ASTM D1785-21a

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120

Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120

ABSTRACT

This specification covers poly(vinyl chloride) (PVC) plastic pipe, schedules 40, 80, and 120 for use with the distribution of pressurized liquids only. This specification also includes classification criteria, nomenclature system, test methods, requirements, workmanship, dimensions, sustained pressure, burst pressure, flattening, extrusion quality, finish, appearance, and marking methods for PVC plastic pipe. PVC pipe covered are marked with one of six type/grade/design stress designation and defined by four hydrostatic design stresses. PVC plastics are categorized by short-term and long term-strength tests.

SCOPE

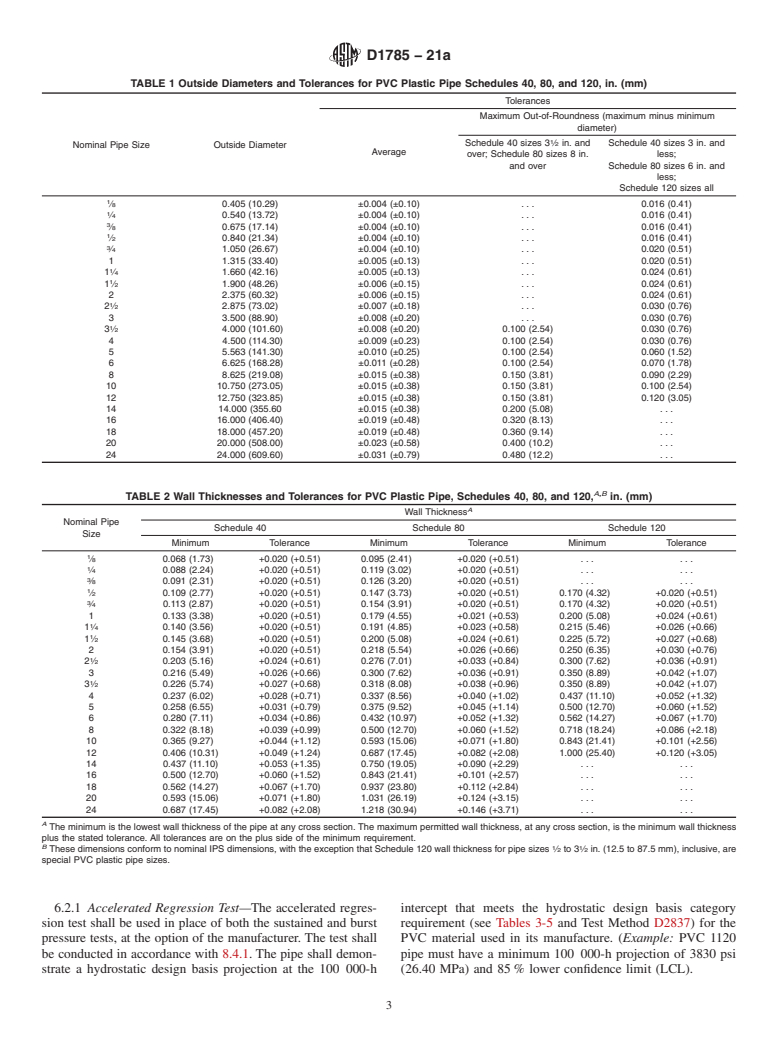

1.1 This specification covers poly(vinyl chloride) (PVC) pipe made in Schedule 40, 80, and 120 sizes and pressure-rated for water (see Appendix X1). Included are criteria for classifying PVC plastic pipe materials and PVC plastic pipe, a system of nomenclature for PVC plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, flattening, and extrusion quality. Methods of marking are also given.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the piping materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 1: Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious saftey hazards should a system fail for any reason.

Note 2: This standard specifies dimensional, performance and test requirements for plumbing and fluid handling applications only. It does not include provisions for the use of these products for venting of combustion gases. UL 1738 is a standard that does include specific testing and marking requirements for flue gas venting products, including PVC.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.A specific precautionary statement is given in Note 9.

Note 3: CPVC plastic pipes, Schedules 40 and 80, which were formerly included in this specification, are now covered by Specification F441/F441M.

Note 4: The sustained and burst pressure test requirements, and the pressure ratings in the Appendix X1, are calculated from stress values obtained from tests made on pipe 4 in. (100 mm) and smaller. However, tests conducted on pipe as large as 24 in. (600 mm) diameter have shown these stress values to be valid for larger diameter PVC pipe.

Note 5: PVC pipe made to this specification is often belled for use as line pipe. For details of the solvent cement bell, see Specification D2672 and for details of belled elastomeric joints, see Specifications D3139 and D3212.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Sta...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D1785 −21a An American National Standard

Standard Specification for

Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80,

1

and 120

This standard is issued under the fixed designation D1785; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

1.1 This specification covers poly(vinyl chloride) (PVC)

of this standard to establish appropriate safety, health, and

pipemadeinSchedule40,80,and120sizesandpressure-rated

environmental practices and determine the applicability of

for water (see Appendix X1). Included are criteria for classi-

regulatory limitations prior to use.A specific precautionary

fying PVC plastic pipe materials and PVC plastic pipe, a

statement is given in Note 9.

systemofnomenclatureforPVCplasticpipe,andrequirements

and test methods for materials, workmanship, dimensions,

NOTE 3—CPVC plastic pipes, Schedules 40 and 80, which were

formerly included in this specification, are now covered by Specification

sustained pressure, burst pressure, flattening, and extrusion

F441/F441M.

quality. Methods of marking are also given.

