ASTM B560-00

(Specification)Standard Specification for Modern Pewter Alloys

Standard Specification for Modern Pewter Alloys

SCOPE

1.1 This specification covers three alloy types, made from tin, antimony, and copper, used in the fabrication of pewter articles by casting, spinning, drawing, or forming. The metal may be supplied in the form of bars, ingots, rolled sheet, and circles.

1.2 Pewter alloy shall be defined as having a composition within the range from 90 to 98 % tin, 1 to 8 % antimony, and 0.25 to 3 % copper. Compositions are given in Table 1.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 560 – 00

Standard Specification for

Modern Pewter Alloys

This standard is issued under the fixed designation B 560; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

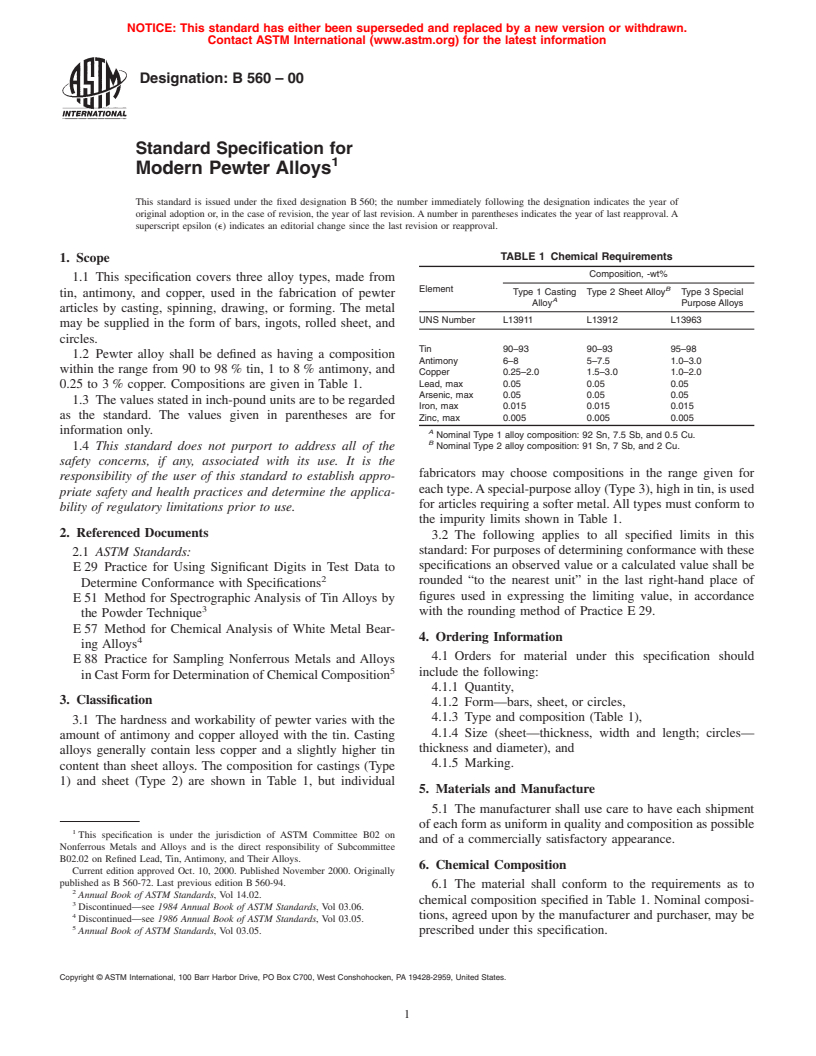

TABLE 1 Chemical Requirements

1. Scope

Composition, -wt%

1.1 This specification covers three alloy types, made from

Element B

Type 1 Casting Type 2 Sheet Alloy Type 3 Special

tin, antimony, and copper, used in the fabrication of pewter

A

Alloy Purpose Alloys

articles by casting, spinning, drawing, or forming. The metal

UNS Number L13911 L13912 L13963

may be supplied in the form of bars, ingots, rolled sheet, and

circles.

Tin 90–93 90–93 95–98

1.2 Pewter alloy shall be defined as having a composition

Antimony 6–8 5–7.5 1.0–3.0

within the range from 90 to 98 % tin, 1 to 8 % antimony, and

Copper 0.25–2.0 1.5–3.0 1.0–2.0

Lead, max 0.05 0.05 0.05

0.25 to 3 % copper. Compositions are given in Table 1.

