ASTM A139/A139M-16

(Specification)Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over)

Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over)

ABSTRACT

This specification covers five grades of electric-fusion(arc)-welded straight-seam or helical steel pipe including pipe of NPS 4 and over. The required chemical composition, tensile requirements of the steel, and the tensile requirements of the production welds are presented. Heat analysis of each heat of steel was made to determine the percentage of the elements as per chemical requirements. Tests to be performed shall include one longitudinal tension test for the steel, one reduced-section production weld test for the pipe, and hydrostatic test for each length of the pipe.

SCOPE

1.1 This specification covers five grades of electric-fusion (arc)-welded straight-seam or helical-seam steel pipe. Pipe of NPS 4 (Note 1) and larger with nominal (average) wall thickness of 1.0 in. [25.4 mm] and less are covered. Listing of standardized dimensions are for reference (Note 2). The grades of steel are pipe mill grades having mechanical properties which differ from standard plate grades. The pipe is intended for conveying liquid, gas, or vapor.

Note 1: The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

Note 2: A comprehensive listing of standardized pipe dimensions is contained in ASME B36.10M.

Note 3: The suitability of pipe for various purposes is somewhat dependent on its dimensions, properties, and conditions of service. For example, for high-temperature service see applicable codes and Specification A691.

1.2 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values in each system are not exact equivalents; therefore, each system is to be used independently of the other.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A139/A139M −16

Standard Specification for

1

Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over)

This standard is issued under the fixed designationA139/A139M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.2 American Welding Society Standard:

AWS B2.1 Standard for Welding Procedure and Perfor-

1.1 This specification covers five grades of electric-fusion

mance Qualifications Welding Handbook, Vol 1, 8th ed

(arc)-welded straight-seam or helical-seam steel pipe. Pipe of

4

2.3 ASME Standards:

NPS4(Note 1) and larger with nominal (average) wall

ASME B36.10M Welded and Seamless Wrought Steel Pipe

thickness of 1.0 in. [25.4 mm] and less are covered. Listing of

ASME B36.19M Stainless Steel Pipe

standardized dimensions are for reference (Note 2).The grades

ASME Boiler and Pressure Vessel Code, Section IX

of steel are pipe mill grades having mechanical properties

which differ from standard plate grades. The pipe is intended

3. Ordering Information

for conveying liquid, gas, or vapor.

3.1 Orders for material under this specification should

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

include the following, as required, to describe the desired

been substituted in this standard for such traditional terms as “nominal

material adequately:

diameter,” “size,” and “nominal size.”

3.1.1 Quantity (feet, metres, or number of lengths),

NOTE 2—A comprehensive listing of standardized pipe dimensions is

contained in ASME B36.10M. 3.1.2 Name of material (electric-fusion-(arc) welded steel

NOTE 3—The suitability of pipe for various purposes is somewhat

pipe),

dependent on its dimensions, properties, and conditions of service. For

3.1.3 Grade (Table 1),

example, for high-temperature service see applicable codes and Specifi-

3.1.4 Size (NPS, or outside diameter, and nominal wall

cation A691.

thickness, or schedule number),

1.2 The values stated in either inch-pound units or in SI

3.1.5 Lengths (specific or random, Section 17),

units are to be regarded separately as standard. Within the text,

3.1.6 End finish (Section 18),

the SI units are shown in brackets. The values in each system

3.1.7 Hydrostatic test pressure (Section 16, Note 8, and

are not exact equivalents; therefore, each system is to be used

Note 9),

independently of the other.

3.1.8 ASTM specification designation, and

3.1.9 End use of material.

2. Referenced Documents

4. Process

2

2.1 ASTM Standards:

4.1 The steel shall be made by one or more of the following

A370 Test Methods and Definitions for Mechanical Testing

processes: open-hearth, basic-oxygen, or electric-furnace.

of Steel Products

A691 Specification for Carbon and Alloy Steel Pipe,

4.2 Steel may be cast in ingots or may be strand cast. When

Electric-Fusion-WeldedforHigh-PressureServiceatHigh

steels of different grades are sequentially strand cast, identifi-

Temperatures

cation of the resultant transition material is required. The

A751 Test Methods, Practices, and Terminology for Chemi-

producer shall remove the transition material by any estab-

cal Analysis of Steel Products

lished procedure that positively separates the grades.

NOTE 4—The term “basic-oxygen steelmaking” is used generically to

describe processes in which molten iron is refined to steel under a basic

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, slag in a cylindrical furnace lined with basic refractories, by directing a jet

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

of high-purity gaseous oxygen onto the surface of the hot metal bath.

A01.09 on Carbon Steel Tubular Products.

