ASTM D5272-92(1999)

(Practice)Standard Practice for Outdoor Exposure Testing of Photodegradable Plastics

Standard Practice for Outdoor Exposure Testing of Photodegradable Plastics

SCOPE

1.1 This practice defines test conditions applicable when Practices D1435 and G7 are employed for the outdoor exposure testing of photodegradable plastics.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-There is no ISO standard that is equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5272–92 (Reapproved 1999)

Standard Practice for

Outdoor Exposure Testing of Photodegradable Plastics

This standard is issued under the fixed designation D5272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope exposure angle used in this practice represents typical condi-

tions for degradation experienced by litter.

1.1 This practice defines test conditions applicable when

4.2 Thispracticerequirescharacterizationofthedurationof

Practices D1435 and G7 are employed for the outdoor

exposure in terms of solar-ultraviolet radiation. Solar-

exposure testing of photodegradable plastics.

ultraviolet radiation varies considerably as a function of

1.2 This standard does not purport to address all of the

location and time of year. This can cause dramatic differences

safety concerns, if any, associated with its use. It is the

inthetimerequiredtoproduceaspecifiedlevelofdegradation

responsibility of the user of this standard to establish appro-

in a polymer. Daro has shown that when the same lot of

priate safety and health practices and determine the applica-

polyethylenecontaininganiron-saltprodegradantisexposedat

bility of regulatory limitations prior to use.

various times of the year in a single location, the time required

NOTE 1—There is no ISO standard that is equivalent to this standard.

to produce an average of two chain scissions per molecule

varied by over 130%. Daro, and Zerlaut and Anderson have

2. Referenced Documents

shown that this variability can be significantly reduced when

2.1 ASTM Standards:

total solar or solar-ultraviolet radiation, or both, is used to

D882 Test Methods for Tensile Properties of Thin Plastic

characterize the exposure increments.

Sheeting

4.3 In addition to variations in level of daylight and solar-

D883 Terminology Relating to Plastics

ultraviolet radiation, there are significant differences in tem-

D1435 Practice for Outdoor Weathering of Plastics

perature,andmoisturestressesbetweendifferentlocations,and

D1898 Practice for Sampling of Plastics

between different years, or periods within a single year, at a

D3593 Test Method for Molecular Weight Averages and

singlelocation.Becauseofthisvariability,resultsfromthistest

Molecular Weight Distribution of Certain Polymers by

cannot be used to predict the absolute rate at which photode-

Liquid Size-Exclusion Chromatography (Gel Permeation

gradable plastics degrade. Results from this test can be used to

Chromatograph GPC) Using Universal Calibration

compare relative rates of degradation for materials exposed at

D3826 Practice for Determining Degradation End Point in

the same time in the same location. Results from multiple

Degradable Polyolefins Using a Tensile Test

exposures of a common lot of material (during different

E772 Terminology Relating to Solar Energy Conversion

seasons over several years) at different sites can be used to

G 7 Practice for Atmospheric Environmental Exposure

compare the relative rates at which a particular photodegrad-

Testing of Nonmetallic Materials

able plastic will degrade in each location.

3. Terminology

NOTE 2—Aninherentlimitationinsolar-radiationmeasurementsisthat

they do not reflect the effects of variations in temperature and moisture

3.1 The terminology given in Terminology E772 and Ter-

exposure, which often can be as important as solar radiation. The same

minology D883 is applicable to this practice.

solar-ultraviolet radiation increment will not necessarily give the same

changes in properties of the test specimen in different exposure sites.

4. Significance and Use

Results from this practice must be regarded as giving only a general

4.1 When discarded as litter, articles made using photode-

indication of the degree of degradability and should always be considered

gradable plastics are subject to attack by daylight (particularly in terms of characteristics of the exposure site as well.

solar-ultraviolet radiation), oxygen, heat, and water. The 5°

4.4 Where measurement of total solar-ultraviolet radiation

is not possible, exposure duration can be determined by the

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.96 on Environmentally

Degradable Plastics. Daro,A.,etal,“DegradationofPolymerBlendsIV,NaturalWeatheringofLow

Current edition approved July 15, 1992. Published September 1992. DensityandLinearLowDensityPolyethylene,”EuropeanPolymerJournal,Vol26,

Annual Book of ASTM Standards, Vol 08.01. No. 1, 1990, pp. 47–52.

3 7

Annual Book of ASTM Standards, Vol 08.02. Zerlaut, G. L., and Anderson, T. A., “Ultraviolet Radiation as a Timing

Annual Book of ASTM Standards, Vol 12.02. TechniqueforOutdoorWeatheringofMaterials,”SocietyofAutomotiveEngineers,

Annual Book of ASTM Standards, Vol 14.02. SAE Technical Paper Number 850348, 1985.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5272

