ASTM D2774-21a

(Practice)Standard Practice for Underground Installation of Thermoplastic Pressure Piping

Standard Practice for Underground Installation of Thermoplastic Pressure Piping

SIGNIFICANCE AND USE

4.1 This practice may not apply to products which shall be subject to failure at relatively low strains. For low ductility materials, the installed pipe/soil system shall be sufficiently rigid to prevent pipe deformations which could strain the piping material beyond its safe strain limit.

SCOPE

1.1 This practice governs procedures and references ASTM specifications for underground installation of thermoplastic pressure piping, 63 in. (1372 mm) nominal size and smaller. It is beyond the scope of this practice to describe these procedures in detail since it is recognized that significant differences exist in their implementation depending on kind and type of pipe material, pipe size and wall thickness, soil conditions, and the specific end use.

1.1.1 This practice assumes that over the range of anticipated operating conditions, including maximum external loading and minimum internal pressure, the soil/pipe system will offer sufficient structural stability to resist possible excessive diametrical deformation, or even collapse. In cases, particularly with large diameter thinner-walled pipe, for which the validity of this assumption may be in question, the selection of pipe and recommended installation conditions shall be determined by a qualified engineer.

1.1.2 Specific pipe characteristics and end-use requirements shall dictate addition to, or modification of the procedures stated or referenced herein.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Sections 10 and 11.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2774 − 21a An American National Standard

Standard Practice for

1

Underground Installation of Thermoplastic Pressure Piping

This standard is issued under the fixed designation D2774; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Ingeneral,thermoplasticspressurepipingmaterialsbehaveasductilematerialsunderload,meaning

thattheycanundergoconsiderabledeformationwithoutdamage.Pipingmadefromsuchmaterialshas

theabilitytobendunderaloadwithoutbreakingandtodeforminotherways,whileofferingcontinued

resistance. This flexibility allows ductile thermoplastic pipe to activate through pipe deformation

lateral soil forces which create a pipe/soil system capable of safely supporting–even in pipes subject

to little or no internal pressure–the earth and superimposed loads which are encountered in most pipe

installations. However, proper installation techniques are required to ensure that the necessary support

at the bottom and passive soil pressures at the sides of the pipe are developed and maintained.

Soils in which trenches are dug shall be examined and identified and the trenches prepared and

backfilled in accordance with sound bedding procedures and this practice.

1. Scope* 1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice governs procedures and referencesASTM

responsibility of the user of this standard to establish appro-

specifications for underground installation of thermoplastic

priate safety, health, and environmental practices and deter-

pressure piping, 63 in. (1372 mm) nominal size and smaller. It

mine the applicability of regulatory limitations prior to use.

is beyond the scope of this practice to describe these proce-

Specific precautionary statements are given in Sections 10 and

dures in detail since it is recognized that significant differences

11.

exist in their implementation depending on kind and type of

1.4 This international standard was developed in accor-

pipe material, pipe size and wall thickness, soil conditions, and

dance with internationally recognized principles on standard-

the specific end use.

ization established in the Decision on Principles for the

1.1.1 This practice assumes that over the range of antici-

Development of International Standards, Guides and Recom-

pated operating conditions, including maximum external load-

mendations issued by the World Trade Organization Technical

ing and minimum internal pressure, the soil/pipe system will

Barriers to Trade (TBT) Committee.

offer sufficient structural stability to resist possible excessive

diametrical deformation, or even collapse. In cases, particu-

2. Referenced Documents

larly with large diameter thinner-walled pipe, for which the

2

2.1 ASTM Standards:

validity of this assumption may be in question, the selection of

D1600 Terminology forAbbreviatedTerms Relating to Plas-

pipe and recommended installation conditions shall be deter-

tics

mined by a qualified engineer.