NOTE 4—The sustained and burst pressure test requirements, and the

1.2 The products covered by this specification are intended

pressure ratings in the Appendix X1, are calculated from stress values

obtained from tests made on pipe 4 in. (100 mm) and smaller. However,

for use with the distribution of pressurized liquids only, which

tests conducted on pipe as large as 24 in. (600 mm) diameter have shown

are chemically compatible with the piping materials. Due to

these stress values to be valid for larger diameter PVC pipe.

inherent hazards associated with testing components and sys-

NOTE 5—PVC pipe made to this specification is often belled for use as

tems with compressed air or other compressed gases some

line pipe. For details of the solvent cement bell, see Specification D2672

manufacturersdonotallowpneumatictestingoftheirproducts. and for details of belled elastomeric joints, see Specifications D3139 and

D3212.

Consult with specific product/component manufacturers for

their specific testing procedures prior to pneumatic testing. 1.6 This international standard was developed in accor-

NOTE 1—Pressurized (compressed) air or other compressed gases

dance with internationally recognized principles on standard-

contain large amounts of stored energy which present serious saftey

ization established in the Decision on Principles for the

hazards should a system fail for any reason.

Development of International Standards, Guides and Recom-

NOTE 2—This standard specifies dimensional, performance and test

mendations issued by the World Trade Organization Technical

requirements for plumbing and fluid handling applications only. It does

not include provisions for the use of these products for venting of Barriers to Trade (TBT) Committee.

combustion gases. UL1738 is a standard that does include specific testing

and marking requirements for flue gas venting products, including PVC.

2. Referenced Documents

1.3 The text of this specification references notes, footnotes, 2

2.1 ASTM Standards:

and appendixes which provide explanatory material. These

D618 Practice for Conditioning Plastics for Testing

notesandfootnotes(excludingthoseintablesandfigures)shall

D1598 Test Method for Time-to-Failure of Plastic Pipe

not be considered as requirements of the specification.

Under Constant Internal Pressure

1.4 The values stated in inch-pound units are to be regarded D1599 Test Method for Resistance to Short-Time Hydraulic

as standard. The values given in parentheses are mathematical

Pressure of Plastic Pipe, Tubing, and Fittings

conversions to SI units that are provided for information only D1600 Terminology forAbbreviatedTerms Relating to Plas-

and are not considered standard.

tics

D1784 Classification System and Basis for Specification for

1.5 The following safety hazards caveat pertains only to the

Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlo-

test methods portion, Section 8, of this specification: This

rinated Poly(Vinyl Chloride) (CPVC) Compounds

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

2

Based Pipe.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1785 − 21 D1785 − 21a An American National Standard

Standard Specification for

Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80,

1

and 120

This standard is issued under the fixed designation D1785; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers poly(vinyl chloride) (PVC) pipe made in Schedule 40, 80, and 120 sizes and pressure-rated for water

(see Appendix X1). Included are criteria for classifying PVC plastic pipe materials and PVC plastic pipe, a system of nomenclature

for PVC plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst

pressure, flattening, and extrusion quality. Methods of marking are also given.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are

chemically compatible with the piping materials. Due to inherent hazards associated with testing components and systems with

compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with

specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

NOTE 1—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious saftey hazards should a

system fail for any reason.

NOTE 2—This standard specifies dimensional, performance and test requirements for plumbing and fluid handling applications only. It does not include

provisions for the use of these products for venting of combustion gases. UL 1738 is a standard that does include specific testing and marking requirements

for flue gas venting products, including PVC.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.A specific precautionary statement is given in Note 9.

NOTE 3—CPVC plastic pipes, Schedules 40 and 80, which were formerly included in this specification, are now covered by Specification F441/F441M.

NOTE 4—The sustained and burst pressure test requirements, and the pressure ratings in the Appendix X1, are calculated from stress values obtained from

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl Based

Pipe.

Current edition approved May 1, 2021Aug. 1, 2021. Published May 2021October 2021. Originally approved in 1960. Last previous edition approved in 20152021 as

ɛ1

D1785 – 15D1785 – 21. . DOI: 10.1520/D1785-21.10.1520/D1785-21A.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1785 − 21a

tests made on pipe 4 in. (100 mm) and smaller. However, tests conducted on pipe as large as 24 in. (600 mm) diameter have shown these stress values

to be valid for larger diameter PVC pipe.

NOTE 5—PVC pipe made to this specification is often belled for use as line pipe. For details of the solvent cement bell, see Specification D2672 and for

details of belled elastomeric joints, see Specifications D3139 and D3212.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of Int

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.