ASTM F2676-16

(Test Method)Standard Test Method for Determining the Protective Performance of an Arc Protective Blanket for Electric Arc Hazards

Standard Test Method for Determining the Protective Performance of an Arc Protective Blanket for Electric Arc Hazards

SIGNIFICANCE AND USE

5.1 This test method determines the effectiveness of arc protective blankets in suprressing the combined effects of an arc flash and arc blast.

5.2 The arc exposure energy is produced from controlled phase-to-ground arc fault. The resulting arc flash and blast energy are intentionally directed onto the test specimen to simulate worst case conditions.

5.3 Test results will describe the maximum arc current and product of arc current and cycles at which test specimens block the energy without breakopen, ability to self-extinguish afterflaming, afterflame time and the detection of mechanical attachment failures during testing. Mechanical attachment failure and afterflame time are obtained from visual observations and video recording after each arc exposure.

5.4 This test method maintains the arc protective blanket in a vertical position and does not involve movement except that resulting from the arc exposure.

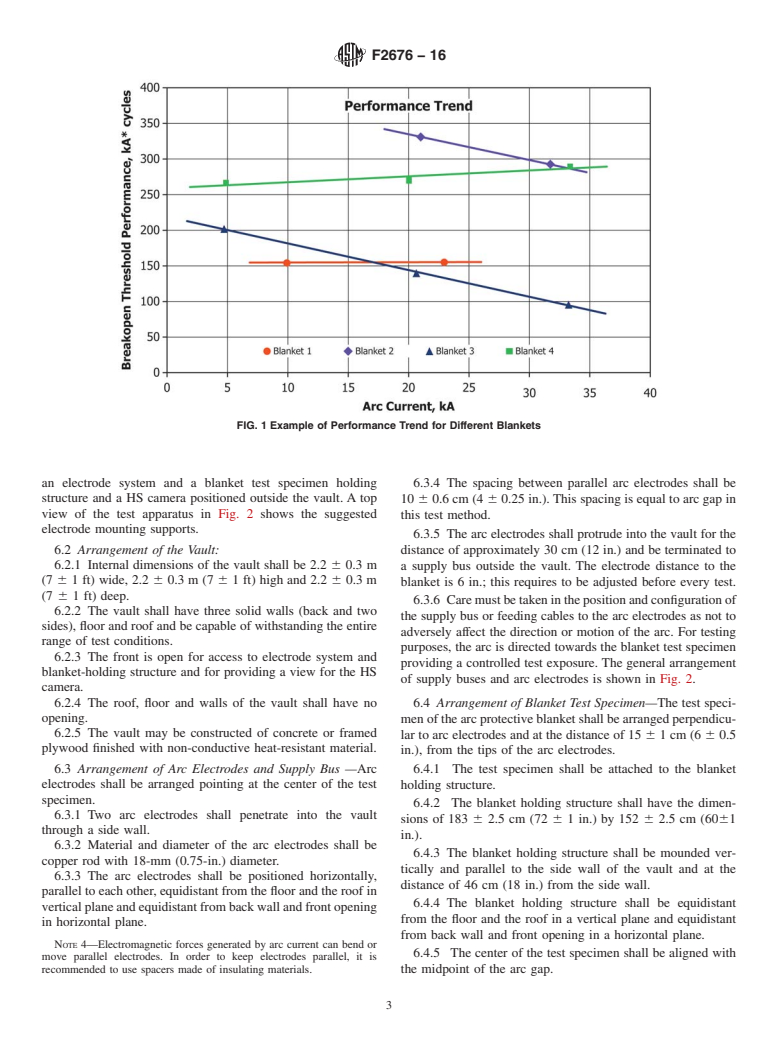

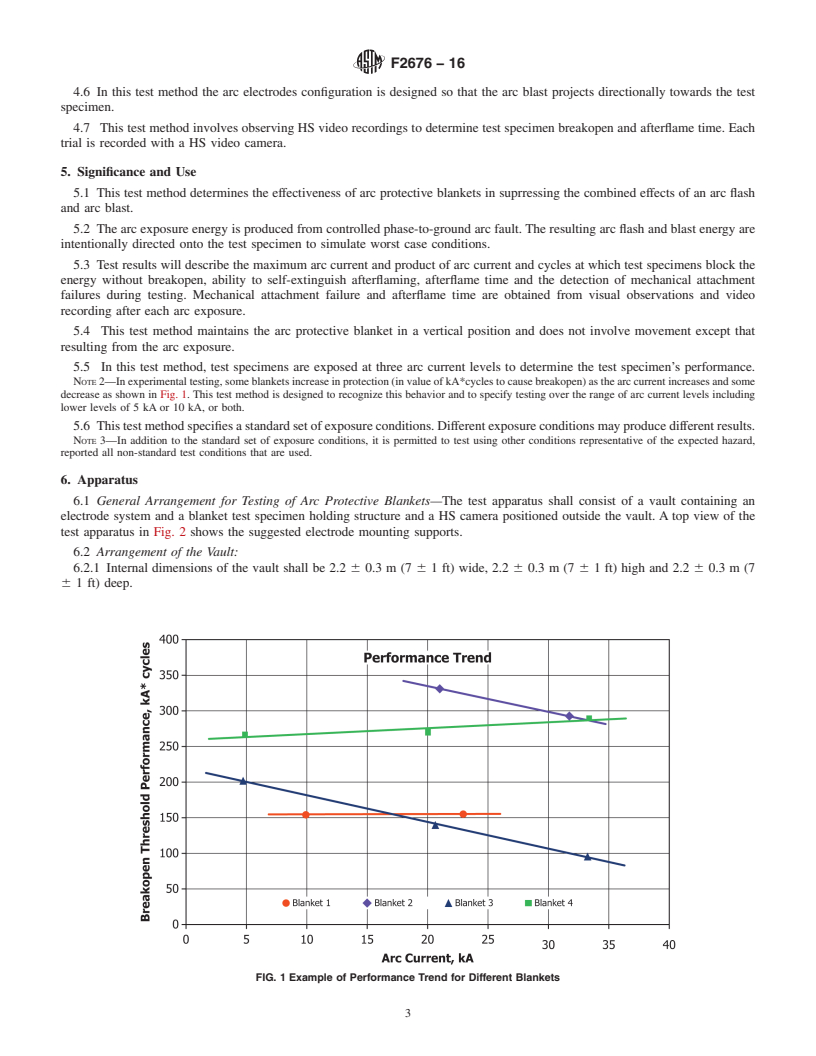

5.5 In this test method, test specimens are exposed at three arc current levels to determine the test specimen’s performance.

Note 2: In experimental testing, some blankets increase in protection (in value of kA*cycles to cause breakopen) as the arc current increases and some decrease as shown in Fig. 1. This test method is designed to recognize this behavior and to specify testing over the range of arc current levels including lower levels of 5 kA or 10 kA, or both.

5.6 This test method specifies a standard set of exposure conditions. Different exposure conditions may produce different results.

Note 3: In addition to the standard set of exposure conditions, it is permitted to test using other conditions representative of the expected hazard, reported all non-standard test conditions that are used.

SCOPE

1.1 This test method is used to evaluate the ability of the arc protective blankets to withstand the effects of arc flash and arc blast in a configuration in which the blanket is hung or anchored near energized equipment. Specifically, this test method is used to determine the arc protective blanket’s (1) resistance to breakopen, (2) mechanical strength, and (3) ability to self-extinguish flames following a controlled arc exposure.

1.2 This method is used to determine the performance of arc protective blankets in terms of: maximum arc current level expressed in kA and BTP (BTP) expressed as the product of arc current in kA and arc duration in number of cycles to cause breakopen (kA*cycles). Cycles are on the basis of 60 Hz.

