ASTM D1710-15

(Specification)Standard Specification for Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled Tubing and Basic Shapes

Standard Specification for Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled Tubing and Basic Shapes

ABSTRACT

This specification covers the testing and requirements of extruded and compression molded polytetrafluoroethylene (PTFE) rods and heavy-walled tubing manufactured from virgin or reprocessed PTFE resin. Covered here are three types of PTFE fluorocarbon materials as follows: Type I (premium), materials having maximum physical and electrical properties to meet rigid requirements; Type II (general purpose), materials having properties required of general electrical, mechanical, and chemical applications; and Type III, materials for noncritical chemical, electrical, and mechanical applications. These types are further subdivided into two grades, and even further into four classes as appropriate. Sampled specimens shall be appropriately tested on the following: workmanship and appearance (color, finish, and internal defects); specific gravity; tensile strength and elongation; dielectric strength; dimensional stability; and melting point.

SCOPE

1.1 This specification covers extruded polytetrafluoroethylene (PTFE) rod, heavy-walled tubing, and basic shapes manufactured from the PTFE resin of Specification D4894 and reprocessed PTFE resin (as defined in Guide D7209).

1.2 The specification covers all sizes of rod, tubing, and basic shapes with a wall thickness of 1.6 mm (1/16 in.) or greater. These materials must be made wholly from PTFE and produced in accordance with good commercial ram extrusion practices.

Note 1: This specification and ISO/DIS 13000-1 (1997) and ISO/DIS 13000-2 (1997) differ in approach, however, data obtained using either are technically equivalent.

Note 2: For compression molded PTFE materials, see Specification D3294. Material that can be certified to Specification D3294 may be substituted for Specification D1710, however the reverse in not true.

1.3 The values stated in SI units, as detailed in IEEE/ASTM SI 10 are to be regarded as the standard. The inch-pound units given in parentheses are provided for information only.

1.4 The following precautionary caveat pertains to the test methods portion, Section 12, only of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1710 −15

Standard Specification for

Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled

1

Tubing and Basic Shapes

This standard is issued under the fixed designation D1710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* at Commercial Power Frequencies

D374Test Methods for Thickness of Solid Electrical Insu-

1.1 This specification covers extruded polytetrafluoroethyl-

3

lation (Withdrawn 2013)

ene (PTFE) rod, heavy-walled tubing, and basic shapes manu-

D618Practice for Conditioning Plastics for Testing

factured from the PTFE resin of Specification D4894 and

D792Test Methods for Density and Specific Gravity (Rela-

reprocessed PTFE resin (as defined in Guide D7209).

tive Density) of Plastics by Displacement

1.2 The specification covers all sizes of rod, tubing, and

D883Terminology Relating to Plastics

1

basic shapes with a wall thickness of 1.6 mm ( ⁄16 in.) or

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

greater. These materials must be made wholly from PTFE and

tics

produced in accordance with good commercial ram extrusion

D3892Practice for Packaging/Packing of Plastics

practices.

D4894 Specification for Polytetrafluoroethylene (PTFE)

Granular Molding and Ram Extrusion Materials

NOTE 1—This specification and ISO/DIS 13000-1 (1997) and ISO/DIS

13000-2(1997)differinapproach,however,dataobtainedusingeitherare

D5740Guide for Writing Material Standards in the Classi-

technically equivalent.

fication Format

NOTE 2—For compression molded PTFE materials, see Specification

D5947Test Methods for Physical Dimensions of Solid

D3294. Material that can be certified to Specification D3294 may be

Plastics Specimens

substituted for Specification D1710, however the reverse in not true.

D7209Guide for Waste Reduction, Resource Recovery, and

1.3 ThevaluesstatedinSIunits,asdetailedinIEEE/ASTM

UseofRecycledPolymericMaterialsandProducts(With-

SI 10 are to be regarded as the standard. The inch-pound units

3

drawn 2015)

given in parentheses are provided for information only.

E94Guide for Radiographic Examination

1.4 The following precautionary caveat pertains to the test

IEEE/ASTM SI 10Standard for the Use of the International

4

methods portion, Section 12, only of this specification: This

System of Units (SI): The Modern Metric System

standard does not purport to address all of the safety concerns,

5

2.2 ISO Standards:

if any, associated with its use. It is the responsibility of the user

ISO 13000-1 (2005) Plastics—Polytetrafluoroethylene

of this standard to establish appropriate safety and health

(PTFE) Semi-Finished Products, Part 1: Basis for Speci-

practices and determine the applicability of regulatory limita-

fication

tions prior to use.

