ASTM E675-94(1998)

(Specification)Standard Specification for Interchangeable Taper-Ground Stopcocks And Stoppers

Standard Specification for Interchangeable Taper-Ground Stopcocks And Stoppers

SCOPE

1.1 The specification provides standard dimensional requirements for obtaining, within practical limits, interchangeability in stopcocks and stoppers for ordinary laboratory and industrial applications. It covers dimensional interchangeability of the ground surfaces only and does not involve design characteristics of the item except where specified. Note 1-The dimensions pertaining to stopcocks and stoppers were taken from the Commercial Standard CS 21 of the U.S. Department of Commerce. Note 2-Although glass is the most commonly used material for stopcocks and stoppers, other materials may be used as specified. Stopcocks and stoppers constructed from glass should conform to Specifications E438 and E671.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: E 675 – 94 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Interchangeable Taper-Ground Stopcocks And Stoppers

This standard is issued under the fixed designation E 675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The specification provides standard dimensional re-

quirements for obtaining, within practical limits, interchange-

ability in stopcocks and stoppers for ordinary laboratory and

industrial applications. It covers dimensional interchangeabil-

ity of the ground surfaces only and does not involve design

characteristics of the item except where specified.

NOTE 1—The dimensions pertaining to stopcocks and stoppers were

taken from the Commercial Standard CS 21 of the U.S. Department of

Commerce.

NOTE 2—Although glass is the most commonly used material for

stopcocks and stoppers, other materials may be used as specified.

Stopcocks and stoppers constructed from glass should conform to Speci-

fications E 438 and E 671.

