ASTM D7060-04

(Test Method)Standard Test Method for Determination of the Maximum Flocculation Ratio and Peptizing Power in Residual and Heavy Fuel Oils (Optical Detection Method)

Standard Test Method for Determination of the Maximum Flocculation Ratio and Peptizing Power in Residual and Heavy Fuel Oils (Optical Detection Method)

SCOPE

1.1 This test method covers a procedure for quantifying the maximum flocculation ratio of the asphaltenes in the oil and the peptizing power of the oil medium, by an automatic instrument using an optical device.

1.2 This test method is applicable to atmospheric or vacuum distillation residues, thermally cracked residue, intermediate and finished residual fuel oils, containing at least 1 mass % asphaltenes. This test method has not been developed for asphalts.

Note 1—An optical probe detects the formation of flocculated asphaltenes. The start of flocculation is interpreted when a significant and sustained increase in rate-of-change of signal, as measured by the optical probe, ensures flocculation is in progress. The start of flocculation can be detected unambiguously when the sample contains at least 1 % mass asphaltenes as measured by Test Method D 6560.

Note 2—This test method is applicable to products typical of Specification D 396-Grades 5L, 5H, and 6, and Specification D 2880-Grades 3-GT and 4-GT.

1.3 This test method was evaluated in a within-laboratory study in the range of 16 to 57 for the maximum flocculation ratio and in the ranges of 27 to 96 for peptizing power.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 7060 – 04

Standard Test Method for

Determination of the Maximum Flocculation Ratio and

Peptizing Power in Residual and Heavy Fuel Oils (Optical

Detection Method)

This standard is issued under the fixed designation D 7060; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This test method covers a procedure for quantifying the

D 4177 Practice for Automatic Sampling of Petroleum and

maximumflocculationratiooftheasphaltenesintheoilandthe

Petroleum Products

peptizingpoweroftheoilmedium,byanautomaticinstrument

D 4870 TestMethodforDeterminationofTotalSedimentin

using an optical device.

Residual Fuels

1.2 Thistestmethodisapplicabletoatmosphericorvacuum

D 6560 Test Method for Determination of Asphaltenes

distillation residues, thermally cracked residue, intermediate

(Heptane Insolubles) in Crude Petroleum and Petroleum

and finished residual fuel oils, containing at least 1 mass %

Products

asphaltenes. This test method has not been developed for

D 6792 Guide for Quality System in Petroleum Products

asphalts.

and Lubricants Testing Laboratories

NOTE 1—An optical probe detects the formation of flocculated asphalt-

enes. The start of flocculation is interpreted when a significant and

3. Terminology

sustained increase in rate-of-change of signal, as measured by the optical

3.1 Definitions:

probe, ensures flocculation is in progress. The start of flocculation can be

3.1.1 asphaltene, n—in petroleum technology, a molecule

detected unambiguously when the sample contains at least 1 % mass

of high molecular mass, high carbon/hydrogen ratio, and

asphaltenes as measured by Test Method D 6560.

NOTE 2—This test method is applicable to products typical of Specifi- containing heteroatoms.

cation D 396—Grades 5L, 5H, and 6, and Specification D 2880—Grades

3.1.1.1 Discussion—Asphaltenes are found largely in crude

3-GT and 4-GT.

oils and in heavy fuel oils containing residual fractions. They

1.3 This test method was evaluated in a within-laboratory are insoluble in alkanes such as n-heptane and cetane, but

study in the range of 16 to 57 for the maximum flocculation soluble in aromatic solvents such as benzene, toluene, and

ratio and in the ranges of 27 to 96 for peptizing power. 1-methylnaphthalene.

1.4 This standard does not purport to address all of the 3.1.2 compatibility, n—of crude oils or of heavy fuel oils,

safety concerns, if any, associated with its use. It is the the ability of two or more crude oils or fuel oils to blend

responsibility of the user of this standard to establish appro- together within certain concentration ranges without evidence

priate safety and health practices and determine the applica- of separation, such as the formation of multiple phases.

bility of regulatory limitations prior to use. 3.1.2.1 Discussion—Incompatible heavy fuel oils or crude

oils, when mixed or blended, result in the flocculation or

2. Referenced Documents

precipitation of asphaltenes. Some oils may be compatible

2.1 ASTM Standards: within certain concentration ranges in specific mixtures, but

D 396 Specification for Fuel Oils

incompatible outside those ranges.

