ASTM A775/A775M-07a

(Specification)Standard Specification for Epoxy-Coated Steel Reinforcing Bars

Standard Specification for Epoxy-Coated Steel Reinforcing Bars

SCOPE

1.1 This specification covers deformed and plain steel reinforcing bars with protective epoxy coating applied by the electrostatic spray method.Note 1

The coating applicator is identified throughout this specification as the manufacturer.

1.2 Other organic coatings may be used provided they meet the requirements of this specification.

1.3 Requirements for coatings are contained in Annex A1.

1.4 Requirements for patching material are contained in Annex A2.

1.5 Guidelines for construction practices at the job-site are presented in Appendix X1.

1.6 This specification is applicable for orders in either SI units (as Specification A 775M) or inch-pound units [as Specification A 775].

1.7 &combined-units;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 775/A 775M – 07a

Standard Specification for

1

Epoxy-Coated Steel Reinforcing Bars

ThisstandardisissuedunderthefixeddesignationA775/A775M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A 706/A 706M Specification for Low-Alloy Steel De-

formed and Plain Bars for Concrete Reinforcement

1.1 This specification covers deformed and plain steel

A944 Test Method for Comparing Bond Strength of Steel

reinforcing bars with protective epoxy coating applied by the

ReinforcingBarstoConcreteUsingBeam-EndSpecimens

electrostatic spray method.

A996/A996M Specification for Rail-Steel and Axle-Steel

NOTE 1—The coating applicator is identified throughout this specifica-

Deformed Bars for Concrete Reinforcement

tion as the manufacturer.

B117 Practice for Operating Salt Spray (Fog) Apparatus

1.2 Other organic coatings may be used provided they meet

D374 Test Methods for Thickness of Solid Electrical Insu-

the requirements of this specification.

lation

1.3 Requirements for coatings are contained in Annex A1.

D2967 Test Method for Corner Coverage of Powder Coat-

1.4 Requirements for patching material are contained in

ings

Annex A2.

D4060 Test Method for Abrasion Resistance of Organic

1.5 Guidelines for construction practices at the job-site are

Coatings by the Taber Abraser

presented in Appendix X1.

G8 Test Methods for Cathodic Disbonding of Pipeline

1.6 This specification is applicable for orders in either SI

Coatings

units (as SpecificationA775M) or inch-pound units [as Speci-

G14 Test Method for Impact Resistance of Pipeline Coat-

fication A775].

ings (Falling Weight Test)

1.7 The values stated in either SI units or inch-pound units

G20 Test Method for Chemical Resistance of Pipeline

are to be regarded separately as standard. The values stated in

Coatings

each system may not be exact equivalents; therefore, each

G62 Test Methods for Holiday Detection in Pipeline Coat-

system shall be used independently of the other. Combining

ings

3

values from the two systems may result in non-conformance

2.2 NACE International Standard:

with the standard.

RP-287-87 Field Measurement of Surface Profile of Abra-

1.8 This standard does not purport to address all of the

sive Blast-Cleaned Steel Surface Using a Replica Tape

4

safety concerns, if any, associated with its use. It is the

2.3 Society for Protective Coatings Specifications:

responsibility of the user of this standard to establish appro-

SSPC-SP10 Near-White Blast Cleaning

priate safety and health practices and determine the applica-

SSPC-VIS1 Pictorial Surface Preparation Standards for

bility of regulatory limitations prior to use.

