ASTM D7451-08a(2013)

(Test Method)Standard Test Method for Water Separation Properties of Light and Middle Distillate, and Compression and Spark Ignition Fuels

Standard Test Method for Water Separation Properties of Light and Middle Distillate, and Compression and Spark Ignition Fuels

SIGNIFICANCE AND USE

5.1 The primary use of this test method is to evaluate new additive packages in specific fuels to ensure that fuel-water separability will not be compromised by the use of the additive package, either at their normal treat rates or at several times the intended treat rate to evaluate the impact of potential overtreatment.

5.1.1 Water Volume Changes—Using this technique reveal the presence of water-soluble components, such as alcohols, in the fuel.

5.1.2 Interface Condition Ratings—Using this technique reveal the presence of partially soluble components, such as surfactants, in the fuel.

5.2 Additives or contaminants that affect the interface could harm water separation properties of fuels in equipment and quickly inhibit the free flow of fuel through filters and injection equipment, causing a decrease in combustion performance.

SCOPE

1.1 This test method covers the evaluation of the tendency of water and fuels with a final boiling point of less than 390°C, as measured in Test Method D86, to separate cleanly rather than create emulsions when they may contain potential emulsion forming additives or components, or have been additized with potential emulsion forming additives, or components.

1.2 This test method applies primarily to gasoline, diesel, kerosine, and distillate grades of gas turbine, marine, home heating oils and furnace fuels (see Specifications D396, D975, D2880, D3699, D4814, and D6985). For fuel components such as biodiesel or alcohol, refer to X1.2 and X1.3.

1.3 This test method is not meant to certify or qualify fuels for sale, but it is intended for use by additive suppliers to determine the need for demulsifier components in their additive packages.

1.4 This test method is not meant for testing of fuels containing large amounts of aqueous soluble components, such as E85, or for testing of water emulsified fuels, or for testing of aviation fuels.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7451 − 08a(Reapproved 2013)

Standard Test Method for

Water Separation Properties of Light and Middle Distillate,

and Compression and Spark Ignition Fuels

This standard is issued under the fixed designation D7451; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D86 Test Method for Distillation of Petroleum Products at

Atmospheric Pressure

1.1 This test method covers the evaluation of the tendency

D396 Specification for Fuel Oils

of water and fuels with a final boiling point of less than 390°C,

D975 Specification for Diesel Fuel Oils

as measured in Test Method D86, to separate cleanly rather

D1193 Specification for Reagent Water

than create emulsions when they may contain potential emul-

D2274 Test Method for Oxidation Stability of Distillate Fuel

sion forming additives or components, or have been additized

Oil (Accelerated Method)

with potential emulsion forming additives, or components.

D2880 Specification for Gas Turbine Fuel Oils

1.2 This test method applies primarily to gasoline, diesel,

D3699 Specification for Kerosine

kerosine, and distillate grades of gas turbine, marine, home

D4057 Practice for Manual Sampling of Petroleum and

heating oils and furnace fuels (see Specifications D396, D975,

Petroleum Products

D2880, D3699, D4814, and D6985). For fuel components such

D4176 Test Method for FreeWater and Particulate Contami-

as biodiesel or alcohol, refer to X1.2 and X1.3.

nation in Distillate Fuels (Visual Inspection Procedures)

D4177 Practice for Automatic Sampling of Petroleum and

1.3 This test method is not meant to certify or qualify fuels

for sale, but it is intended for use by additive suppliers to Petroleum Products

D4814 Specification for Automotive Spark-Ignition Engine

determinetheneedfordemulsifiercomponentsintheiradditive

packages. Fuel

D6985 Specification for Middle Distillate Fuel Oil—

1.4 This test method is not meant for testing of fuels

Military Marine Applications (Withdrawn 2010)

containing large amounts of aqueous soluble components, such

2.2 ASTM Adjuncts:

as E85, or for testing of water emulsified fuels, or for testing of

Distillate Fuel Bar Chart

aviation fuels.

Fuel Clarity Rating Standard

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.6 This standard does not purport to address all of the

3.1.1 film, n—thin, translucent layer that does not adhere to

safety concerns, if any, associated with its use. It is the

the wall of the glass test tube.

responsibility of the user of this standard to establish appro-

3.1.2 heavy scum, n—assessment that the fuel/water inter-

priate safety and health practices and determine the applica-

face is covered with more than 50% scum that extends into

bility of regulatory limitations prior to use.

either of the two layers or forms an emulsion (1 mL or greater

in volume), or both.

