ASTM D3309-96a(2002)

(Specification)Standard Specification for Polybutylene (PB) Plastic Hot- and Cold-Water Distribution Systems (Withdrawn 2010)

Standard Specification for Polybutylene (PB) Plastic Hot- and Cold-Water Distribution Systems (Withdrawn 2010)

ABSTRACT

This specification covers requirements, test methods, and methods of marking for polybutylene plastic system components. These components comprise pipe and tubing, socket-fusion fittings, compression fittings, mechanical fittings, and plastic-to-metal transition fittings. The components covered by this specification are intended for use in hot- and cold-water potable water service and distribution systems and such non-potable water applications. The components are classified as follows: pipe, tubing, and socket-fusion fittings; plastic-to-metal transition fittings; and compression and mechanical plastic fittings. The following tests shall be performed: sustained hydrostatic pressure; thermocycling; hydrostatic burst strength; assembly; excessive temperature and pressure capability of tubing and pipe; and elongation value at break.

SCOPE

1.1 This specification covers requirements, test methods, and methods of marking for polybutylene plastic system components made in one standard dimension ratio and intended for 0.69 MPa (100 psi) water service up to and including 82°C (180°F). These components comprise pipe and tubing, socket-fusion fittings, compression fittings, mechanical fittings, and plastic-to-metal transition fittings. Requirements and test methods are included for sustained, hydrostatic pressure strength, thermocycling resistance, joint strength, and dimensions and tolerances for pipe and socket fusion fittings. The components covered by this specification are intended for use in hot- and cold-water potable water service and distribution systems and such non-potable water applications as building services piping, water heating and cooling systems, fire sprinkler applications, and other miscellaneous applications involving the transport of water, ethylene glycol solutions, or other aqueous liquids shown not to adversely affect PB performance.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values in SI units are the standard. The values stated in parentheses are for information only.

Note 1—Suggested hydrostatic design stresses and hydrostatic pressure ratings for pipe, tubing, and fittings are listed in Appendix X1. Design, assembly, and installation considerations are discussed in . An optional performance qualification and an in-plant quality control program are recommended in Appendix X3.

1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D3309 – 96a (Reapproved 2002)

Standard Specification for

Polybutylene (PB) Plastic Hot- and Cold-Water Distribution

1

Systems

This standard is issued under the fixed designation D3309; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

