ASTM D4682-87(2002)

(Specification)Standard Specification for Miscibility with Gasoline and Fluidity of Two-Stroke-Cycle Gasoline Engine Lubricants

Standard Specification for Miscibility with Gasoline and Fluidity of Two-Stroke-Cycle Gasoline Engine Lubricants

ABSTRACT

This standard specification describes four categories of two-stroke-cycle gasoline engine lubricants based on their miscibility with gasoline and their low-temperature fluidity. The lubricant categories are classified according to the temperature at which the tests are conducted. The lubricants shall meet the requirements for viscosity and miscibility with gasoline. Miscibility test method shall be done using a rotator, graduated cylinders, stoppered flask, and freezer, and shall use reference oil and any full-boiling-range gasoline as indicated in the specification. Fluidity test method shall be done using Brookfield viscometer and its associated equipment. All test method shall be in accordance with the calibration and standardization procedure indicated in the specification.

SCOPE

1.1 This specification describes four categories of lubricants intended for use in two-stroke-cycle spark-ignition gasoline engines based on their miscibility with gasoline and their low-temperature fluidity.

1.2 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values for temperature, pressure, and so forth stated in SI units are the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4682 – 87 (Reapproved 2002)

Standard Specification for

Miscibility with Gasoline and Fluidity of Two-Stroke-Cycle

Gasoline Engine Lubricants

This standard is issued under the fixed designation D4682; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 miscibility—of two-stroke-cycle gasoline engine lubri-

cants, an inverse function of the time required for a fuel and

1.1 Thisspecificationdescribesfourcategoriesoflubricants

lubricant introduced into the apparatus as separate phases to

intended for use in two-stroke-cycle spark-ignition gasoline

produce a single-phase mixture by agitation under controlled

engines based on their miscibility with gasoline and their

conditions.

low-temperature fluidity.

1.2 Thefollowing safety hazards caveatpertainsonlytothe

4. Classification

testmethodsdescribedinthisspecification. This standard does

4.1 The candidate oils are classified into Categories 1

not purport to address all of the safety concerns, if any,

through 4 according to the temperature at which the tests are

associated with its use. It is the responsibility of the user of this

conducted; respectively, 0°C (32°F),−10°C (14°F),−25°C

standard to establish appropriate safety and health practices

(−13°F), and−40°C (−40°F). Each category has its own

and determine the applicability of regulatory limitations prior

reference oil, which is the same for both the miscibility and

to use.

fluidity tests.

1.3 Thevaluesfortemperature,pressure,andsoforthstated

in SI units are the standard.

5. Qualification Requirements

5.1 Miscibility—When tested in accordance with Section 6,

2. Referenced Documents

candidate oils that mix with the gasoline in not more than 110

2.1 ASTM Standards:

2 %ofthenumberofinversionsoftheapparatusrequiredtomix

D97 Test Method for Pour Point of Petroleum Products

the reference oil, and that do not separate on standing, qualify

D439 Specification for Automotive Gasoline

as miscible.

D445 Test Method for Kinematic Viscosity of Transparent

2 5.2 Fluidity—When tested in accordance with Section 7,

and Opaque Liquids

candidate oils meet the requirements for fluidity if their

D874 Test Method for SulfatedAsh from Lubricating Oils

2 viscosity is not more than 10 % higher than that of the

and Additives

reference oil.

D2983 Test Method for Low-Temperature Viscosity of

Lubricants Measured by Brookfield Viscometer

TEST METHODS

3. Terminology

6. Miscibility Test Method

3.1 Definitions of Terms Specific to This Standard:

6.1 Summary of Test Method—The candidate oil and gaso-

3.1.1 fluidity—of two-stroke-cycle gasoline engine lubri-

line are placed as separate phases in a stoppered-glass cylinder

cants, following industry practice, this term is used to desig-

and mixed by end-over-end rotation of the cylinder under

nate the absolute viscosity in millipascal·seconds (centipoises)

controlled conditions at the temperature appropriate to the

of the lubricant under test. In general usage, fluidity is the

category of the oil.

reciprocal of absolute viscosity.

NOTE 1—This procedure specifies that the lubricant be mixed with

gasoline. Some fuels in current use are partially or predominately

composed of oxygenated compounds such as alcohols, and some lubri-

This specification is under the jurisdiction of ASTM Committee D02 on

cantsthatmixreadilywithgasolinemaynotmixwithsuchfuels.Avariant

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

procedure can be run to determine the ability of a lubricant to mix

D02.B0 on Automotive Lubricants.

satisfactorily with a fuel consisting partially or wholly of oxygenates. In

Current edition approved May 15, 1987. Published November 1987. Originally

this case, the miscibility test must be run using the candidate oil in the

published as D 4682 – 87. Last previous edition D 4682 – 87 (1996).

oxygenate or oxygenate-containing fuel against the reference oil in

Annual Book of ASTM Standards, Vol 05.01.