2. Referenced Documents

2.1 ASTM Standards:

E 438 Specification for Glasses in Laboratory Apparatus

E 671 Specification for Maximum Permissible Thermal Re-

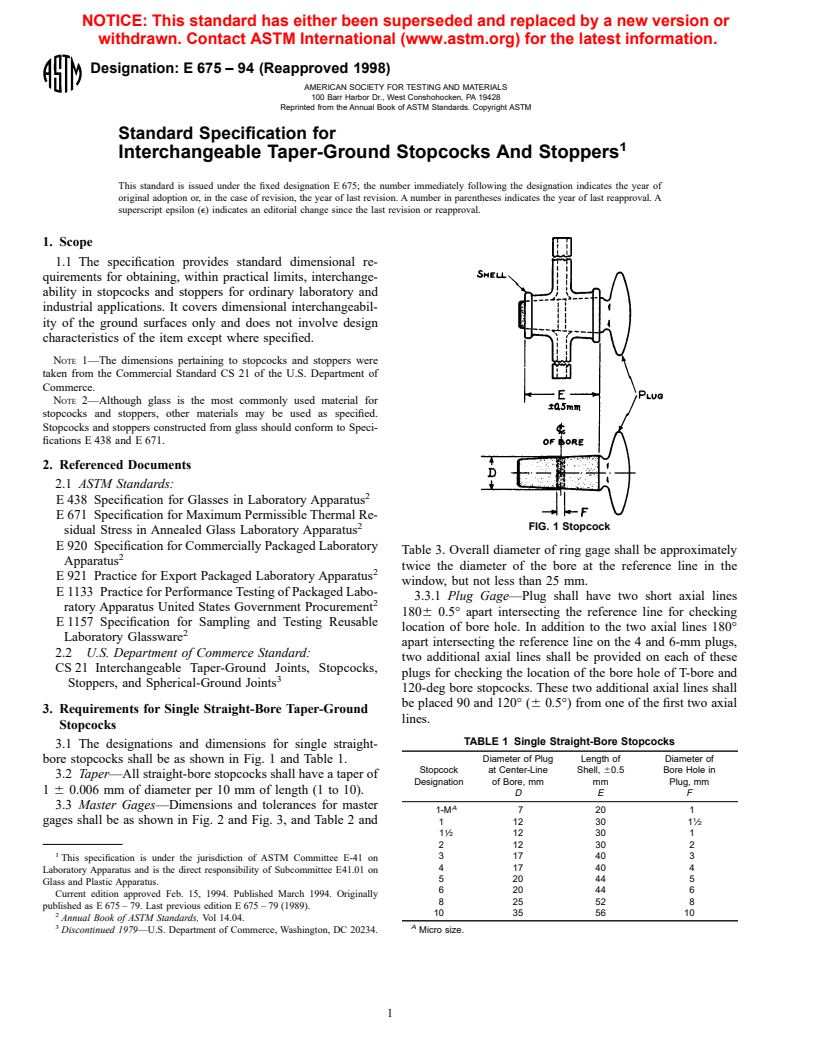

2 FIG. 1 Stopcock

sidual Stress in Annealed Glass Laboratory Apparatus

E 920 Specification for Commercially Packaged Laboratory

Table 3. Overall diameter of ring gage shall be approximately

Apparatus

twice the diameter of the bore at the reference line in the

E 921 Practice for Export Packaged Laboratory Apparatus

window, but not less than 25 mm.

E 1133 Practice for Performance Testing of Packaged Labo-

3.3.1 Plug Gage—Plug shall have two short axial lines

ratory Apparatus United States Government Procurement

1806 0.5° apart intersecting the reference line for checking

E 1157 Specification for Sampling and Testing Reusable

location of bore hole. In addition to the two axial lines 180°

Laboratory Glassware

apart intersecting the reference line on the 4 and 6-mm plugs,

2.2 U.S. Department of Commerce Standard:

two additional axial lines shall be provided on each of these

CS 21 Interchangeable Taper-Ground Joints, Stopcocks,

plugs for checking the location of the bore hole of T-bore and

Stoppers, and Spherical-Ground Joints

120-deg bore stopcocks. These two additional axial lines shall

be placed 90 and 120° (6 0.5°) from one of the first two axial

3. Requirements for Single Straight-Bore Taper-Ground

lines.

Stopcocks

TABLE 1 Single Straight-Bore Stopcocks

3.1 The designations and dimensions for single straight-

Diameter of Plug Length of Diameter of

bore stopcocks shall be as shown in Fig. 1 and Table 1.

Stopcock at Center-Line Shell, 60.5 Bore Hole in

3.2 Taper—All straight-bore stopcocks shall have a taper of

Designation of Bore, mm mm Plug, mm

1 6 0.006 mm of diameter per 10 mm of length (1 to 10).

D E F

3.3 Master Gages—Dimensions and tolerances for master

A

1-M 720 1

gages shall be as shown in Fig. 2 and Fig. 3, and Table 2 and 112 30 1 ⁄2

1 ⁄2 12 30 1

212 30 2

317 40 3

This specification is under the jurisdiction of ASTM Committee E-41 on

417 40 4

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

520 44 5

Glass and Plastic Apparatus.

620 44 6

Current edition approved Feb. 15, 1994. Published March 1994. Originally

825 52 8

published as E 675 – 79. Last previous edition E 675 – 79 (1989).

2 10 35 56 10

Annual Book of ASTM Standards, Vol 14.04.

A

Discontinued 1979—U.S. Department of Commerce, Washington, DC 20234. Micro size.

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

E 675

TABLE 2 Master Plug Gages for Single Straight-Bore Stopcocks

Distance from

Length of Tapered Diameter at Large End of

Stopcock Portion +2.0 mm, Gaging Point Tapered Portion

Designation −0 mm 60.003 mm to Gaging

EE DD Point, mm

NN

A

1-M 32 7 20

142 12 25

1 ⁄2 42 12 25

242 12 25

352 17 30

452 17 30

556 20 32

656 20 32

864 25 36

10 68 35 38

A

Micro size.

TABLE 3 Master Ring Gages for Single Straight-Bore Stopcocks

Length of Inside Diameter Distance from

Stopcock Ring, +0.2 at Gaging Point, Top to Gaging

Designation mm, −0 mm 60.003 mm Point, mm

EE DD NN

FIG. 2 Master Plug Gage for Single Straight-Bore Stopcocks

A

1-M 20 7 10

1 301215

1 ⁄2 30 12 15

2 301215

3 401720

4 401720

5 442022

6 442022

8 522526

10 56 35 28

A

Micro size.

