ASTM F2806-10

(Specification)Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe (Metric SDR-PR)

Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe (Metric SDR-PR)

ABSTRACT

This specification covers acrylonitrile-butadiene-styrene (ABS) pipe produced by single extrusion in standard thermoplastic pipe dimension ratios and pressure rated for water. Included are criteria for classifying ABS plastic pipe materials and ABS plastic pipe, a system of nomenclature for ABS plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and extrusion quality. Methods of marking are also given. The products covered by this specification are intended for use with the distribution of pressurized liquids, which are chemically compatible with the piping materials. Requirements cover workmanship, dimensions and tolerances (outside diameters and wall thickness), sustained pressure, burst pressure, and impact.

SCOPE

1.1 This specification covers acrylonitrile-butadiene-styrene (ABS) pipe produced by single extrusion in standard thermoplastic pipe dimension ratios and pressure rated for water (see Appendix X1). Included are criteria for classifying ABS plastic pipe materials and ABS plastic pipe, a system of nomenclature for ABS plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and extrusion quality. Methods of marking are also given.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids, which are chemically compatible with the piping materials. Consult with the manufacturer and local building codes before use in other applications. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 1—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy, which present serious safety hazards should a system fail for any reason.

Note 2—This specification addresses only pipe for use in above ground service. For buried service consult the manufacturer and local building codes.

Note 3—Exposure to ultraviolet radiation over a long period of time may affect the physical properties of ABS pipe. Consult the manufacturer for recommendations for handling, storage, and installations that are not protected by insulation.

1.3 Pipe meeting the requirements of this standard are not compatible with IPS sized DWV fittings. The ABS pipe covered in this standard is intended for pressure service and it shall be joined to pressure fittings. Non-pressure fittings, such as DWV fittings from any material (ABS, PVC, CPVC, etc.), are not acceptable for pressure applications.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 The text of this specification references notes, footnotes, and appendixes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2806 – 10

Standard Specification for

Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe (Metric

SDR-PR)

This standard is issued under the fixed designation F2806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The text of this specification references notes, footnotes,

and appendixes, which provide explanatory material. These

1.1 This specification covers acrylonitrile-butadiene-styrene

notesandfootnotes(excludingthoseintablesandfigures)shall

(ABS) pipe produced by single extrusion in standard thermo-

not be considered as requirements of the specification.

plastic pipe dimension ratios and pressure rated for water (see

1.6 This standard does not purport to address all of the

AppendixX1).IncludedarecriteriaforclassifyingABSplastic

safety concerns, if any, associated with its use. It is the

pipe materials andABS plastic pipe, a system of nomenclature

responsibility of the user of this standard to establish appro-

for ABS plastic pipe, and requirements and test methods for

priate safety and health practices and determine the applica-

materials, workmanship, dimensions, sustained pressure, burst

bility of regulatory limitations prior to use.

pressure, and extrusion quality. Methods of marking are also

given.

2. Referenced Documents

1.2 The products covered by this specification are intended

2.1 ASTM Standards:

for use with the distribution of pressurized liquids, which are

D618 Practice for Conditioning Plastics for Testing

chemically compatible with the piping materials. Consult with

D1598 Test Method for Time-to-Failure of Plastic Pipe

the manufacturer and local building codes before use in other

Under Constant Internal Pressure

applications. Due to inherent hazards associated with testing

D1600 Terminology for Abbreviated Terms Relating to

components and systems with compressed air or other com-

Plastics

pressed gases some manufacturers do not allow pneumatic

D2122 Test Method for Determining Dimensions of Ther-

testing of their products. Consult with specific product/

moplastic Pipe and Fittings

component manufacturers for their specific testing procedures

D2837 TestMethodforObtainingHydrostaticDesignBasis

prior to pneumatic testing.

forThermoplastic Pipe Materials or Pressure Design Basis

NOTE 1—Pressurized (compressed) air or other compressed gases

for Thermoplastic Pipe Products

contain large amounts of stored energy, which present serious safety

D3965 Specification for Rigid Acrylonitrile-Butadiene-

hazards should a system fail for any reason.

Styrene (ABS) Materials for Pipe and Fittings

NOTE 2—Thisspecificationaddressesonlypipeforuseinaboveground

F412 Terminology Relating to Plastic Piping Systems

service. For buried service consult the manufacturer and local building

2.2 Federal Standard:

codes.

NOTE 3—Exposure to ultraviolet radiation over a long period of time

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

may affect the physical properties ofABS pipe. Consult the manufacturer

2.3 Military Standard:

for recommendations for handling, storage, and installations that are not

MIL-STD-129 Marking for Shipment and Storage

protected by insulation.

2.4 NSF/ANSI Standard:

1.3 Pipe meeting the requirements of this standard are not

Standard No. 14 for Plastic Piping Components and Related

compatible with IPS sized DWV fittings. The ABS pipe

Materials

covered in this standard is intended for pressure service and it

Standard No. 61 Drinking Water System Components -

shall be joined to pressure fittings. Non-pressure fittings, such

Health Effects

as DWV fittings from any material (ABS, PVC, CPVC, etc.),

are not acceptable for pressure applications.

