ASTM B524/B524M-99(2005)

(Specification)Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR, 1350/6201)

Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR, 1350/6201)

ABSTRACT

This specification covers concentric-lay-stranded conductors made from round aluminum 1350-H19 (extra hard) wires and round aluminum-alloy 6201-T81 (hard, solution heat treated, cold worked, and then artificially aged) core wires for use as overhead electrical conductors. Conductors shall conform to construction requirements in terms of mass, mass per unit length, recommended reel sizes, and shipping lengths. Wires shall also be tested to evaluate their conformance to physical, mechanical, and electrical properties such as density, cross sectional area, breaking strength, and mass electrical resistance.

SCOPE

1.1 This specification covers concentric-lay-stranded conductors made from round aluminum 1350-H19 (extra hard) wires and round aluminum-alloy 6201-T81 (hard: solution heat treated, cold worked, and then artificially aged) core wires for use as overhead electrical conductors (Explanatory ).Note 1

The aluminum, alloy, and temper designations conform to ANSI H35.1/ANSI H35.1[M]. Aluminum 1350 and Alloy 6201 correspond to unified numbering system A91350 and A96201, respectively, in accordance with Practice E 527.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B524/B524M – 99 (Reapproved 2005)

Standard Specification for

Concentric-Lay-Stranded Aluminum Conductors, Aluminum-

1

Alloy Reinforced (ACAR, 1350/6201)

This standard is issued under the fixed designation B524/B524M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B398/B398M Specification for Aluminum-Alloy 6201-T81

Wire for Electrical Purposes

1.1 This specification covers concentric-lay-stranded con-

B682 Specification for Metric Sizes of Electrical Conduc-

ductors made from round aluminum 1350-H19 (extra hard)

tors

wiresandroundaluminum-alloy6201-T81(hard:solutionheat

E29 Practice for Using Significant Digits in Test Data to

treated, cold worked, and then artificially aged) core wires for

Determine Conformance with Specifications

use as overhead electrical conductors (Explanatory Note 1).

E527 Practice for Numbering Metals and Alloys in the

NOTE 1—The aluminum, alloy, and temper designations conform to

Unified Numbering System (UNS)

ANSI H35.1/ANSI H35.1[M]. Aluminum 1350 and Alloy 6201 corre-

2.3 ANSI Standard:

spond to unified numbering systemA91350 andA96201, respectively, in

ANSI H35.1 American National Standard for Alloy and

accordance with Practice E527.

3

Temper Designation Systems for Aluminum

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

ANSI H35.1[M] American National Standard forAlloy and

as standard. The values given in parentheses are mathematical

3

Temper Designation Systems for Aluminum

conversions to SI units that are provided for information only

2.4 NIST Document:

and are not considered standard.

4

NBS Handbook 100 Copper Wire Tables

1.2.1 For density, resistivity and temperature, the values

stated in SI units are to be regarded as standard.

3. Ordering Information

1.3 This standard does not purport to address all of the

3.1 Ordersformaterialunderthisspecificationshallinclude

safety concerns, if any, associated with its use. It is the

the following information:

responsibility of the user of this standard to establish appro-

3.1.1 Quantity of each size and stranding;

priate safety and health practices and determine the applica-

3.1.2 Conductor size (see 7.1);

bility of regulatory limitations prior to use.

3.1.3 Total number of wires, aluminum 1350 and aluminum

alloy 6201 (Table 1 or Table 2);

2. Referenced Documents

3.1.4 Direction of lay of outer layer of wires if other than

2.1 The following documents of the issue in effect on date

right-hand (see 6.2);

of material purchase form a part of this specification to the

3.1.5 Special tension test, if required (see 8.2);

extent referenced herein:

3.1.6 Place of inspection (see 14.1);

2

2.2 ASTM Standards:

3.1.7 Package size and type (see 16.1);

B230/B230M Specification for Aluminum 1350−H19 Wire

3.1.8 Heavy wood lagging, if required (Section 16); and

for Electrical Purposes

3.1.9 Special package marking, if required (Section 15).

B263 Test Method for Determination of Cross-Sectional

Area of Stranded Conductors

4. Requirement for Wires

B354 Terminology Relating to Uninsulated Metallic Elec-

4.1 Beforestranding,the1350-H19wireusedshallmeetthe

trical Conductors

requirements of Specification B230/B230M.