Discontinued; see 1990 Annual Book of ASTM Standards, Vol 05.01. gasoline.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

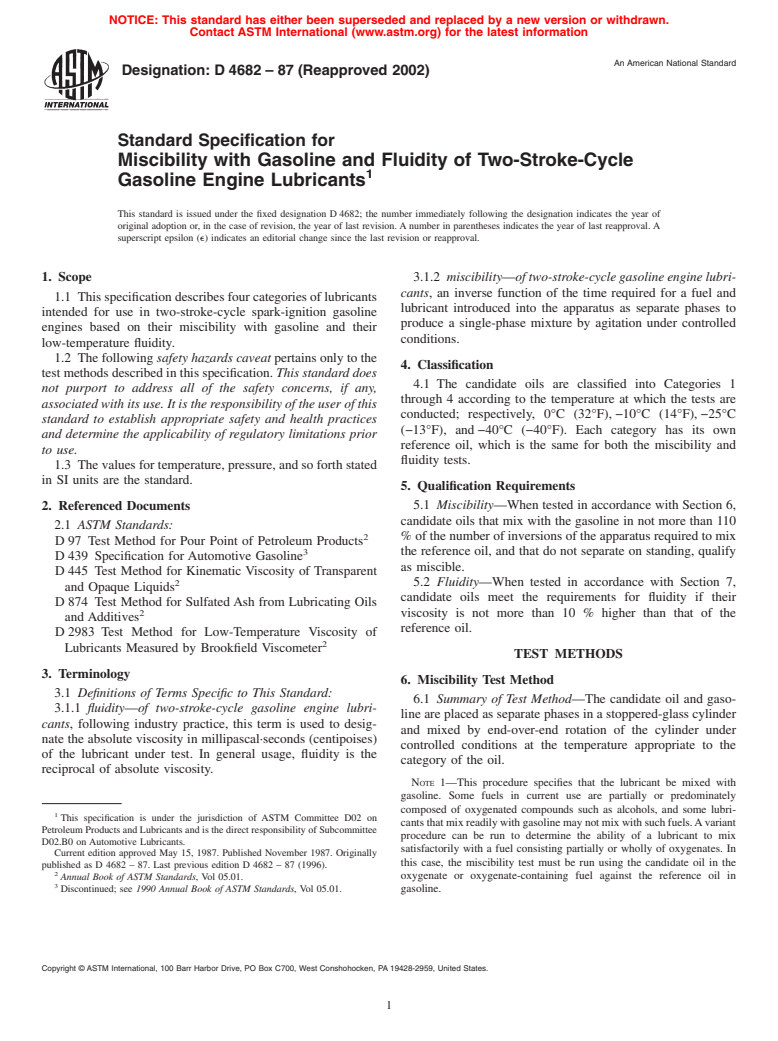

D 4682 – 87 (2002)

6.2 Significance and Use: 1, ASTM reference oil VI-GG; for Category 2, ASTM

6.2.1 The lubricants used in two-stroke-cycle gasoline en- reference oil VI-FF; for Category 3, ASTM reference oil

6 5

gines normally reach the surfaces to be lubricated as a mixture VI-D; and for Category 4, ASTM reference oil VI-II. See

with the fuel. This mixture can either be prepared in advance, AnnexA1forinformationonthecompositionandpropertiesof

usually in the engine fuel tank, or can be produced by the these oils.

metered injection of oil into the fuel stream at some point 6.4.2 Any full-boiling-range gasoline meeting the general

before its entry into the engine crankcase. In either case, the requirements of Specification D439 volatility ClassesA, B, or

fuelandlubricantshallbereadilymiscible,andifthelubricant C can be used.When this procedure is run in conjunction with

ismeteredintothefuelstream,itmustbereadilypumpable.As an engine performance test, it is the normal practice to use the

it cannot be known in advance whether a given lubricant will gasoline specified for the performance test. Oxygenate blends

be mixed with the fuel in advance or be injected into the fuel and other fuels containing nonhydrocarbon blending compo-

stream by a metering pump, both miscibility and fluidity shall nents shall not be used.

be determined. 6.5 Calibration and Standardization—As a reference oil is

6.2.2 The temperature at which the miscibility and fluidity tested simultaneously with each set of candidate oils, no other

ofanoilisdetermineddoesnotnecessarilyreflecttheexpected standardization procedure is required.

temperature of use. For example, outboard motor manufactur- 6.6 Procedure:

ers normally require the use of oils of Category 3, which are 6.6.1 Approximately 25 mL of the oil to be tested and 450

testedat−25°C(−13°F),eventhoughoutboardsarerarelyused mL of gasoline shall be available for each sample to be run,

at such temperatures. The reason is that Category 3 oils are including the reference oil.

readily pumpable and will mix quite rapidly with gasoline at 6.6.2 Pour 19 to 21 mLeach of the reference oil and of the

temperaturesaboveabout5°C(40°F)withlittleornoagitation. candidate oil(s) into separate 500-mL mixing cylinders and

This is an important consideration for boats with outboard insert their stoppers.

motors using a fuel-oil mix that is made up in large built-in 6.6.3 It is preferred, but not mandatory, to purge the

tanks which cannot readily be stirred or shaken. cylinders with nitrogen before inserting the stoppers.

