ASTM F2321-14

(Specification)Standard Specification for Flexible and Rigid Insulated Temporary By-Pass Jumpers

Standard Specification for Flexible and Rigid Insulated Temporary By-Pass Jumpers

SCOPE

1.1 These specifications cover the manufacture and testing of flexible insulated temporary By-Pass jumpers (By-Pass jumpers) used on energized power lines and equipment.

1.2 It is common practice for the user of this protective equipment to prepare complete instructions and safety regulations to govern in detail the correct and safe use of such equipment. Also see 4.2.

1.3 The use and maintenance of this equipment are beyond the scope of these specifications.

1.4 These specifications for a system of By-Pass jumpers is covered in four parts as follows:

Title

Sections

Clamps for By-Pass Jumpers

5 – 17

Ferrules for By-Pass Jumpers

18 – 31

Cable for By-Pass Jumpers

32 – 40

By-Pass Jumpers (complete assembly

with clamps, ferrules, and cable)

41 – 55

1.5 Each of the four parts is an entity of itself, but is listed as a part of the system for completeness and clarification.

1.6 The values stated in SI units are to be regarded as the standard. See IEEE/ASTM SI 10.

1.7 The following precautionary caveat pertains only to the test method portions, Sections 13, 26, 48, and 55 of these specifications. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2321 −14

Standard Specification for

1

Flexible and Rigid Insulated Temporary By-Pass Jumpers

This standard is issued under the fixed designation F2321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Wire for Electrical Purposes

B172 Specification for Rope-Lay-Stranded Copper Conduc-

1.1 These specifications cover the manufacture and testing

torsHavingBunch-StrandedMembers,forElectricalCon-

of flexible insulated temporary By-Pass jumpers (By-Pass

ductors

jumpers) used on energized power lines and equipment.

B173 Specification for Rope-Lay-Stranded Copper Conduc-

1.2 It is common practice for the user of this protective

tors Having Concentric-Stranded Members, for Electrical

equipment to prepare complete instructions and safety regula-

Conductors

tions to govern in detail the correct and safe use of such

D2768 Specification for General-Purpose Ethylene-

equipment. Also see 4.2.

Propylene Rubber Jacket for Wire and Cable (Withdrawn

3

2007)

1.3 The use and maintenance of this equipment are beyond

the scope of these specifications. D2770 Specification for Ozone-Resisting Ethylene-

Propylene Rubber Integral Insulation and Jacket for Wire

1.4 These specifications for a system of By-Pass jumpers is

3

and Cable (Withdrawn 2007)

covered in four parts as follows:

D2802 Specification for Ozone-Resistant Ethylene-Alkene

Title Sections

Polymer Insulation for Wire and Cable

Clamps for By-Pass Jumpers 5–17

D2865 Practice for Calibration of Standards and Equipment

Ferrules for By-Pass Jumpers 18–31

Cable for By-Pass Jumpers 32–40

for Electrical Insulating Materials Testing

By-Pass Jumpers (complete assembly 41–55

E8 Test Methods for Tension Testing of Metallic Materials

with clamps, ferrules, and cable)

F819 Terminology Relating to Electrical Protective Equip-

1.5 Each of the four parts is an entity of itself, but is listed

ment for Workers

as a part of the system for completeness and clarification.

IEEE/ASTM SI 10 American National Standard for Metric

1.6 The values stated in SI units are to be regarded as the

Practice

standard. See IEEE/ASTM SI 10.

4

2.2 ANSI Standards:

1.7 The following precautionary caveat pertains only to the

ANSI C39.5 Safety Requirements for Electrical and Elec-

test method portions, Sections 13, 26, 48, and 55 of these

tronic Measuring and Controlling Instruments

specifications. This standard does not purport to address all of

ANSIC84.1 VoltageRatingsforElectricPowerSystemsand

the safety concerns, if any, associated with its use. It is the

Equipment (60 Hz)

responsibility of the user of this standard to establish appro-

ANSI C119.4 American National Standard for Electrical

priate safety and health practices and determine the applica-

Connectors

bility of regulatory requirements prior to use.

