ASTM G129-00(2006)

(Practice)Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking

Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking

SCOPE

1.1 This practice covers procedures for the design, preparation, and use of axially loaded, tension test specimens and fatigue pre-cracked (fracture mechanics) specimens for use in slow strain rate (SSR) tests to investigate the resistance of metallic materials to environmentally assisted cracking (EAC). While some investigators utilize SSR test techniques in combination with cyclic or fatigue loading, no attempt has been made to incorporate such techniques into this practice.

1.2 Slow strain rate testing is applicable to the evaluation of a wide variety of metallic materials in test environments which simulate aqueous, nonaqueous, and gaseous service environments over a wide range of temperatures and pressures that may cause EAC of susceptible materials.

1.3 The primary use of this practice is to furnish accepted procedures for the accelerated testing of the resistance of metallic materials to EAC under various environmental conditions. In many cases, the initiation of EAC is accelerated through the application of a dynamic strain in the gauge section or at a notch tip or crack tip, or both, of a specimen. Due to the accelerated nature of this test, the results are not intended to necessarily represent service performance, but rather to provide a basis for screening, for detection of an environmental interaction with a material, and for comparative evaluation of the effects of metallurgical and environmental variables on sensitivity to known environmental cracking problems.

1.4 Further information on SSR test methods is available in ISO 7539 and in the references provided with this practice ().

1.5 &si-value;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Furthermore, in some cases, special facilities will be required to isolate these tests from laboratory personnel if high pressures or toxic chemical environments, or both, are utilized in SSR testing.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G129 − 00(Reapproved 2006)

Standard Practice for

Slow Strain Rate Testing to Evaluate the Susceptibility of

Metallic Materials to Environmentally Assisted Cracking

This standard is issued under the fixed designation G129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers procedures for the design,

responsibility of the user of this standard to establish appro-

preparation, and use of axially loaded, tension test specimens

priate safety and health practices and determine the applica-

andfatiguepre-cracked(fracturemechanics)specimensforuse

bility of regulatory limitations prior to use. Furthermore, in

in slow strain rate (SSR) tests to investigate the resistance of

some cases, special facilities will be required to isolate these

metallicmaterialstoenvironmentallyassistedcracking(EAC).

tests from laboratory personnel if high pressures or toxic

While some investigators utilize SSR test techniques in com-

chemical environments, or both, are utilized in SSR testing.

bination with cyclic or fatigue loading, no attempt has been

made to incorporate such techniques into this practice.

2. Referenced Documents

1.2 Slowstrainratetestingisapplicabletotheevaluationof 3

2.1 ASTM Standards:

awidevarietyofmetallicmaterialsintestenvironmentswhich

A370Test Methods and Definitions for Mechanical Testing

simulate aqueous, nonaqueous, and gaseous service environ-

of Steel Products

ments over a wide range of temperatures and pressures that

B557Test Methods for Tension Testing Wrought and Cast

may cause EAC of susceptible materials.

Aluminum- and Magnesium-Alloy Products

D1193Specification for Reagent Water

1.3 The primary use of this practice is to furnish accepted

procedures for the accelerated testing of the resistance of E4Practices for Force Verification of Testing Machines

E6Terminology Relating to Methods of Mechanical Testing

metallic materials to EAC under various environmental condi-

tions. In many cases, the initiation of EAC is accelerated E8Test Methods for Tension Testing of Metallic Materials

E399Test Method for Linear-Elastic Plane-Strain Fracture

throughtheapplicationofadynamicstraininthegaugesection

oratanotchtiporcracktip,orboth,ofaspecimen.Duetothe Toughness K of Metallic Materials

Ic

E602Test Method for Sharp-Notch Tension Testing with

accelerated nature of this test, the results are not intended to

necessarily represent service performance, but rather to pro- Cylindrical Specimens (Withdrawn 2010)

E616Terminology Relating to Fracture Testing (Discontin-

vide a basis for screening, for detection of an environmental

interaction with a material, and for comparative evaluation of ued 1996) (Withdrawn 1996)

E647 Test Method for Measurement of Fatigue Crack

the effects of metallurgical and environmental variables on

sensitivity to known environmental cracking problems. Growth Rates

E1681Test Method for DeterminingThreshold Stress Inten-

1.4 Further information on SSR test methods is available in

sityFactorforEnvironment-AssistedCrackingofMetallic

ISO 7539 and in the references provided with this practice

Materials

(1-6).