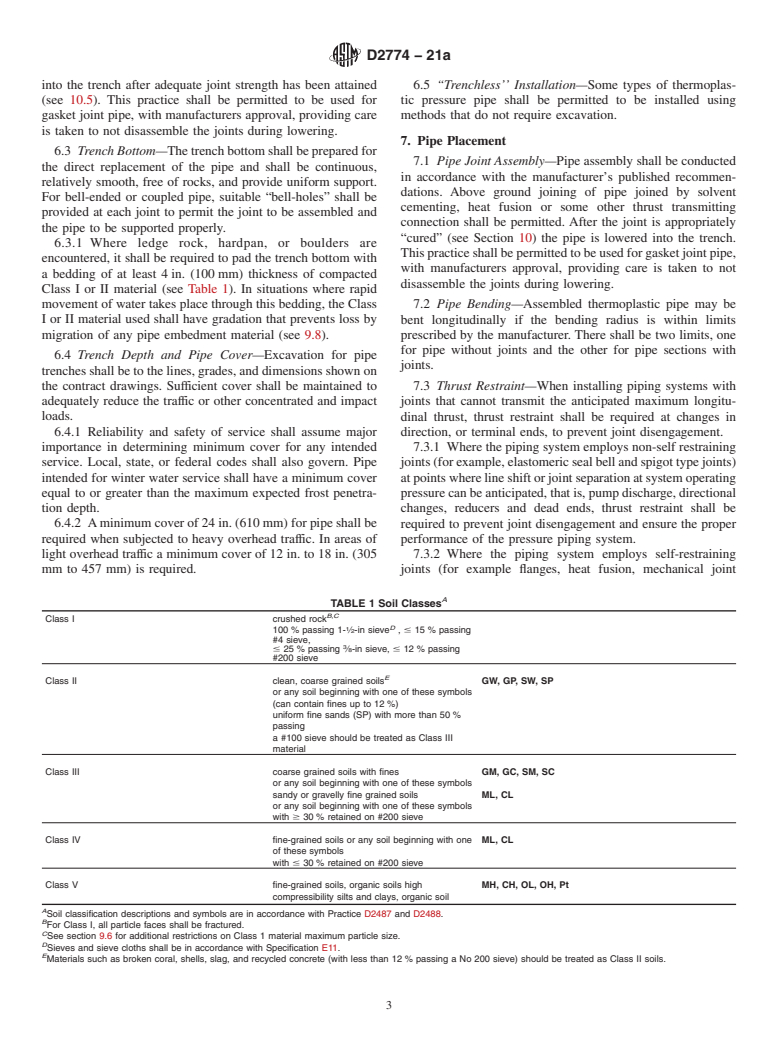

D2487 Practice for Classification of Soils for Engineering

1.1.2 Specific pipe characteristics and end-use requirements

Purposes (Unified Soil Classification System)

shall dictate addition to, or modification of the procedures

D2488 Practice for Description and Identification of Soils

stated or referenced herein.

(Visual-Manual Procedures)

1.2 The values stated in inch-pound units are to be regarded

E11 Specification for Woven Wire Test Sieve Cloth and Test

as standard. The values given in parentheses are mathematical

Sieves

conversions to SI units that are provided for information only

F412 Terminology Relating to Plastic Piping Systems

and are not considered standard.

F1668 Guide for Construction Procedures for Buried Plastic

Pipe

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2021. Published October 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2021 as D2774 – 21. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2774-21A. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2774 − 21 D2774 − 21a An American National Standard

Standard Practice for

1

Underground Installation of Thermoplastic Pressure Piping

This standard is issued under the fixed designation D2774; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

In general, thermoplastics pressure piping materials behave as ductile materials under load, meaning

that they can undergo considerable deformation without damage. Piping made from such materials has

the ability to bend under a load without breaking and to deform in other ways, while offering continued

resistance. This flexibility allows ductile thermoplastic pipe to activate through pipe deformation

lateral soil forces which create a pipe/soil system capable of safely supporting–even in pipes subject

to little or no internal pressure–the earth and superimposed loads which are encountered in most pipe

installations. However, proper installation techniques are required to ensure that the necessary support

at the bottom and passive soil pressures at the sides of the pipe are developed and maintained.

Soils in which trenches are dug shall be examined and identified and the trenches prepared and

backfilled in accordance with sound bedding procedures and this practice.

1. Scope*

1.1 This practice governs procedures and references ASTM specifications for underground installation of thermoplastic pressure

piping, 63 in. (1372 mm) nominal size and smaller. It is beyond the scope of this practice to describe these procedures in detail

since it is recognized that significant differences exist in their implementation depending on kind and type of pipe material, pipe

size and wall thickness, soil conditions, and the specific end use.

1.1.1 This practice assumes that over the range of anticipated operating conditions, including maximum external loading and

minimum internal pressure, the soil/pipe system will offer sufficient structural stability to resist possible excessive diametrical

deformation, or even collapse. In cases, particularly with large diameter thinner-walled pipe, for which the validity of this

assumption may be in question, the selection of pipe and recommended installation conditions shall be determined by a qualified

engineer.

1.1.2 Specific pipe characteristics and end-use requirements shall dictate addition to, or modification of the procedures stated or

referenced herein.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific precautionary statements are given in Sections 10 and 11.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

Current edition approved March 1, 2021July 1, 2021. Published March 2021October 2021. Originally approved in 1969. Last previous edition approved in 20202021 as

D2774 – 20.D2774 – 21. DOI: 10.1520/D2774-21.10.1520/D2774-21A.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2774 − 21a

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2487 Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)

D2488 Practice for Description and Identification of Soils (Visual-Manual Procedures)

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

F412 Terminology Relatin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.