5

2.3 NEMA Standard:

WC 8 Ethylene-Propylene-Rubber Insulated Wire and Cable

2. Referenced Documents

for theTransmission and Distribution of Electrical Energy

2

2.1 ASTM Standards:

(formerly ICEA S-68-516)

B33 Specification for Tin-Coated Soft or Annealed Copper

3. Terminology

1 3.1 Definitions:

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.45 on Mechanical Apparatus.

Current edition approved Aug. 15, 2014. Published October 2014. Originally

3

approvedin2003.Lastpreviouseditionapprovedin2013asF2321–05(2013).DOI: The last approved version of this historical standard is referenced on

10.1520/F2321-14. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM 4th Floor, New York, NY 10036.

5

Standards volume information, refer to the standard’s Document Summary page on Available from National Electrical Manufacturers Association (NEMA), 1300

the ASTM website. N. 17th St., Suite 1847, Rosslyn, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2321−14

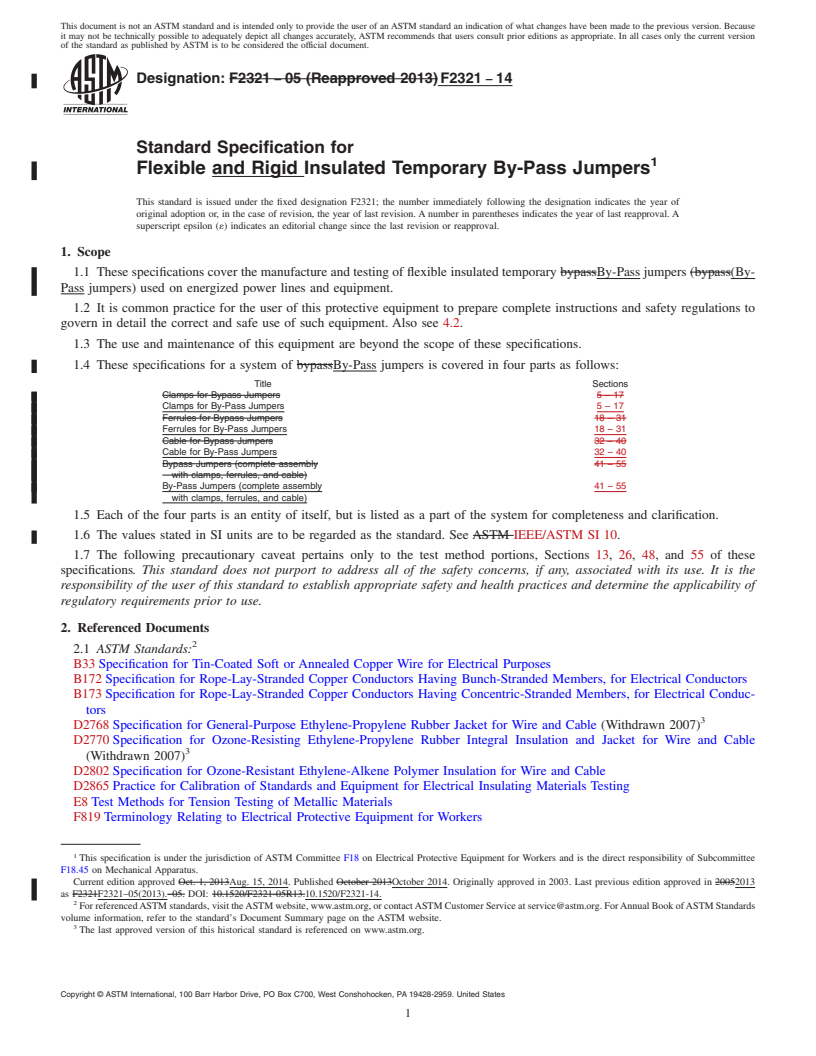

TABLE 1 Proof Test/Use Voltage Relationship

3.1.1 flexible and rigid insulated temporary By-Pass

jumpers—devices designed and used to keep electric supply Maximum AC Proof DC Proof