G15TerminologyRelatingtoCorrosionandCorrosionTest-

1.5 The values stated in SI units are to be regarded as

ing (Withdrawn 2010)

standard. The values given in parentheses are for information

G49Practice for Preparation and Use of Direct Tension

only.

Stress-Corrosion Test Specimens

G111Guide for Corrosion Tests in High Temperature or

High Pressure Environment, or Both

This practice is under the jurisdiction ofASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

tally Assisted Cracking. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2006. Published December 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 2000 as G129–00. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0129-00R06. the ASTM website.

2 4

The boldface numbers in parentheses refer to a list of references at the end of The last approved version of this historical standard is referenced on

this standard. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G129 − 00 (2006)

G142Test Method for Determination of Susceptibility of constant extension rate on the specimen while monitoring load

Metals to Embrittlement in Hydrogen Containing Envi- and extension of the specimen. The SSR test always produces

ronments at High Pressure, High Temperature, or Both

fracture of the test specimen. Typically, the results from tests

conductedinthetestenvironmentarecomparedtocorrespond-

2.2 ISO Standard:

ISO 7539Part 7, Slow Strain Rate Testing ing test results for the same material in a control environment.

The degree of susceptibility to EAC is generally assessed

3. Terminology

through observation of the differences in the behavior of the

material in tests conducted in a test environment from that

3.1 For purposes of this practice the following terms are

defined: obtained from tests conducted in the control environment. For

smoothtensionspecimens,eitherchangesintime-to-failure,or

3.2 control environment—an environment in which SSR

specimenductility,orvisualindicationsofEAC,oroftensome

specimens are tested that has been shown not to cause EAC or

combination of these methods, are utilized in determining

excessive corrosion of the material. The results of tests

susceptibilitytoEAC.Fornotchedtensionspecimens,changes

conducted in this environment may be used as a basis for

in the notch tensile strength and visual indications of EAC on

comparison with corresponding tests conducted in the test

the primary fracture surface are used in determining suscepti-

environment(s), usually at the same temperature as the test

bility to EAC. For fatigue pre-cracked specimens, changes in

environment.

the threshold stress intensity factor and visual indications of

3.3 environmentally assisted cracking (EAC)— cracking of

EAC on the primary fracture surface are used in determining

a material caused by the combined effects of stress and the

susceptibility to EAC.

surrounding environment, for example, stress corrosion crack-

ing, hydrogen embrittlement cracking, sulfide stress cracking

5. Significance and Use

and liquid metal embrittlement.

5.1 The slow strain rate test is used for relatively rapid

3.4 slow strain rate (SSR)—a dynamic slowly increasing

screening or comparative evaluation, or both, of environmen-

strain imposed by an external means on the gauge section or

tal, processing or metallurgical variables, or both, that can

notchtipofauniaxialtensionspecimenorcracktipofafatigue

pre-cracked specimen for purposes of materials evaluation. affect the resistance of a material to EAC. For example, this

The strain rate for a plain or smooth specimen (given in units testing technique has been used to evaluate materials, heat

of extension divided by the gage length per unit time) or the treatments, chemical constituents in the environment, and

strainrateatanotchtipofanotchedtensionspecimenorcrack

temperature and chemical inhibitors.

tip of a fatigue pre-cracked specimen is applied through the

5.2 Wherepossible,theapplicationoftheSSRtestanddata

application of a slow constant extension rate (given in units of

derived from its use should be used in combination with

extension per unit time). The slow constant extension rate

service experience or long-term EAC data, or both, obtained

produces a gauge section strain rate, which is usually in the

through literature sources or additional testing using other

−4 −7 −1

range from 10 to 10 /s . Rigorous analytical solutions of

testingtechniques.Inapplicationswheretherehasbeenlittleor

the local strain rate at a notch tip of a tension specimen or at a

no prior experience with SSR testing or little EAC data on the

crack tip of a fatigue pre-cracked specimen are not available.