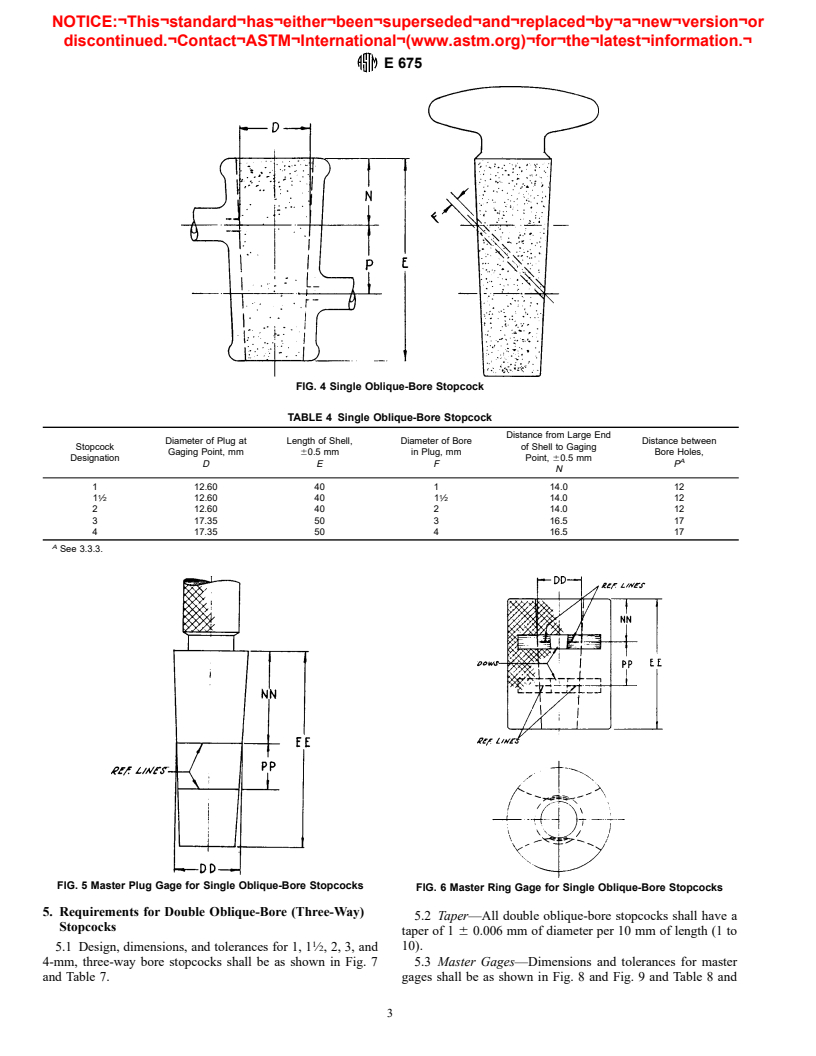

4. Requirements for Single Oblique-Bore Stopcocks

4.1 Design, dimensions, and tolerances for 1, 1 ⁄2,2,3,and

4-mm oblique-bore stopcocks shall be as shown in Fig. 4 and

Table 4.

4.2 Taper—All single oblique-bore stopcocks shall have a

taper of 1 6 0.006 mm of diameter per 10 mm of length (1 to

10).

4.3 Master Gages—The dimensions and tolerances for mas-

ter gages shall be as shown in Fig. 5 and Fig. 6 and Table 5 and

Table 6. The overall diameter of the ring gage shall be

approximately twice the diameter of the bore at its midpoint,

but not less than 25 mm.

4.3.1 Plug Gage—The upper circumferential reference line

shall be the gaging point. Each reference line shall have a short

FIG. 3 Master Ring Gage for Single Straight-Bore Stopcocks

axial line intersecting it, the two axial lines being on opposite

3.3.2 Ring Gage—The central milled recess, or window, sides of the plug and in the same plane running through the axis

shall be placed approximately midway between the ends of the (180 6 0.5° apart) for checking location of bore holes.

ring gage. Width of recess measured parallel with the axis shall 4.3.2 Ring Gage—The width of the milled recesses, or

be approximately one fourth of the length of the ring, and the windows, measured parallel with the axis shall be approxi-

width of the opening at the inner surface of ring, measured mately one fourth of the length of the ring, and the width of the

perpendicular to the axis, shall not exceed one fourth of the

opening at the inner surface of ring, measured perpendicular to

length of the ring. Reference line in recess shall be placed the axis, shall not exceed one fourth of the length of the ring.

