ASTM F1741-08(2016)

(Practice)Standard Practice for Installation of Machine Spiral Wound Poly (Vinyl Chloride) (PVC) Liner Pipe for Rehabilitation of Existing Sewers and Conduits

Standard Practice for Installation of Machine Spiral Wound Poly (Vinyl Chloride) (PVC) Liner Pipe for Rehabilitation of Existing Sewers and Conduits

SIGNIFICANCE AND USE

4.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the rehabilitation of non-pressure sewers and conduits. Modifications may be required for specific job conditions.

SCOPE

1.1 This practice describes the procedures for the rehabilitation of sewer lines and conduits for existing pipelines 6 to 180 in. in diameter by the insertion of a machine-made field-fabricated spiral wound liner pipe into the existing pipeline using a winding machine which remains stationary in the insertion pit or, alternatively, which travels along the interior of the existing pipeline. These rehabilitation processes can be used in a variety of gravity applications such as sanitary sewers, storm sewers, culverts, and process piping.

1.1.1 When using stationary installation equipment for existing pipelines 6 to 48 in., after insertion, the spiral wound liner pipe is expanded until it presses against the interior surface of the existing pipeline. Alternatively, for existing pipelines 6 to 108 in. in diameter, the spiral wound liner pipe is inserted as a fixed diameter into the existing pipeline and is not expanded, and the annular space between the spiral wound liner pipe and the existing pipe is grouted.

1.1.2 When using the traveling installation equipment for existing pipelines 6 to 180 in. the spiral wound liner pipe is installed in contact with the interior surface of the existing pipeline to form a close fit liner, except in the corners of rectangular pipes or where obstructions or offsets occur. Alternatively, for existing pipelines 6 to 180 in. in diameter and for similar sized existing non circular pipelines such as arched or oval or rectangular shapes, the spiral wound liner is installed as a fixed diameter into the exiting pipeline to form a non-close fit liner and the annular space between the spiral wound liner pipe and the existing pipe is grouted.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3.1 Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined spaces.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1741 −08 (Reapproved 2016)

Standard Practice for

Installation of Machine Spiral Wound Poly (Vinyl Chloride)

(PVC) Liner Pipe for Rehabilitation of Existing Sewers and

Conduits

This standard is issued under the fixed designation F1741; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice describes the procedures for the rehabili-

responsibility of the user of this standard to establish appro-

tation of sewer lines and conduits for existing pipelines 6 to

priate safety and health practices and determine the applica-

180 in. in diameter by the insertion of a machine-made

bility of regulatory limitations prior to use.

field-fabricated spiral wound liner pipe into the existing

1.3.1 Particular attention is drawn to those safety regula-

pipeline using a winding machine which remains stationary in

tions and requirements involving entering into and working in

the insertion pit or, alternatively, which travels along the

confined spaces.

interior of the existing pipeline. These rehabilitation processes

canbeusedinavarietyofgravityapplicationssuchassanitary

2. Referenced Documents

sewers, storm sewers, culverts, and process piping.

2.1 ASTM Standards:

1.1.1 When using stationary installation equipment for ex-

C39/C39MTest Method for Compressive Strength of Cylin-

isting pipelines 6 to 48 in., after insertion, the spiral wound

drical Concrete Specimens

liner pipe is expanded until it presses against the interior

C109/C109MTest Method for Compressive Strength of

surface of the existing pipeline. Alternatively, for existing

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

pipelines 6 to 108 in. in diameter, the spiral wound liner pipe

Specimens)

is inserted as a fixed diameter into the existing pipeline and is

C495Test Method for Compressive Strength of Lightweight

not expanded, and the annular space between the spiral wound

Insulating Concrete

liner pipe and the existing pipe is grouted.