particular material/environment combination of interest, the

Theaverageorlocalstrainrateshouldbeslowenoughtoallow

following steps are recommended:

time for certain corrosion processes to take place, but fast

5.2.1 The SSR tests should be conducted over a range of

enough to produce failure or cracking of the specimen in a

applied extension rates (that is, usually at least one order of

reasonable period of time for evaluation purposes. In cases

−6

magnitude in applied extension rate above and below 10 in/s

where extremely slow strain rates are being utilized (that is,

−7 −8 −1 –5

(2.54 × 10 mm/s) to determine the effect of strain rate or rate

10 to10 /s forsmoothtensionspecimens),aninterrupted

of increase of the stress or stress intensity factor on suscepti-

SSR test can be employed whereby the specimen is strained

bility to EAC.

into the plastic range at the intended strain rate followed by

more rapid straining to failure.

5.2.2 Constant load or strain EAC tests should also be

conducted in simulated service environments, and service

3.5 The terminology found inTest Methods and Definitions

experience should be obtained so that a correlation between

A370, Test Method B557, and Test Method E602 along with

SSR test results and anticipated service performance can be

thedefinitionsgiveninTerminologiesE6,E616,andG15shall

developed.

apply to the terms used in this practice.

5.3 In many cases the SSR test has been found to be a

4. Summary of Practice

conservative test for EAC. Therefore, it may produce failures

4.1 This practice describes the use of tension and fatigue

in the laboratory under conditions which do not necessarily

pre-cracked specimens for the determination of resistance to

cause EAC under service application. Additionally, in some

EAC of metallic materials. The procedure involves the appli-

limitedcases,EACindicationsarenotfoundinsmoothtension

cation of very slow strain rates, which are achieved by a

SSR tests even when service failures have been observed.This

effect usually occurs when there is a delay in the initiation of

5 localizedcorrosionprocesses.Therefore,thesuggestionsgiven

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. in 5.2 are strongly encouraged.

G129 − 00 (2006)

5.4 In some cases, EAC will only occur in a specific range test cell or autoclave can be found in Test Method G142. The

ofstrainrates.Therefore,wherethereislittlepriorinformation test specimen is loaded with a grip assembly and load frame

available,testsshouldbeconductedoverarangeofstrainrates inside the autoclave. The autoclave is equipped with a tensile

as discussed in 5.2. loadingfeed-throughtoprovidetransmissionofloadsfromthe

tensile machine to the specimen using a pull rod in combina-

6. Apparatus

tionwiththefeed-through.SomeSSRtestingmachinesmaybe

able to test more than one specimen at a time in a particular

6.1 Testing Machines:

6.1.1 Tension testing machines used for SSR testing shall environment. However, this type of machine should only be

used if it can be shown that failure of one or multiple

conform to the requirements of Practices E4.

6.1.2 The loads used in SSR testing shall be within the specimens does not influence the behavior of the other speci-

mens.

calibrated load ranges of the testing machine in accordance

with Practices E4.

6.2 Gripping Devices—The types of gripping devices that

6.1.3 The testing machines used for SSR testing shall be

may be used to transmit the applied load from the testing

capable of accurate application of extension rates in the range

machinetothetensionspecimenconformtothosedescribedin

of interest for evaluation of EAC. These extension rates are

Test Methods E8. Alignment procedures are provided in Test

−4 −7 –3

usually between 10 and 10 in/s (2.54 × 10 and 2.54 ×

Method E8.

–6

10 mm/s).

