ASTM D402-02

(Test Method)Standard Test Method for Distillation of Cut-Back Asphaltic (Bituminous) Products

Standard Test Method for Distillation of Cut-Back Asphaltic (Bituminous) Products

SIGNIFICANCE AND USE

This procedure measures the amount of the more volatile constituents in cut-back asphaltic products. The properties of the residue after distillation are not necessarily characteristic of the bitumen used in the original mixture, nor of the residue which may be left at any particular time after field application of the cut-back asphaltic product. The presence of silicone in the cut-back may affect the distillation residue by retarding the loss of volatile material after the residue has been poured into the residue container.

SCOPE

1.1 This test method covers a distillation test for cut-back asphaltic (bituminous) products.

1.2 The values given in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation: D 402 – 02 Highway and Transportation Officials Standard

AASHTO No.: T78

27/74 (88)

Standard Test Method for

1

Distillation of Cut-Back Asphaltic (Bituminous) Products

This standard is issued under the fixed designation D402; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. This method was adopted as a joint ASTM-IP

standard in 1961.

1. Scope 3. Summary of Method

1.1 This test method covers a distillation test for cut-back 3.1 Two hundred millilitres of the sample are distilled in a

asphaltic (bituminous) products. 500-mLflask,atacontrolledrate,toatemperatureintheliquid

1.2 The values given in SI units are to be regarded as the of 360°C (680°F), and the volumes of distillate obtained at

standard. The inch-pound units given in parentheses are for specified temperatures are measured. The residue from the

information only. distillation, and also the distillate, may be tested as required.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This procedure measures the amount of the more vola-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- tile constituents in cut-back asphaltic products. The properties

oftheresidueafterdistillationarenotnecessarilycharacteristic

bility of regulatory limitations prior to use.

of the bitumen used in the original mixture, nor of the residue

2. Referenced Documents

which may be left at any particular time after field application

2.1 ASTM Standards: of the cut-back asphaltic product. The presence of silicone in

D86 Test Method for Distillation of Petroleum Products at the cut-back may affect the distillation residue by retarding the

2

Atmospheric Pressure loss of volatile material after the residue has been poured into

D370 Test Method for Dehydration of Oil-Type Preserva- the residue container.

3

tives

4 5. Apparatus

E1 Specification for ASTM Thermometers

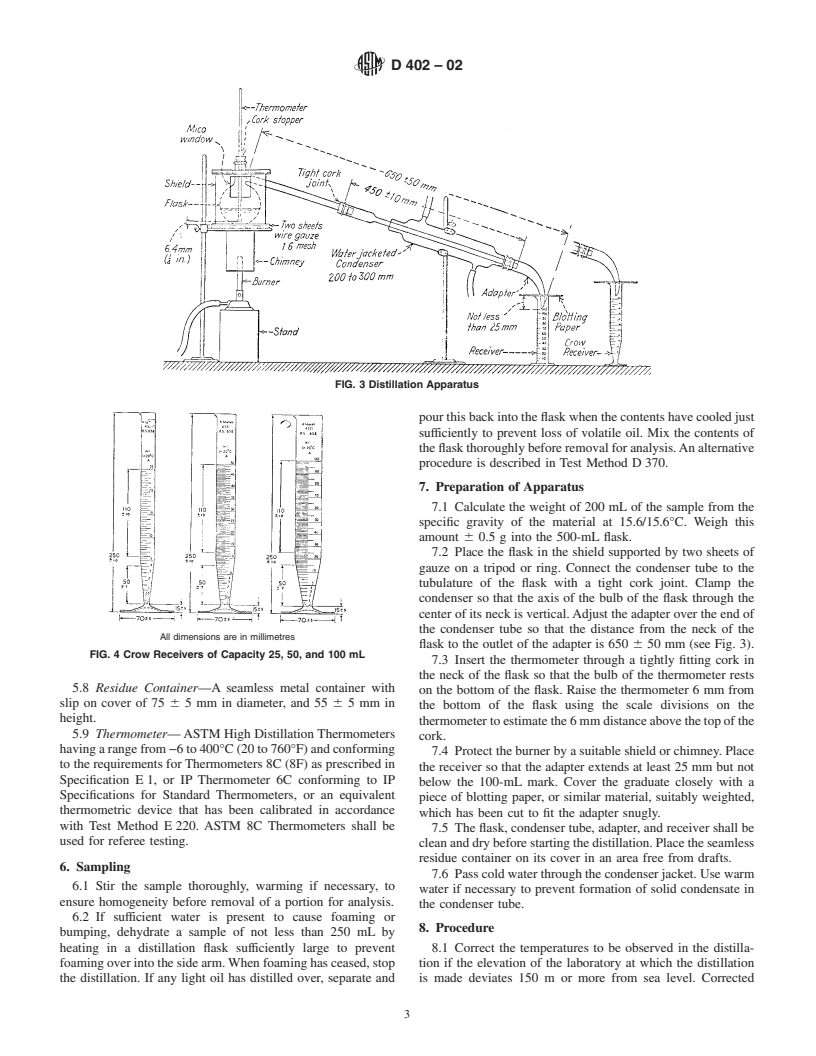

5

E133 Specification for Distillation Equipment 5.1 Distillation Flask, 500-mLside-arm, having the dimen-

sions shown in Fig. 1.

E220 Test Method for Calibration of Thermocouples by

4

Comparison Techniques 5.2 Condenser, standard glass-jacketed, of nominal jacket

length from 200 to 300 mm and overall tube length of 450 6

2.2 IP Standards:

IP 123/ASTM D86, Distillation of Petroleum Products 10 mm (see Fig. 3).

5.3 Adapter, heavy-wall (1-mm) glass, with reinforced top,

Thermometers as specified in IP Standards

Crow Receiver as specified in British Standards658:1989 having an angle of approximately 105°.The inside diameter at

the large end shall be approximately 18 mm, and at the small

C.O.3—Standard Methods for Testing Tar and its Products

(Published by the U.K. Standardization of Tar Products end,notlessthan5mm.Thelowersurfaceoftheadaptershall

be on a smooth descending curve from the larger end to the

Tests Committee)

smaller. The inside line of the outlet end shall be vertical, and

the outlet shall be cut or ground (not fire-polished) at an angle

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

of 45 6 5° to the inside line.

and Paving Materials and is the direct responsibility of Subcommittee D04.46 on

5.4 Shield, steel, lined with 3-mm fire proof insulation and

Durability and Distillation Tests.

fitted with transparent mica windows, of the form and dimen-

Current edition approved Dec. 10, 2002. Published February 2003. Originally

sionsshowninFig.2,usedtoprotecttheflaskfromaircurrents

approved in 1934. Last previous edition approved in 1997 as D402–97.

IntheIP,thismethodisunderthejurisdictionoftheStandardizationCommittee.

and to reduce radiation. The cover (top) shall be made in two

2

Annual Book of ASTM Standards, Vol 05.01.

parts of 6.4-mm fire proof insulation.

3

Annual Book of ASTM Standards, Vol 04.09.

2

4 5.5 Shield and Flask Support—Two 15-cm sheets of 16-

Annual Book of ASTM Standards, Vol 14.03.

5

Annual Book of ASTM Standards, Vol 14.02. mesh Chromel wire gauze on a tripod or ring.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D402–02

FIG. 1 Distillation Flask

FIG. 2 Shield

5.6 Heat Source— 5.7 Receiver—A standard 100-mL graduated cylinder con-

5.6.1 Adjustable Tirrill-type gas burner or equivalent.

forming to dimensions of Specification E133, or a100-mL

5.6.2 An electric heater equipped

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.