ISO 13000-2 (2005) Plastics—Polytetrafluoroethylene

(PTFE) Semi-Finished Products, Part 2: Preparation of

2. Referenced Documents

Test Specimen and Determination of Properties

2

2.1 ASTM Standards:

D149Test Method for Dielectric Breakdown Voltage and

3. Terminology

DielectricStrengthofSolidElectricalInsulatingMaterials

3.1 Definitions:

3.1.1 Definitions are in accordance with Terminology D883

1

This specification is under the jurisdiction of ASTM Committee D20 on unless otherwise specified.

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Sept. 1, 2015. Published September 2015. Originally

3

approved in 1960. Last previous edition approved in 2008 as D1710-08. DOI: The last approved version of this historical standard is referenced on

10.1520/D1710-15. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from ASTM International, 100 Barr Harbor Drive, West

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Conshohocken, PA 19428.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1710−15

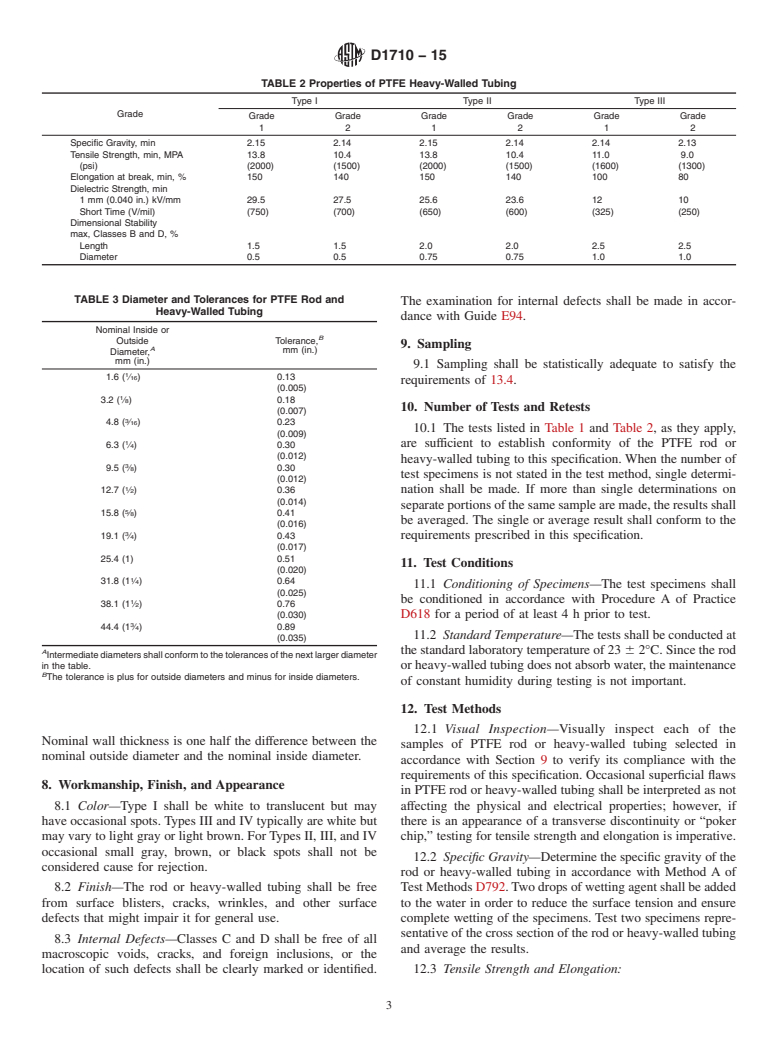

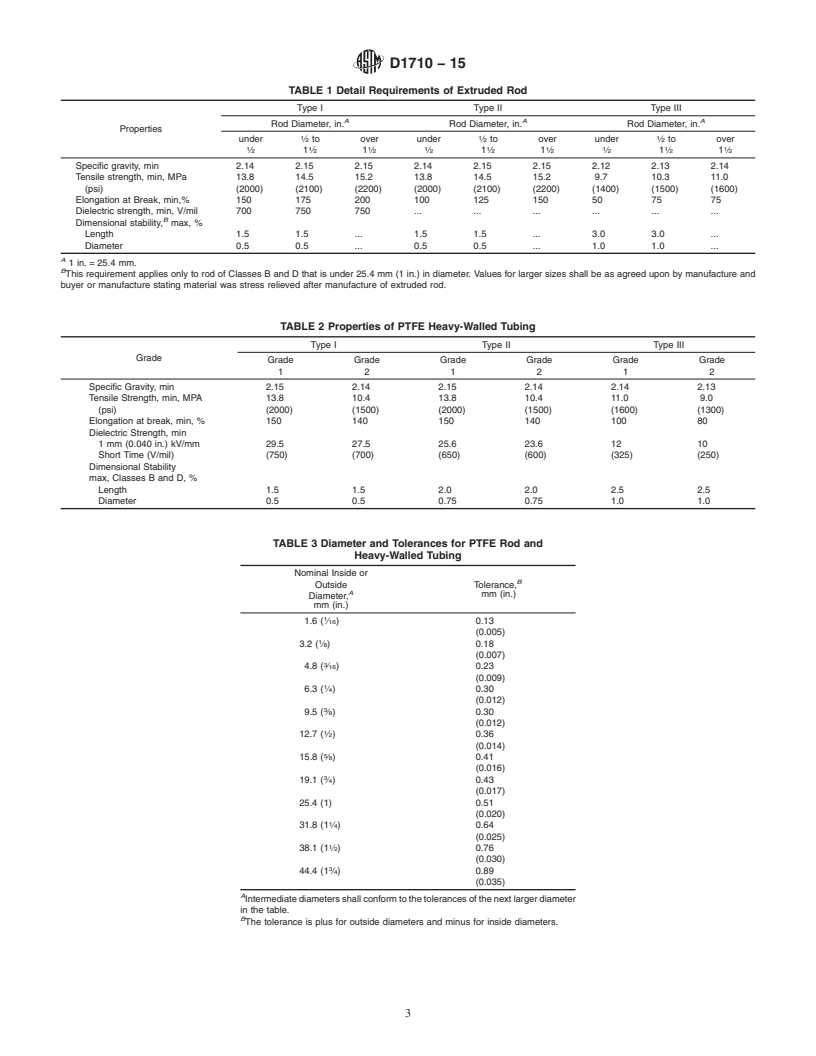

TABLE 1 Detail Requirements of Extruded Rod

Type I Type II Type III

A A A

Rod Diameter, in. Rod Diameter, in. Rod Diameter, in.

Properties

1 1 1

under ⁄2 to over under ⁄2 to over under ⁄2 to over

1 1 1 1 1 1 1 1 1

⁄2 1 ⁄2 1 ⁄2 ⁄2 1 ⁄2 1 ⁄2 ⁄2 1 ⁄2 1 ⁄2

Speci

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1710 − 08 D1710 − 15

Standard Specification for

Extruded Polytetrafluoroethylene (PTFE) Rod, Heavy Walled

1

Tubing and Basic Shapes

This standard is issued under the fixed designation D1710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers extruded polytetrafluoroethylene (PTFE) rod, heavy-walled tubing, and basic shapes manufactured

from the PTFE resin of Specification D4894 and reprocessed PTFE resin (as defined in GuidesGuide D5033 and D7209).

1

1.2 The specification covers all sizes of rod, tubing, and basic shapes with a wall thickness of 1.6 mm ( ⁄16 in.) or greater. These

materials must be made wholly from PTFE and produced in accordance with good commercial ram extrusion practices.

