ASTM F1970-99

(Specification)Standard Specification for Special Engineered Fittings, Appurtenances or Valves for use in Poly (Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl Chloride) (CPVC) Systems

Standard Specification for Special Engineered Fittings, Appurtenances or Valves for use in Poly (Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl Chloride) (CPVC) Systems

SCOPE

1.1 This specification covers fittings, appurtenances and valves which are to be used with pipe and tubing complying with Specifications D1785, D2241, D2846, F441 or F442, or other piping as specified by the fittings manufacturer. These products, such as unions, flanges or valves, are not included in the scope of existing ASTM specifications. This specification includes minimum requirements for testing, materials, dimensions, workmanship, marking, and in-plant quality control.

1.2 Fittings or appurtenances covered by this specification are generally either molded, fabricated, or assembled from molded or machined components. The materials used in components include rigid thermoplastics, thermoplastic elastomers, elastomerics, and metals. The body or main portion of the fitting, appurtenance or valve is typically PVC, CPVC, PE or PA (nylon). All products covered by this standard are intended to be used in PVC or CPVC plastic piping systems, or as a transition from these to metal systems.

1.3 The application of these products to gas service is beyond the scope of this specification.

1.4 Fittings which rely on heat fusion welding for connection to the piping system are outside the scope of this specification.

1.5 Check valves (including foot valves) covered by this specification shall not be considered backflow prevention devices and shall not be used for the protection of a potable water supply. For definitions and requirements of backflow prevention devices, consult model plumbing codes and ASSE.

1.6 Due to the complex and installation-specific concerns surrounding chemical resistance and corrosion, this specification does not address the compatibility of the products with all possible end-use environments. Additional testing specific to the end-use environment is recommended if the system is conveying liquids other than potable water.

1.7 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are given for information only.

1.8 The following safety caveat applies only to the test methods and in-plant quality control portions, section of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1970 – 99 An American National Standard

Standard Specification for

Special Engineered Fittings or Appurtenances for use in

Poly (Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl

Chloride) (CPVC) Systems

This standard is issued under the fixed designation F 1970; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope as the standard. The SI units given in parentheses are given for

information only.

1.1 This specification covers fittings and appurtenances

1.8 The following safety caveat applies only to the test

which are to be used with pipe and tubing complying with

methods and in-plant quality control portions, section of this

Specifications D 1785, D 2241, D 2846, F 441 or F 442, or

specification: This standard does not purport to address all of

other piping as specified by the fittings manufacturer. These

the safety concerns, if any, associated with its use. It is the

products, such as unions, flanges or valves, are not included in

responsibility of the user of this standard to establish appro-

the scope of existing ASTM specifications. This specification

priate safety and health practices and determine the applica-

includes minimum requirements for testing, materials, dimen-

bility of regulatory limitations prior to use.

sions, workmanship, marking, and in-plant quality control.

1.2 Fittings or appurtenances covered by this specification

2. Referenced Documents

are generally either molded, fabricated, or assembled from

2.1 ASTM Standards:

molded or machined components. The materials used in

D 1598 Test Method for Time-to-Failure of Plastic Pipe

components include rigid thermoplastics, thermoplastic elas-

Under Constant Internal Load

tomers, elastomerics, and metals. The body or main portion of

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

the fittings is typically PVC, CPVC, PE or PA (nylon). All

sure of Plastic Pipe, Tubing, and Fittings

products covered by this standard are intended to be used in

D 1600 Terminology for Abbreviated Terms Relating to

PVC or CPVC plastic piping systems, or as a transition from

Plastics

these to metal systems.

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

1.3 The application of these products to gas service is

Compounds and Chlorinated Poly(Vinyl Chloride)

beyond the scope of this specification.

(CPVC) Compounds

1.4 Fittings which rely on heat fusion welding for connec-

D 1785 Specification for Poly(Vinyl Chloride) (PVC) Plas-

tion to the piping system are outside the scope of this

tic Pipe, Schedules 40, 80, and 120

specification.

D 1898 Practice for Sampling of Plastics

1.5 Check valves (including foot valves) covered by this

D 2000 Classification System for Rubber Products in Auto-

specification shall not be considered backflow prevention

motive Applications

devices and shall not be used for the protection of a potable

D 2122 Test Method for Determining Dimensions of Ther-

water supply. For definitions and requirements of backflow

2 moplastic Pipe and Fittings

prevention devices, consult model plumbing codes and ASSE.