D 2880 Specification for Gas Turbine Fuel Oils 3.1.3 flocculation, n—of asphaltenes from crude oils or

heavy fuel oils, the aggregation of colloidally dispersed as-

phaltenes into visibly larger masses which may or may not

settle.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.4 peptization, n—of asphaltenes in crude oils or heavy

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

fuel oils, the dispersion of asphaltenes to produce a colloidal

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved Sept. 1, 2004. Published September 2004.

dispersion.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.5 stability reserve, n—in petroleum technology, the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

property of an oil to maintain asphaltenes in a peptized state

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and prevent flocculation of the asphaltenes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7060–04

3.1.5.1 Discussion—An oil with a low stability reserve is sion of asphaltene molecules is disturbed through excess stress

likelytoundergoflocculationofasphalteneswhenstressed(for or incompatibility. This test method provides compatibility

example, extended heated storage) or blended with a range of parameters, which can be used to assess stability reserve and

other oils.Two oils each with a high stability reserve are likely compatibility.

to maintain asphaltenes in a peptized state and not lead to

5.2 Ablend is considered stable when the blend’s peptizing

,

3 4

flocculation when blended together.

powerishigherthantheblend’smaximumflocculationratio;

3.2 Definitions of Terms Specific to This Standard:

both of them can be calculated using empirical blend rules.

3.2.1 critical cetane dilution, n—number of millilitres of Refineries and terminal owners can prevent the flocculation of

cetane with which1gof undiluted sample can be diluted until

asphaltenes due to incompatibility by assessing the compatibil-

it just does not flocculate the asphaltenes. ity of fuels beforehand.

3.2.2 flocculation ratio at critical dilution, n—percentage

NOTE 3—See Appendix X1 for an example of prediction of compat-

by volume of 1-methylnaphthalene in a mixture of

ibility.

1-methylnaphthalene and cetane at the inflection point.

3.2.3 inflection point, n—last step during the titration with

6. Interferences

cetane, where flocculation of asphaltenes is not detected by the

6.1 High content of insoluble inorganic matter (sediment)

optical probe as a significant and sustained increase in rate-of-

has some interference in this test method. In this case, the

change of signal.

insoluble matter shall be removed by filtration according to

3.2.4 maximum flocculation ratio, n—of asphaltenes, mini-

Test Method D 4870.

mum required solvency power, expressed as percentage by

6.2 The presence of wax, present in paraffinic crudes or

volume of 1-methylnaphthalene in a mixture of

fuels from such crudes, does not interfere.

1-methylnaphthalene and cetane, to keep the asphaltenes in a

colloidal solution.

7. Apparatus

3.2.4.1 Discussion—Maximumflocculationratioisthefloc-

culation ratio at extrapolated infinite dilution of the sample.