1.3 Blanket test specimens used in this test method are test size blankets of 152 ± 5 cm (60 ± 2 in.) by 122 ± 5 cm (48 ± 2 in.). The test specimen size is for testing purposes only. Commercially available arc protective blankets either larger or smaller than the test specimen size are covered by this standard.

1.4 The arc protective blankets described in this test method are made of flame-resistant materials and are available in varying sizes and configurations based on the application.

1.5 This test method shall be used to measure and describe the properties of materials, products, or assemblies in response to incident thermal (convective and radiant) and pressure energies generated by an electric arc under controlled laboratory conditions.

1.6 The values stated in SI units shall be regarded as standard. The values given in parentheses are mathematical conversion to inch-pound or other units commonly used for arc testing.

1.7 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire assessment, which takes into account all of the factors, which are pertinent to an assessment of the fire hazard of a particular end use.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this stan...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2676 − 16

Standard Test Method for

Determining the Protective Performance of an Arc

1

Protective Blanket for Electric Arc Hazards

This standard is issued under the fixed designation F2676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope under actual fire conditions. However, results of this test may

be used as elements of a fire assessment, which takes into

1.1 Thistestmethodisusedtoevaluatetheabilityofthearc

account all of the factors, which are pertinent to an assessment

protective blankets to withstand the effects of arc flash and arc

of the fire hazard of a particular end use.

blast in a configuration in which the blanket is hung or

1.8 This standard does not purport to address all of the

anchored near energized equipment. Specifically, this test

safety concerns, if any, associated with its use. It is the

method is used to determine the arc protective blanket’s (1)

responsibility of the user of this standard to establish appro-

resistance to breakopen, (2) mechanical strength, and (3)

priate safety and health practices and determine the applica-

ability to self-extinguish flames following a controlled arc

bility of regulatory limitations prior to use. For specific

exposure.

precautions, see Section 7.

1.2 This method is used to determine the performance of

arc protective blankets in terms of: maximum arc current level

2. Referenced Documents

expressedinkAandBTP(BTP)expressedastheproductofarc

2

2.1 ASTM Standards:

current in kA and arc duration in number of cycles to cause

D4391 Terminology Relating to The Burning Behavior of

breakopen (kA*cycles). Cycles are on the basis of 60 Hz.