D883Terminology Relating to Plastics

1.1.2 When using the traveling installation equipment for

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

existing pipelines 6 to 180 in. the spiral wound liner pipe is

tics

installed in contact with the interior surface of the existing

F412Terminology Relating to Plastic Piping Systems

pipeline to form a close fit liner, except in the corners of

F1417Practice for Installation Acceptance of Plastic Non-

rectangular pipes or where obstructions or offsets occur.

pressure Sewer Lines Using Low-Pressure Air

Alternatively,forexistingpipelines6to180in.indiameterand

F1697Specification for Poly(Vinyl Chloride) (PVC) Profile

for similar sized existing non circular pipelines such as arched

StripforMachineSpiral-WoundLinerPipeRehabilitation

orovalorrectangularshapes,thespiralwoundlinerisinstalled

of Existing Sewers and Conduit

asafixeddiameterintotheexitingpipelinetoformanon-close

2.2 Uni-Bell Standard:

fit liner and the annular space between the spiral wound liner

UNI-B-5-89 Recommended Practice for the Installation of

pipe and the existing pipe is grouted. 3

PVC Sewer Pipe

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

3. Terminology

as standard. The values given in parentheses are mathematical

3.1 General—DefinitionsareinaccordancewithTerminolo-

conversions to SI units that are provided for information only

and are not considered standard. gies D883 and F412. Abbreviations are in accordance with

Terminology D1600, unless otherwise indicated.

1 2

This practice is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.67 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Trenchless Plastic Pipeline Technology. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2016. Published May 2016. Originally the ASTM website.

approved in 1996. Last previous edition approved in 2008 as F1741–08. DOI: Available from Uni-Bell, 2655Villa Creek Drive, Suite 155, DallasTX 75234.

10.1520/F1741-08R16.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1741−08 (2016)

3.2 Definitions of Terms Specific to This Standard: 5.2 The profile strip should be coiled onto a reel in a

3.2.1 extruded PVC profile strip—a product available in continuous length for storage and shipping to the job site.

various widths, consisting of a smooth inside surface and a Handling and storage should be in accordance with the

ribbedoutersurfacewithmechanicallylockedmaleandfemale manufacturer’s published recommendations.

edges which are self interlocking, or separate locking strips

5.3 The adhesive or sealants, or both, used with the male

which serve the same purposeTypeAandType B are different

and female mechanical locking elements should be compatible

profiles and are installed by different installation methods. See

with the PVC compound and the spiral wound liner pipe

Fig. 1 and Table 1 for TypeAand Fig. 2 and Table 2 for Type

process so as not to affect the properties of the spiral wound

B. See Fig. 1 and Fig. 3 for installation method forTypeAand

finished liner pipe.

Fig. 2 and Fig. 4 for installation method for Type B.

5.4 Thesteelreinforcingstripsshallbeusedtoreinforcethe

3.2.2 insertion point—an existing manhole, existing access

extruded PVC profile strip, where the design conditions re-

shaft,orexcavatedpitthatservesasthepointwhereawinding

quires additional stiffness, such as for non-circular shaped

machine field fabricates the spiral wound liner pipe and

pipes.

simultaneously inserts the spiral wound liner pipe into the

existing pipeline.

6. Installation Recommendations

3.2.3 non-circular pipe—arched, oval or rectangular or a

6.1 Cleaning and Inspection:

combination thereof.

6.1.1 Prior to entering access areas such as manholes and

3.2.4 production run—a continuous extrusion of a given

performing inspection or cleaning operations, an evaluation of

profile type.

theatmospheretodeterminethepresenceoftoxicorflammable

3.2.5 spiral wound liner pipe—a product field fabricated

vapors or lack of oxygen must be undertaken in accordance

from extruded PVC profile strip to a round shape, or noncir-

with local, state, or federal safety regulations .

cularshape,suchasarchedorovalorrectangular.(SeeFig.5.)

6.1.2 Cleaning of Pipeline—Internal debris should be re-

moved from the existing pipeline. Gravity pipes should be

3.2.6 steel reinforcement— a shaped steel strip or clip

cleaned with hydraulically powered equipment, high-velocity

insertedintotheinsideofthePVCprofiletoprovideadditional

jetcleaners,ormechanicallypoweredequipmentinaccordance

reinforcement and stiffening. (See Fig. 3 and Fig. 4.)

with NASSCO recommended specifications.

