shall designate the type of wire and type

of coating, if any, to be used in the conductor.

8.1 Tests for the electrical properties of wires composing

11.1.1 Before stranding, uncoated wire shall meet the re-

conductors made from soft or annealed copper wire, bare or

quirements of Specification B 3.

coated, shall be made before stranding.

11.1.2 Before stranding, tinned wire shall meet the require-

8.2 Tests for the physical properties of soft or annealed

ments of Specification B 33.

copper wire, bare or coated, may be made upon the wires

11.1.3 Before stranding, lead coated and lead-alloy coated

before stranding or upon wires removed from the completed

wire shall meet the requirements of Specification B 189.

stranded conductors, but need not be made upon both. Care

11.2 These requirements shall not prohibit the manufacture

shall be taken to avoid mechanical injury and stretching when

of conductors from uncoated hard-drawn wires which are

removing wires from the conductor for the purpose of testing.

annealed after stranding.

8.3 The physical properties of wire when tested before

stranding shall conform to the applicable requirements of 11.1.

12. Variation in Area

8.4 The physical properties of wires removed from the

12.1 The calculated area of cross section of a stranded

completed stranded conductor shall be permitted to vary from

conductor expressed in circular mils shall be the product of the

the applicable requirements of 11.1 by the following amounts:

square of the specified diameter in mils of the individual wires

(Explanatory Note 4):

times the number of wires prescribed (Note 1).

8.4.1 Average of Results Obtained on All Wires Tested—The

percent minimum elongation may be reduced by the value of

NOTE 1—The calculated area of such cables as may incorporate more

5 % from the values required for unstranded wires as specified than one size of component wires should be the sum of the areas of the

different sizes of wires.

by Specifications B 3, B 33, or B 189, as applicable. For

example, where the unstranded w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.