2. Referenced Documents

3.1.3 scum, n—layer thicker than film (up to 1 mL in

2.1 ASTM Standards:

volume) or that adheres to the wall of the glass test tube, or

both.

This test method is under the jurisdiction of ASTM Committee D02 on

3.2 Definitions of Terms Specific to This Standard:

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved May 1, 2013. Published August 2013. Originally

approved in 2008. Last previous edition approved in 2008 as D7451 – 08a. DOI: The last approved version of this historical standard is referenced on

10.1520/D7451-08AR13. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from ASTM International Headquarters. Order Adjunct No.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ADJD417601. Original adjunct produced in 1991.

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD7451. Original adjunct produced in 2008.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7451 − 08a (2013)

3.2.1 interface condition rating, n—qualitative assessment 5.1.2 Interface Condition Ratings—Using this technique

of the tendency of a mixture of water and fuel to form interface reveal the presence of partially soluble components, such as

films or precipitates. surfactants, in the fuel.

3.2.2 water separation rating, n—qualitative assessment of

5.2 Additives or contaminants that affect the interface could

thetendencyofcomponentsinthefueltoproduceemulsionsor

harm water separation properties of fuels in equipment and

precipitates, or both, in separated fuel and water layers.

quicklyinhibitthefreeflowoffuelthroughfiltersandinjection

equipment, causing a decrease in combustion performance.

3.2.3 water volume change, n—qualitative indication of the

presence of water-soluble components in fuels, or the decrease

in water returned during the test due to the formation of scum 6. Apparatus

or emulsions.

6.1 Graduated Glass Tube—Sealable, blunt-tipped, 100-mL

3.2.3.1 Discussion—For example, the alcohol component in

with ⁄2-mLgraduationsfrom1to10mLand2-mLgraduations

an ethanol-blended gasoline would be extracted into the

from10to100mLnotencompassingthewholediameterofthe

aqueous phase, thus increasing the volume of the aqueous

tube as to interfere with the clarity rating. The dimensions of

phase by the approximate volume of the ethanol present in the

the tube are as follows:

sample.

6.1.1 Overall length = 200 6 5 mm.

6.1.2 Outer diameter of the tube portion = 38 mm.

4. Summary of Test Method

6.1.3 Neck length = 25 mm.

4.1 The cleanliness of the glass test tube is tested prior to

6.1.4 Headspace from 100-mLgraduation to tube neck = 50

use in the test.

6 5 mm.

4.2 A sample of the fuel is shaken at room temperature

6.1.5 Tip length = 30 mm with a 45° taper.

using a standardized technique with an aqueous phase in

NOTE 1—Contact Subcommittee D02.14 for a list of possible suppliers

thoroughly cleaned glassware.

for the tubes and caps.

4.3 The change in volume of the aqueous layer, the appear-

6.2 Shaking Apparatus (Optional)—An explosion–proof ap-

ance of the interface and the clarity of the fuel are reported as

paratus capable of shaking the tubes as prescribed in 10.2 is

an indication of the water separation properties of the fuel.

preferred for testing consistency. However, any method that

facilitates shaking at the prescribed stroke length, frequency,

5. Significance and Use

and sample orientation as outlined in 10.2 is acceptable.

5.1 The primary use of this test method is to evaluate new

NOTE 2— No suitable vendor for such a machine has been identified. It

additive packages in specific fuels to ensure that fuel-water

remains the responsibility of the user to select an apparatus that meets

these criteria.

separability will not be compromised by the use of the additive

package,eitherattheirnormaltreatratesoratseveraltimesthe

6.3 Rating Chart—The line card and fuel clarity rating chart

intended treat rate to evaluate the impact of potential overtreat-

from ASTM Adjuncts ADJD417601 and ADJD7451, respec-

ment.

tively. (See 10.4.2.)

5.1.1 Water Volume Changes—Using this technique reveal

NOTE 3—If the line card is not available or fuel clarity is not readily

the presence of water-soluble components, such as alcohols, in

discerniblefromusingthelinecard,thenprintedtextasdescribedinTable

the fuel. 1 may be used to assess fuel clarity.