3.2.7 termination point—an existing manhole, existing ac-

6.1.3 Inspection of Pipelines—Inspection of pipelines

cessshaft,oranexcavatedpitthatservesasthepointofexitof

should be performed by experienced personnel trained in

the spiral wound liner pipe from the existing pipe.

locating breaks, obstacles, and service connections by closed-

circuit television or by direct visual inspection. The interior of

4. Significance and Use

the pipeline should be carefully inspected to determine the

4.1 This practice is for use by designers and specifiers,

location of any conditions that may prevent proper installation

regulatory agencies, owners, and inspection organizations who

of the spiral wound liner pipe, such as protruding service taps,

are involved in the rehabilitation of non-pressure sewers and

collapsed or crushed pipe, out-of-roundness, significant line

conduits. Modifications may be required for specific job

sags, and deflected joints. These conditions should be noted

conditions.

and corrected, if necessary, prior to installation.

6.1.4 Line Obstructions—The existing pipeline should be

5. Materials

clear of obstructions that will prevent the proper insertion, and

5.1 The extruded profile strip used for the field fabrication expansion if required, of the spiral wound liner pipe. Obstruc-

of spiral wound liner pipe shall be in accordance with tions could include dropped or offset joints of more than

Specification F1697. 12.5% of inside pipe diameter, service connections that

NOTE 1—For values of width, height, and waterway minimum wall, see Table 1.

FIG. 1Type A-Typical PVC Profile Strip

F1741−08 (2016)

TABLE 1 Type A Typical Profile Strip Moments of Inertia and Stiffness Factors

C

Moment of Inertia, I Depth to Neutral Axis, y¯ Minimum Height, H Profile Area Minimum Stiffness Factor, EI

AB

Profile Type

4 4 2 2 3 2 3

in. /in. (mm /m) in. (mm) in. (mm) in. /in. (mm /mm) in. ·lbf/in. (MPa·mm )

1 0.00047 ( 7.70) 0.077 (1.98) 0.216 ( 5.5) 0.118 (3.00) 188.0 ( 21.2× 10 )

2 0.00140 ( 23.00) 0.130 (3.30) 0.314 ( 8.0) 0.146 (3.70) 561 ( 63.4× 10 )

3 0.00537 (88.00) 0.206 (5.24) 0.511 (13.0) 0.205 (5.20) 2148 (242.7 × 10 )

4 0.00386 ( 63.30) 0.200 (5.08) 0.480 (12.2) 0.125 (3.18) 1600.0 (180.8 × 10 )

5 0.00400 ( 65.50) 0.180 (4.57) 0.488 (12.4) 0.125 (3.18) 1600.0 (180.8 × 10 )

6 0.00400 ( 65.50) 0.180 (4.57) 0.488 (12.4) 0.125 (3.18) 1600.0 (180.8 × 10 )

A

Other profiles, possibly using supplementary stiffener elements, may be available. Consult the manufacturer.

B

The spacing of the ribs may vary for each profile type.

C

Stiffness factors listed are the minimum values that will be provided by the manufacturer for the given profile type.