D 2241 Specification for Poly(Vinyl Chloride) (PVC)

1.6 Due to the complex and installation-specific concerns

Pressure-Rated Pipe (SDR Series)

surrounding chemical resistance and corrosion, this specifica-

D 2466 Specification for Poly(Vinyl Chloride) (PVC) Plas-

tion does not address the compatibility of the products with all

tic Pipe Fittings, Schedule 40

possible end-use environments. Additional testing specific to

D 2467 Specification for Socket-type Poly(Vinyl Chloride)

the end-use environment is recommended if the system is

(PVC) Plastic Pipe Fittings, Schedule 80

conveying liquids other than potable water.

D 2846 Specification for Chlorinated Poly(Vinyl Chloride)

1.7 The values stated in inch-pound units are to be regarded

(CPVC) Plastic Hot-and-Cold-Water Distribution Sys-

tems

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved April 10, 1999. Published August 1999. Annual Book of ASTM Standards, Vol 08.04.

2 4

American Society of Sanitary Engineering, 28901 Clemens Rd., Suite 100, Annual Book of ASTM Standards, Vol 08.01.

Westlake, OH 44145. Annual Book of ASTM Standards, Vol 09.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1970

D 3350 Specification for Polyethylene Plastics Pipe and mensions meeting the requirements of schedule 40 pipe (see

Fittings Materials Specification D 1785 for dimensions of schedule 40 pipe).

D 4066 Classification System for Nylon Injection and Ex- 3.2.6 lot size—the total number of completely finished

trusion Materials (PA) fittings or appurtenances that are manufactured under condi-

F 412 Terminology Relating to Plastic Piping Systems tions of production that are considered uniform.

F 438 Specification for Socket-Type Chlorinated Poly(Vi- 3.2.7 referee test—testing conducted to compare perfor-

nyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 40 mance of the product against all requirements of this specifi-

F 439 Specification for Socket-Type Chlorinated Poly(Vi- cation. In-plant QC testing is not considered referee testing.

nyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

4. Materials and Manufacture

F 441/F 441M Specification for Chlorinated Poly(Vinyl

3 4.1 The elastomeric seals designed for push-on joints,

Chloride) (CPVC) Plastic Pipe, Schedules 40 and 80

which require no internal or external pressure to effect the

F 442/F 442M Specification for Chlorinated Poly(Vinyl

3 initial seal, shall comply with the requirements of Specification

Chloride) (CPVC) Plastic Pipe (SDR-PR)

F 477, Table 1 for thermoset, Table 2 for thermoplastic.

F 477 Specification for Elastomeric Seals (Gaskets) for

3 4.2 All other elastomeric seals shall be designed to meet the

Joining Plastic Pipe

product performance requirements stated within this document

F 1498 Specification for Taper Pipe Threads 60° for Ther-

3 and be specified in accordance with Classification D 2000.

moplastic Pipe and Fittings

4.3 Materials used in components which provide structural

2.2 ASME Standards:

7 integrity of the fitting or appurtenance shall meet the require-

B1.20.1 Pipe Threads, General Purpose (Inch)

7 ments of 4.3.1, 4.3.2, 4.3.3 or 4.4.

B16.5 Pipe Flanges and Flanged Fittings

2.3 NSF Standards:

NOTE 1—Components which provide structural integrity include the

NSF 14 Plastics Piping Components and Related Materials body; connections such as sockets, compression joint components,

saddles, and flanges.

NSF 61 Drinking Water System Components - Health

Effects

4.3.1 PVC materials shall meet the minimum requirements

2.4 ISA Standard:

for a cell-classification of 12454, 13354, 11443 or 14333 as

ISA S75.02 Control Valve Capacity Test Procedure

defined by Specification D 1784.

2.5 ASQ Standard:

4.3.2 CPVC materials shall meet the minimum require-

ANSI/ASQ Z1.4 Sampling Procedures and Tables for In-

ments for a cell-classification of 23447 or 23448 as defined in

spection by Attributes

Specification D 1784.

4.3.3 Polyamide (nylon) materials shall meet the minimum

3. Terminology

requirements for a cell-classification of PA0110, PA0120,

3.1 General—Definitions are in accordance with the Defi-

PA0210 or PA0220 and shall meet the detail requirements

nitions in F 412 and abbreviations are in accordance with given in Table A or B for classifications A2242 or B4544, as

D 1600 unless otherwise specified.

defined in Classification D 4066.