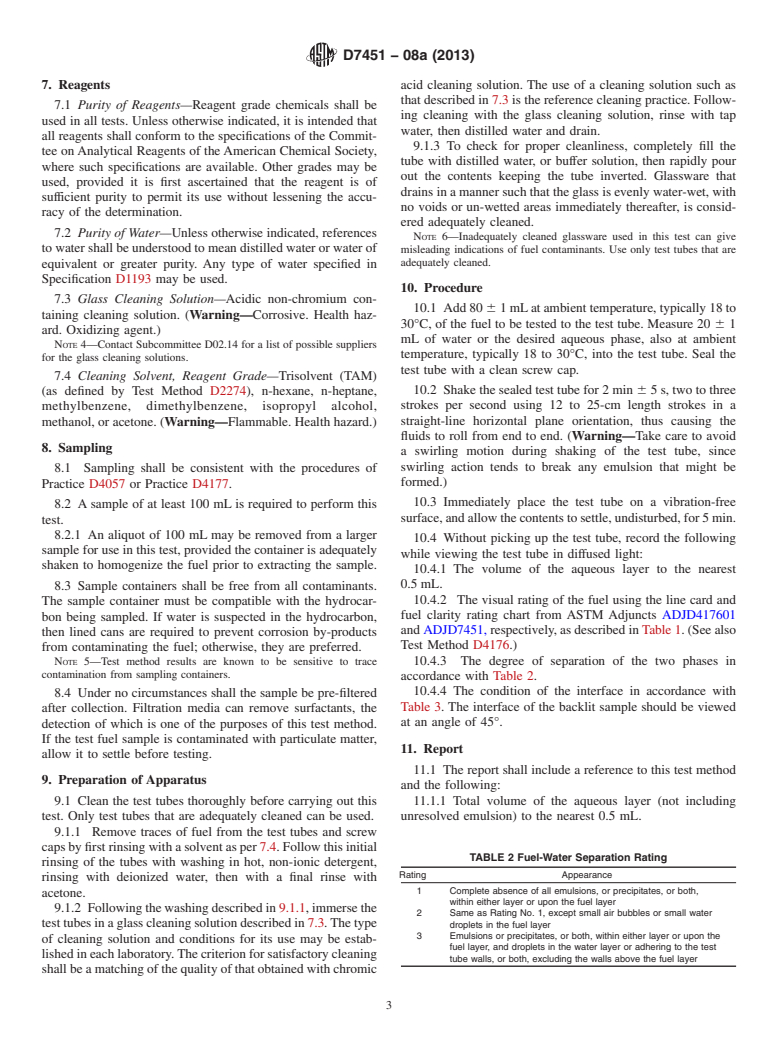

TABLE 1 Fuel Clarity Ratings

NOTE 1—These rating systems have been determined for use in the tubes described in 6.1. The use of narrower or wider tube would give potentially

different ratings than those outlined in the tables.

Rating Appearance

1 Clear and bright, equal to the base fuel

2 Very slight haze

Black 10 pt bold Times New Roman font on a white background readily readable through tube, or

Volume markings and numbers on glassware readily readable through tube

3 Slight haze

Black 10 pt bold Times New Roman font on a white background visible but not readable through tube, or

Volume marking and numbers on glassware visible through tube

4 Slight haze

Black 10 pt bold Times New Roman font on a white background not readable through tube, or

Volume markings and numbers on glassware visible but not readable through tube

5 Hazy/translucent

Black 10 pt bold Times New Roman font on a white background not visible through tube, or

Volume markings and numbers on glassware barely visible through tube

6 Opaque

D7451 − 08a (2013)

7. Reagents acid cleaning solution. The use of a cleaning solution such as

that described in 7.3 is the reference cleaning practice. Follow-

7.1 Purity of Reagents—Reagent grade chemicals shall be

ing cleaning with the glass cleaning solution, rinse with tap

used in all tests. Unless otherwise indicated, it is intended that

water, then distilled water and drain.

all reagents shall conform to the specifications of the Commit-

9.1.3 To check for proper cleanliness, completely fill the

tee onAnalytical Reagents of theAmerican Chemical Society,

tube with distilled water, or buffer solution, then rapidly pour

where such specifications are available. Other grades may be

out the contents keeping the tube inverted. Glassware that

used, provided it is first ascertained that the reagent is of

drains in a manner such that the glass is evenly

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.