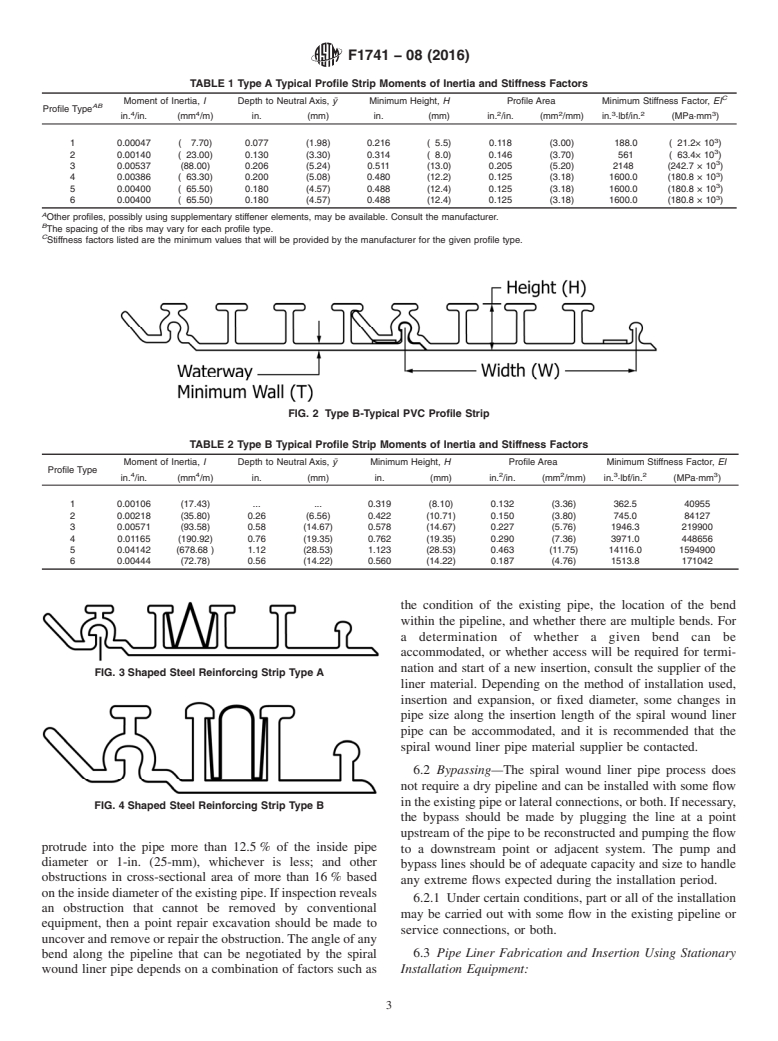

FIG. 2 Type B-Typical PVC Profile Strip

TABLE 2 Type B Typical Profile Strip Moments of Inertia and Stiffness Factors

Moment of Inertia, I Depth to Neutral Axis, y¯ Minimum Height, H Profile Area Minimum Stiffness Factor, EI

Profile Type

4 4 2 2 3 2 3

in. /in. (mm /m) in. (mm) in. (mm) in. /in. (mm /mm) in. ·lbf/in. (MPa·mm )

1 0.00106 (17.43) . . 0.319 (8.10) 0.132 (3.36) 362.5 40955

2 0.00218 (35.80) 0.26 (6.56) 0.422 (10.71) 0.150 (3.80) 745.0 84127

3 0.00571 (93.58) 0.58 (14.67) 0.578 (14.67) 0.227 (5.76) 1946.3 219900

4 0.01165 (190.92) 0.76 (19.35) 0.762 (19.35) 0.290 (7.36) 3971.0 448656

5 0.04142 (678.68 ) 1.12 (28.53) 1.123 (28.53) 0.463 (11.75) 14116.0 1594900

6 0.00444 (72.78) 0.56 (14.22) 0.560 (14.22) 0.187 (4.76) 1513.8 171042

the condition of the existing pipe, the location of the bend

within the pipeline, and whether there are multiple bends. For

a determination of whether a given bend can be

accommodated, or whether access will be required for termi-

nation and start of a new insertion, consult the supplier of the

FIG. 3Shaped Steel Reinforcing Strip Type A

liner material. Depending on the method of installation used,

insertion and expansion, or fixed diameter, some changes in

pipe size along the insertion length of the spiral wound liner

pipe can be accommodated, and it is recommended that the

spiral wound liner pipe material supplier be contacted.

6.2 Bypassing—The spiral wound liner pipe process does

not require a dry pipeline and can be installed with some flow

intheexistingpipeorlateralconnections,orboth.Ifnecessary,

FIG. 4Shaped Steel Reinforcing Strip Type B

the bypass should be made by plugging the line at a point

upstream of the pipe to be reconstructed and pumping the flow

protrude into the pipe more than 12.5% of the inside pipe

to a downstream point or adjacent system. The pump and

diameter or 1-in. (25-mm), whichever is less; and other

bypass lines should be of adequate capacity and size to handle

obstructions in cross-sectional area of more than 16% based

any extreme flows expected during the installation period.

ontheinsidediameteroftheexistingpipe.Ifinspectionreveals

6.2.1 Under certain conditions, part or all of the installation

an obstruction that cannot be removed by conventional

may be carried out with some flow in the existing pipeline or

equipment, then a point repair excavation should be made to

service connections, or both.

uncoverandremoveorrepairtheobstruction.Theangleofany

6.3 Pipe Liner Fabrication and Insertion Using Stationary

bend along the pipeline that can be negotiated by the spiral

wound liner pipe depends on a combination of factors such as Installation Equipment:

F1741−08 (2016)

FIG. 5 Typical Spiral Wound Liner Pipe

6.3.1 A winding machine should be placed in the insertion 6), thus releasing the profile strip to slide freely along the

pitandorientedsothatthelinerpipecanbespirallywoundand primary rock when a torque is applied to the inserted spiral

inserted(rotatedandpushed)directlyintotheexistingpipeline. wound liner pipe. The winding operation should be