4.2 Beforestranding,the6201-T81wireusedshallmeetthe

1

requirements of Specification B398/B398M.

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

Conductors of Light Metals.

Current edition approved March 1, 2005. Published March 2005. Originally

approved in 1970. Last previous edition approved in 1999 as B524–99. DOI:

10.1520/B0524_B0524M-99R05.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

4

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B524/B524M – 99 (2005)

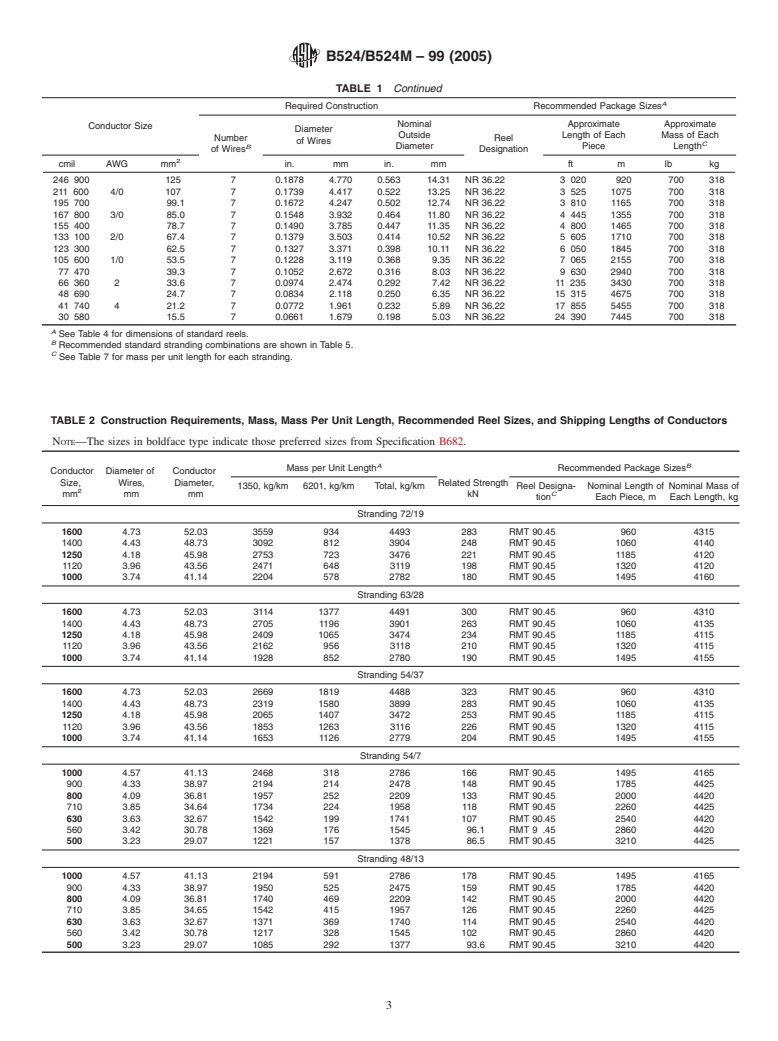

TABLE 1 Construction Requirements of Concentric-Lay-Stranded Aluminum Conductors, Aluminum Alloy Reinforced

A

Required Construction Recommended Package Sizes

Nominal Approximate Approximate

Conductor Size

Diameter

Outside Length of Each Mass of Each

Number Reel

of Wires

C

B

Diameter Piece Length

of Wires Designation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.