Painting Steel Surfaces

SSPC-PA2 Measurement of Dry Coating Thickness with

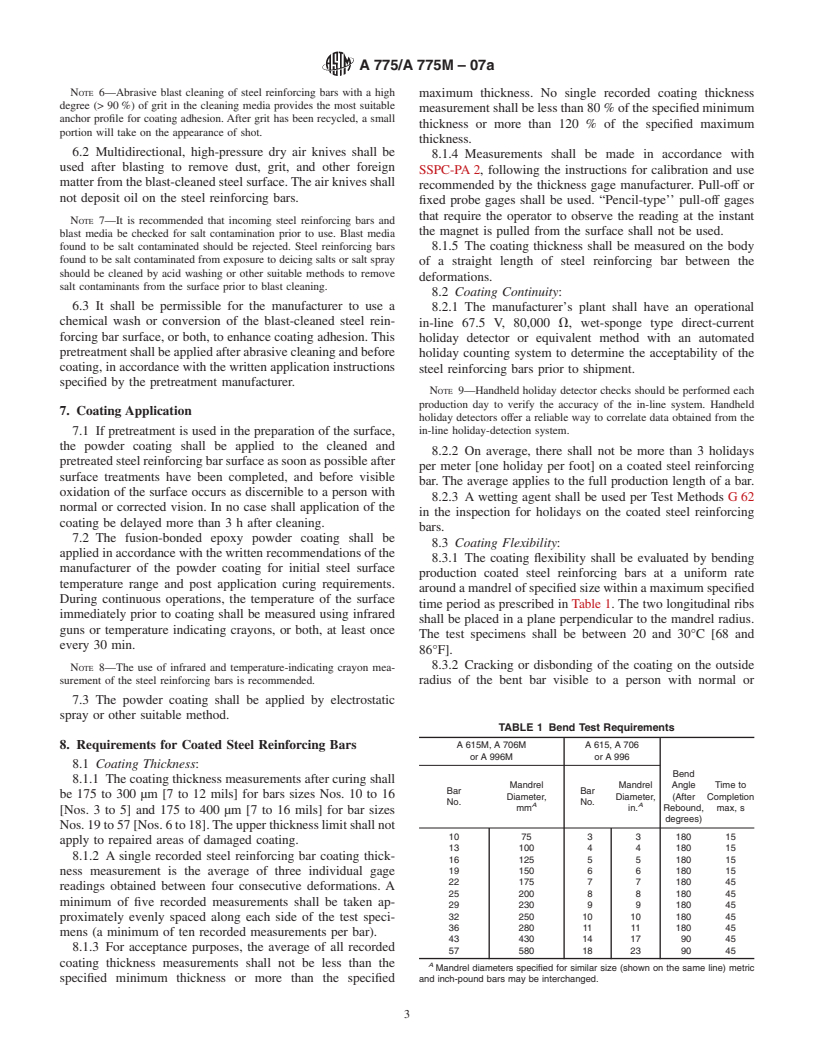

2. Referenced Documents

Magnetic Gages

2

5

2.1 ASTM Standards:

2.4 Concrete Reinforcing Steel Institute:

A 615/A 615M Specification for Deformed and Plain

“VoluntaryCertificationProgramforFusionBondedEpoxy

Carbon-Steel Bars for Concrete Reinforcement

Coating Applicator Plants”

6

2.5 American Concrete Institute Standard:

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

3

A01.05 on Steel Reinforcement. Available from NACE International, 1440 South Creek, Houston, TX 77084.

4 th

Current edition approved Sept. 1, 2007. Published October 2007. Originally Available fromThe Society for Protective Coatings, 40 24 St., Pittsburgh, PA

approved in 1981. Last previous edition approved in 2007 as A775/A775M–07. 15222–4656.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Concrete Reinforcing Steel Institute, 933 N. Plum Grove Rd.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Schaumburg, IL 60173–4758.

6

Standards volume information, refer to the standard’s Document Summary page on Available from American Concrete Institute, 38800 Country Club Dr., Farm-

the ASTM website. ington Hills, MI 48331.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 775/A 775M – 07a

ACI301 Specifications for Structural Concrete 5. Materials

5.1 Steel reinforcing bars to be coated shall meet the

3. Terminology

requirements of one of the following specifications: A615M,

A706M, orA996M [A615,A706, orA996], as specified by

3.1 Definitions of Terms Specific to This Stan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.