Current edition approved March 1, 2016. Published March 2016. Originally

approved in 1932. Last previous edition approved in 2015 as A139/A139M–04

3

(2015). DOI: 10.1520/A0139_A0139M-16. Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Miami, FL 33126, http://www.aws.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A139/A139M−16

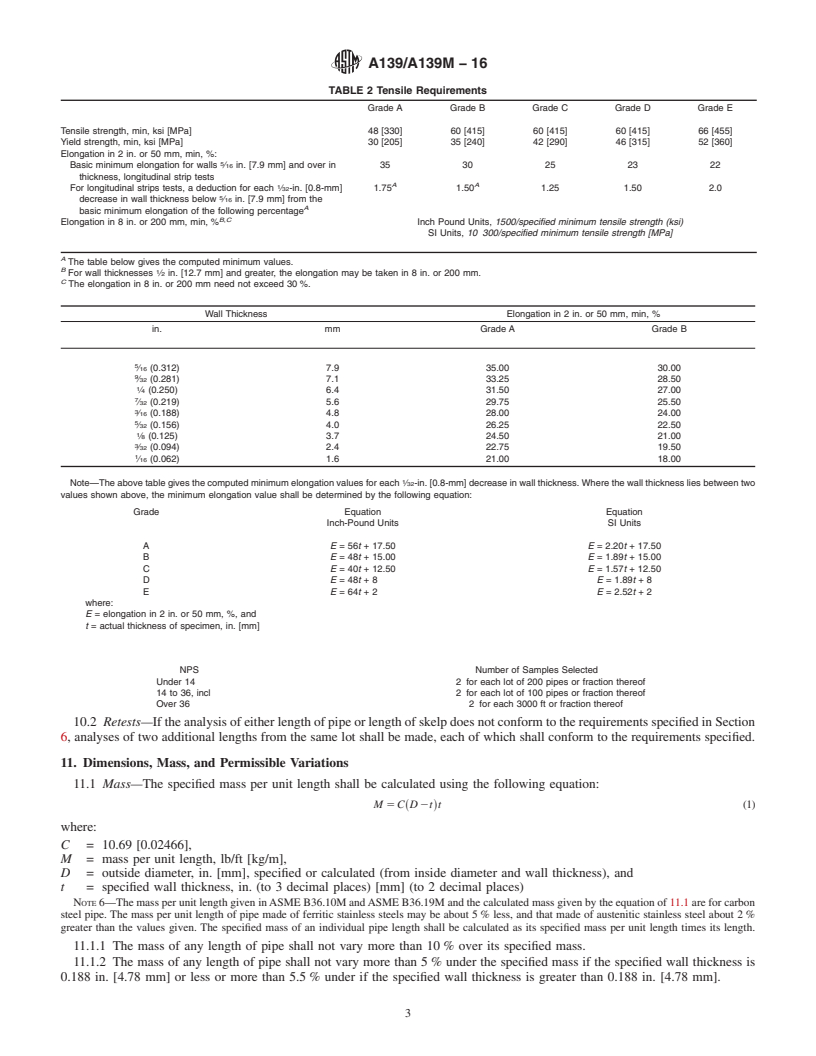

TABLE 1 Chemical Requi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A139/A139M − 04 (Reapproved 2015) A139/A139M − 16

Standard Specification for

1

Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over)

This standard is issued under the fixed designation A139/A139M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers five grades of electric-fusion (arc)-welded straight-seam or helical-seam steel pipe. Pipe of NPS

4 (Note 1) and larger with nominal (average) wall thickness of 1.0 in. [25.4 mm] and less are covered. Listing of standardized

dimensions are for reference (Note 2). The grades of steel are pipe mill grades having mechanical properties which differ from

standard plate grades. The pipe is intended for conveying liquid, gas, or vapor.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,”“

size,”diameter,” “size,” and “nominal size.”

NOTE 2—A comprehensive listing of standardized pipe dimensions is contained in ASME B36.10M.

NOTE 3—The suitability of pipe for various purposes is somewhat dependent on its dimensions, properties, and conditions of service. For example,

for high-temperature service see applicable codes and Specification A691.

1.2 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, the SI

units are shown in brackets. The values in each system are not exact equivalents; therefore, each system is to be used independently

of the other.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A691 Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

3

E59 Practice for Sampling Steel and Iron for Determination of Chemical Composition (Withdrawn 1996)

3

2.2 American Welding Society Standard:

AWS B2.1 Standard for Welding Procedure and Performance Qualifications Welding Handbook, Vol 1, 8th ed

4

2.3 ASME Standards:

ASME B36.10M Welded and Seamless Wrought Steel Pipe

ASME B36.19M Stainless Steel Pipe

ASME Boiler and Pressure Vessel Code, Section IX

3. Ordering Information

3.1 Orders for material under this specification should include the following, as required, to describe the desired material

adequately:

3.1.1 Quantity (feet, metres, or number of lengths),

3.1.2 Name of material (electric-fusion-(arc) welded steel pipe),

3.1.3 Grade (Table 1),

3.1.4 Size (NPS, or outside diameter, and nominal wall thickness, or schedule number),

3.1.5 Lengths (specific or random, Section 17),

3.1.6 End finish (Section 18),

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved Sept. 1, 2015March 1, 2016. Published September 2015March 2016. Originally approved in 1932. Last previous edition approved in 20102015

as A139/A139M–04 (2010).(2015). DOI: 10.1520/A0139_A0139M-04R15.10.1520/A0139_A0139M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Welding Society (AWS), 550 NW LeJeune Rd., Miami, FL 33126, http://www.aws.org.

4

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A139/A139M − 16

TABLE 1 Chemical Requirements

Element Composition, max, %

Grade A Grade B Grade C Grade D Grade E

Carbon 0.25 0.26 0.28 0.30 0.30

Manganese 1.00 1.00 1.20 1.30 1.40

Phosphorus 0.035 0.035 0.035 0.035 0.035

Sulfur 0.035 0.035 0.035 0.035 0.035

3.1.7 Hydrostatic test pressure (Section 16, Note 8, and Note 9),

3.1.8 ASTM specification designation, and

3.1.9 End use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.