approximately midway between ends of ring gage. The recesses shall be so placed that the reference lines fall

3.3.3 Fit of Product in Working Gages—The product (both approximately midway in the recess.

inner and outer members) shall fit the corresponding working 4.3.3 Fit of Product in Working Gages—The product (both

gages so that the centerline through the bore corresponds with inner and outer members) shall fit the corresponding working

the reference line on the gage within 6 0.3 mm for 1, 1 ⁄2, and gages so that the centerlines through the openings correspond

2-mm bores;6 0.5 mm for 3 and 4-mm bores; and 6 1.0 mm with the reference lines on the gages within 6 0.3 mm for 1,

for 5-mm and larger bores. 1 ⁄2, and 2-mm bores, and 6 0.5 mm for 3 and 4-mm bores.

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

E 675

FIG. 4 Single Oblique-Bore Stopcock

TABLE 4 Single Oblique-Bore Stopcock

Distance from Large End

Diameter of Plug at Length of Shell, Diameter of Bore Distance between

Stopcock of Shell to Gaging

Gaging Point, mm 60.5 mm in Plug, mm Bore Holes,

Designation Point, 60.5 mm

A

D E F P

N

1 12.60 40 1 14.0 12

1 1

1 ⁄2 12.60 40 1 ⁄2 14.0 12

2 12.60 40 2 14.0 12

3 17.35 50 3 16.5 17

4 17.35 50 4 16.5 17

A

See 3.3.3.

FIG. 5 Master Plug Gage for Single Oblique-Bore Stopcocks

FIG. 6 Master Ring Gage for Single Oblique-Bore Stopcocks

5. Requirements for Double Oblique-Bore (Three-Way)

5.2 Taper—All double oblique-bore stopcocks shall have a

Stopcocks

taper of 1 6 0.006 mm of diameter per 10 mm of length (1 to

5.1 Design, dimensions, and tolerances for 1, 1 ⁄2,2,3,and 10).

4-mm, three-way bore stopcocks shall be as shown in Fig. 7 5.3 Master Gages—Dimensions and tolerances for master

and Table 7. gages shall be as shown in Fig. 8 and Fig. 9 and Table 8 and

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

E 675

TABLE 5 Master Plug Gages for Single Oblique-Bore Stopcocks

Length of Distance from Large End of Distance from Gaging Point

Diameter at Gaging

Tapered Portion, Tapered Portion to Gaging to Lower Reference

Stopcock Designation Point, 60.003 mm

+2.0 mm, −0 mm Point +1.5 mm, −0 mm Line 60.03 mm

DD

EE NN PP

1 52 12.60 24.5 12

1 ⁄2 52 12.60 24.5 12

2 52 12.60 24.5 12

3 62 17.35 27.0 17

4 62 17.35 27.0 17

TABLE 6 Master Ring Gages for Single Oblique-Bore Stopcocks

Distance from Gaging

Length of Ring, +0.2 Inside Diameter at Gaging Point

Distance from Top to Gaging

mm, −0 mm Point, 60.003 mm to Lower Reference Point,

Stopcock Designation Point (Approximate)

EE DD 60.03 mm

NN

PP

1 40 12.60 14.0 12

1 ⁄2 40 12.60 14.0 12

2 40 12.60 14.0 12

3 50 17.35 16.5 17

4 50 17.35 16.5 17

FIG. 7 Double Oblique-Bore Stopcock

Table 9. The overall diameter of the ring gage shall be The recesses shall be so placed that the reference lines fall

approximately twice the diameter of the bore at the reference approximately midway in the recesses.

line in the central window. 5.3.3 Fit of Product in Working Gages—The product (both

5.3.1 Plug Gage—The central circumferential reference inner and outer members) shall fit the corresponding working

line shall be the gaging point. A short axial reference line shall gages so that the centerlines through the openings correspond

intersect each of the circumferential reference lines. The axial with the reference lines on the gage within 6 0.3 mm for 1,

line intersecting the central circumferential reference line shall 1 ⁄2, and 2-mm bores, and 6 0.5 mm for 3 and 4-mm bores.

be on the opposite side of the plug from the other two axial

6. Requirements for T-Bore and 120-deg Bore Stopcocks

lines. All three axial lines shall be in the same plane running

through t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.