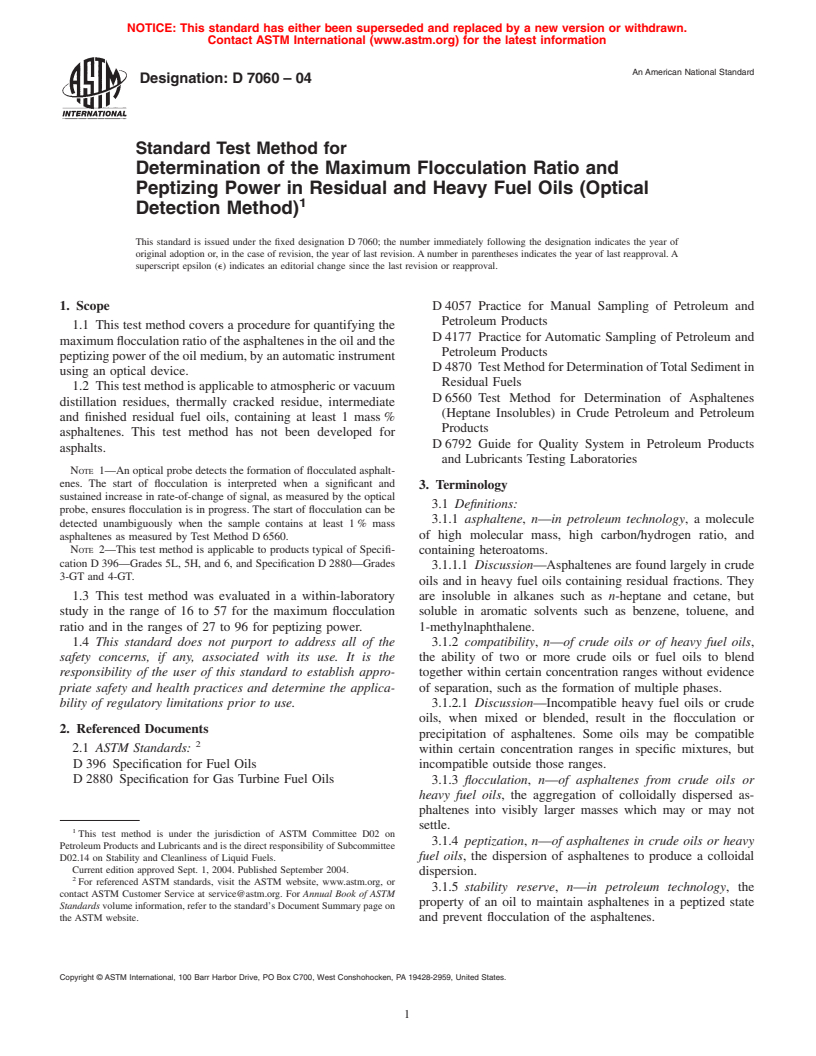

7.1 Integrated Automated Analytical Measurement

3.2.5 peptizing power, n—available solvency power, ex- System—This test method uses an integrated automated ana-

pressed as percentage by volume of 1-methylnaphthalene in a

lytical measurement system comprised of a PC–based com-

mixture of 1-methylnaphthalene and cetane, to keep asphalt- puter and two titration stations (Fig. 1). See Annex A1 for

enes in a colloidal solution.

detailed information.

3.2.6 reciprocal dilution, n—dilution ratio of sample in

7.2 The computer controls test sequencing, acquires and

solvent mixture of 1-methylnaphthalene and cetane.

accumulates optical probe signal data, provides processing

3.3 Symbols:

calculations, and automatically produces a report of important

test parameters. The computer is capable of controlling one or

two independent titration stations.

FR = maximum flocculation ratio

max

7.3 Each titration station consists of the following:

FR = flocculation ratio at critical dilution

x

7.3.1 Automatic titration unit,

Po = peptizing power

7.3.2 Heater,

Xmin = critical cetane dilution

Xc = critical dilution 7.3.3 Magnetic stirrer,

7.3.4 Optical probe, and

4. Summary of Test Method

7.3.5 Reaction cell plus lid.

4.1 Six portions of the sample are diluted in various ratios 7.4 Magnetic Stirrer/Hotplate, thermostatically controlled.

with 1-methylnaphthalene. Each solution is inserted into the

7.5 Stirring Bar, magnetic, PFTE-coated, 25 mm in length.

automatic apparatus, and titrated with cetane until flocculation

of asphaltenes is detected by the optical probe. The first two

8. Reagents and Materials

solutions are titrated with cetane in coarse determinations in

8.1 Purity of Reagents—Reagent grade chemicals shall be

which the flocculation ratio is decreased in 5 % steps. The

used in all tests. Unless otherwise indicated, it is intended that

coarse determinations help to establish suitable starting values

all reagents conform to the specifications of the Committee on

for the fine determinations, in which the flocculation ratio is

Analytical Reagents of the American Chemical Society where

decreased in 1 % steps. The four flocculation ratios at critical

dilution, measured during the fine determinations, are used to

calculate the maximum flocculation ratio of the sample’s

asphaltenes and the peptizing power of the sample’s oil

Berryman, T. J., and Lewis, C. P. G., “The Stability of Residual Fuels. Theory

and Practice of the Shell Concept,” 16th CIMAC Conference, Oslo, 1985.

medium.

Berg van den, F. G. A., “Developments in Fuel Oil Blending,” IASH 7th

International Conference, Graz, Austria, 2000.

5. Significance and Use

The following instrument has been found satisfactory for this purpose—

Automated Stability Analyser available from Zematra, 3194 DG Hoogvliet, The

5.1 Asphaltenes are naturally occurring materials in crude

Netherlands. If you are aware of alternative suppliers, please provide this informa-

petroleum and petroleum products containing residual mate-

tion to ASTM International Headquarters. Your comments will receive careful

rial. The asphaltenes are usually present in colloidal suspen-

consideration at a meeting of the responsible technical committee, which you may

sions, but they may agglomerate and flocculate if the suspen- attend.

D7060–04

FIG. 1 Titration Stations of Integrated Automated Analytical Measurement System

such specifications are available. Other grades may be used, mass % asphaltenes and has approximate viscosities in the

provided it is first ascertained that the reagent is of sufficiently range of 180 to 380 mm /s at 50°C.

high purity to permit its use without lessening the accuracy of

9. Sampling and Test Specimens

the determination.