3.2 Definitions of Terms Specific to This Standard: 4.3.4 Polyethylene (PE) materials shall meet the minimum

3.2.1 activation pressure—the activation pressure of a requirements for a cell classification of 213333 (PE2406,

check valve is that inlet pressure, exceeding the outlet pressure, PE3406 or PE3408) as defined in Specification D 3350.

required to open the check valve and allow water to flow. 4.4 Rework Material—The manufacturers shall use only

3.2.2 appurtenances—accessories of a plastic piping system their own clean rework fitting material and the fittings pro-

designed for special applications or end-uses. Appurtenances duced shall meet the requirements of this specification. Mate-

may include, but are not limited to pipes, fittings, valves, rials containing contaminants from other base materials or

storage tanks, mechanical devices and expansion tanks. elastomerics shall not be used in the manufacture of fittings or

3.2.3 connections—the portion of the fitting intended to join appurtenances under this specification.

the fitting with the rest of the piping system (see 5.1).

5. Requirements

3.2.4 CTS—abbreviation for “copper tube size”, indicating

5.1 Dimensions:

an outside-diameter controlled tubing with outside diameter

5.1.1 Seal Dimensions—Seal dimensions shall be in accor-

dimensions meeting the tube specifications given in Specifica-

dance with the manufacturer’s standard design dimensions and

tion D 2846.

tolerances. The seal shall be designed to provide an adequate

3.2.5 IPS—abbreviation for “iron pipe size”, indicating an

compressive force against the mating parts after assembly to

outside-diameter controlled tubing with outside diameter di-

effect a positive seal under all combinations of permitted fitting

and seal tolerances.

5.1.2 Solvent-Weld Connections—Sockets shall comply

Annual Book of ASTM Standards, Vol 08.02.

with the fittings dimensions applicable to the size of pipe being

American Society of Mechanical Engineers, Three Park Ave., New York, NY

joined. Dimensioning of sockets shall be conducted in accor-

10016.

NSF International, P.O. Box 130140, Ann Arbor, MI 48113-0140.

dance with 8.2.

Instrument Society of America, 67 Alexander Drive, Research Triangle Park,

5.1.2.1 Socket connections for solvent-weld to IPS pipe

NC 27709.

10 shall comply with the socket dimensions given in Specification

American Society for Quality, 611 East Wisconsin Ave., Milwaukee, WI

53201-3005. D 2467 for Sch 80 PVC, Specification D 2466 for Sch 40 PVC,

F 1970

Specification F 439 for Sch 80 CPVC or Specification F 438 (non-magnified) inspection of the components and surfaces.

for Sch 40 CPVC. 6.2 All surfaces of the fitting or assembly against which a

5.1.2.2 Socket connections for solvent-weld to CTS pipe seal may rest shall be free of imperfections that could adversely

shall comply with the socket dimensions given in D 2846. affect the performance of the fitting or assembly.

5.1.3 Threaded Connections—For all thermoplastic compo- 6.3 The surfaces of all thermoplastic and metallic compo-

nents having taper pipe threads, thermoplastic threads shall nents shall be free from defects which will adversely affect the

conform to Specification F 1498 and be gaged in accordance performance and service of the fitting or assembly.

with 8.2.2. The tolerance on thermoplastic threads, when 6.4 The thermoplastic materials, after molding or fabrica-

measured using gages, shall be 61.5 turns. For all metallic tion, shall be as uniform as commercially practical in color and

components having taper pipe threads, threads shall conform to opacity.

ANSI/ASME B1.20.1. The tolerance on metallic threads when

7. Sample Conditioning

measured using gages shall be 61 turn.

7.1 For referee testing, all samples shall be conditioned at

5.1.4 Flange Connections—Flanges and flange-connections

73 6 3.6°F (23 6 2°C) for not less than 40 hours immediately

on assemblies shall meet the bolt-pattern requirements of

preceding testing.

ANSI/ASME B16.5.

7.2 For in-plant quality control testing purposes, samples

5.1.5 Spigot Connections—Spigot ends of fittings shall

shall be conditioned at ambient temperature.

meet the requirements for average outside diameter, out-of-

roundness and minimum wall thickness of the corresponding

8. Test Methods

pipe.

8.1 Dimensioning:

5.1.6 Other dimensions shall be in accordance with the

8.1.1 Measure dimensions in accordance with D 2122. For

manufacturer’s standard dimensions and tolerances.

those part dimensions that are not covered by Test Method

5.2 Internal Pressure Tests—Fittings shall meet the mini-

D 2122, note the method of determining dimensions on the test

mum requirements for resistance to hydrostatic pressure when

report.

tested in accordance with 8.2.

8.1.2 Threads—Gage all thermoplastic taper pipe threads in

5.2.1 Valves—Valves shall be tested in both the open (shell

accordance with Specification F 1498.

test) and shut-off (seat test) configurations for compliance with

8.1.3 Threads—Gage all metal taper pipe threads in accor-

this section. Valves without a specified flow direction shall be

dance with ANSI/ASME B1.20.1.

tested in shut-off position from each possible flow direction.