Areel of extruded PVC profile strip should be positioned near

recommenced,therebycreatingatorquewhichisappliedtothe

the insertion point.The initial winding process begins with the released end, thus causing a radial growth or expansion over

profile strip being fed into the winding machine, forming the

the released length of the spiral wound liner pipe. The initial

profile strip into the required spiral wound liner pipe diameter,

radialgrowthshouldbepermittedtocontinueuntilthereleased

which is simultaneously rotated and pushed along the existing

end of the spiral wound liner pipe is pressed against the

pipeline for its full length to the termination point. As the

existing pipeline (see Fig. 6), thus halting radially growth and

profile strip is formed into a spiral, wound liner pipe in the

torsionally restraining the spiral wound liner pipe. Subsequent

winding machine, the required sealant or adhesive, or both

secondary lock release and winding should continue until the

unless already in place, shall be placed within the primary and

spiral wound liner pipe is pressed against the full length of the

secondary locks of the locking configuration at the edge of the

existing pipe. The annular space between the expanded spiral

profile strip, and wire is placed between the primary and

wound liner pipe and the existing pipeline should be sealed at

secondary locks of the locking configuration when the spiral

the ends with a sealing material that is compatible with the

wound liner pipe is to be expanded (see Fig. 6 and Fig. 7).

spiral wound liner pipe material.

6.3.2 Whenthespiralwoundlinerpipeistobeexpandedas

6.4 Pipe Liner Fabrication Using Traveling Installati

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1741 − 08 F1741 − 08 (Reapproved 2016)

Standard Practice for

Installation of Machine Spiral Wound Poly (Vinyl Chloride)

(PVC) Liner Pipe for Rehabilitation of Existing Sewers and

Conduits

This standard is issued under the fixed designation F1741; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice describes the procedures for the rehabilitation of sewer lines and conduits for existing pipelines 6 to 180 in.

in diameter by the insertion of a machine-made field-fabricated spiral wound liner pipe into the existing pipeline using a winding

machine which remains stationary in the insertion pit or, alternatively, which travels along the interior of the existing pipeline.

These rehabilitation processes can be used in a variety of gravity applications such as sanitary sewers, storm sewers, culverts, and

process piping.

1.1.1 When using stationary installation equipment for existing pipelines 6 to 48 in., after insertion, the spiral wound liner pipe

is expanded until it presses against the interior surface of the existing pipeline. Alternatively, for existing pipelines 6 to 108 in. in

diameter, the spiral wound liner pipe is inserted as a fixed diameter into the existing pipeline and is not expanded, and the annular

space between the spiral wound liner pipe and the existing pipe is grouted.

1.1.2 When using the traveling installation equipment for existing pipelines 6 to 180 in. the spiral wound liner pipe is installed

in contact with the interior surface of the existing pipeline to form a close fit liner, except in the corners of rectangular pipes or

where obstructions or offsets occur. Alternatively, for existing pipelines 6 to 180 in. in diameter and for similar sized existing non

circular pipelines such as arched or oval or rectangular shapes, the spiral wound liner is installed as a fixed diameter into the exiting

pipeline to form a non-close fit liner and the annular space between the spiral wound liner pipe and the existing pipe is grouted.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.3.1 Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined

spaces.

2. Referenced Documents

2.1 ASTM Standards:

C39/C39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C495 Test Method for Compressive Strength of Lightweight Insulating Concrete

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

F412 Terminology Relating to Plastic Piping Systems

F1417 Practice for Installation Acceptance of Plastic Non-pressure Sewer Lines Using Low-Pressure Air

F1697 Specification for Poly(Vinyl Chloride) (PVC) Profile Strip for Machine Spiral-Wound Liner Pipe Rehabilitation of

Existing Sewers and Conduit

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 on Trenchless Plastic

Pipeline Technology.

