ASTM F919-00

(Specification)Standard Specification for Slicing Machines, Food, Electric

Standard Specification for Slicing Machines, Food, Electric

SCOPE

1.1 This specification covers commercial food slicers having electrically-driven rotating slicing blades.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 919 – 00

Standard Specification for

Slicing Machines, Food, Electric

This standard is issued under the fixed designation F 919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.4 ANSI Standard:

ANSI Z1.4 Sampling Procedures and Tables for Inspection

1.1 This specification covers commercial food slicers hav-

by Attributes

ing electrically driven rotating slicing blades.

2.5 Military Standards:

1.2 The values stated in inch-pound units are to be regarded

MIL-STD-1399/300 Interface Standard for Shipboard Sys-

as the standard. The values given in parentheses are for

tems, Section 300A, Electric Power, Alternating Current

information only.

MIL-STD-167/1 MechanicalVibration of Shipboard Equip-

1.3 The following precautionary caveat pertains only to the

ment (Type I—Environmental and Type II—Internally

test method portion, Section 9, of this specification: This

Excited)

standard does not purport to address all of the safety concerns,

MIL-STD-461 Requirements for the Control of Electro-

if any, associated with its use. It is the responsibility of the user

magnetic Interference Characteristics for Subsystems and

of this standard to establish appropriate safety and health

Equipment

practices and determine the applicability of regulatory limita-

tions prior to use.

3. Terminology

2. Referenced Documents 3.1 Definitions:

3.1.1 carriage—the device for holding food product that is

2.1 ASTM Standards:

manually or automatically reciprocated to bring the product in

F 760 Specification for Food Service Equipment Manuals

contact with the knife.

F 1166 Practice for Human Engineering Design for Marine

3.1.2 feed chute—a device that can replace or supplement

Systems, Equipment, and Facilities

the carriage for the purpose of slicing multiple small cross-

D 3951 Practice for Commercial Packaging

sectional food products. This device also includes an end

2.2 NSF International Standards:

weigh or spring to permit slicing of product to within the last

ANSI/NSF Standard No. 8 Commercial Powered Food

one-quarter inch.

Preparation Equipment

5 3.1.3 gage plate—the device that determines the thickness

NSF Food Service Equipment Listing (current year)

of an individual slice of food product.

2.3 Underwriters Laboratories Standards:

3.1.4 gage plate adjuster—the manually operated device

UL 763 Motor-Operated Commercial Food Preparing Ma-

(usually a dial or a lever) that is used by the operator to set the

chines

6 gage plate. Usual practice is to indicate the thickness by a

UL 969 Marking and Labeling Systems

graduated scale with a 0 (zero) setting to indicate that the gage

plate is completely closed.

3.1.5 sharpener—the device for holding the sharpening and

This specification is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.04 on truing stones.The sharpener can be either attached to the slicer

Mechanical Preparation Equipment.

or removable from the slicer’s sharpener attachment point. If it

Current edition approved Oct. 10, 2000. Published December 2000. Originally

is removable, a storage location within the machine structure

published as F 919 – 85. Last previous edition F 919 – 95a.

shall be provided.

Annual Book of ASTM Standards, Vol 15.07.

Annual Book of ASTM Standards, Vol 01.07.

Annual Book of ASTM Standards, Vol 15.09.

5 7

Available from NSF International, 789 Dixboro Rd., P.O. Box 130140, Ann Available from American National Standards Institute, 11 W. 42nd St., 13th

Arbor, MI 48113-0140. Floor, New York, NY 10036.

6 8

Available from Global Engineering Documents, 15 Inverness Way East, AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Englewood, CO 80112. Robbins Ave., Philadelphia, PA 19111-5094.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 919

4. Classification Standard8.Housingsshallbeofcorrosion-resistant,nonporous

materials. Aluminum parts contacting food shall be anodized.

4.1 Food slicers covered in this specification are of the

6.2 Sharpening Device—The slicer shall have a sharpening

following types and classes.

device included with and attachable to the machine. The

4.2 Types:

sharpening device shall be accessible without lifting or tilting

4.2.1 Type I—Fully automatic (powered carriage):

the machine. The sharpening device shall be capable of

4.2.1.1 Style 1—Gravity product feed.

sharpening the knife to produce product slices that are smooth

(a) (a) Rate 1—Single carriage speed.

and free from tears and bruises as required under Section 8.

