ASTM D2609-00

(Specification)Standard Specification for Plastic Insert Fittings for Polyethylene (PE) Plastic Pipe

Standard Specification for Plastic Insert Fittings for Polyethylene (PE) Plastic Pipe

SCOPE

1.1 This specification covers plastic insert fittings for polyethylene (PE) plastic pipe. Included are requirements for materials, workmanship, dimensions, and burst pressure.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: D 2609 – 00

Standard Specification for

Plastic Insert Fittings for Polyethylene (PE) Plastic Pipe

This standard is issued under the fixed designation D 2609; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Extrusion Materials

D 2239 Specification for Polyethylene (PE) Plastic Pipe

1.1 This specification covers plastic insert fittings for poly-

(SIDR-PR) Based on Controlled Inside Diameter

ethylene (PE) plastic pipe. Included are requirements for

F 412 Terminology Relating to Plastic Piping Systems

materials, workmanship, dimensions, and burst pressure.

F 1498 Specification for Taper Pipe Threads 60° for Ther-

1.2 The text of this specification references notes, footnotes,

moplastic Pipe and Fittings

and appendixes which provide explanatory material. These

2.2 NSF Standards:

notesandfootnotes(excludingthoseintablesandfigures)shall

Standard No. 14 for Plastic Piping Components and Related

not be considered as requirements of the specification.

Materials

1.3 The values stated in inch-pound units are to be regarded

Standard No. 61 for Drinking Water System Components—

as the standard. The values given in parentheses are provided

Health Effects

for information only.

1.4 The following safety hazards caveat pertains only to

3. Terminology

the test methods portion, Section 8, of this specification: This

3.1 Definitions are in accordance with Terminology F 412

standarddoesnotpurporttoaddressallofthesafetyconcerns,

and abbreviations are in accordance withTerminology D 1600,

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

unless otherwise specified.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

4. Classification

tions prior to use.

4.1 Thisspecificationcoversoneclassoffittingssuitablefor

use with PE plastic pipe that meet the requirements of

2. Referenced Documents

applicable ASTM specifications. At present, these are Specifi-

2.1 ASTM Standards:

cations D 2104 and D 2239.

D 618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

5. Materials

D 789 Test Methods for Determination of Relative Viscos-

5.1 Types of Plastics—The fittings shall be made from one

ity, Melting Point, and Moisture Content of Polyamide

of the following plastics: (See Note).

(PA)

5.1.1 Nylon plastics (NP) meeting the requirements of

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

either Type I or Type II (except Grade 2A) in Test Methods

sure of Plastic Pipe, Tubing, and Fittings

D 789.

D 1600 Terminology for Abbreviated Terms Relating to

5.1.2 Propylene plastics (PP) meeting the requirements of

Plastics

Type II, Grade 05207, in Specification D 2146.

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

5.1.3 Poly(vinyl chloride) plastics (PVC) meeting the re-

Compounds and Chlorinated Poly(Vinyl Chloride)

2 quirements of 12454-B, 12454-C, 11443-B, or 14333-D, in

(CPVC) Compounds

Specification D 1784.

D 2104 Specification for Polyethylene (PE) Plastic Pipe,

3 5.2 Rework Material—The manufacturers shall use only

Schedule 40

their own clean rework fitting material and the fittings pro-

D 2146 Specification for Propylene Plastic Molding and

duced shall meet all the requirements of this specification. The

types of materials specified in 5.1 shall not be mixed with one

another.