1.4 Units—The values stated in SI units are to be regarded

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

as standard. No other units of measurement are included in this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

standard.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. dodssp.daps.dla.mil.

Current edition approved June 1, 2010. Published July 2010. DOI: 10.1520/ Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

F2806–10. Arbor, MI 48113-0140, http://www.nsf.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2806 – 10

2.5 ISO Standard: is carried out in accordance with Test Method D1598 to find

ISO 1167 Thermoplastic pipes, fittings and assemblies for the HDB value. The HDB shall be a minimum of 17.2 MPa.

the conveyance of fluids—Determination of the resistance 4.4 Compound—TheABS plastic extrusion compound shall

to internal pressure—Part 1: General method meet the requirements ofABS Classes 42222, 20643, or 30444

ISO 3127 Thermoplastic pipes—Determination of resis- as described in Specification D3965.

tance to external blows—Round-the-clock method 4.5 Rework Material—The manufacturers shall use only

their own clean rework pipe material and the pipe produced

3. Terminology

shall meet all the requirements of this specification.

3.1 General—Definitions are in accordance with Terminol-

5. Pipe Classification

ogy F412. Abbreviations are in accordance with Terminology

5.1 General—This specification coversABS pipe produced

D1600, unless otherwise indicated. The abbreviation for

by single extrusion.

acrylonitrile-butadiene-styrene plastic is ABS.

5.2 Standard Dimension Ratios (SDR)—This specification

3.2 Definitions of Terms Specific to This Standard:

coversABS pipe in eight standard dimension ratios. These are

3.3 acrylonitrile-butadiene-styrene (ABS) pipe and fitting

SDR 9, 11, 13.5, 17, 21, 26, 32.5, and SDR 41. The pressure

plastics—plastics containing polymers or blends of polymers,

rating is uniform for all nominal pipe sizes for a given ABS

or both, in which the minimum butadiene content is 6 %, the

pipe material and SDR.

minimum acrylonitrile content is 15 %, the minimum styrene

or substituted styrene content, or both, is 15 %, and the 6. Requirements

maximum content of all other monomers is not more than 5 %,

6.1 Workmanship—The pipe shall be homogeneous

and lubricants, stabilizers, and colorants.

throughout and free of visible cracks, holes, foreign inclusions,

3.4 mominal outside diameter (d )—specified outside di-

n

or other defects. The pipe shall be as uniform as commercially

ameter of a component, which is identical to the minimum

practicable in color, opacity, density, and other physical prop-

mean outside diameter, in millimeters

erties.

3.5 pressure rating (PR)—numerical designation used for

6.2 Dimensions and Tolerances:

reference purposes and related to the mechanical characteris-

6.2.1 Outside Diameters—The outside diameters and toler-

tics of the components of a piping system.

ances and out-of-roundness shall be as shown in Table 1 when

3.6 relation between standard dimension ratio, hydrostatic

measured in accordance with 7.4 and 7.4.1.

design basis (HDB), and pressure rating (PR)——the follow-

6.2.2 Wall Thickness—The wall thicknesses and tolerances

ing expression is used in this specification to relate standard

shall be as shown in Table 2 when measured in accordance

dimension ratio, hydrostatic design basis, and pressure rating:

with 7.4 and 7.4.2.

PR5 2 HDB/~SDR21! or PR52 HDB/~~D /t!21! (1) 6.3 Sustained Pressure—The pipe shall not fail, balloon,

O

burst, or weep as defined in ISO 1167 at the test pressures

where:

given in Table 3 when tested in accordance with 7.5.

6.4 Burst Pressure—The minimum burst pressures forABS

HDB = Hydrostatic design basis, MPa

plastic pipe shall be the pressure rating (PR) multiplied by a

PR = Pressure rating, MPa

factor of 3.2, when determined in accordance with 7.6.

DO = average outside diameter, mm

6.5 Impact —The pipe shall meet the impact requirements

t = minimum wall thickness mm, and

when tested in accordance with 7.7.

SDR = standard dimension ratio (D /t)

O

7. Test Methods

4. Materials 7.1 Conditioning—Condition the test specimens at 23 6

2°Cand50 65%relativehumidityfornotlessthan40hprior

4.1 General—Acrylonitrile-butadiene-styrene plastics used

to test in accordance with Procedure A of Practice D618 for

to make pipe meeting the requirements of this specification are

those tests where conditioning is required.

categorized by means of two criteria namely (1) short-term

7.2 Test Conditions—Conduct the tests in the Standard

tests and (2) long-term strength tests.

Laboratory Atmosphere of 23 6 2°C and 50 6 5 % relative

4.2 Basic Materials—The material properties of the grade

humidity, unless otherwise specified in the test methods or in

of ABS plastic are characterized using short-term tests as

this specification.

defined in Specification D3965.