Arsenic, max 0.05 0.05 0.05

1.3 The values stated in inch-pound units are to be regarded

Iron, max 0.015 0.015 0.015

as the standard. The values given in parentheses are for

Zinc, max 0.005 0.005 0.005

information only. A

Nominal Type 1 alloy composition: 92 Sn, 7.5 Sb, and 0.5 Cu.

B

Nominal Type 2 alloy composition: 91 Sn, 7 Sb, and 2 Cu.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

fabricators may choose compositions in the range given for

responsibility of the user of this standard to establish appro-

each type.Aspecial-purpose alloy (Type 3), high in tin, is used

priate safety and health practices and determine the applica-

for articles requiring a softer metal.All types must conform to

bility of regulatory limitations prior to use.

the impurity limits shown in Table 1.

2. Referenced Documents

3.2 The following applies to all specified limits in this

standard: For purposes of determining conformance with these

2.1 ASTM Standards:

specifications an observed value or a calculated value shall be

E 29 Practice for Using Significant Digits in Test Data to

rounded “to the nearest unit” in the last right-hand place of

Determine Conformance with Specifications

figures used in expressing the limiting value, in accordance

E 51 Method for Spectrographic Analysis of Tin Alloys by

with the rounding method of Practice E 29.

the Powder Technique

E 57 Method for Chemical Analysis of White Metal Bear-

4. Ordering Information

ing Alloys

4.1 Orders for material under this specification should

E 88 Practice for Sampling Nonferrous Metals and Alloys

include the following:

in Cast Form for Determination of Chemical Composition

4.1.1 Quantity,

3. Classification

4.1.2 Form—bars, sheet, or circles,

4.1.3 Type and composition (Table 1),

3.1 The hardness and workability of pewter varies with the

4.1.4 Size (sheet—thickness, width and length; circles—

amount of antimony and copper alloyed with the tin. Casting

thickness and diameter), and

alloys generally contain less copper and a slightly higher tin

4.1.5 Marking.

content than sheet alloys. The composition for castings (Type

1) and sheet (Type 2) are shown in Table 1, but individual

5. Materials and Manufacture

5.1 The manufacturer shall use care to have each shipment

of each form as uniform in quality and composition as possible

This specification is under the jurisdiction of ASTM Committee B02 on

and of a commercially satisfactory appearance.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

6. Chemical Composition

Current edition approved Oct. 10, 2000. Published November 2000. Originally

published as B 560-72. Last previous edition B 560-94.

6.1 The material shall conform to the requirements as to

Annual Book of ASTM Standards, Vol 14.02.

chemical composition specified in Table 1. Nominal composi-

Discontinued—see 1984 Annual Book of ASTM Standards, Vol 03.06.

tions, agreed upon by the manufacturer and purchaser, may be

Discontinued—see 1986 Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.05. prescribed under this specification.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 560

7. Dimensions, Mass, and Permissible Variations 1000 lb (454 kg). The bars shall be selected at random,

preferably under such conditions that every piece in the lot is

7.1 Sheet pewter is commercially available in thicknesses

accessible for selection (for example, while shipment is being

from 0.031 to 0.064 6 0.002 in. (0.79 to 1.63 mm) (Table 2).

loaded or unloaded).Asaw cut shall be made entirely through

Thinner sheet down to a thickness of 0.010 in. (0.25 mm) can

the piece on its long axis and the saw chips collected. Sawings

be supplied to special order. Sheet can be supplied in widths up

thoroughly mixed and split into three parts shall constitute the

to 2 ft (0.6 m) and lengths up to 4 ft (1.2 m).

samples for chemical analysis (Practice E 88).

7.2 Circles are available in diameters from 2 to 20 in. (50.8

9.4 For sheet, circles, and discs, a sample shall consist of

to 508 mm) and in thicknesses from 0.031 to 0.064 6 0.002 in.

clippings from not more than 2 % of the shipment. The

(Table 2).

minimum mass of sample shall be 250 g.

7.3 Bars or ingots are nominally 5 lb (2.27 kg) in mass.

8. Workmanship, Finish, and Appearance

10. Chemical Analysis

8.1 Surface defects in bars or ingots are of no importance.

10.1 In case of dispute, the chemical analysis shall be made

Surface defects in sheet pewter or circles may be a c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.