(b) (b) Rate 2—Variable or multiple carriage speed.

6.3 Feet—Class A slicers shall have three or more nonme-

(c) (c) Rate 3—Two-speed carriage.

tallic, nonskid feet with provisions for attachment to either a

4.2.1.2 Style 2—Powered product feed.

bench or a stand.

(a) (a) Rate 1—Single carriage speed.

6.4 Motor(s)—The slicer motor(s) shall be of continuous

(b) (b) Rate 2—Variable or multiple carriage speed.

duty type.

(c) (c) Rate 3—Two-speed carriage.

6.5 Assembly and Disassembly—The slicer shall be simple

4.2.1.3 Style 3—With grouping and shingling-capability

to disassemble and reassemble for cleaning and sanitizing.The

discharge conveyor attachment, and stand.

4.2.2 TypeII—Semiautomatic(manuallyoperatedcarriage). slicer shall not require special tools or equipment to disas-

semble for cleaning.

(a) (a) Style 1—Compact unit.

(b) (b) Style 2—Standard size unit. 6.6 Ease of Operation—The slicer, when viewed from the

4.3 Classes: normal operating position, shall have all controls visible and

4.3.1 Class A—Bench mounted. readily accessible.

4.3.2 Class B—Pedestal mounted. 6.7 Electrical Devices—The slicer shall be furnished with a

4.3.3 Class C—Stand mounted with casters.

6-ft (1.83-m) minimum length cord and plug with ground or

shall be double insulated. The cord and plug shall be appro-

NOTE 1—Classes not applicable to Type I, Style 3.

priate for the specified electrical characteristics.

5. Ordering Information 6.7.1 The slicer shall be furnished with a switch which shall

open all motor leads. The slicer shall be furnished with a pilot

5.1 Purchasers should select the slicer and any preferred

light to indicate when the slicer is running.

options and include the following information in the purchas-

6.8 Receiving Tray—A receiving tray for sliced product

ing document:

shall be furnished with the slicer, either built in or as an

5.1.1 Title, number, and date of this specification.

accessory.

5.1.2 Type, style, rate, and class of machine required (see

6.9 Product Carriage—The product carriage and any de-

4.2 and 4.3).

vices for clamping or pushing the product shall hold the

5.1.3 Electrical power supply characteristics; voltage,

product securely in the cutting position. The product carriage

phase, frequency.

shall employ bearings fabricated from cast iron on steel, oilite

5.1.4 Labeling requirements (if different from 6.1.1, 6.1.2,

bearing surfaces or roller bearings. Drive gears shall be

13.1, and 13.2).

gear-grade laminated phenolic or bronze. Parallelism between

5.1.5 Quantity of slicers to be furnished.

knife and carriage shall be maintained within plus and minus

5.1.6 Accessory equipment, spare, and maintenance parts

one degree.

required.

5.1.7 Any special requirements or deviation from this speci- 6.9.1 The slicer shall be designed to prevent contact be-

tween the slicing knife and the carriage, the gage plate and the

fication.

spike assembly of the meat grip.

6. Physical Requirements

6.10 Product Feed Limit—The Type I, Style 2 or Style 3

slicer shall have a meat grip integral with the carriage that

6.1 DesignandManufacture—Theslicershallmeetthethen

secures the end of the product and allows the product to be

current applicable requirements of NSF Standard 8 and UL

uniformly sliced to within the last 1 in. (25 mm). The Type I,

Standard 763.

Style 1, or Type II slicer shall have a toothed product pusher

6.1.1 Compliance with NSF Standard 8—Acceptable evi-

plate, integral with the carriage, that permits slicing to within

dence of meeting the requirements of NSF Standard 8 shall be

the last ⁄4 in. (6 mm).