7.3 Test Specimens—Not less than 50 % of the test speci-

4.3 Hydrostatic Design Basis (HDB)—This specification

mens required for any pressure test shall have at least a part of

covers pipe made from material, which has been evaluated in

the marking in their central sections. The central section is that

accordance with Test Method D2837 where a pressure testing

portion of pipe, which is at least one pipe diameter away from

an end closure.

7.4 Dimensions and Tolerances—Use any length of pipe to

Available from International Organization for Standardization (ISO), 1, ch. de

determine the dimensions. Measure in accordance with Test

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch. Method D2122.

F2806 – 10

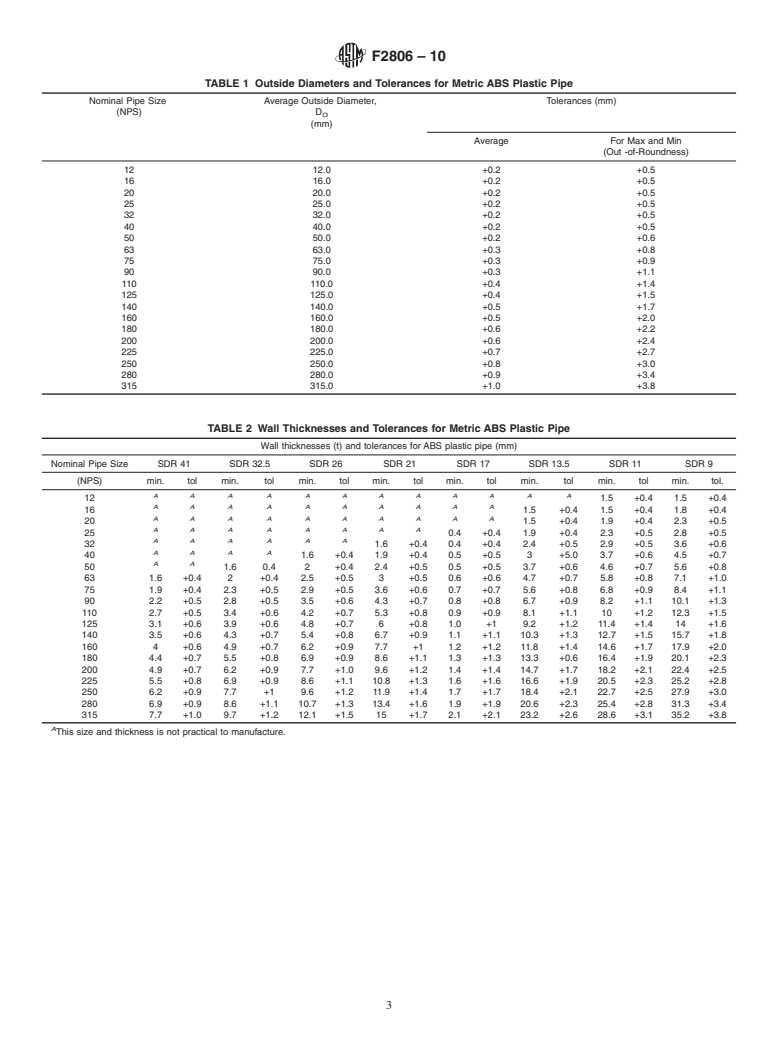

TABLE 1 Outside Diameters and Tolerances for Metric ABS Plastic Pipe

Nominal Pipe Size Average Outside Diameter, Tolerances (mm)

(NPS) D

O

(mm)

Average For Max and Min

(Out -of-Roundness)

12 12.0 +0.2 +0.5

16 16.0 +0.2 +0.5

20 20.0 +0.2 +0.5

25 25.0 +0.2 +0.5

32 32.0 +0.2 +0.5

40 40.0 +0.2 +0.5

50 50.0 +0.2 +0.6

63 63.0 +0.3 +0.8

75 75.0 +0.3 +0.9

90 90.0 +0.3 +1.1

110 110.0 +0.4 +1.4

125 125.0 +0.4 +1.5

140 140.0 +0.5 +1.7

160 160.0 +0.5 +2.0

180 180.0 +0.6 +2.2

200 200.0 +0.6 +2.4

225 225.0 +0.7 +2.7

250 250.0 +0.8 +3.0

280 280.0 +0.9 +3.4

315 315.0 +1.0 +3.8

TABLE 2 Wall Thicknesses and Tolerances for Metric ABS Plastic Pipe

Wall thicknesses (t) and tolerances for ABS plastic pipe (mm)

Nominal Pipe Size SDR 41 SDR 32.5 SDR 26 SDR 21 SDR 17 SDR 13.5 SDR 11 SDR 9

(NPS) min. tol min. tol min. tol min. tol min. tol min. tol min. tol min. to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.