8.2 Asphaltene Solution (3 g/L)—Dissolve 0.15 g of dry

9.1 Sampling:

asphaltenes in 1-methylnaphthalene and dilute to 50 mL. A

9.1.1 Obtain samples in accordance with Practices D 4057

procedure to obtain asphaltenes is described in Appendix X2.

or D 4177.

Prepare fresh daily, as needed.

9.1.2 Samples of very viscous materials may be warmed

8.3 Cetane (n-Hexadecane).(Warning—Irritating to respi-

until they are reasonably fluid before they are sampled.

ratory system and skin.)

9.1.3 Store samples prior to taking test specimens at ambi-

8.4 Cleaning Solvent, technical grade, 95 % purity, for

ent temperatures.

cleaning. It consists of one of the following:

9.2 Test Specimen Preparation:

8.4.1 Tetrahydrofuran, stabilized. (Warning—Extremely

9.2.1 Sample Fuel Temperature—Warm viscous samples

flammable. Irritating to eyes and respiratory system.)

until they can be mixed readily before opening the storage

8.4.2 Toluene.(Warning—Flammable. Health Hazard.)

container. For fuels with a high wax content (high pour point)

8.4.3 Xylene.(Warning—Flammable. Harmful by inhala-

the temperature shall be at least 15°C above the pour point.

tion and in contact with skin. Irritating to skin.)

9.2.2 Shake or mix the sample thoroughly. If the sample

8.5 n-Heptane.(Warning—Flammable.Vapor harmful.Va-

contains a high content of insoluble matter, filter the sample

por may cause flash fire.)

through a 47-mm diameter glass fiber filter medium (such as

8.6 1-Methylnaphthalene.(Warning—Harmful if swal-

Whatman Grade GF/A) using the Test Method D 4870 filtra-

lowed. Irritating to skin.)

tion apparatus.

8.7 Quality Control (QC) Sample, a stable and homoge-

9.2.3 Preparation of Six Specimen Blends—Visually check

neous residual fuel oil. The QC sample contains at least 1

the reaction cell and the lid for cleanliness. Dissolve specimen

in 1-methylnaphthalene in several different ratios of solvent

according to Table 1. Prepare the blends shortly before the test

procedure. Generally follow the sequence: (1) prepare and test

Reagent Chemicals, American Chemical Society Specifications, American

BlendsA1 and B1, (2) prepare and test BlendsA2 and B2, and

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

(3) prepare and test Blends C, and D.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

NOTE 4—Blends A1 and B1 can be omitted when the coarse determi-

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. nations are skipped.

D7060–04

TABLE 1 Typical Specimen and 1-Methylnaphthalene Solutions

11.2 Performance Check—Check the instrument’s perfor-

Determination Specimen, 1-Methylnaphthalene, Reciprocal Dilution, mance after the installation.

Blend

Mode g mL g/mL

11.3 Performance Check Procedures—Perform the maxi-

A1 Coarse 5 5 1

mum flocculation ratio and the peptizing power determination

B1 Coarse 7 3.5 2

on the asphaltene solution (8.2) according to Sections 12 and

A2 Fine 5 5 1

13. The instrument’s performance is acceptable when the

B2 Fine 7 3.5 2

C Fine 7.5 2.5 3

peptizing power is 100 6 10 % (V/V).

DFine 9 1.5 6

11.4 QC—Confirmtheperformanceoftheinstrumentorthe

test procedure by analyzing a QC sample.

11.4.1 When QC/Quality Assurance (QA) protocols are

9.2.3.1 Weigh,accordingtoTable1,specimentothenearest

already established in the testing facility, these can be used

0.01 g into a clean reaction cell and add a PFTE-coated

when they confirm the reliability of the test result.

magneticstirringbar.Placethereactioncellinthecenterofthe

11.4.2 When there is no QC/QA protocol established in the

preheated (approximately 150°C) magnetic stirrer/hotplate and

testing facility, use Guide D 6792 for guidance.

switchonthemagneticstirrer.Allowthespecimentowarmup,

until its viscosity is low enough to obtain a smooth stirring

12. Procedure

performance.

12.1 Analyze the blends (9.2.3) according to the following

9.2.3.2 Add, according to Table 1, while continuously

test sequence.

stirring, an appropriate volume of 1-methylnaphthalene to the

12.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.