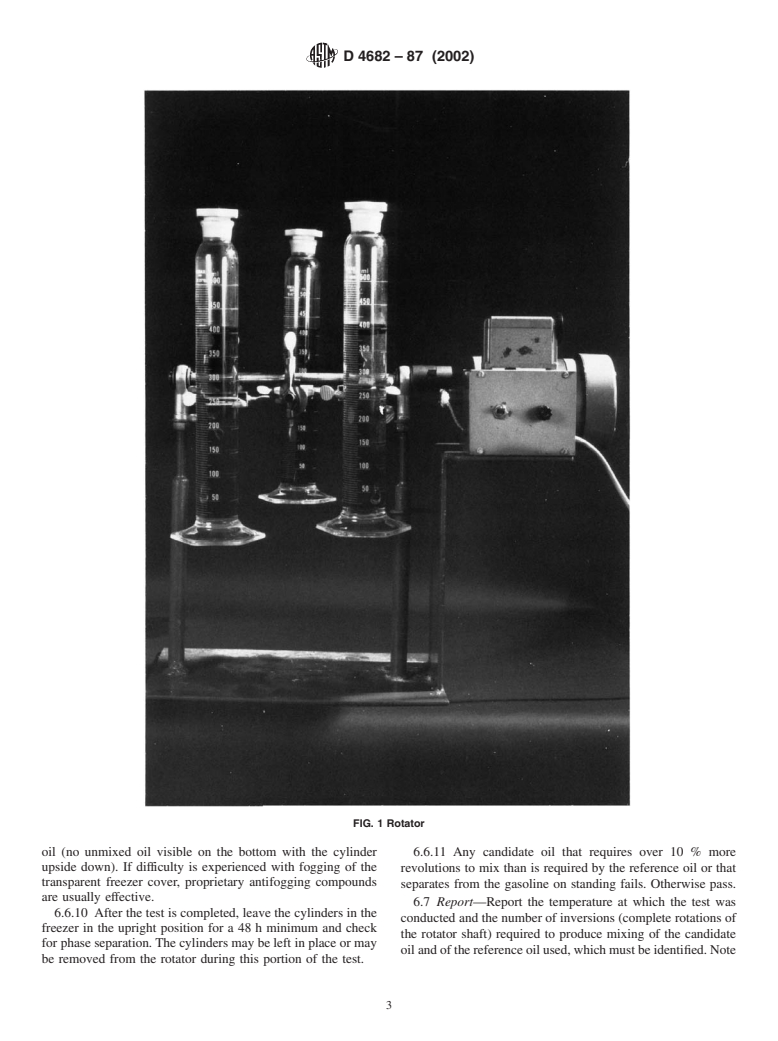

6.3 Apparatus: 6.6.4 Prepare one 395- to 405-mL sample of gasoline in a

6.3.1 Rotator—This consists of three or four standard ap- stoppered flask for each oil sample to be tested, including the

paratus clamps to carry the cylinders specified in 6.3.2 reference oil.

mounted on a horizontal shaft of about 12- to 14-mm (0.4- to 6.6.5 Place the cylinders and the gasoline samples with the

0.6-in.) diameter and about 300 mm (12 in). long mounted rotator into a freezer at the required test temperature for a

between antifriction bearings, driven by an electric motor, and minimumof16h.Thecylindersmaybeattachedtotherotator

providedwitharevolutioncounter.Theshaftisrotatedatabout or may be stored separately in the freezer at this time.

10 to 14 r/min so that the cylinders are continuously being 6.6.6 At the end of the soak period (if this has not already

invertedastheshaftrotates.Amaximumofthreecandidateoils been done), mount the mixing cylinders onto the rotator at

canberunagainstonereferenceoil.Whileitwouldbepossible about 30° to the vertical, clamping them at about the 350-mL

todesignapparatustohandleagreaternumberofsamples,four mark.

appears to be a practical limit for ease of operation. In Fig. 1 6.6.7 Remove the stopper and empty one of the gasoline

a photograph of a suitable rotator is shown. samples into each cylinder in turn, pouring carefully down the

6.3.2 Four (or Fewer) Graduated Cylinders, 500 mL, ca- side so as to minimize mixing. Replace and secure the stopper

pable of remaining securely stoppered in any attitude. The of each cylinder as soon as it has been filled.

length-to-diameter ratio of the cylinders may be in the range 6.6.8 When all cyli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.