NOTE 1—This specification and ISO/DIS 13000-1 (1997) and ISO/DIS 13000-2 (1997) differ in approach, however, data obtained using either are

technically equivalent.

NOTE 2—For compression molded PTFE materials, see Specification D3294. Material that can be certified to Specification D3294 may be substituted

for Specification D1710, however the reverse in not true.

1.3 The values stated in SI units, as detailed in IEEE/ASTM SI 10 are to be regarded as the standard. The inch-pound units given

in parentheses are provided for information only.

1.4 The following precautionary caveat pertains to the test methods portion, Section 12, only of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

3

D374 Test Methods for Thickness of Solid Electrical Insulation (Withdrawn 2013)

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D3892 Practice for Packaging/Packing of Plastics

D4894 Specification for Polytetrafluoroethylene (PTFE) Granular Molding and Ram Extrusion Materials

3

D5033 Guide for Development of ASTM Standards Relating to Recycling and Use of Recycled Plastics (Withdrawn 2007)

D5740 Guide for Writing Material Standards in the Classification Format

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D7209 Guide for Waste Reduction, Resource Recovery, and Use of Recycled Polymeric Materials and Products (Withdrawn

3

2015)

E94 Guide for Radiographic Examination

4

IEEE/ASTM SI 10 Standard for the Use of the International System of Units (SI): The Modern Metric System

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved April 1, 2008Sept. 1, 2015. Published May 2008September 2015. Originally approved in 1960. Last previous edition approved in 20022008 as

D1710 - 02.D1710 - 08. DOI: 10.1520/D1710-08.10.1520/D1710-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1710 − 15

5

2.2 ISO Standards:

ISO 13000-1 (2005) Plastics—Polytetrafluoroethylene (PTFE) Semi-Finished Products, Part 1: Basis for Specification

ISO 13000-2 (2005) Plastics—Polytetrafluoroethylene (PTFE) Semi-Finished Products, Part

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.