8.2 Resistance to Hydrostatic Pressure:

5.2.2 Blind Flanges—Blind flanges shall be tested in addi-

8.2.1 Test specimens shall consist of assemblies of fittings

tion to any other flange configurations for compliance with this

and pipe, using pipe sufficient to withstand the internal

section.

hydrostatic pressure until completion of the test. The assem-

5.3 Valves and Check Valves:

blies used for each test shall contain the same fittings in the

5.3.1 Pressure Drop Across Valves and Check Valves—

same configuration. Each individual assembly shall contain at

When tested in accordance with 8.4, the pressure drop across

least two of each fitting being tested.

the valve shall not exceed the manufacturer’s published values

8.2.2 The test temperature, with a tolerance of 6 3.6°F

at 25, 50, 75 and 100 % of maximum flow. The maximum flow

(2°C), shall be the maximum operating temperature for which

rate shall be either as specified by the manufacturer, or the flow

the piping system component’s nominal pressure is being

achieved with 80 psig (550 kPa) inlet (at no flow condition)

verified.

pressure and pipe of the same nominal size as the valve. For

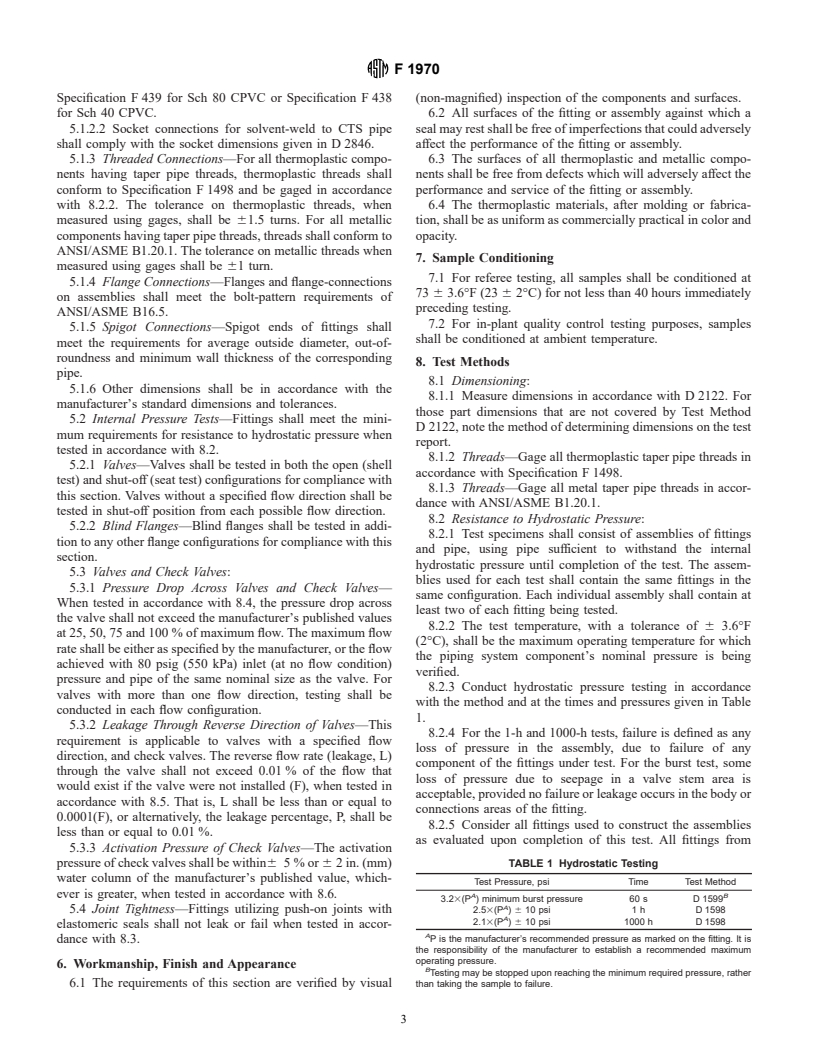

8.2.3 Conduct hydrostatic pressure testing in accordance

valves with more than one flow direction, testing shall be

with the method and at the times and pressures given in Table

conducted in each flow configuration.

1.

5.3.2 Leakage Through Reverse Direction of Valves—This

8.2.4 For the 1-h and 1000-h tests, failure is defined as any

requirement is applicable to valves with a specified flow

loss of pressure in the assembly, due to failure of any

direction, and check valves. The reverse flow rate (leakage, L)

component of the fittings under test. For the burst test, some

through the valve shall not exceed 0.01 % of the flow t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.