This specification is under the jurisdiction ofASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved April 10, 2000. Published June 2000. Originally

published as D 2609 – 67. Last previous edition D 2609 – 97. Discontinued—see 1984 Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 08.01. Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

Annual Book of ASTM Standards, Vol 08.04. MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2609

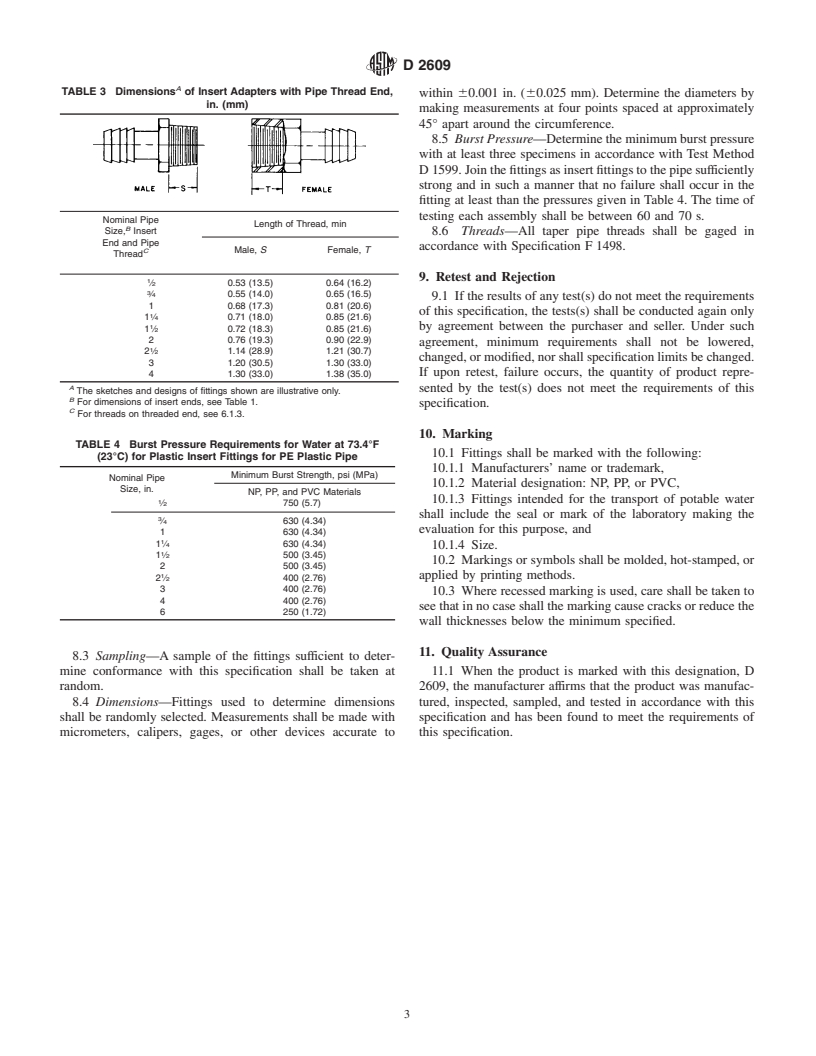

A

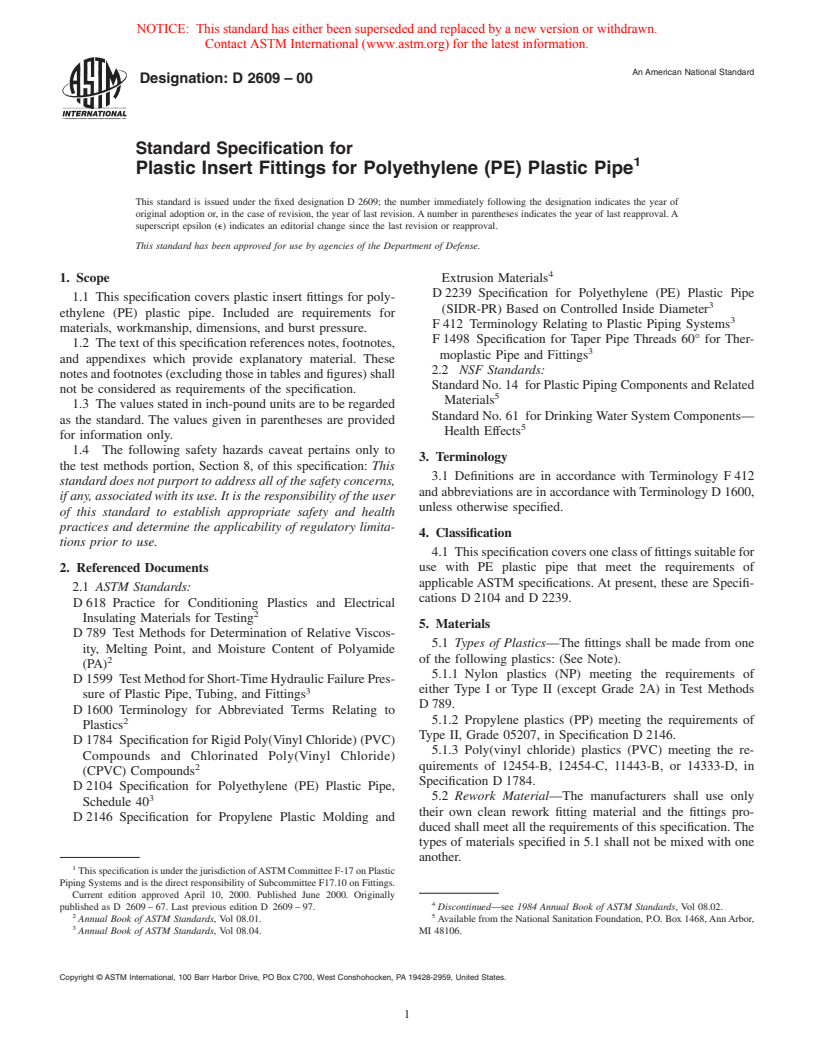

TABLE 2 Dimensions of Insert Elbow and Tee, in. (mm)

6. Requirements

6.1 Dimensions and Tolerances—The dimensions and tol-

erances shall be as shown in Tables 1-3 when measured in

accordance with 8.4. The negative tolerance on all minimum

dimensions is zero.

6.1.1 Alignment—The alignment of all openings of fittings

shall be within ⁄4in./ft.

6.1.2 Fittings Not Illustrated—All fittings, whether illus-

trated in Tables 1-3 or not, shall have insert ends in accordance

with Table 1 or threaded ends in accordance with Table 3. For

insert ends, which have more than four barbs, the first four

barbs,startingfromtheopenendofthefittingconnection,shall

meetallrequirementsofTable1Theremainingbarbsshallalso

meet Table 1, with the exception that mold marks left as a

Nominal Pipe Laying Length Tee and Elbow, min G

B

result of the manufacturing process, such as ejector pin marks,