Voltage

Use Voltage Test Voltage Test Voltage

circuits effectively continuous (electrically bridged) for short

Rating

(rms) V (rms) V (avg) V

periods of time at work locations when conductors or equip-

15 kV 15 000 20 000 50 000

ment may otherwise

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2321 − 05 (Reapproved 2013) F2321 − 14

Standard Specification for

1

Flexible and Rigid Insulated Temporary By-Pass Jumpers

This standard is issued under the fixed designation F2321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These specifications cover the manufacture and testing of flexible insulated temporary bypassBy-Pass jumpers (bypass(By-

Pass jumpers) used on energized power lines and equipment.

1.2 It is common practice for the user of this protective equipment to prepare complete instructions and safety regulations to

govern in detail the correct and safe use of such equipment. Also see 4.2.

1.3 The use and maintenance of this equipment are beyond the scope of these specifications.

1.4 These specifications for a system of bypassBy-Pass jumpers is covered in four parts as follows:

Title Sections

Clamps for Bypass Jumpers 5 – 17

Clamps for By-Pass Jumpers 5 – 17

Ferrules for Bypass Jumpers 18 – 31

Ferrules for By-Pass Jumpers 18 – 31

Cable for Bypass Jumpers 32 – 40

Cable for By-Pass Jumpers 32 – 40

Bypass Jumpers (complete assembly 41 – 55

with clamps, ferrules, and cable)

By-Pass Jumpers (complete assembly 41 – 55

with clamps, ferrules, and cable)

1.5 Each of the four parts is an entity of itself, but is listed as a part of the system for completeness and clarification.

1.6 The values stated in SI units are to be regarded as the standard. See ASTM IEEE/ASTM SI 10.

1.7 The following precautionary caveat pertains only to the test method portions, Sections 13, 26, 48, and 55 of these

specifications. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory requirements prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

B173 Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conduc-

tors

3

D2768 Specification for General-Purpose Ethylene-Propylene Rubber Jacket for Wire and Cable (Withdrawn 2007)

D2770 Specification for Ozone-Resisting Ethylene-Propylene Rubber Integral Insulation and Jacket for Wire and Cable

3

(Withdrawn 2007)

D2802 Specification for Ozone-Resistant Ethylene-Alkene Polymer Insulation for Wire and Cable

D2865 Practice for Calibration of Standards and Equipment for Electrical Insulating Materials Testing

E8 Test Methods for Tension Testing of Metallic Materials

F819 Terminology Relating to Electrical Protective Equipment for Workers

1

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.45 on Mechanical Apparatus.

Current edition approved Oct. 1, 2013Aug. 15, 2014. Published October 2013October 2014. Originally approved in 2003. Last previous edition approved in 20052013

as F2321F2321–05(2013).–05. DOI: 10.1520/F2321-05R13.10.1520/F2321-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2321 − 14

IEEE/ASTM SI 10 American National Standard for Metric Practice

4

2.2 ANSI Standards:

ANSI C39.5 Safety Requirements for Electrical and Electronic Measuring and Controlling Instruments

ANSI C84.1 Voltage Ratings for Electric Power Systems and Equipment (60 Hz)

ANSI C119.4 American National Standard for Electrical Connectors

5

2.3 NEMA Standard:

WC 8 Ethylene-Propylene-Rubber Insulated Wire and Cable for the Transmission and Distribution of Electrical Energy

(formerly ICEA S-68-516)

3. Terminology

3.1 Definitions:

3.1.1 flexible and rigid insulated temporary bypassBy-Pass jumper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.