Textiles

1.3 Blanket test specimens used in this test method are test

F819 Terminology Relating to Electrical Protective Equip-

size blankets of 152 65cm(60 6 2 in.) by 122 65cm(48

ment for Workers

6 2 in.). The test specimen size is for testing purposes only.

3. Terminology

Commercially available arc protective blankets either larger or

smaller than the test specimen size are covered by this

3.1 Definitions:

standard.

3.1.1 arc, n—conductive path in air for the electric current

caused by ionization of air between two electrodes.

1.4 The arc protective blankets described in this test method

are made of flame-resistant materials and are available in

3.1.2 arc induced fragmentation, n—molten metal frag-

varying sizes and configurations based on the application.

ments or other fragments emitted from an electric arc.

1.5 This test method shall be used to measure and describe

3.1.3 arc protective blanket, n—a flat assembly of fabric(s)

the properties of materials, products, or assemblies in response

with locations for attachment used to protect workers from the

to incident thermal (convective and radiant) and pressure

effects of arc flash and arc blast.

energies generated by an electric arc under controlled labora-

3.1.4 arc protective blanket maximum arc current I ,

max

tory conditions.

n—maximum value of RMS arc current that blanket can

1.6 The values stated in SI units shall be regarded as withstand without breakopen for no less than ten cycles of 60

Hz.

standard. The values given in parentheses are mathematical

conversiontoinch-poundorotherunitscommonlyusedforarc 3.1.4.1 Discussion—Standard values of the maximum arc

current for this test method are 15 kA, 25 kA, or 40 kA.

testing.

3.1.5 arc protective blanket breakopen threshold perfor-

1.7 This standard shall not be used to describe or appraise

mance (BTP) , n—the product of the arc current I, kA and arc

the fire hazard or fire risk of materials, products, or assemblies

duration in cycles required for breakopen to occur at this same

arc current level.

1

This test method is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

2

Subcommittee F18.65 on Wearing Apparel. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2016. Published April 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2009. Last previous edition approved in 2009 as F2676-09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2676-16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2676 − 16

3.1.6 breakopen, n—in electrical arc testing, a material 4.3 Three nominal values of I are established in this test

max

response evidence

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2676 − 09 F2676 − 16

Standard Test Method for

Determining the Protective Performance of an Arc

1

Protective Blanket for Electric Arc Hazards

This standard is issued under the fixed designation F2676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is used to evaluate the ability of the arc protective blankets to withstand the effects of arc flash and arc

blast in a configuration in which the blanket is hung or anchored near energized equipment. Specifically, this test method is used

to determine the arc protective blanket’s (1) resistance to breakopen, (2) mechanical strength, and (3) ability to self-extinguish

flames following a controlled arc exposure.

1.2 This method is used to determine the performance of arc protective blankets in terms of: maximum arc current level

expressed in kA and BTP (BTP) expressed as the product of arc current in kA and arc duration in number of cycles to cause

breakopen (kA*cycles). Cycles are on the basis of 60 Hz.

1.3 Blanket test specimens used in this test method are test size blankets of 152 6 5 cm (60 6 2 in.) by 122 6 5 cm (48 6

2 in.). The test specimen size is for testing purposes only. Commercially available arc protective blankets either larger or smaller

than the test specimen size are covered by this standard.

1.4 The arc protective blankets described in this test method are made of flame-resistant materials and are available in varying

sizes and configurations based on the application.

1.5 This test method shall be used to measure and describe the properties of materials, products, or assemblies in response to

incident thermal (convective and radiant) and pressure energies generated by an electric arc under controlled laboratory conditions.

1.6 The values stated in SI units shall be regarded as standard. The values given in parentheses are mathematical conversion

to inch-pound or other units commonly used for arc testing.

1.7 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under

actual fire conditions. However, results of this test may be used as elements of a fire assessment, which takes into account all of

the factors, which are pertinent to an assessment of the fire hazard of a particular end use.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautions, see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D4391 Terminology Relating to The Burning Behavior of Textiles

F819 Terminology Relating to Electrical Protective Equipment for Workers

3. Terminology

3.1 Definitions:

3.1.1 arc, n—conductive path in air for the electric current caused by ionization of air between two electrodes.

3.1.2 arc induced fragmentation, n—molten metal fragments or other fragments emitted from an electric arc.

1

This test method is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.65 on Wearing Apparel.

Current edition approved May 1, 2009April 1, 2016. Published June 2009April 2016. Originally approved in 2009. Last previous edition approved in 2009 as F2676-09.

DOI: 10.1520/F2676-09.10.1520/F2676-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2676 − 16

3.1.3 arc protective blanket, n—a flat assembly of fabric(s) with locations for attachment used to protect workers from the

effects of arc flash and arc blast.

3.1.4 arc protective blanket maximum arc current I ,n—maximum value of RMS arc current that blanket can withstand

max

without breakopen for no less than ten cycles of 60 Hz.

3.1.4.1 Discussion—

Standard values of the maximum arc current for this test method are 15 kA, 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.