ASTM A677M-98a

(Specification)Standard Specification for Nonoriented Electrical Steel, Fully Processed Types (Metric) (Withdrawn 2000)

Standard Specification for Nonoriented Electrical Steel, Fully Processed Types (Metric) (Withdrawn 2000)

SCOPE

1.1 This specification covers the detailed requirements to which flat-rolled nonoriented fully processed electrical steel shall conform.

1.2 This steel is produced to specified maximum core-loss values and is intended primarily for commercial power frequency (50 and 60 Hz) applications in magnetic devices. Desirable core loss and permeability characteristics are developed during mill processing, so further heat treatment by the purchaser is not usually necessary.

1.3 These nonoriented fully processed electrical steels are low-carbon, silicon-iron or silicon-aluminum-iron alloys containing up to about 3.5% silicon and a small amount of aluminum.

Note 1-This specification is the metric companion of Specification A677.

General Information

Standards Content (Sample)

STD-ASTM Ab77M REV A-ENGL 1798 W 075951U Ob32127 72T W

Designation: A 677M - 98a

An American National Standard

METRIC

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Nonoriented Electrical Steel, Fully Processed Types

(Metric) ’

This standard is issued under the fixed designation A 677M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (E) indicates an editorial change since the last revision or reapproval.

A 720 Test Method for Ductility of Nonoriented Electrical

1. Scope

Steel

1.1 This specification covers the detailed requirements to

A 937 Test Method for Determining Interlaminar Resis-

which flat-rolled nonoriented fully processed electrical steel

tance of Insulating Coatings Using Two Adjacent Test

shall conform.

Surfaces2

1.2 This steel is produced to specified maximum core-loss

A 976 Classification of Insulating Coatings by Composi-

values and is intended primarily for commercial power fre-

tion, Relative Insulating Ability and Application’

quency (50- and 60-Hz) applications in magnetic devices.

E 18 Test Methods for Rockwell Hardness and Rockwell

Desirable core-loss and permeability characteristics are devel-

Superficial Hardness of Metallic Materiais

oped during mill processing, so additional heat treatment by

the purchaser is not usually necessary.

3. Terminology

1.3 These nonoriented fully processed electrical steels are

3.1 Dejînitions: The terms and symbols used in this speci-

low-carbon, silicon-iron, or silicon-aluminum-iron alloys con-

fication are defined in Terminology A 340.

taining up to about 3.5 % silicon and a small amount of

aluminum.

4. Classification

NOTE I-This specification is the metric companion of Specification

4.1 The nonoriented electrical steel types described by this

A 677.

specification are as shown in Table I.

2. Referenced Documents

5. Ordering Information

2. I ASTM Standards:

5.1 Orders for material under this specification shall include

A34 Practice for Procurement Testing, and Sampling of

as much of the following information as necessary to describe

Magnetic Materials

the desired material adequately:

A 340 Terminology of Symbols and Definitions Relating to

5.1.1 ASTM specification number.

Magnetic Testing

5.1.2 Core-loss type number.

A 343 Test Method for Alternating-Current Magnetic Prop-

5.1.3 Surface coating type.

erties of Materials at Power Frequencies Using Wattmeter-

5.1.4 Thickness, width, and length (if in cut lengths instead

Ammeter-Voltmeter Method and 25-cm Epstein Test

of coils).

Frame

5.1.5 Total weight of ordered item.

A 664 Practice for Identification of Standard Electrical- and

5.1.6 Limitations in coil size or lift weights.

Lamination-Steel Grades in ASTM Specifications

5.1.7 End Use-The purchaser shall disclose as much

A 700 Practices for Packaging, Marking, and Loading

pertinent information as possible about the intended applica-

Methods for Steel Products for Domestic Shipment

tion to enable the supplier to provide material characteristics

A 717/A 717M Test Method for Surface Insulation Resis-

most suitable for specific fabricating practices.

tivity of Single-Strip Specimens *

5.1.8 Special requirements or exceptions to the provisions

A 719 Test Method for Lamination Factor of Magnetic

of this specification.

Materials

6. Manufacture

6.1 Typical Melting and Casting:

’ This specification is under the jurisdiction of ASTM Committee A-6 on

6.1.1 These fully processed electrical steels may be made by

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

basic-oxygen, electric-fumace, or other steelmaking practice.

