ASTM D607-82(2012)

(Specification)Standard Specification for Wet Ground Mica Pigments

Standard Specification for Wet Ground Mica Pigments

ABSTRACT

This standard specification covers wet ground mica pigments for use in the manufacture of protective coatings. Pigments shall be made by wet grinding muscovite mica. Properties such as density, moisture, grit, coarse particles, residue, ignition loss, and color shall conform to the requirements of the specification.

SCOPE

1.1 This specification covers two types of finely divided muscovite mica, commercially known as wet ground mica, suitable for use in the manufacture of protective coatings.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D607 −82 (Reapproved 2012)

Standard Specification for

Wet Ground Mica Pigments

This standard is issued under the fixed designation D607; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

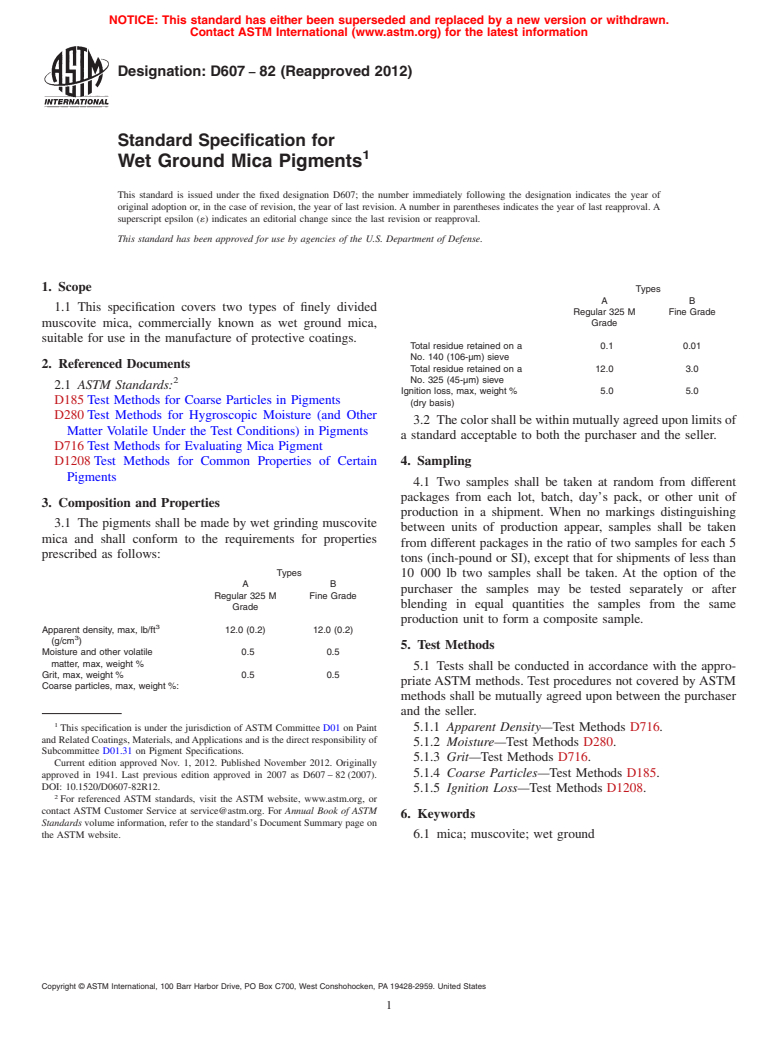

1. Scope

Types

A B

1.1 This specification covers two types of finely divided

Regular 325 M Fine Grade

Grade

muscovite mica, commercially known as wet ground mica,

suitable for use in the manufacture of protective coatings.

Total residue retained on a 0.1 0.01

No. 140 (106-µm) sieve

2. Referenced Documents

Total residue retained on a 12.0 3.0

2 No. 325 (45-µm) sieve

2.1 ASTM Standards:

Ignition loss, max, weight % 5.0 5.0

D185 Test Methods for Coarse Particles in Pigments

(dry basis)

D280 Test Methods for Hygroscopic Moisture (and Other

3.2 The color shall be within mutually agreed upon limits of

Matter Volatile Under the Test Conditions) in Pigments

a standard acceptable to both the purchaser and the seller.

D716 Test Methods for Evaluating Mica Pigment

D1208 Test Methods for Common Properties of Certain 4. Sampling

Pigments

4.1 Two samples shall be taken at random from different

packages from each lot, batch, day’s pack, or other unit of

3. Composition and Properties

production in a shipment. When no markings distinguishing

3.1 The pigments shall be made by wet grinding muscovite

between units of production appear, samples shall be taken

mica and shall conform to the requirements for properties

from different packages in the ratio of two samples for each 5

prescribed as follows:

tons (inch-pound or SI), except that for shipments of less than

Types

10 000 lb two samples shall be taken. At the option of the

A B

purchaser the samples may be tested separately or after

Regular 325 M Fine Grade

blending in equal quantities the samples from the same

Grade

production unit to form a composite sample.

Apparent density, max, lb/ft 12.0 (0.2) 12.0 (0.2)

(g/cm )

5. Test Methods

Moisture and other volatile 0.5 0.5

matter, max, weight %

5.1 Tests shall be conducted in accordance with the appro-

Grit, max, weight % 0.5 0.5

priate ASTM methods. Test procedures not covered by ASTM

Coarse particles, max, weight %:

methods shall be mutually

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.