ASTM G6-07(2013)

(Test Method)Standard Test Method for Abrasion Resistance of Pipeline Coatings

Standard Test Method for Abrasion Resistance of Pipeline Coatings

SIGNIFICANCE AND USE

5.1 This procedure defines a test method for comparing the relative resistance of pipeline coatings to abrasion.

5.2 Abrasion resistance may be used to specify optimum coating thickness of candidate materials both in development and research work to study new coating systems or methods and in quality control.

SCOPE

1.1 This test method of accelerated test is a procedure for determining the relative resistance of steel pipeline coatings to abrasion by a slurry of coarse abrasive and water. The method is intended to apply to the testing of all types of electrical insulating pipeline coatings and tapes, including thermoplastics, thermoset, and bituminous materials.

1.2 Pipeline coatings are not normally subjected to the type of abrasion herein specified.

1.3 Metallic protective coatings such as zinc may be compared visually, but do not meet the electrical requirements of this test method.

1.4 The values stated in SI units to three significant decimals are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G6 − 07 (Reapproved 2013)

Standard Test Method for

Abrasion Resistance of Pipeline Coatings

This standard is issued under the fixed designation G6; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 holidays, n—small faults or pinholes which permit

current drainage through protective coatings on steel pipe.

1.1 This test method of accelerated test is a procedure for

determining the relative resistance of steel pipeline coatings to

4. Summary of Test Method

abrasion by a slurry of coarse abrasive and water. The method

4.1 Apparatus and materials are described whereby coatings

is intended to apply to the testing of all types of electrical

on steel pipe are worn away by an abrasive slurry contained in

insulating pipeline coatings and tapes, including

a horizontally revolving drum. Specimens extend through both

thermoplastics, thermoset, and bituminous materials.

ends of the drum and are electrically insulated from contact

1.2 Pipeline coatings are not normally subjected to the type

with the test apparatus.

of abrasion herein specified.

4.2 Periodic measurement of the electrical resistance be-

1.3 Metallic protective coatings such as zinc may be com-

tween the specimen and the drum indicates the degree of

pared visually, but do not meet the electrical requirements of

abrasion resistance of the coating.

this test method.

5. Significance and Use

1.4 The values stated in SI units to three significant deci-

5.1 This procedure defines a test method for comparing the

mals are to be regarded as the standard. The values given in

relative resistance of pipeline coatings to abrasion.

parentheses are for information only.

5.2 Abrasion resistance may be used to specify optimum

1.5 This standard does not purport to address all of the

coating thickness of candidate materials both in development

safety concerns, if any, associated with its use. It is the

and research work to study new coating systems or methods

responsibility of the user of this standard to establish appro-

and in quality control.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Apparatus