Material Specifications.

Current edition approved Oct. IO, 1998. Published February 1999. Originally

published as A 677M - 83. Last previous edition A 677M - 98.

’ Annual Book of ASTM Standurd.s, Vol 03.04.

Annual Book of ASTM Standards, Vol 01.05. Annual Book of ASTM Síunùurds, Vol 03.01.

I

---------------------- Page: 1 ----------------------

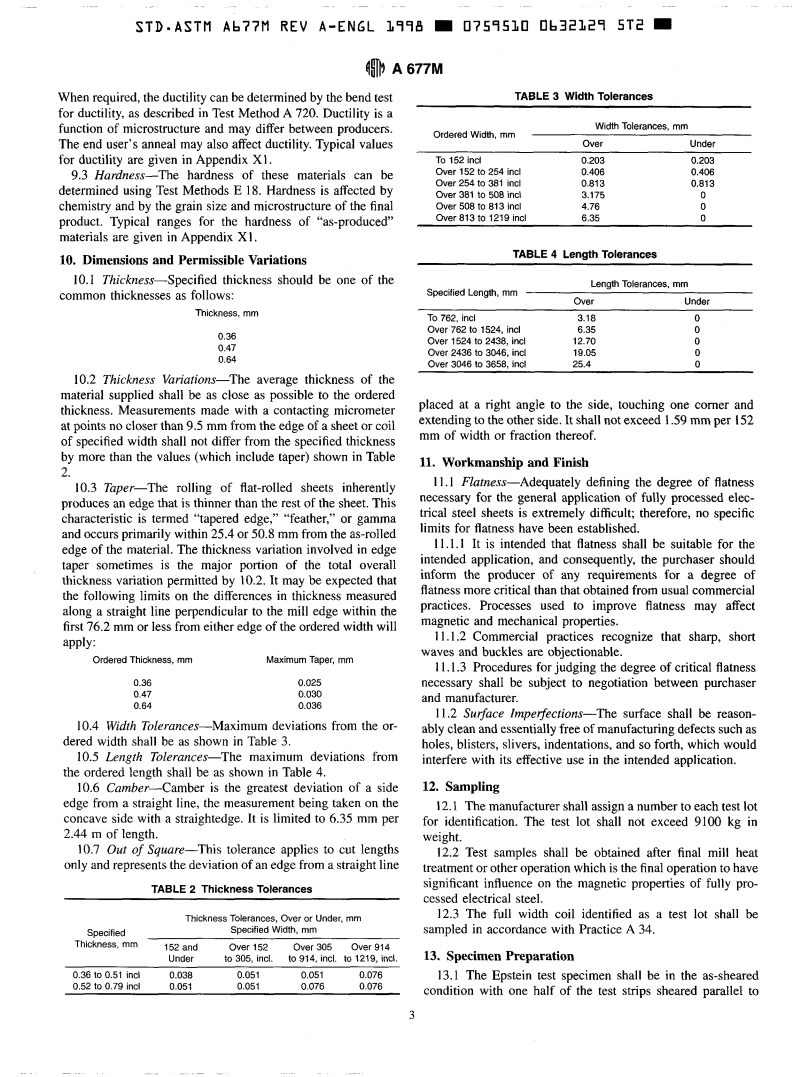

(# A677M

TABLE 1 Core-Loss Types A and Maximum Core Losses Bat 15 T for As-Sheared Epstein Specimens

~~~

0.36-mm Thickness 0.47-mm Thickness 0.64-mm Thickness

~~~ ~

Core-Loss Maximum Core Loss, Wlkg Core-Loss Maximum Core Loss, W/kg Core-Loss Maximum Core Loss, W/kg

Type Type

Type

60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz

36F320M 3.20 2.53 . . . . . .

36F342M 3.42 2.70 47F364M 3.64 2.87 4.41 3.48

64F441 M

36F364M 3.64 2.87 47F397M 3.97 3.13 64F463M 4.63 3.66

36F386M 3.86 3.05 47F419M 4.19 3.31 64F496M 4.96 3.92

36F408M 4.08 3.22 47F441 M 4.41 3.48 64F518M 5.18 4.09

36F430M 4.30 3.40 47F463M 4.63 3.66 64F551 M 5.51 4.35

36F452M 4.52 3.57 47F529M 5.29

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.