the NSF listing mark on the slicer and listing in the NSF

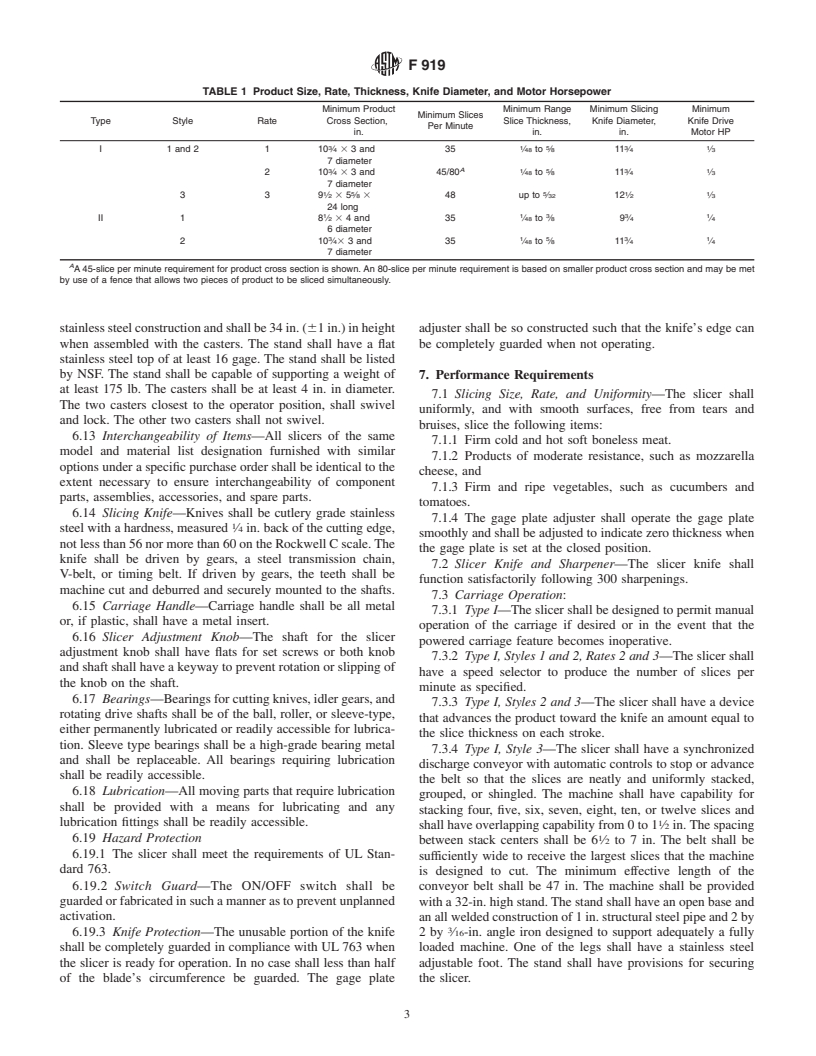

6.11 Product Size, Rate, Thickness, Knife Diameter, and

Official Listing of Food Service Equipment, a certified test

Motor Horsepower—See Table 1.

report from a recognized independent testing laboratory ac-

6.12 Pedestals and Stands:

ceptable to the user, or a certificate issued by NSF under its

special one-time contract evaluation/certification service. 6.12.1 Class B—Slicer shall be identical to equivalent Class

A slicer, except that it shall be supplied with and have

6.1.2 Compliance with UL 763—Acceptable evidence of

meetingtherequirementsofUL763shallbeaULListingmark provisions for attachment to a pedestal. The pedestal shall be

34 in. high (61 in.) with provisions for securing to the floor.

on the slicer, or a certified test report from a recognized

independent testing laboratory acceptable to the user. 6.12.2 Class C—SlicershallbeidenticaltoequivalentClass

6.1.3 Materials—Materials used in the construction of food A slicer, except that it shall be supplied with and have

slicers shall comply with the applicable requirements of NSF provisions for attachment to a stand. The stand shall be of

F 919

TABLE 1 Product Size, Rate, Thickness, Knife Diameter, and Motor Horsepower

Minimum Product Minimum Range Minimum Slicing Minimum

Minimum Slices

Type Style Rate Cross Section, Slice Thickness, Knife Diameter, Knife Drive

Per Minute

in. in. in. Motor HP

3 1 5 3 1

I 1 and 2 1 10 ⁄4 3 3 and 35 ⁄48 to ⁄8 11 ⁄4 ⁄3

7 diameter

A

3 1 5 3 1

210 ⁄4 3 3 and 45/80 ⁄48 to ⁄8 11 ⁄4 ⁄3

7 diameter

1 5 5 1 1

33 9 ⁄2 3 5 ⁄8 3 48 up to ⁄32 12 ⁄2 ⁄3

24 long

1 1 3 3 1

II 1 8 ⁄2 3 4 and 35 ⁄48 to ⁄8 9 ⁄4 ⁄4

6 diameter

3 1 5 3 1

210 ⁄43 3 and 35 ⁄48 to ⁄8 11 ⁄4 ⁄4

7 diameter

A

A 45-slice per minute requirement for product cross section is shown. An 80-slice per minute requirement is based on smaller product cross section and may be met

by use of a fence that allows two pieces of product to be sliced simultaneously.

stainlesssteelconstructionandshallbe34in.(61in.)inheight adjuster shall be so constructed such that the knife’s edge can

when assembled with the casters. The stand shall have a flat be completely guarded when not operating.

stainless steel top of at least 16 gage. The stand shall be listed

by NSF. The stand shall be capable of supporting a weight of

7. Performance Requirements

at least 175 lb. The casters shall be at least 4 in. in diameter.