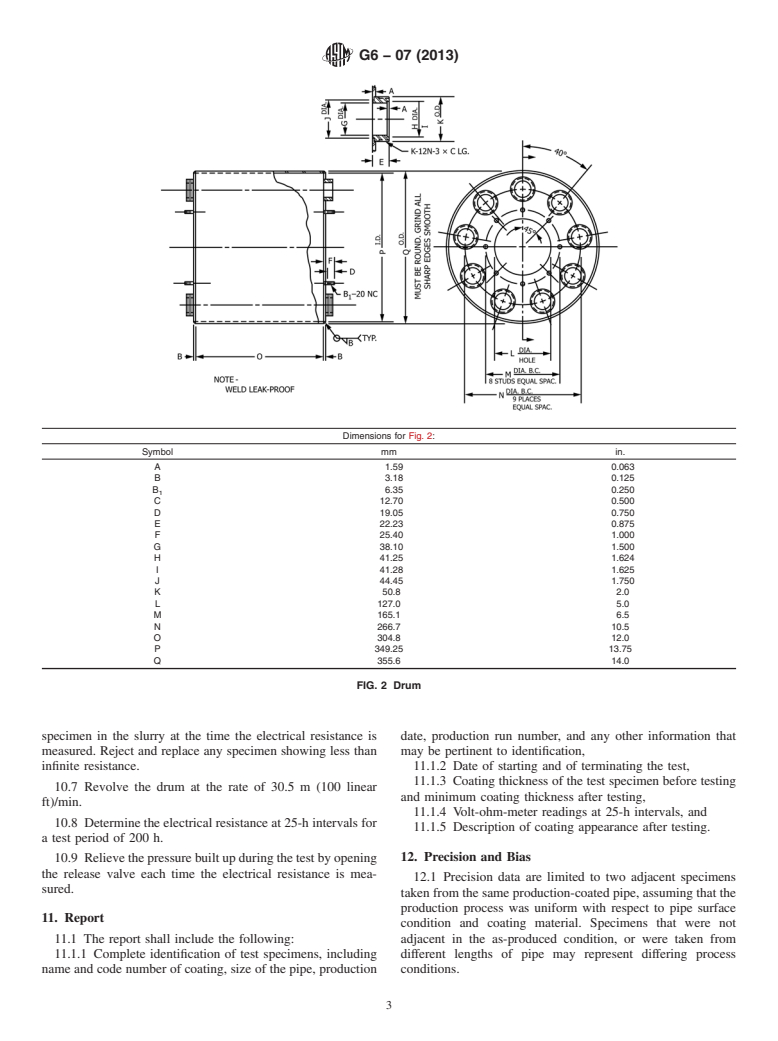

6.1 Drum—A cylindrical steel container suitable for testing

2. Referenced Documents

nine specimens simultaneously. Figs. 1-3 show construction

2.1 ASTM Standards:

details which may be altered at the cap assembly if desired. A

G12 Test Method for Nondestructive Measurement of Film

valve shall be provided to release any pressure built up during

Thickness of Pipeline Coatings on Steel (Withdrawn

test.

2013)

6.2 Apparatus for Revolving the Drum—Any suitable appa-

G62 Test Methods for Holiday Detection in Pipeline Coat-

ratus used to revolve the drum at 30.48 m (100 linear ft)/min.

ings

A modified jar rolling mill has been found satisfactory for

3. Terminology revolving the drum.

3.1 Definitions:

6.3 Thickness Gage, to be used in accordance with Test

Method G12.

6.4 Holiday Detectors, low-voltage wet-sponge type for

This test method is under the jurisdiction of ASTM Committee D01 on Paint

thin film coatings (coatings thinner than 20 mils), and high-

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

voltage type for thick film coatings (coatings thicker than 20

Current edition approved June 1, 2013. Published June 2013. Originally

mils).

approved in 1969. Last previous edition approved in 2007 as G6 – 07. DOI:

10.1520/G0006-07R13.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The sole source of supply known to the committee at this time, to provide a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM means for revolving the drum is Figure 801-V Jar Mill available from U.S.

Standards volume information, refer to the standard’s Document Summary page on Stoneware,Inc.,Akron,OH.Ifyouareawareofalternativesuppliers,pleaseprovide

the ASTM website. this information to ASTM Headquarters. Your comments will receive careful

3 1

The last approved version of this historical standard is referenced on consideration at a meeting of the responsible technical committee, which you may

www.astm.org. attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G6 − 07 (2013)

Dimensions for Fig. 1:

Symbol mm in.

A 0.15 0.006

B 2.28 0.090

C 3.17 0.125

D 4.76 0.188

E 6.35 0.250

F 19.05 0.750

G 25.40 1.000

H 31.75 1.125

I 38.10 1.500

J 47.63 1.875

K 136.53 5.375

L 149.23 5.875

M 355.6 14.0

N 406.4 16.0

NOTE 1—Estimated weight includes water and abrasive 39.5 kg (87 lb).

FIG. 1 Abrasion-Tester Assembly

NOTE 1—Low voltage detectors are used to locate pinholes, voids, or

8.2 Control specimens shall be included in each test, the

thin spots in pipeline coatings. The potential used with wet-sponge

selection of which is optional with the user.

detectors can be up to 100 V DC. Procedures for using these detectors are

found in MethodAof G62. For use of high voltage detectors operating in

9. Conditioning

the 900 to 20 000 Vdc range, see Method B of G62.

9.1 Thespecimenshallbeexposedtoaroomtemperatureof

6.5 Volt-ohm-meter—Anyelectricaltestinstrumentformea-

21 to 25°C (70 to 77°F) for a period of 24 h before beginning

suring electrical resistance of the circuit.

the test.

7. Reagents and Materials

10. Procedure

7.1 The test slurry shall consist of the following:

10.1 Perform the test at a room temperature of 21 to 25°C

7.1.1 Aluminum Oxide Grit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.