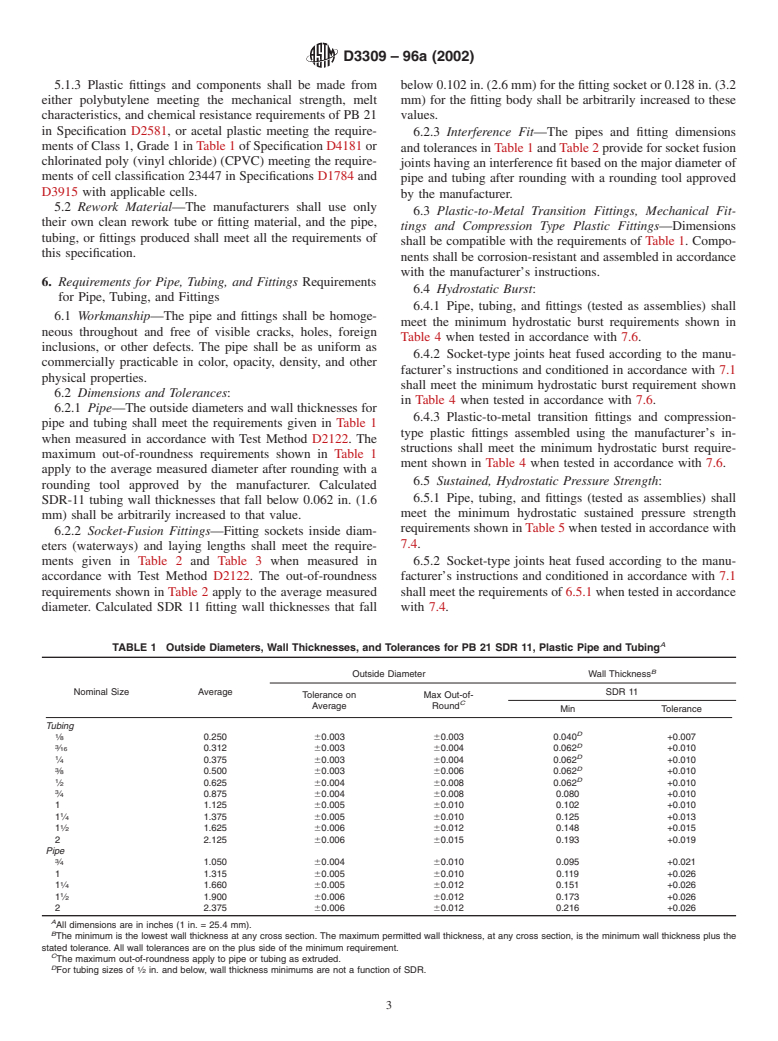

1.1 This specification covers requirements, test methods,

tions prior to use.

and methods of marking for polybutylene plastic system

components made in one standard dimension ratio and in-

2. Referenced Documents

tended for 0.69 MPa (100 psi) water service up to and

2

2.1 ASTM Standards:

including 82°C (180°F). These components comprise pipe and

D618 Practice for Conditioning Plastics for Testing

tubing, socket-fusion fittings, compression fittings, mechanical

D1598 Test Method for Time-to-Failure of Plastic Pipe

fittings, and plastic-to-metal transition fittings. Requirements

Under Constant Internal Pressure

and test methods are included for sustained, hydrostatic pres-

D1599 TestMethodforResistancetoShort-TimeHydraulic

sure strength, thermocycling resistance, joint strength, and

Pressure of Plastic Pipe, Tubing, and Fittings

dimensions and tolerances for pipe and socket fusion fittings.

D1600 Terminology for Abbreviated Terms Relating to

The components covered by this specification are intended for

Plastics

use in hot- and cold-water potable water service and distribu-

D1708 Test Method for Tensile Properties of Plastics by

tion systems and such non-potable water applications as

Use of Microtensile Specimens

building services piping, water heating and cooling systems,

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

fire sprinkler applications, and other miscellaneous applica-

Compounds and Chlorinated Poly(Vinyl Chloride)

tions involving the transport of water, ethylene glycol solu-

(CPVC) Compounds

tions, or other aqueous liquids shown not to adversely affect

D1898 Practice for Sampling of Plastics

PB performance.

D2122 Test Method for Determining Dimensions of Ther-

1.2 Thetextofthisspecificationreferencesnotes,footnotes,

moplastic Pipe and Fittings

and appendixes which provide explanatory material. These

D2581 ClassificationSystemforPolybutylene(PB)Plastics

notesandfootnotes(excludingthoseintablesandfigures)shall

Molding and Extrusion Materials

not be considered as requirements of the specification.

D2749 Symbols for Dimensions of Plastic Pipe Fittings

1.3 ThevaluesinSIunitsarethestandard.Thevaluesstated

D2837 TestMethodforObtainingHydrostaticDesignBasis

in parentheses are for information only.

forThermoplastic Pipe Materials or Pressure Design Basis

NOTE 1—Suggested hydrostatic design stresses and hydrostatic pres-

for Thermoplastic Pipe Products

sure ratings for pipe, tubing, and fittings are listed in Appendix X1.

D3915 Specification for Rigid Poly(Vinyl Chloride) (PVC)

Design, assembly, and installation considerations are discussed inAppen-

and Chlorinated Poly(Vinyl Chloride) (CPVC) Com-

dix X2. An optional performance qualification and an in-plant quality

pounds for Plastic Pipe and Fittings Used in Pressure

control program are recommended in Appendix X3.

Applications

1.4 The following precautionary caveat pertains only to the

D4181 Classification forAcetal (POM) Molding and Extru-

test method portion, Section 7, of this specification: This

3

sion Materials

standard does not purport to address all of the safety concerns,

F412 Terminology Relating to Plastic Piping Systems

if any, associated with its use. It is the responsibility of the user

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 10, 1996. Published November 1996. Originally the ASTM website.

3

publishedasD3309 – 74.LastpreviouseditionD3309 – 96a.DOI:10.1520/D3309- Withdrawn. The last approved version of this historical standard is referenced

96AR02. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3309 – 96a (2002)

F699 PracticeforAcceleratedConditio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.