6.3 Clevices and Fixtures—Aloading clevis that is suitable

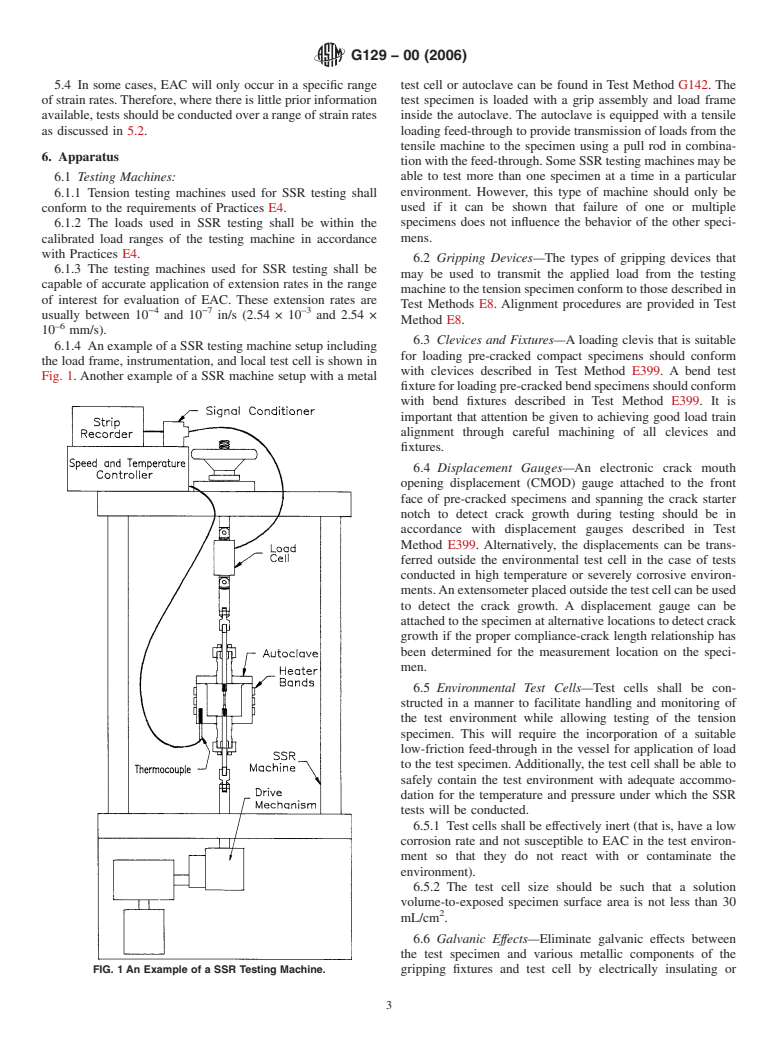

6.1.4 An example of a SSR testing machine setup including

for loading pre-cracked compact specimens should conform

the load frame, instrumentation, and local test cell is shown in

with clevices described in Test Method E399. A bend test

Fig. 1.Another example of a SSR machine setup with a metal

fixtureforloadingpre-crackedbendspecimensshouldconform

with bend fixtures described in Test Method E399.Itis

important that attention be given to achieving good load train

alignment through careful machining of all clevices and

fixtures.

6.4 Displacement Gauges—An electronic crack mouth

opening displacement (CMOD) gauge attached to the front

face of pre-cracked specimens and spanning the crack starter

notch to detect crack growth during testing should be in

accordance with displacement gauges described in Test

Method E399. Alternatively, the displacements can be trans-

ferred outside the environmental test cell in the case of tests

conducted in high temperature or severely corrosive environ-

ments.Anextensometerplacedoutsidethetestcellcanbeused

to detect the crack growth. A displacement gauge can be

attachedtothespecimenatalternativelocationstodetectcrack

growth if the proper compliance-crack length relationship has

been determined for the measurement location on the speci-

men.

6.5 Environmental Test Cells—Test cells shall be con-

structed in a manner to facilitate handling and monitoring of

the test environment while allowing testing of the tension

specimen. This will require the incorporation of a suitable

low-friction feed-through in the vessel for application of load

to the test specimen.Additionally, the test cell shall be able to

safely contain the test environment with adequate accommo-

dation for the temperature and pressure under which the SSR

tests will be conducted.

6.5.1 Test cells shall be effectively inert (that is, have a low

corrosion rate and not susceptible to EAC in the test environ-

ment so that they do not react with or contaminate the

environment).

6.5.2 The test cell size should be such that a solution

volume-to-exposed specimen surface area is not less than 30

mL/cm .

6.6 Galvanic Effects—Eliminate galvanic effects between

the test specimen and various metallic components of the

FIG. 1 An Example of a SSR Testing Machine. gripping fixtures and test cell by electrically insulating or

----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.