Size

are exempt from the “V” dimension requirement, and the

⁄2 0.344 (8.7)

⁄4 0.453 (11.5)

minimum requirement for “Z.” D, Zmax, and F apply in all

1 0.625 (15.9)

cases. For designs where the entire fitting end is barbed, such

1 ⁄4 0.781 (19.8)

as “F” cannot be readily measured, “F” shall be calculated as 1

1 ⁄2 0.875 (22.2)

[(Z–2V)–D]/2. 2 1.125 (28.6)

2 ⁄2 1.625 (41.3)

6.1.3 Threads—For all fittings having taper pipe threads,

3 1.875 (47.6)

threads shall conform to Specification F 1498 and be gaged in

4 2.438 (61.9)

accordance with 8.6. A

The sketches and designs of fittings shown are illustrative only.

B

6.2 Burst Pressure—The minimum burst pressure for the For dimensions not given in this table, see Table 1.

fittings shall be as shown in Table 4, when determined in

accordance with 8.5.

h prior to test in accordance with Procedure A of Practice

7. Workmanship, Finish, and Appearance

D 618, for those tests where conditioning is required. In all

7.1 The fittings shall be homogeneous throughout and free

cases of disagreement, the tolerances shall be 61.8°F (61°C)

of cracks, holes, foreign inclusions, or other defects. The

and 6 2 % relative humidity.

fittings shall be as uniform as commercially practicable in

8.2 Test Conditions—Conduct the tests in the standard

color, opacity, density, and other physical properties.

laboratory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.