Current edition approved Nov. 1, 2008May 1, 2016. Published December 2008May 2016. Originally approved in 1996. Last previous edition approved in 20072008 as

F1741–07.–08. DOI: 10.1520/F1741-08.10.1520/F1741-08R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1741 − 08 (2016)

2.2 Uni-Bell Standard:

UNI-B-5-89 Recommended Practice for the Installation of PVC Sewer Pipe

3. Terminology

3.1 General—Definitions are in accordance with Terminologies D883 and F412. Abbreviations are in accordance with

Terminology D1600, unless otherwise indicated.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 extruded PVC profile strip—a product available in various widths, consisting of a smooth inside surface and a ribbed outer

surface with mechanically locked male and female edges which are self interlocking, or separate locking strips which serve the

same purpose Type A and Type B are different profiles and are installed by different installation methods. See Fig. 1 and Table 1

for Type A and Fig. 2 and Table 2 for Type B. See Fig. 1 and Fig. 3 for installation method for Type A and Fig. 2 and Fig. 4 for

installation method for Type B.

3.2.2 insertion point—an existing manhole, existing access shaft, or excavated pit that serves as the point where a winding

machine field fabricates the spiral wound liner pipe and simultaneously inserts the spiral wound liner pipe into the existing pipeline.

3.2.3 non-circular pipe—arched, oval or rectangular or a combination thereof.

3.2.4 production run—a continuous extrusion of a given profile type.

3.2.5 spiral wound liner pipe—a product field fabricated from extruded PVC profile strip to a round shape, or noncircular shape,

such as arched or oval or rectangular. (See Fig. 5.)

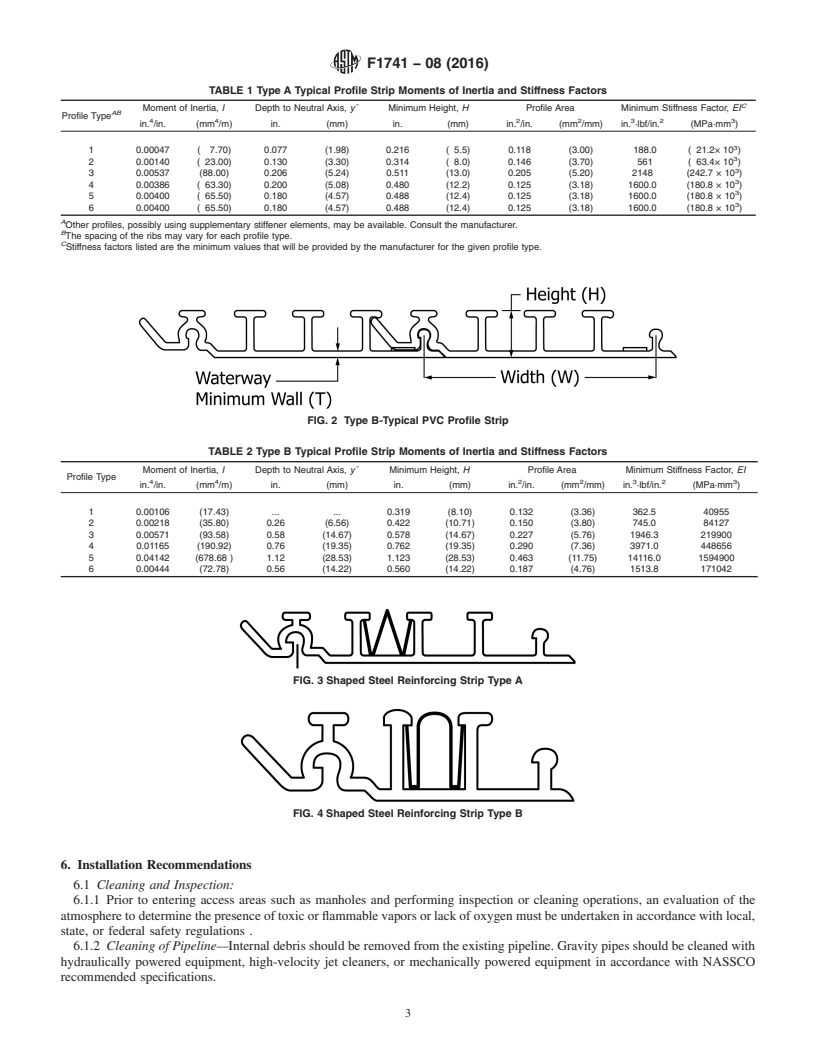

3.2.6 steel reinforcement— a shaped steel strip or clip inserted into the inside of the PVC profile to provide additional

reinforcement and stiffening. (See Fig. 3 and Fig. 4.)