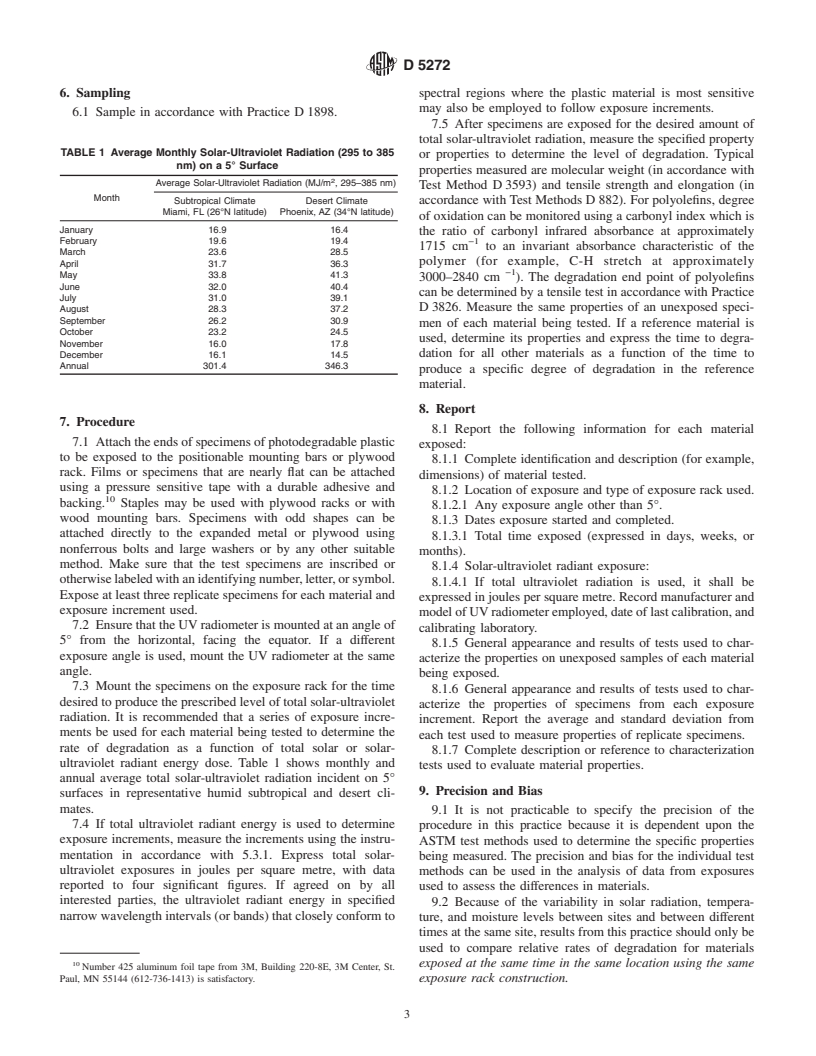

FIG. 1 Typical Rack Construction for Exterior Exposures of Photodegradable Plastics

numberofdays,weeks,ormonthsexposed.Whenthispractice lay (MDO) or high-density overlay (HDO) plywood are

isused,areferencematerialwhosedegradationpropertieshave satisfactory substrates and will require less frequent replace-

been well established must be exposed at the same time as the ment than plywood with no overlay.

other materials being tested. The reference material used must

NOTE 4—There is less air circulation around the specimens when Rack

be agreed upon by all interested parties.The time to produce a

Bexposuresareused.DegradationratesfromexposuresusingRackBwill

specified level of degradation for each material in this simul-

be somewhat faster than those using Rack A because specimen tempera-

taneousexposureisthencompared.Itisalsoagoodpracticeto

tures will be higher. Comparisons between materials should only be made

with exposures conducted at the same time and using the same rack type.

usereferencematerialswhenexposurelengthisdeterminedby

total solar or solar UV radiant exposure.

5.3 Solar Radiometers:

5.3.1 Ultraviolet Radiometer—A total ultraviolet (UV) ra-

NOTE 3—Areference material can be a single lot of material which has

shown consistent results after a number of exposures. It is not necessary diometer that measures ultraviolet radiation in the wavelength

that the composition or properties of the reference material be character-

region from 295 to 385 nm should be used. Calibrate the

ized and certified by a recognized standards agency or group.

radiometerinsuitableradiometricunits,preferablyinwattsper

−2 −1

square metre per volt (Wm V ), and shall be maintained in

5. Apparatus

at least semiannual calibration against a standard source of

5.1 Use exposure racks constructed in accordance with the 9

special irradiance. Narrow band radiometers (for example,

requirements of Practice G7. Unless otherwise specified,

with 20 nm bandpass) can also be used if agreed upon by all

position the exposure racks so that specimens face the equator

interested parties. Narrow band radiometers must also be

and so that the exposed surfaces are 5° from the horizontal. If

calibrated at least semiannually against a standard source of

other exposure rack orientations are used, they must be

spectralirradiance.Acertificateofcalibrationshallbeprovided

reported.

with all total solar-ultraviolet or narrow band irradiance mea-

5.2 Use one of the following rack constructions for expos-

surements. It is recommended that calibrations be traceable to

ing photodegradable plastic specimens:

a recognized national standards agency such as the National

5.2.1 Exposure Rack A—Positionable mounting bars used

Institute for Science and Technology in the United States.

for attaching specimens shall be arrayed over a regular mesh

NOTE 5—The use of narrow band filter UV

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.