7.1 Slicing Size, Rate, and Uniformity—The slicer shall

The two casters closest to the operator position, shall swivel

uniformly, and with smooth surfaces, free from tears and

and lock. The other two casters shall not swivel.

bruises, slice the following items:

6.13 Interchangeability of Items—All slicers of the same

7.1.1 Firm cold and hot soft boneless meat.

model and material list designation furnished with similar

7.1.2 Products of moderate resistance, such as mozzarella

options under a specific purchase order shall be identical to the

cheese, and

extent necessary to ensure interchangeability of component

7.1.3 Firm and ripe vegetables, such as cucumbers and

parts, assemblies, accessories, and spare parts.

tomatoes.

6.14 Slicing Knife—Knives shall be cutlery grade stainless

7.1.4 The gage plate adjuster shall operate the gage plate

steel with a hardness, measured ⁄4 in. back of the cutting edge,

smoothly and shall be adjusted to indicate zero thickness when

notlessthan56normorethan60ontheRockwellCscale.The

the gage plate is set at the closed position.

knife shall be driven by gears, a steel transmission chain,

7.2 Slicer Knife and Sharpener—The slicer knife shall

V-belt, or timing belt. If driven by gears, the teeth shall be

function satisfactorily following 300 sharpenings.

machine cut and deburred and securely mounted to the shafts.

7.3 Carriage Operation:

6.15 Carriage Handle—Carriage handle shall be all metal

7.3.1 Type I—The slicer shall be designed to permit manual

or, if plastic, shall have a metal insert.

operation of the carriage if desired or in the event that the

6.16 Slicer Adjustment Knob—The shaft for the slicer

powered carriage feature becomes inoperative.

adjustment knob shall have flats for set screws or both knob

7.3.2 Type I, Styles 1 and 2, Rates 2 and 3—The slicer shall

and shaft shall have a keyway to prevent rotation or slipping of

have a speed selector to produce the number of slices per

the knob on the shaft.

minute as specified.

6.17 Bearings—Bearingsforcuttingknives,idlergears,and

7.3.3 Type I, Styles 2 and 3—The slicer shall have a device

rotating drive shafts shall be of the ball, roller, or sleeve-type,

that advances the product toward the knife an amount equal to

either permanently lubricated or readily accessible for lubrica-

the slice thickness on each stroke.

tion. Sleeve type bearings shall be a high-grade bearing metal

7.3.4 Type I, Style 3—The slicer shall have a synchronized

and shall be replaceable. All bearings requiring lubrication

discharge conveyor with automatic controls to stop or advance

shall be readily accessible.

the belt so that the slices are neatly and uniformly stacked,

6.18 Lubrication—All moving parts that require lubrication

grouped, or shingled. The machine shall have capability for

shall be provided with a means for lubricating and any

stacking four, five, six, seven, eight, ten, or twelve slices and

lubrication fittings shall be readily accessible. 1

shall have overlapping capability from 0 to 1 ⁄2 in.The spacing

6.19 Hazard Protection

between stack centers shall be 6 ⁄2 to 7 in. The belt shall be

6.19.1 The slicer shall meet the requirements of UL Stan-

sufficiently wide to receive the largest slices that the machine

dard 763.

is designed to cut. The minimum effective length of the

6.19.2 Switch Guard—The ON/OFF switch shall be conveyor belt shall be 47 in. The machine shall be provided

guardedorfabricatedinsuchamannerastopreventunplanned

with a 32-in. high stand.The stand shall have an open base and

activation. anallweldedconstructionof1in.structuralsteelpipeand2by

6.19.3 Knife Protection—The unusable portion of the knife 2by ⁄16-in. angle iron designed to support adequately a fully

shall be completely guarded in compliance with UL 763 when loaded m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.