3.2.7 termination point—an existing manhole, existing access shaft, or an excavated pit that serves as the point of exit of the

spiral wound liner pipe from the existing pipe.

4. Significance and Use

4.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are

involved in the rehabilitation of non-pressure sewers and conduits. Modifications may be required for specific job conditions.

5. Materials

5.1 The extruded profile strip used for the field fabrication of spiral wound liner pipe shall be in accordance with Specification

F1697.

5.2 The profile strip should be coiled onto a reel in a continuous length for storage and shipping to the job site. Handling and

storage should be in accordance with the manufacturer’s published recommendations.

5.3 The adhesive or sealants, or both, used with the male and female mechanical locking elements should be compatible with

the PVC compound and the spiral wound liner pipe process so as not to affect the properties of the spiral wound finished liner pipe.

5.4 The steel reinforcing strips shall be used to reinforce the extruded PVC profile strip, where the design conditions requires

additional stiffness, such as for non-circular shaped pipes.

Available from Uni-Bell, 2655 Villa Creek Drive, Suite 155, Dallas TX 75234.

NOTE 1—For values of width, height, and waterway minimum wall, see Table 1.

FIG. 1 Type A-Typical PVC Profile Strip

F1741 − 08 (2016)

TABLE 1 Type A Typical Profile Strip Moments of Inertia and Stiffness Factors

C

Moment of Inertia, I Depth to Neutral Axis, y¯ Minimum Height, H Profile Area Minimum Stiffness Factor, EI

AB

Profile Type

4 4 2 2 3 2 3

in. /in. (mm /m) in. (mm) in. (mm) in. /in. (mm /mm) in. ·lbf/in. (MPa·mm )

1 0.00047 ( 7.70) 0.077 (1.98) 0.216 ( 5.5) 0.118 (3.00) 188.0 ( 21.2× 10 )

2 0.00140 ( 23.00) 0.130 (3.30) 0.314 ( 8.0) 0.146 (3.70) 561 ( 63.4× 10 )

3 0.00537 (88.00) 0.206 (5.24) 0.511 (13.0) 0.205 (5.20) 2148 (242.7 × 10 )

4 0.00386 ( 63.30) 0.200 (5.08) 0.480 (12.2) 0.125 (3.18) 1600.0 (180.8 × 10 )

5 0.00400 ( 65.50) 0.180 (4.57) 0.488 (12.4) 0.125 (3.18) 1600.0 (180.8 × 10 )

6 0.00400 ( 65.50) 0.180 (4.57) 0.488 (12.4) 0.125 (3.18) 1600.0 (180.8 × 10 )

A

Other profiles, possibly using supplementary stiffener elements, may be available. Consult the manufacturer.

B

The spacing of the ribs may vary for each profile type.

C

Stiffness factors listed are the minimum values that will be provided by the manufacturer for the given profile type.

FIG. 2 Type B-Typical PVC Profile Strip

TABLE 2 Type B Typical Profile Strip Moments of Inertia and Stiffness Factors

Moment of Inertia, I Depth to Neutral Axis, y¯ Minimum Height, H Profile Area Minimum Stiffness Factor, EI

Profile Type

4 4 2 2 3 2 3

in. /in. (mm /m) in. (mm) in. (mm) in. /in. (mm /mm) in. ·lbf/in. (MPa·mm )

1 0.00106 (17.43) . . 0.319 (8.10) 0.132 (3.36) 362.5 40955

2 0.00218 (35.80) 0.26 (6.56) 0.422 (10.71) 0.150 (3.80) 745.0 84127

3 0.00571 (93.58) 0.58 (14.67) 0.578 (14.67) 0.227 (5.76) 1946.3 219900

4 0.01165 (190.92) 0.76 (19.35) 0.762 (19.35) 0.290 (7.36) 3971.0 448656

5 0.04142 (678.68 ) 1.12 (28.53) 1.123 (28.53) 0.463 (11.75) 14116.0 1594900

6 0.00444 (72.78) 0.56 (14.22) 0.560 (14.22) 0.187 (4.76) 1513.8 171042

FIG. 3 Shaped Steel Reinforcing Strip Type A

FIG. 4 Shaped Steel Reinforcing Strip Type B

6. Installation Recommendations

6.1 Cleaning and Inspection:

6.1.1 Prior to entering access areas such as manholes and performing inspection or cleaning operations, an evaluation of the

atmosphere to determine the presence of toxic or flammable vapors or lack of oxygen must be undertaken in accordance with local,

state, or federal safety regulations .

6.1.2 Cleaning of Pipeline—Internal debris should be removed from the existing pipeline. Gravity pipes should be cleaned with

hydraulically powered equipment, high-velocity jet cleaners, or mechanically powered equipment in accordance with NASSCO

recommended specifications.

F1741 − 08 (2016)

FIG. 5 Typical Spiral Wound Liner Pipe

6.1.3 Inspection of Pipelines—Inspection of pipelines should be performed by experienced personnel trained in locating breaks,

obstacles, and service connections by closed-circuit television or by direct visual inspection. The interior of the pipeline should

be carefully inspected to determine the location of any conditions that may prevent proper installation of the spiral wound liner

pipe, such as protruding service taps, collapsed or crushed pipe, out-of-roundness, significant line sags, and deflected joints. These

conditions should be noted and corrected, if necessary, prior to installation.

6.1.4 Line Obstructions—The existing pipeline should be clear of obstructions that will prevent the proper insertion, and

expansion if required, of the spiral wound liner pipe. Obstructions could include dropped or offset joints of more than 12.5 % of

inside pipe diameter, service connections that protrude into the pipe more than 12.5 % of the inside pipe diameter or 1-in. (25-mm),

whichever is less; and other obstructions in cross-sectional area of more than 16 % based on the inside diameter of the existing

pipe. If inspection reveals an obstruction that cannot be removed by conventional equipment, then a point repair excavation should

be made to uncover and remove or repair the obstruction. The angle of any bend along the pipeline that can be negotiated by the

spiral wound liner pipe depends on a combination of factors such as the condition of the existing pipe, the location of the bend

within the pipeline, and whether there are multiple bends. For a determination of whether a given bend can be accommodated, or

whether access will be required for termination and start of a new insertion, consult the supplier of the liner material. Depending

on the method of installation used, insertion and expansion, or fixed diameter, some changes in pipe size along the insertion length

of the spiral wound liner pipe can be accommodated, and it is recommended that the spiral wound liner pipe material supplier be

contacted.

6.2 Bypassing—The spiral wound liner pipe process does not require a dry pipeline and can be installed with some flow in the

existing pipe or lateral connections, or both. If necessary, the bypass should be made by plugging the line at a point upstream of

the pipe to be reconstructed and pumping the flow to a downstream point or adjacent system. The pump and bypass lines should

be of adequate capacity and size to handle any extreme flows expected during the installation period.

6.2.1 Under certain conditions, part or all of the installation may be carried out with some flow in the existing pipeline or service

connections, or both.

6.3 Pipe Liner Fabrication and Insertion Using Stationary Installation Equipment:

6.3.1 A winding machine should be placed in the insertion pit and oriented so that the liner pipe can be spirally wound and

inserted (rotated and pushed) directly into the existing pipeline. A reel of extruded PVC profile strip should be positioned near the

insertion point. The initial winding process begins with the profile strip being fed into the winding machine, forming the profile

strip into the required spiral wound liner pipe diameter, which is simultaneously rotated and pushed along the existing pipeline for

its full length to the termination point. As the profile strip is formed into a spiral, wound liner pipe in the winding machine, the

required sealant or adhesive, or both unless already in place, shall be placed within the primary and secondary locks of the locking

configuration at the edge of the profile strip, and wire is placed between the primary and secondary locks of the locking

configuration when the spiral wound liner pipe is to be expanded (see Fig. 6 and Fig. 7).

6.3.2 When the spiral wound liner pipe is to be expanded as shown in Fig. 6, the end of the spiral wound liner pipe at the

termination point should be torsionally restrained. A specific length of the inserted spiral wound liner pipe is released at the

termination point by pulling the wire out of the expandable interlocked joint, thereby severing the secondary lock (see Fig. 6), thus

releasing the profile strip to slide freely along the primary rock when a torque is applied to the inserted spiral w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.